Patents

Literature

39results about How to "Satisfied with the appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

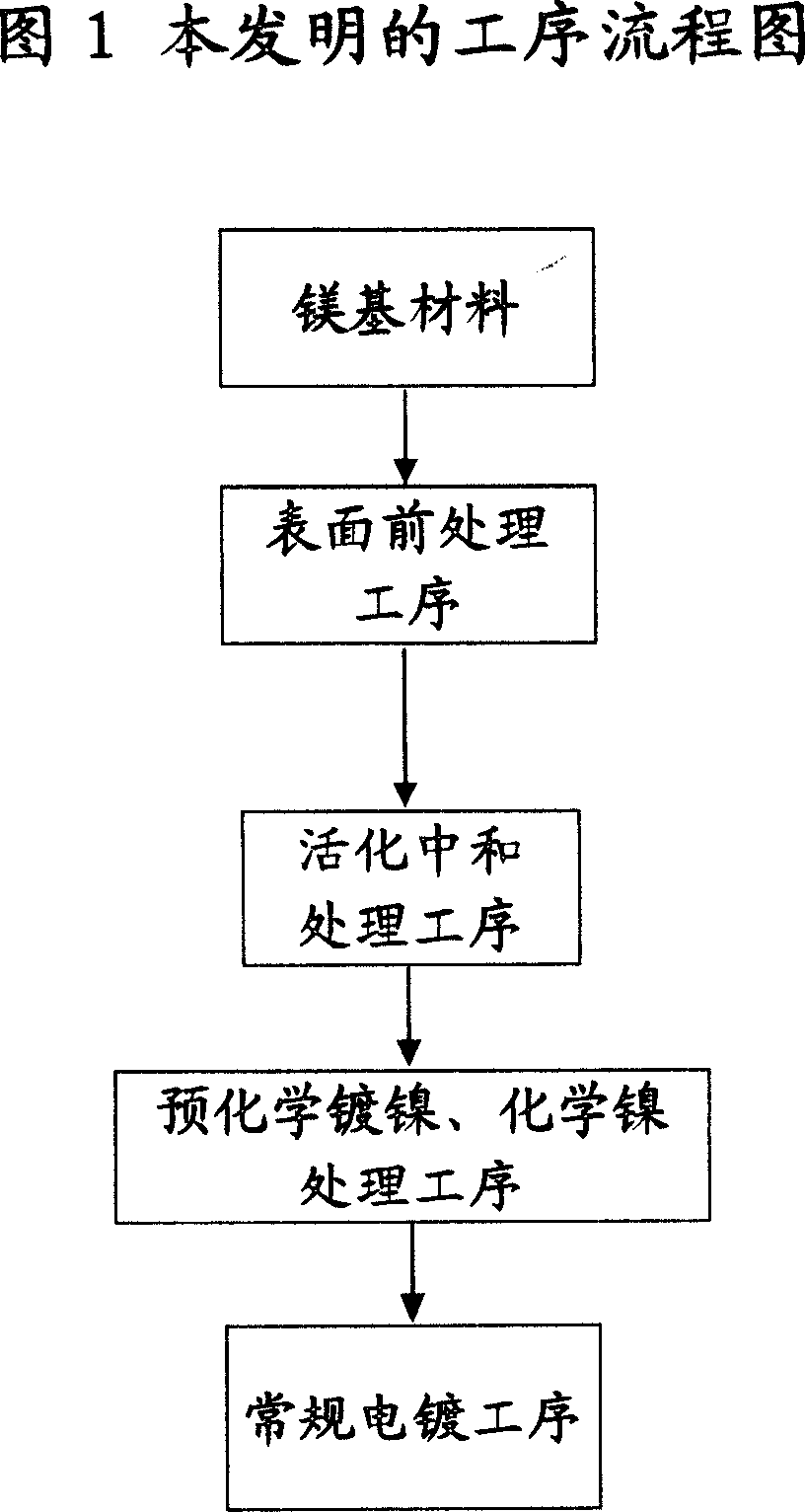

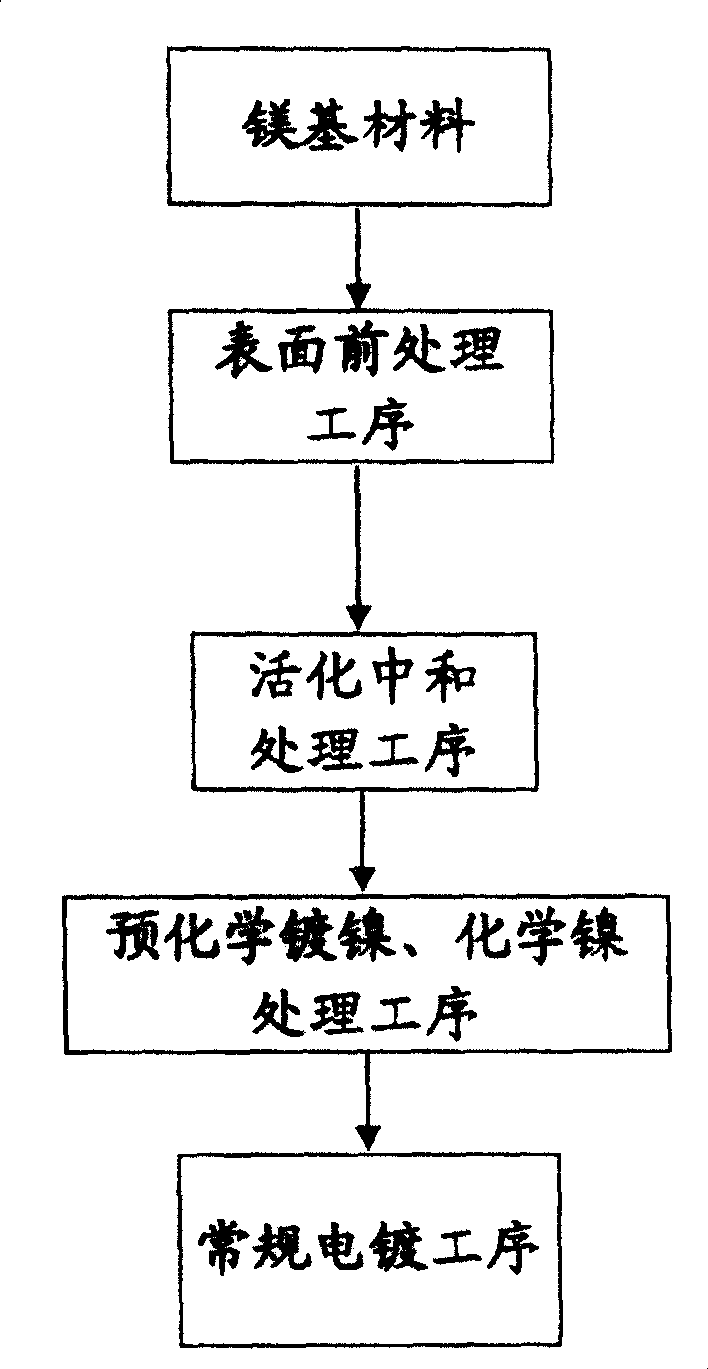

Chemical plating method for Mg and its alloy

InactiveCN1928156ASatisfied with the appearanceLiquid/solution decomposition chemical coatingNickel saltChemical plating

The chemical plating process for magnesium-base material includes the following steps: 1. alkaline dewaxing the magnesium-base material; 2. activating with acid solution containing fluoric salt and no chlorine ion and in pH 2.0-5.0, and treating with alkaline neutralizing solution containing alkali metal salt of pyrophosphoric acid, fluoric salt and hypophosphite in pH 8.0-12.0; 3. chemical nickel pre-plating with the plating solution containing nickel salt in 10-80 g / L concentration, fluoric salt in 5-50 g / L concentration, pyrophosphite in 20-100 g / L concentration and no chlorine ion and in pH 5.0-9.0; 4. chemical nickel plating with the plating solution containing nickel salt in 10-100 g / L concentration, pyrophosphite in 10-80 g / L concentration and no chlorine ion and in pH 3-7; and 5. optional heat treatment. The said process can form homogeneous compact nickel layer with sufficient binding force on magnesium-base material.

Owner:李克清

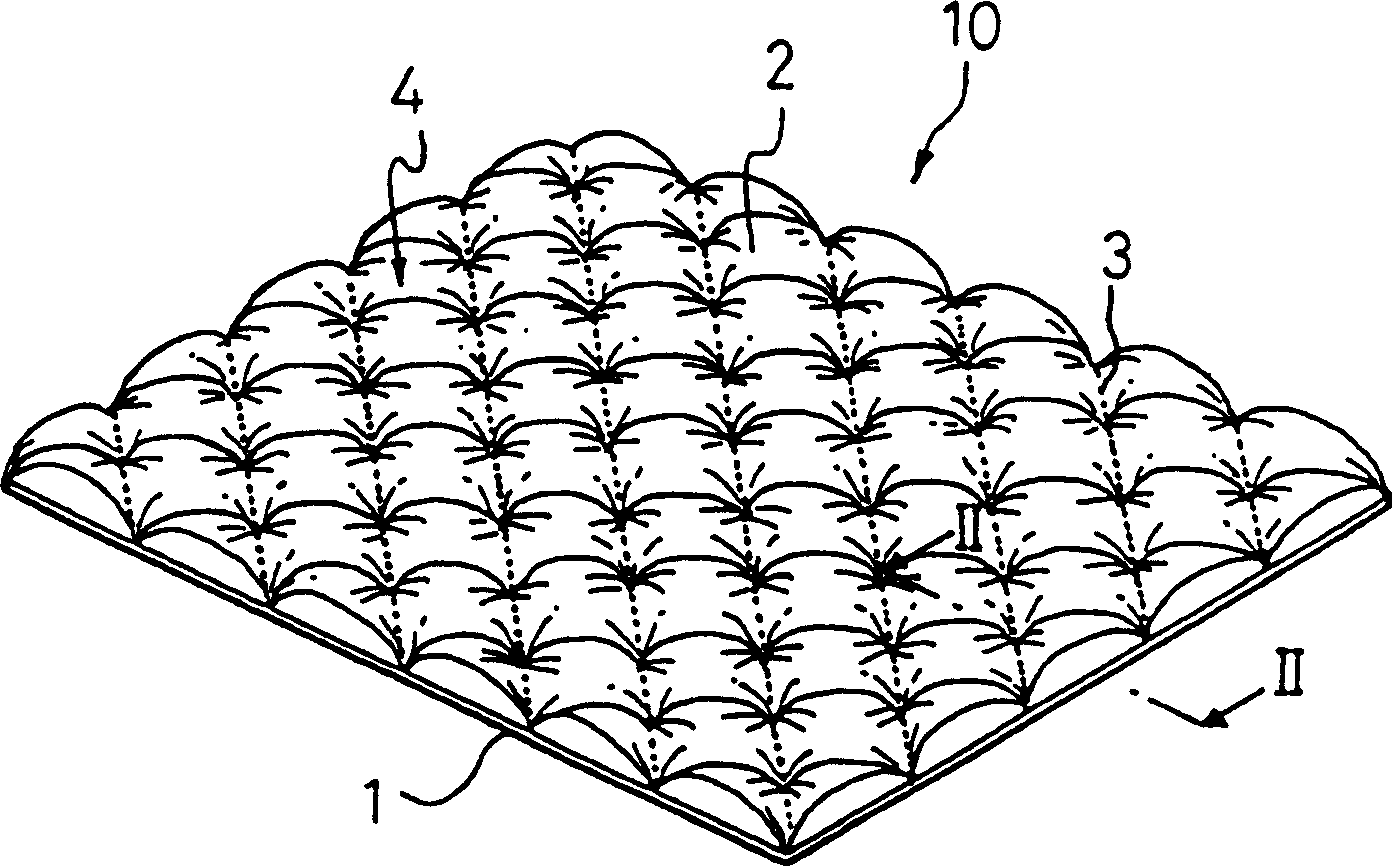

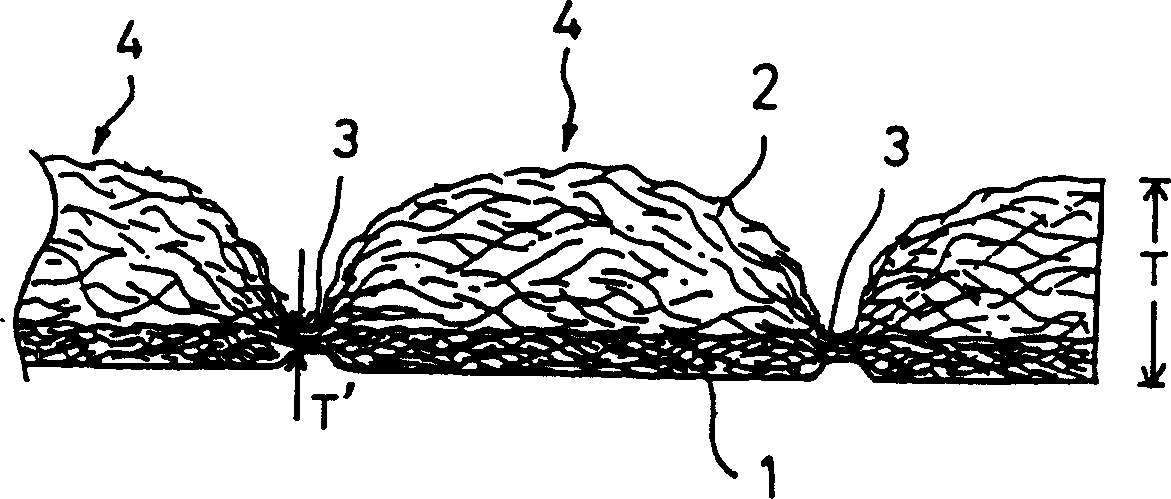

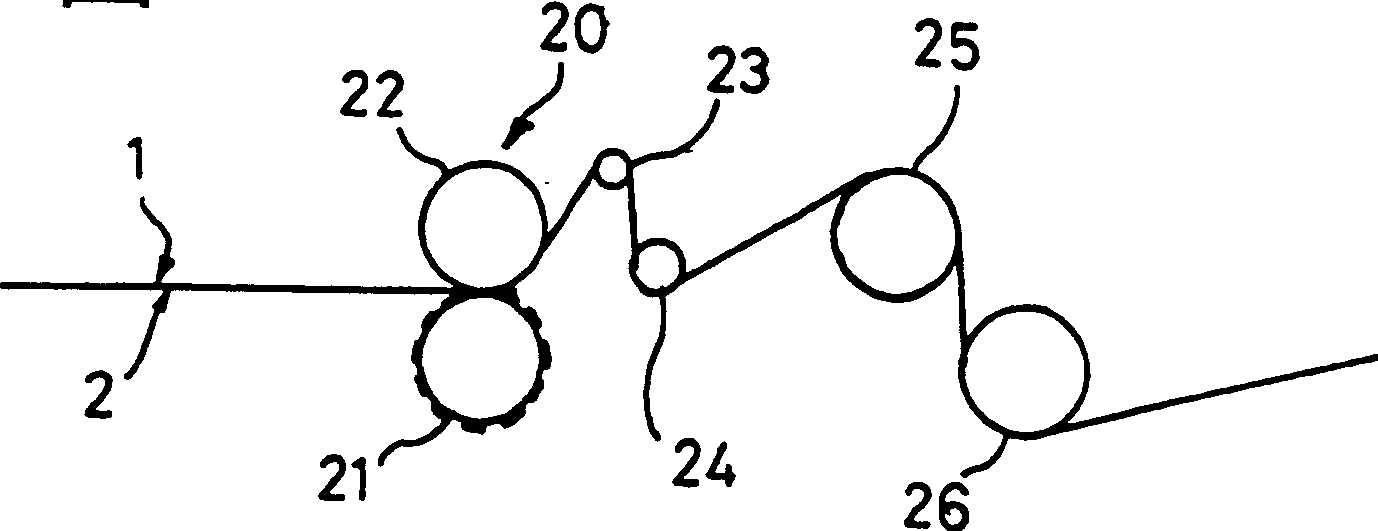

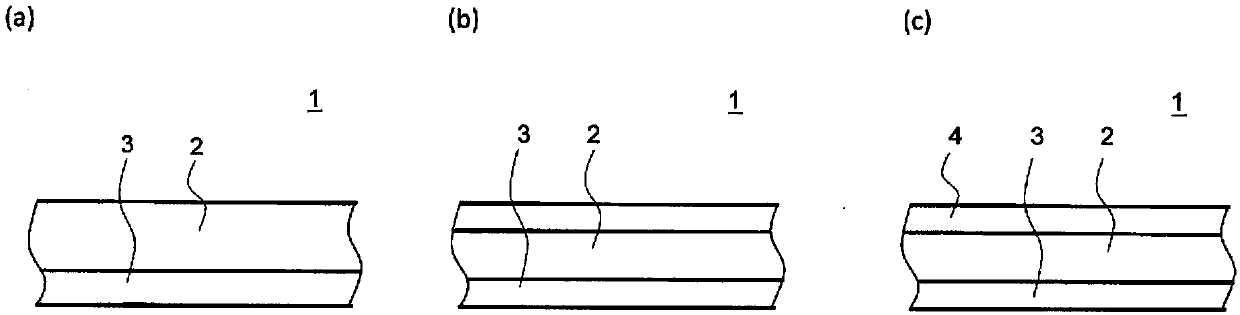

Bulk thin sheet material with 3-D embossment

InactiveCN1441102AImprove textureSatisfied with the appearanceLayered productsWoven fabricsThin sheetMelting point

Owner:KAO CORP

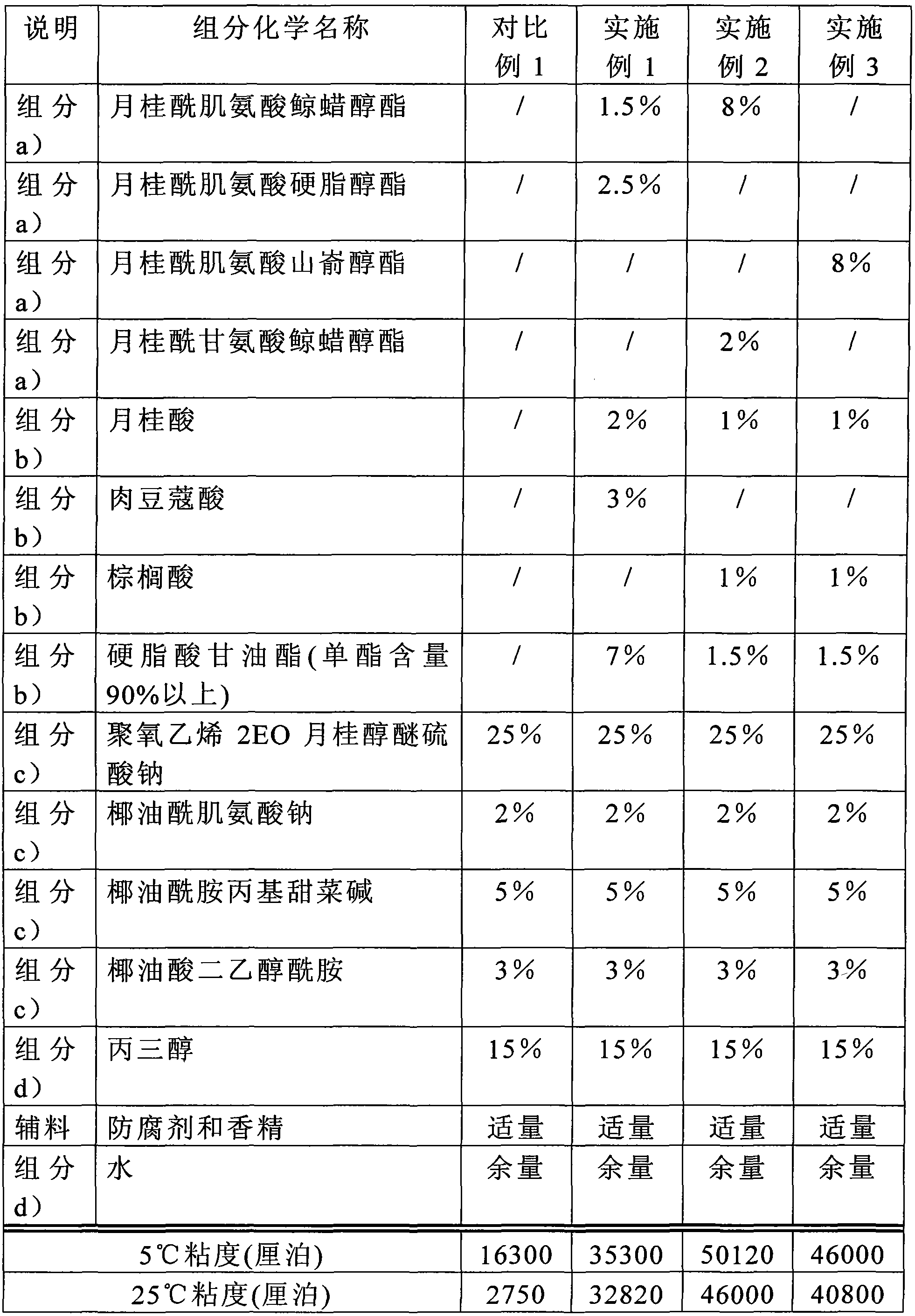

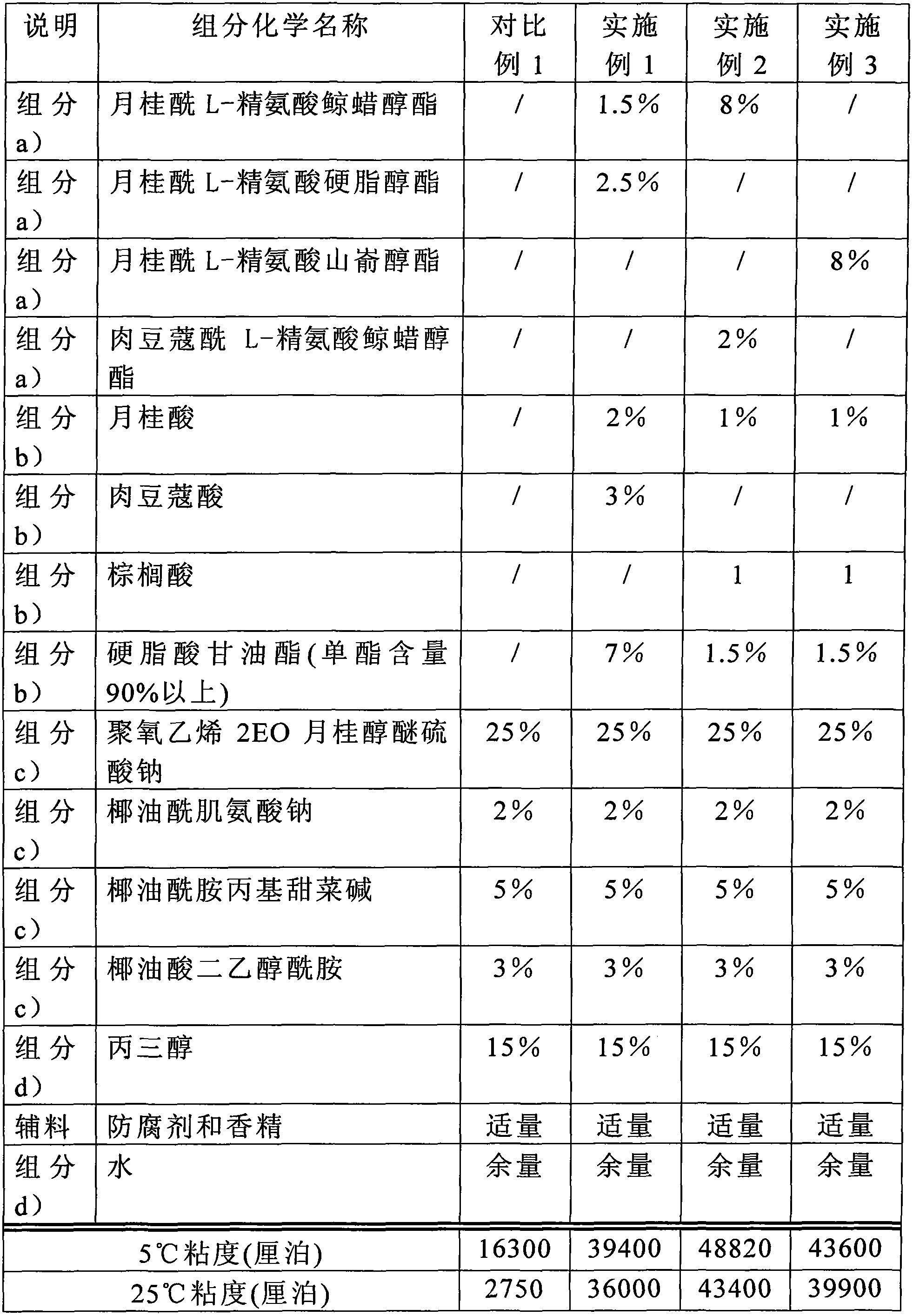

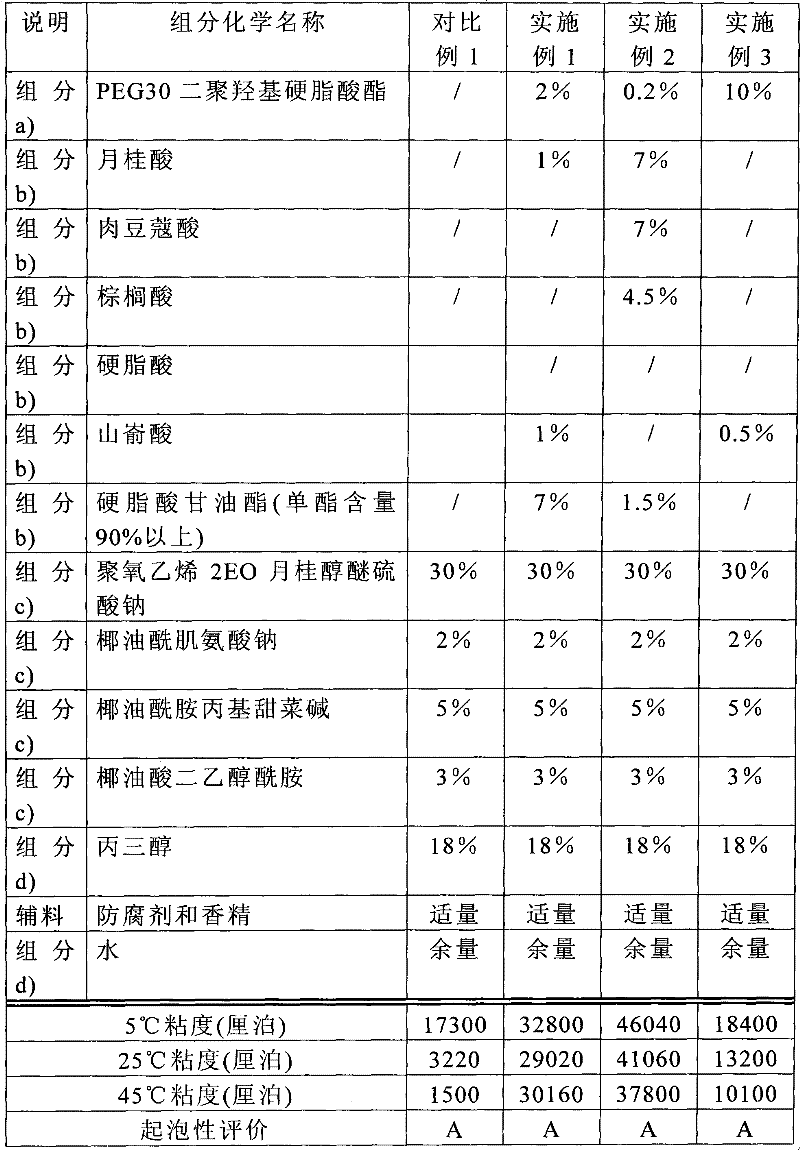

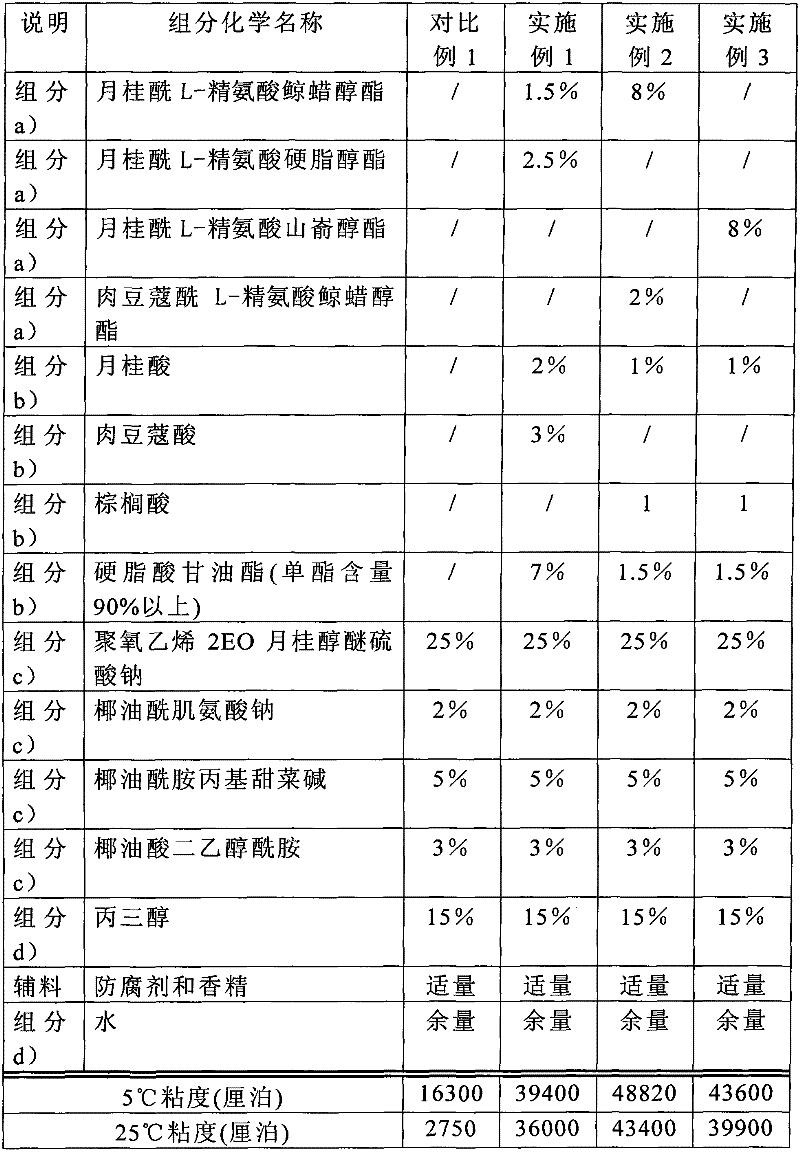

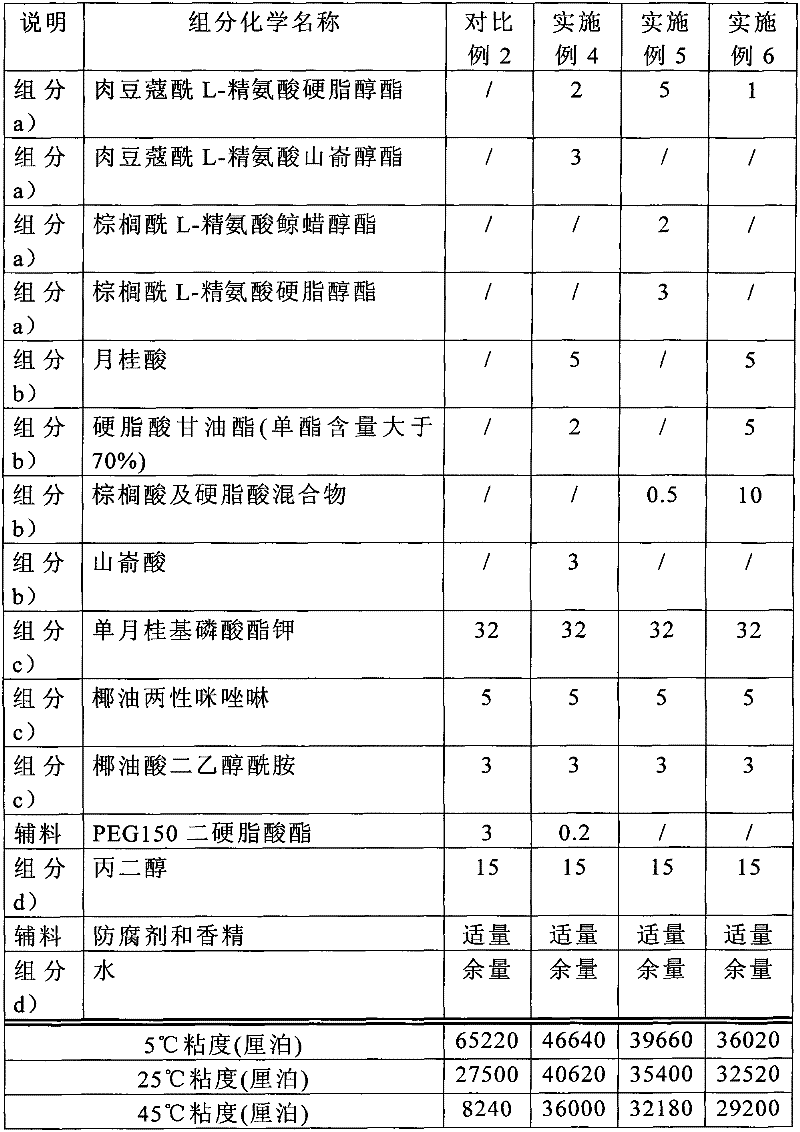

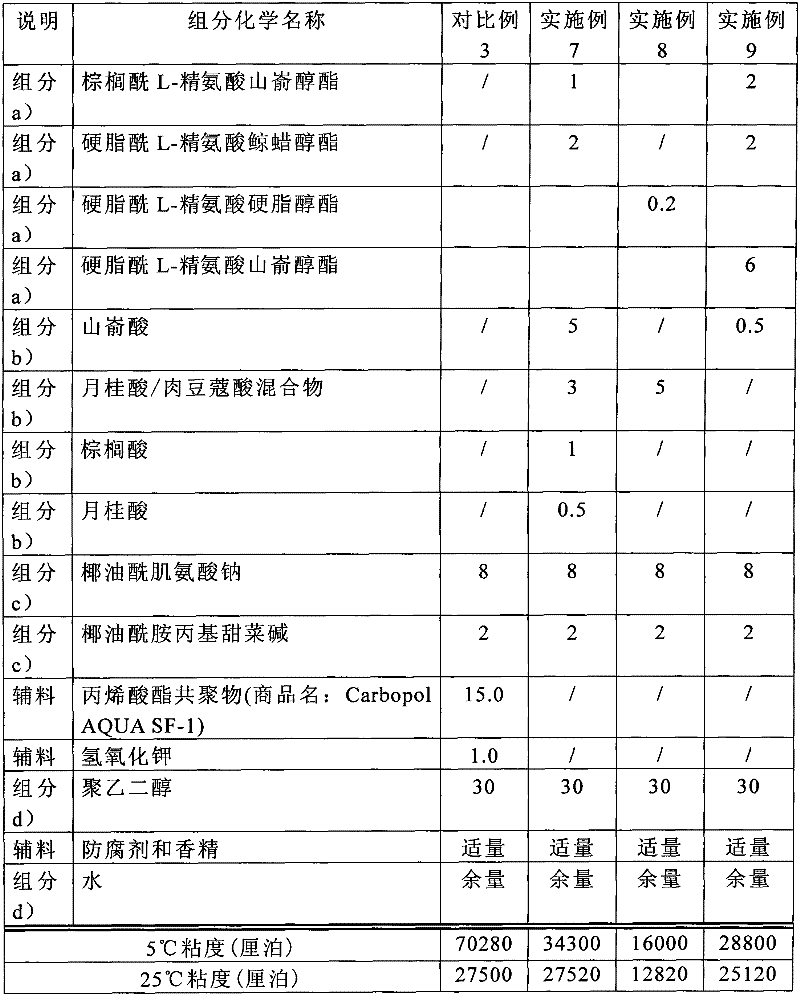

Stiff cleaning composite

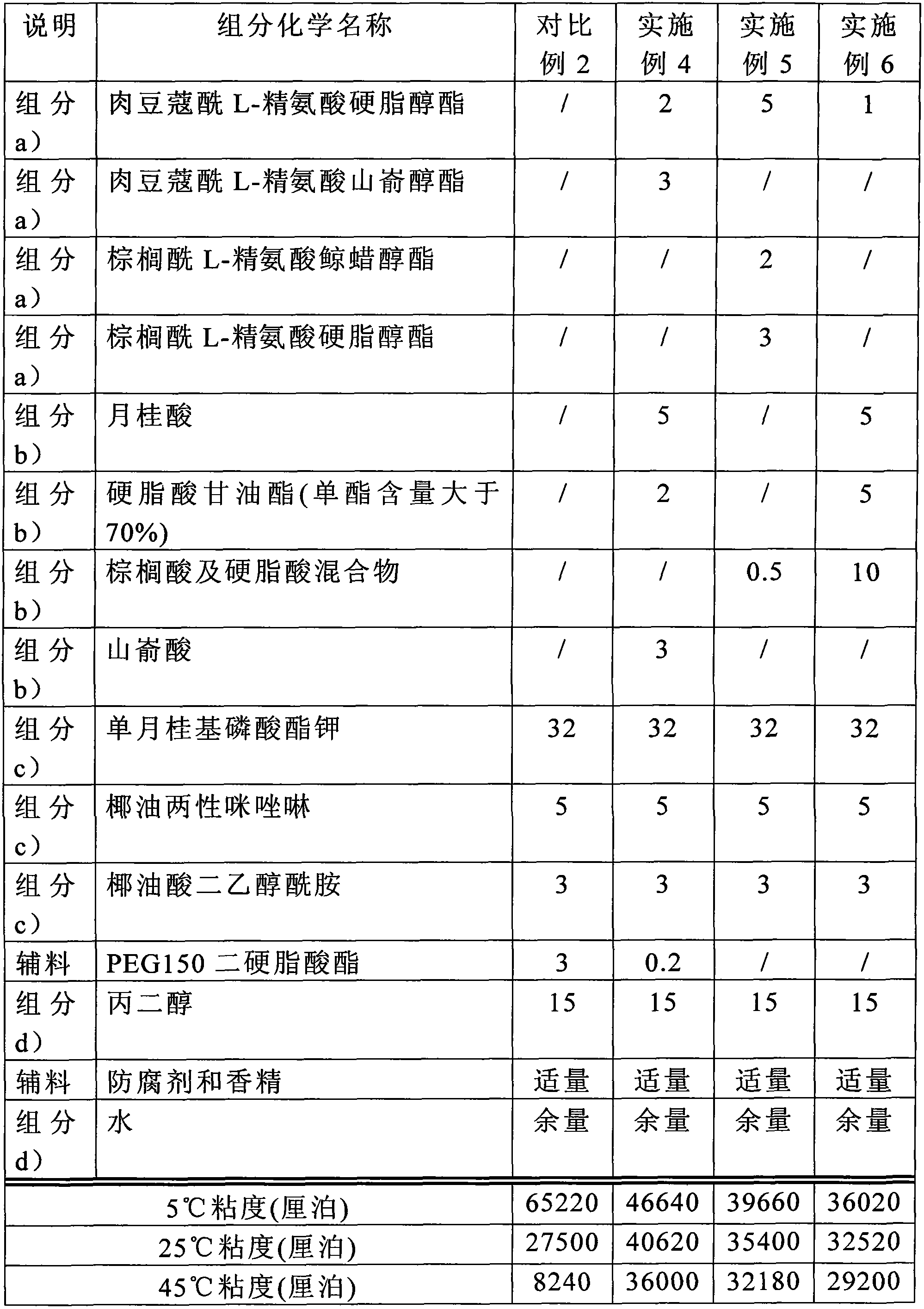

ActiveCN102058489AHigh viscosityFoaming fastCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlcohol

The invention discloses a stiff cleaning composite, relating to a stiff cleaning composition used for cleaning skin, eyes, teeth and hair in the field of personal care products. The cleaning composite comprises long-chain fatty acyl neutral amino-acid ester, a fatty compound, surfactant, solvent and beautifying and cleaning assistant solvent, wherein the fatty compound is one of fatty acid, fatty alcohol, fatty alcohol ether or polyol fatty acid ester; the solvent is composed of water, lower alcohol, polyalcohol and polyalcohol ether; and the beautifying and cleaning assistant solvent is used for skin, eyes, teeth and hair. The cleaning composite can obtain satisfactory stiff appearance when being used for cleaning skin and hair, can maintain stable viscosity at different temperatures, is easy to smear and quick to foam and has good foaming quality when being used by consumers.

Owner:SUZHOU ELECO CHEM IND

Preparation method of UV light stabilizing agent for water building outer wall coating material

The preparation method of UV stabilizer for water exterior wall coating material is characterized by that it uses nano silicone dioxide as main raw material, adds the moistening dispersing agent, multifunctional dispersing agent, humectant, stabilizing agent, defoaming agent and fungicide and adopts the processes of stirring and ball-grinding so as to obtain the invented product which can greatly raise ageing resistanice of coating material. It is awater slurry body, and is friendly to environment when it is used, and has good compatibility with various water coatings, such as phenylpropyl water coating, pure propyl water coating, silicopropyl water coating ,ethylpropyl water coating and common latex paint and water-soluble resin, and can be added in the any process of coating production.

Owner:北京金隅涂料有限责任公司 +1

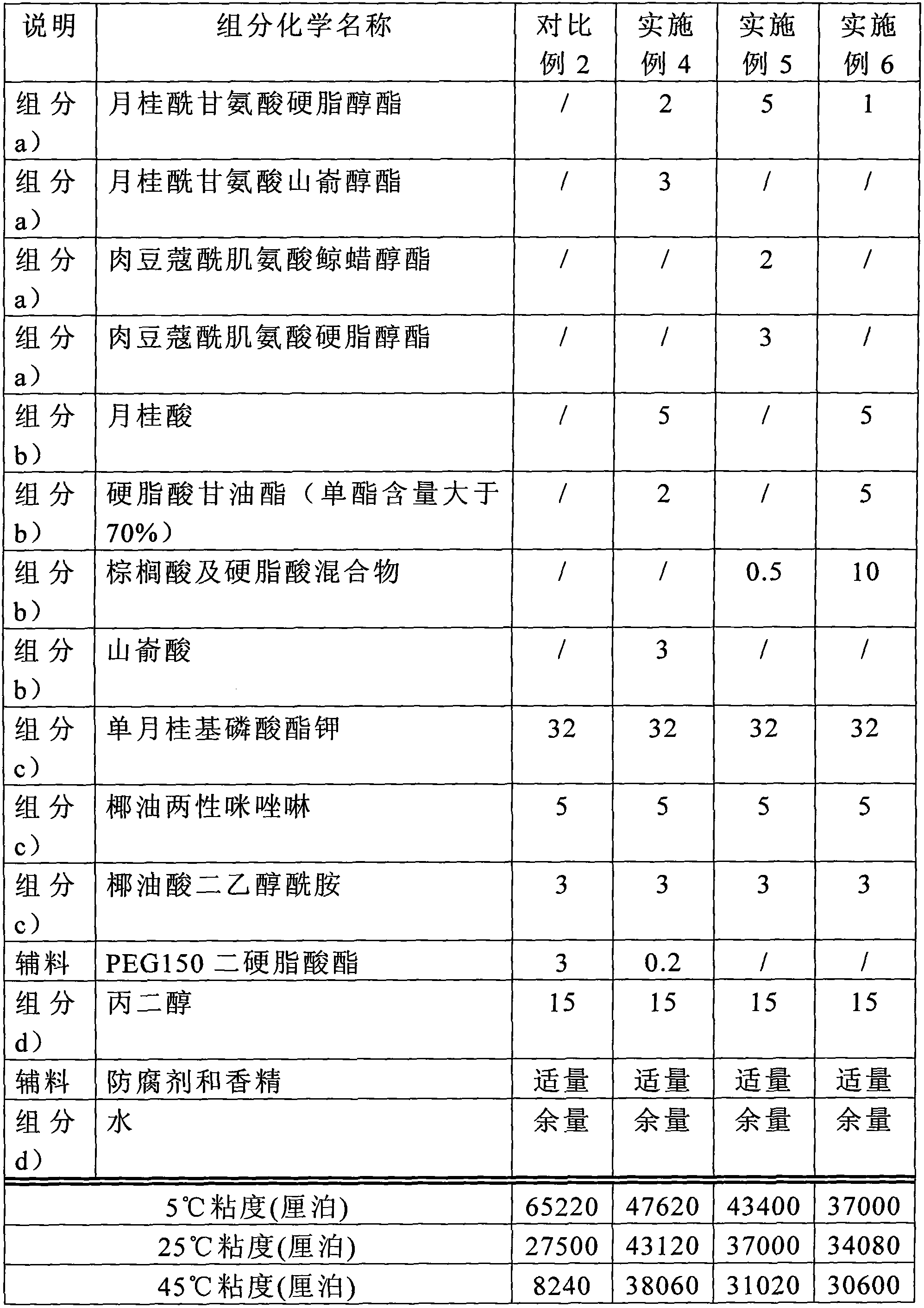

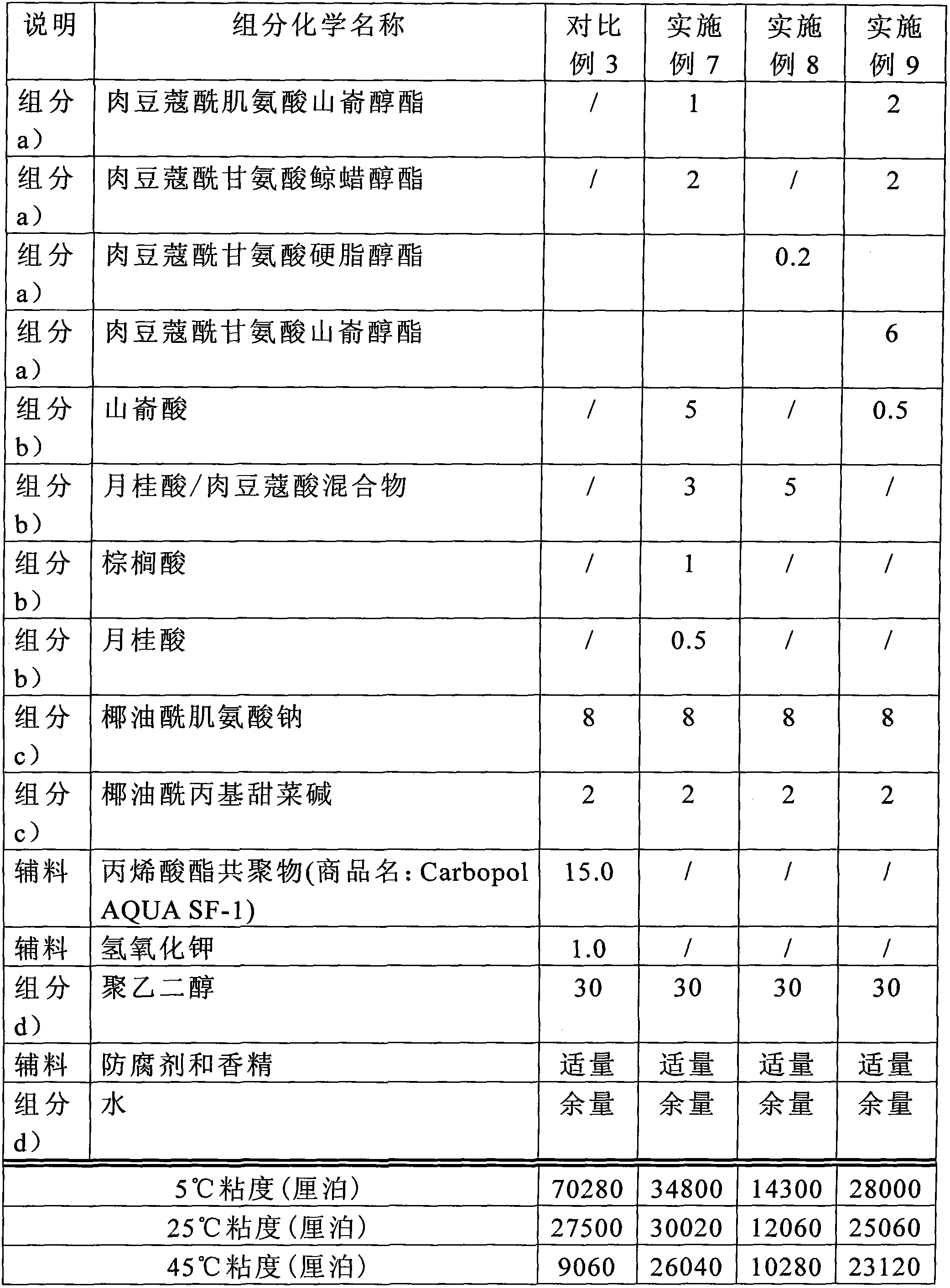

Thick cleaning composite

The invention relates to a thick cleaning composite, in particular to a thick cleaning composite used for cleaning skin, eyes, teeth and hair in the field of personal care products. The cleaning composite comprises long-chain fatty acyl basic amino acid ester, fatty compound of fatty acid, fatty alcohol, fatty alcohol ether or polyalcohol fatty acid ester, surfactant, solvent composed of water, lower alcohol, polyalcohol and polyalcohol ether as well as auxiliary reagent used for beautifying and cleaning skin, eyes, teeth and hair. The cleaning composite is used for cleaning skin and hair, can obtain satisfactory thick appearance and ensures viscosity to be stable at different temperatures, thus being easy for a consumer to smear when in use and realizing rapid foaming and good foam quality.

Owner:SUZHOU ELECO CHEM IND

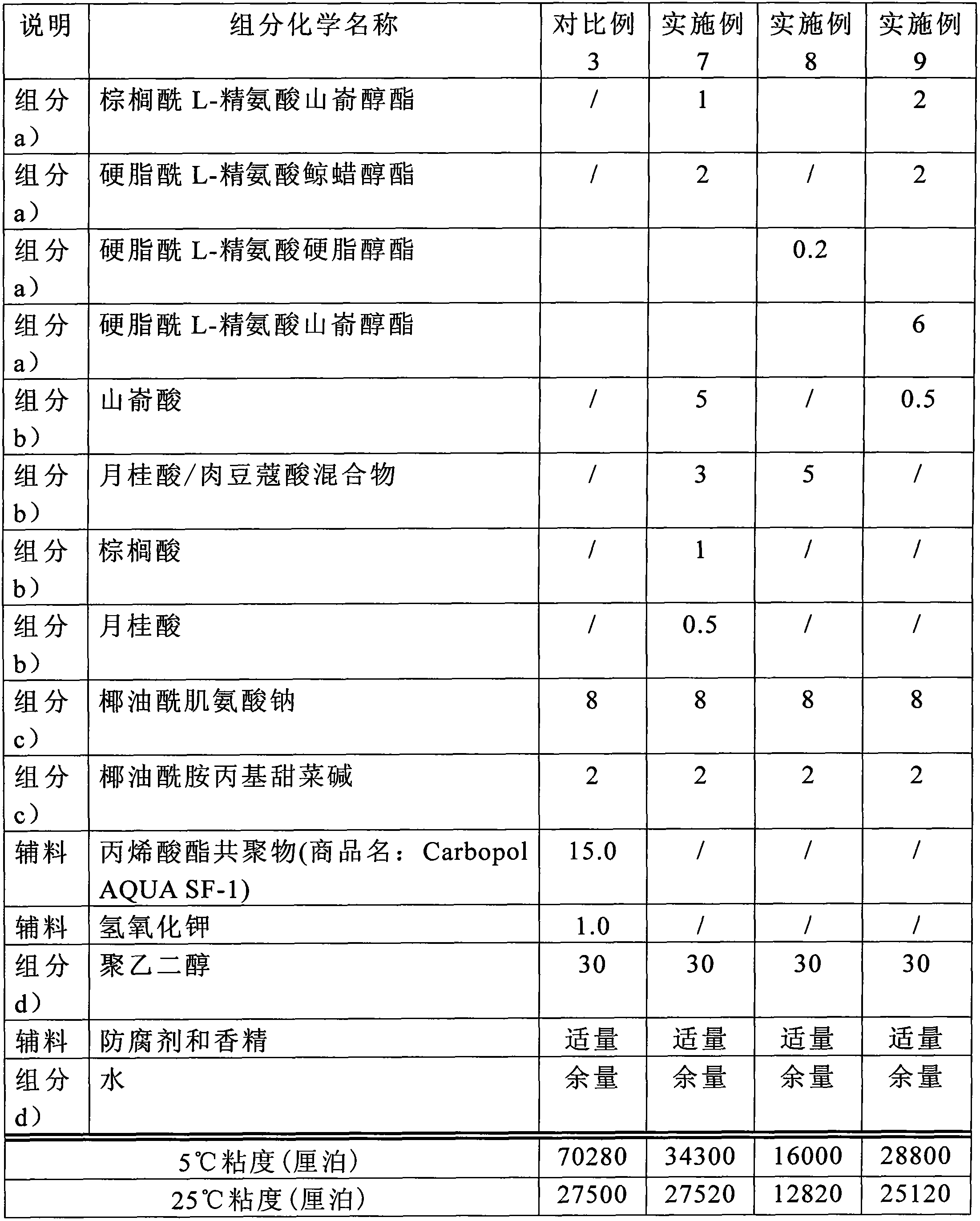

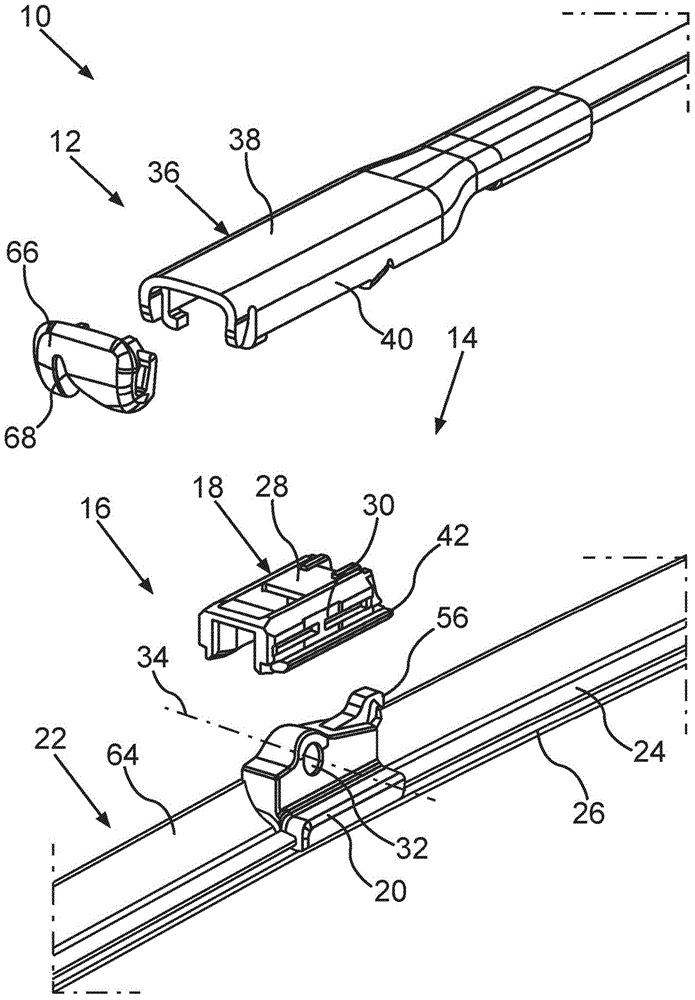

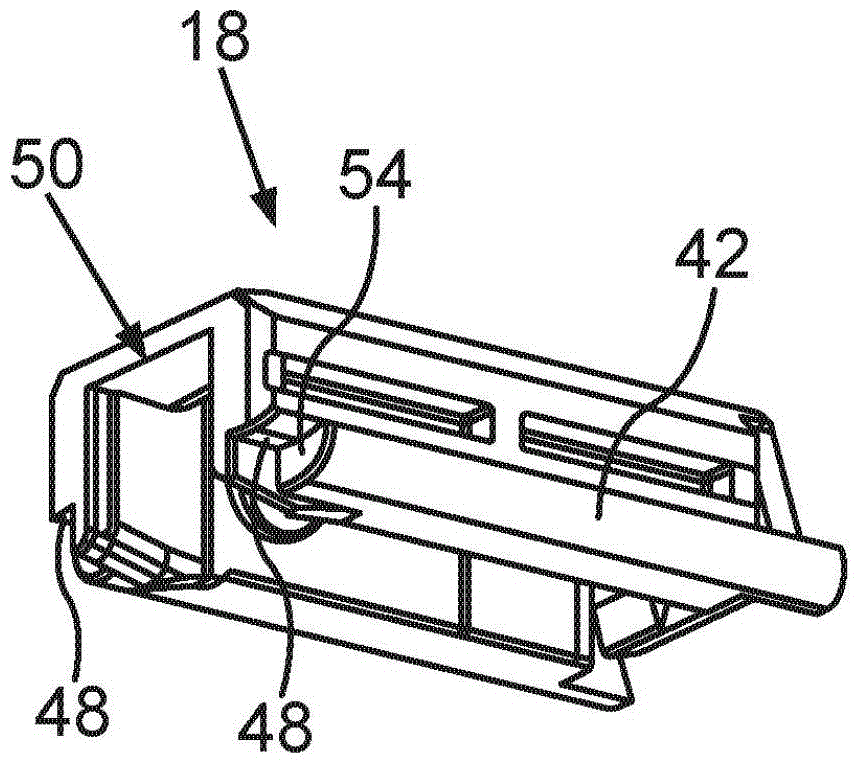

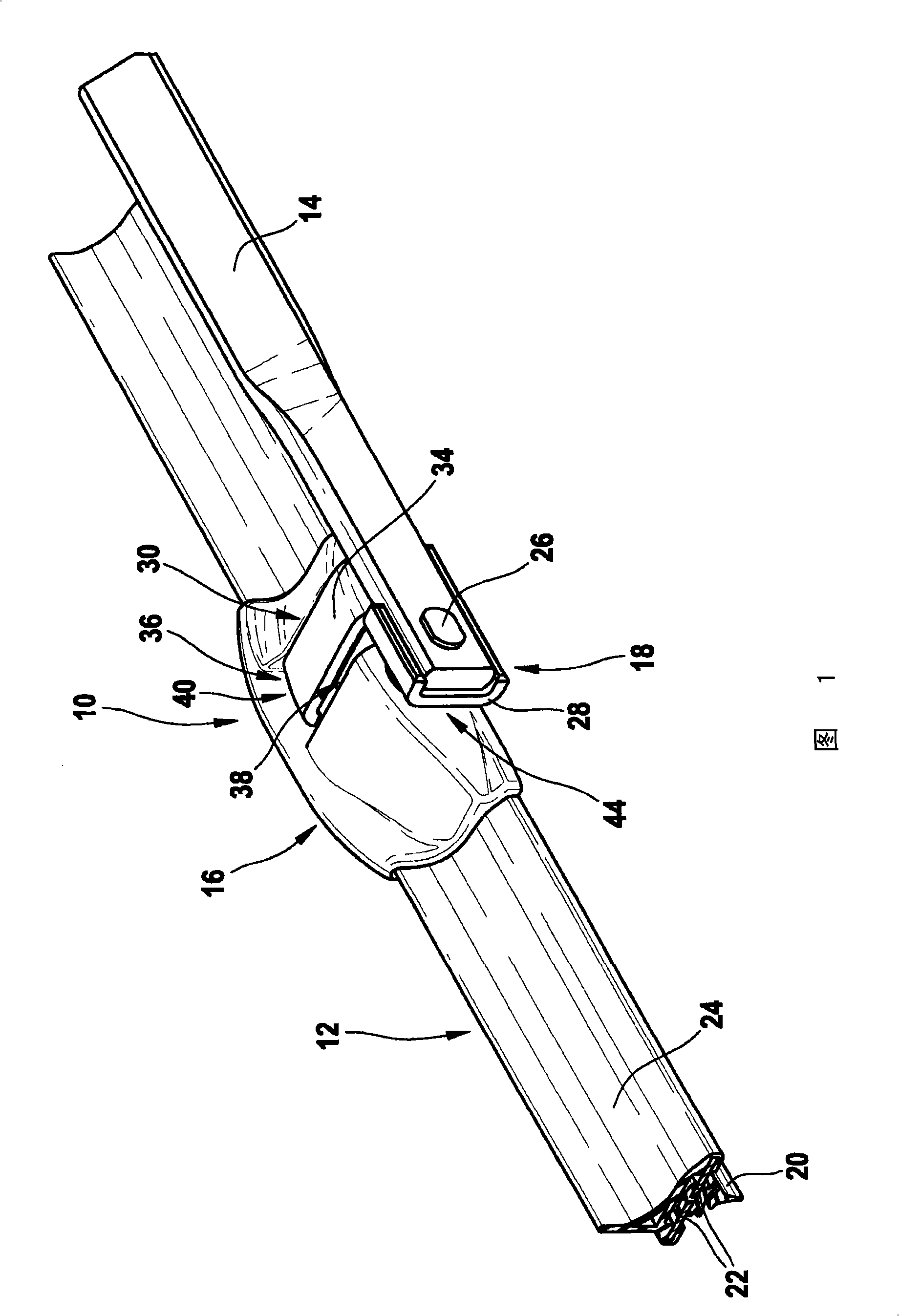

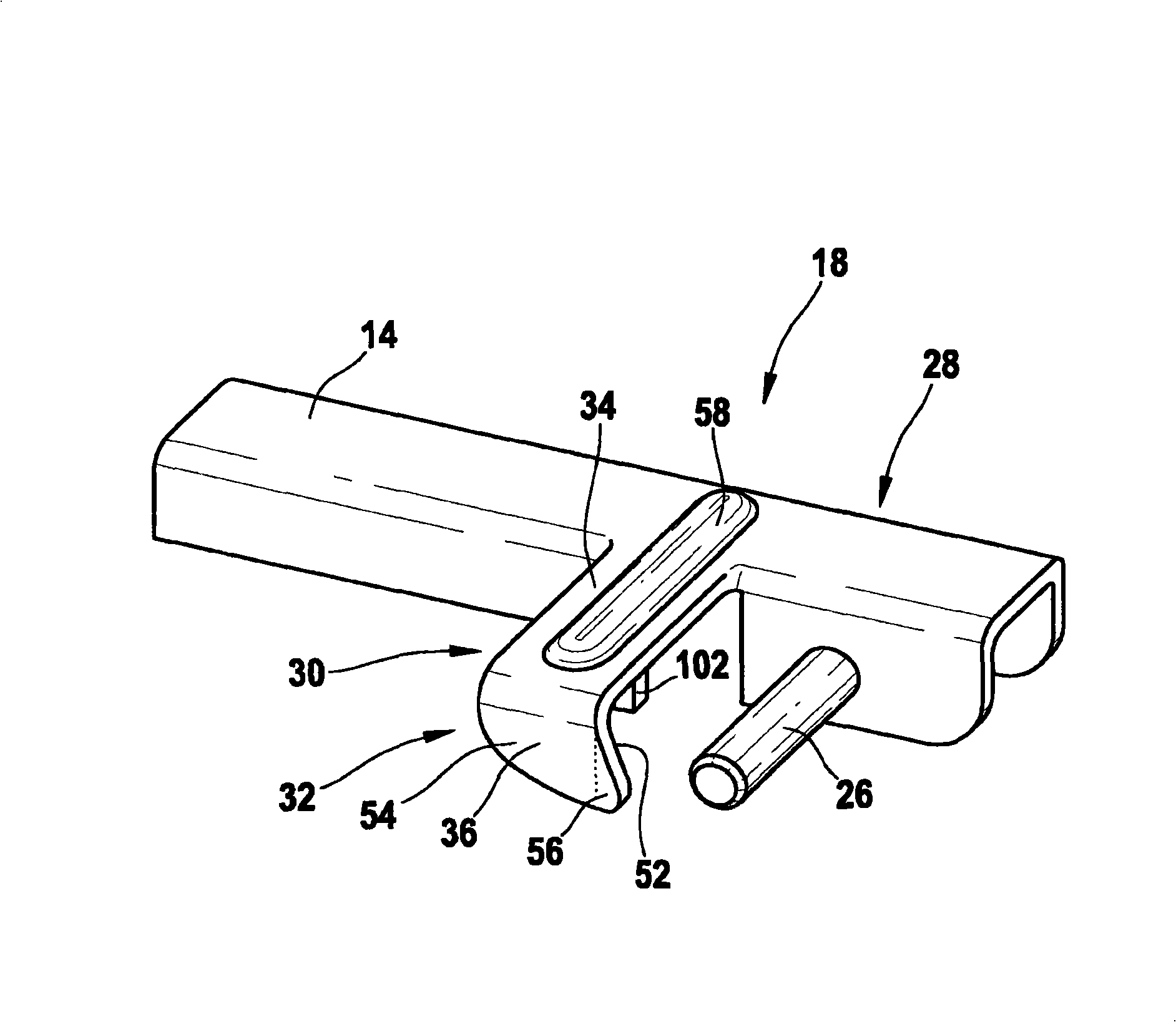

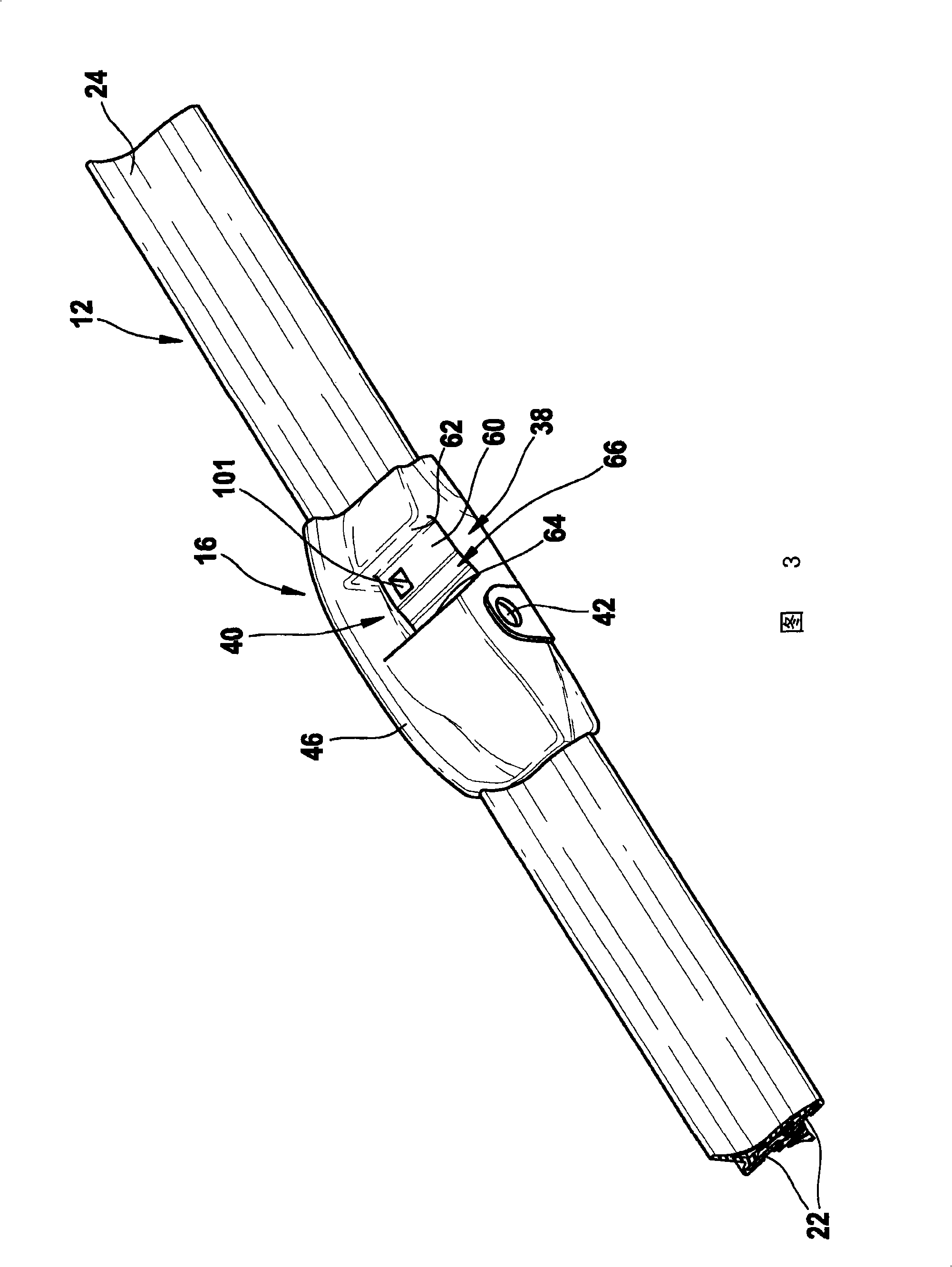

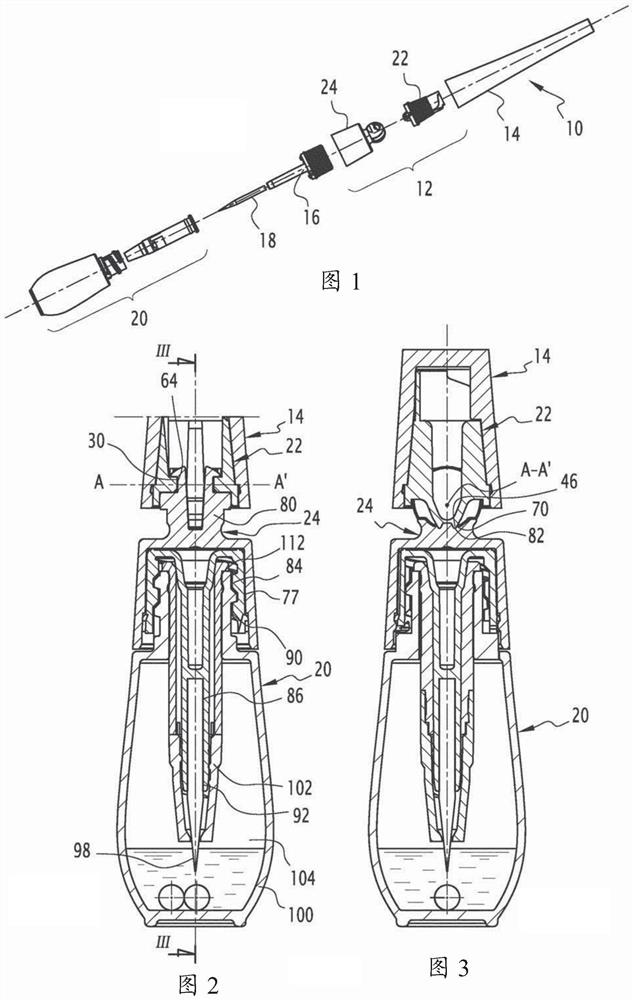

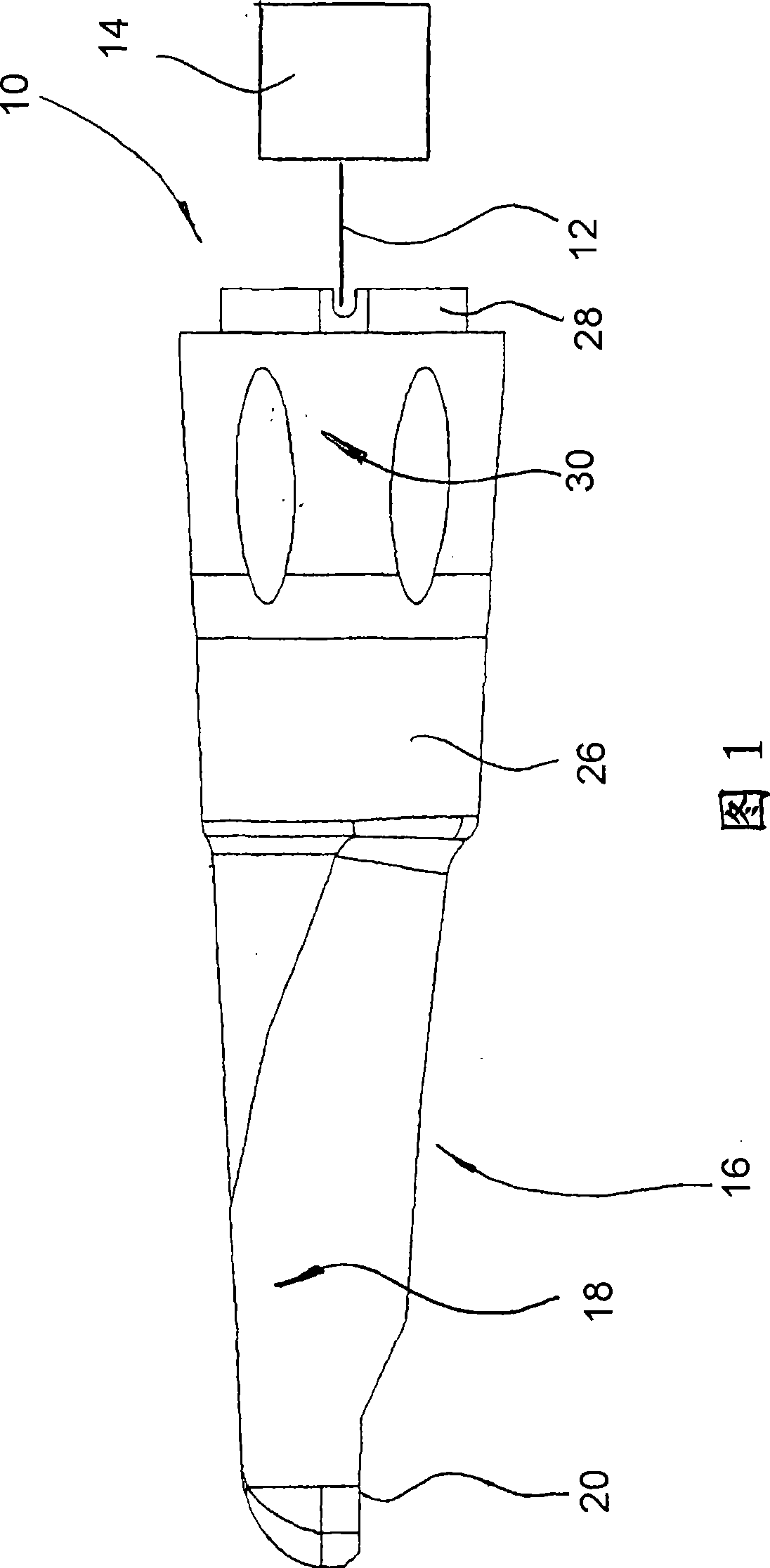

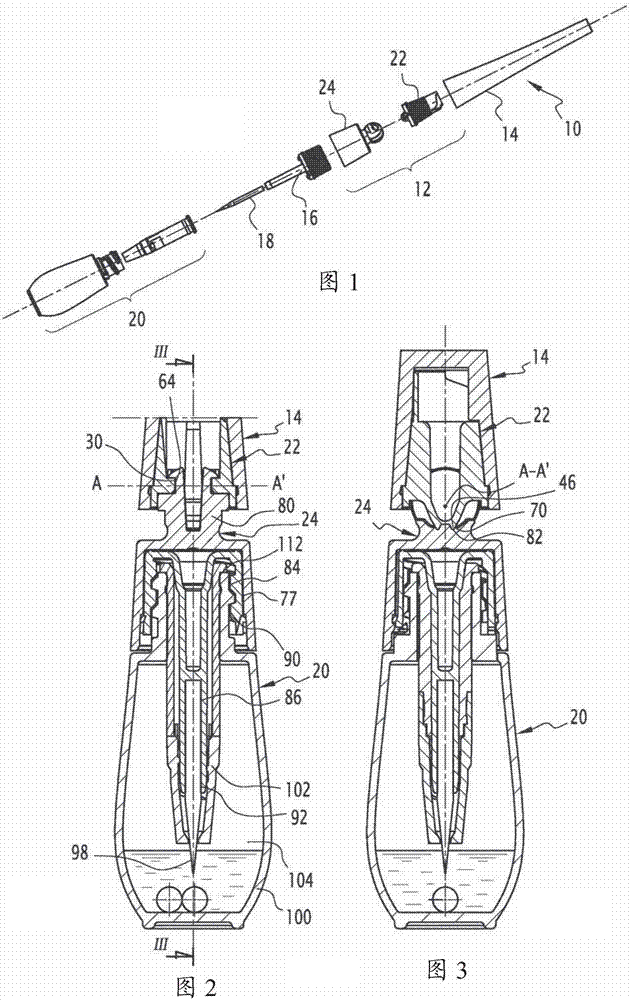

Wiper blade, wiper arm and connection arrangement for a windscreen wiper system of a vehicle

The invention relates to a wiper blade (14) for a windscreen wiper system of a vehicle, comprising an attachment element (16) which comprises an upper piece (18) designed to secure the attachment element (16) to a wiper arm (12) of the windscreen wiper system. A lower piece (20), which holds a base of the wiper blade (14), is rotatably mounted on the upper piece (18) about an axis of rotation. The attachment element (16) can be moved into a function position which allows the windscreen to be wiped and in which at least one latching element (52) located on the upper piece (18) is latched to a counter piece (44) provided on the sides of the wiper arm (12). The at least one latching element (52) can be moved into a release position by displacing the lower piece (20) relative to the upper piece (18), in which release position the attachment element (16) can be detached from the wiper arm (12). The invention further relates to a wiper arm (12) and to a connection arrangement (10) for a windscreen wiper system.

Owner:DAIMLER AG

Flower box holding device

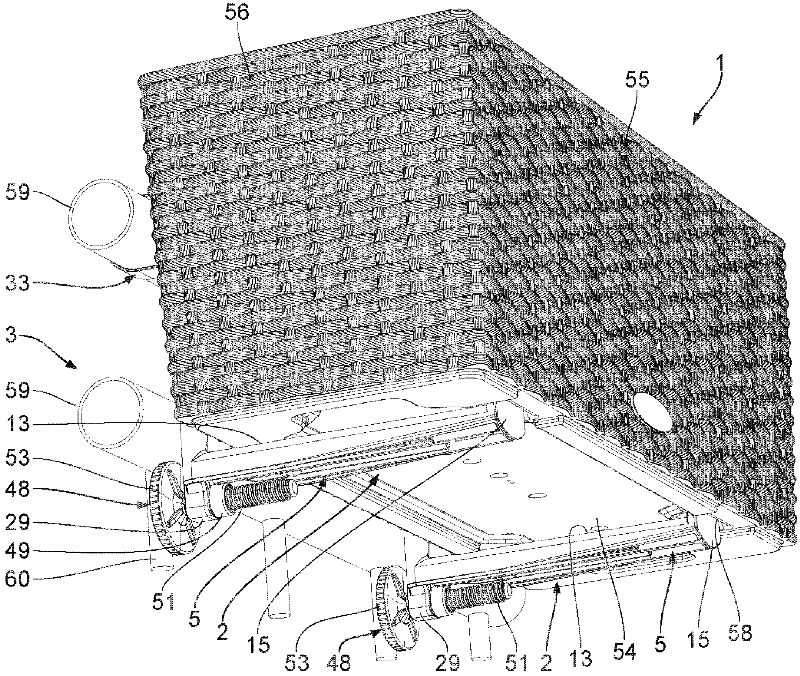

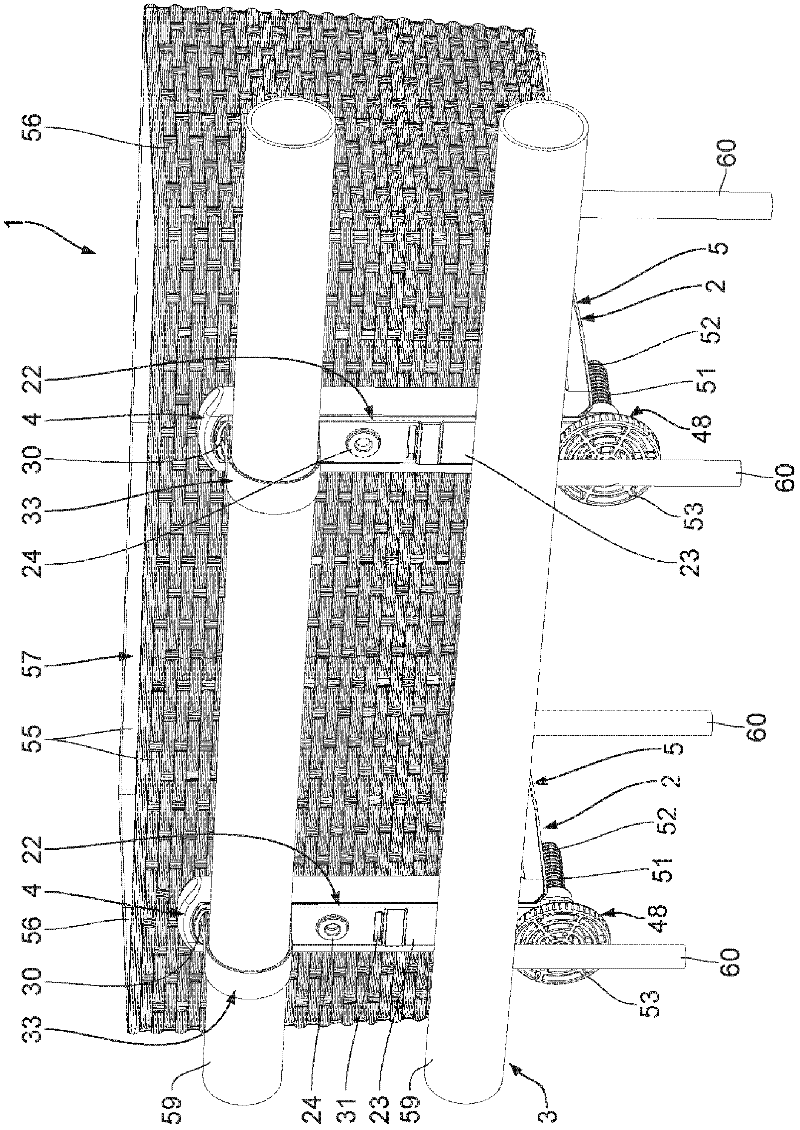

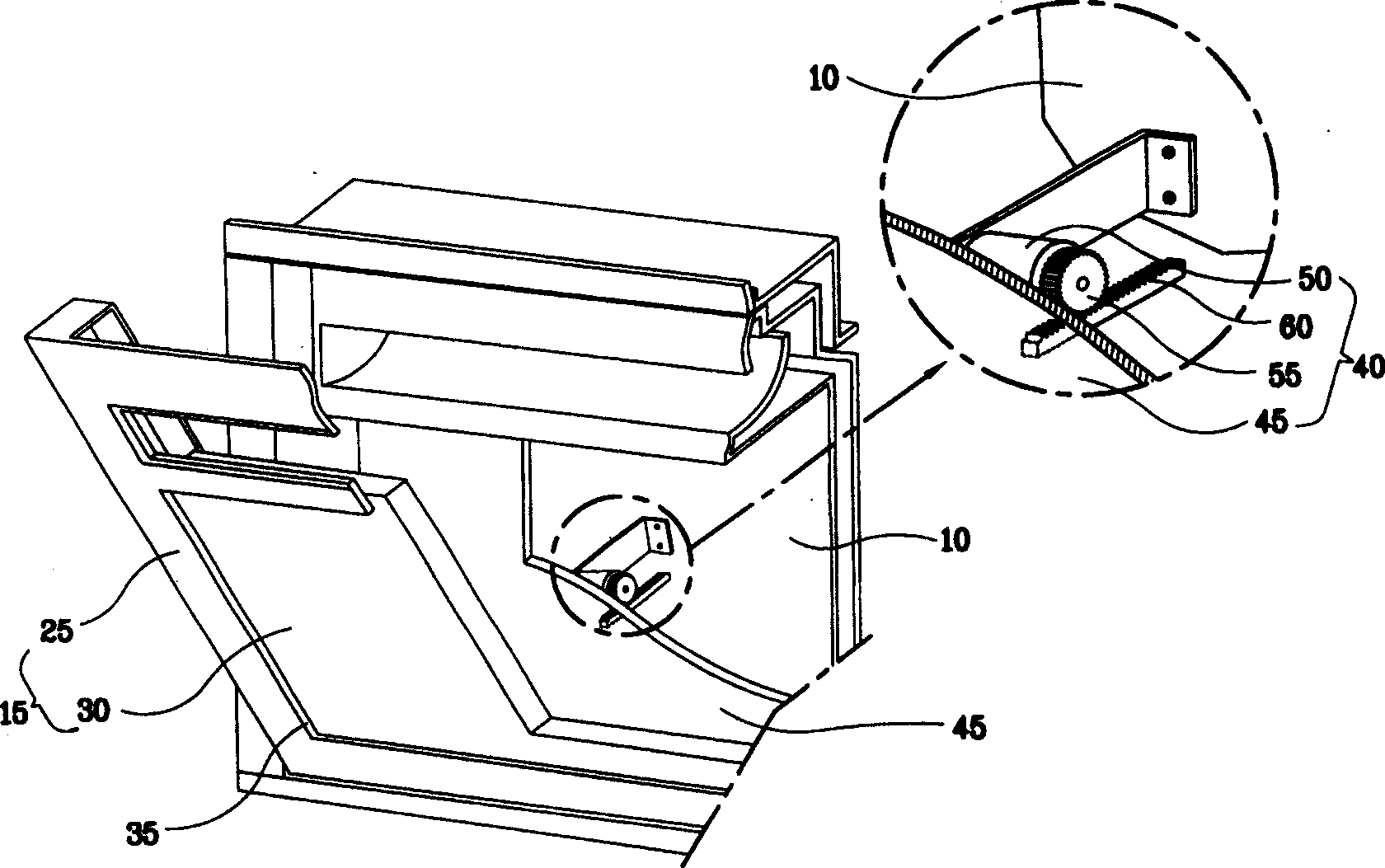

InactiveCN102308734AImprove matchReliable holdFlower tablesReceptacle cultivationEngineeringMechanical engineering

The invention relates to a flower box holding device which is applied for retaining at least one flower box (1) on a railing (3). The device has a base body (22) including a contact surface for fastening at a railing (3). A retaining strap (33) embraces a railing bar (59) of the railing and holds the base body (22) at the railing, and a hold part (2) is fastened at the base body (22). The strap comprises two strap ends, where one of the strap ends is fixed at the base body (22). A fixing unit adjustably defines a region of the strap at the base body, where the region of the strap is spaced to the strap end. The fixing unit is movable between a release position and a stop position.

Owner:GEOBRA BRANDSTATTER GMBH & CO KG

Thick cleaning composition

The invention discloses a thick cleaning composition, which relates to a thick cleaning composition for cleaning skin, eyes, teeth and hairs in the field of personal care articles. The cleaning composition comprises polyhydroxyalkanoates, a fatty compound with the melting point higher than 25 DEG C such as fatty acid, fatty alcohol, ethoxylated fatty alcohol or polyol fatty acid ester, a surfactant, a solvent and a beautifying and cleaning assistant agent for skin, eyes, teeth and hairs, wherein the solvent consists of water, lower alcohol, polylol and polyol ether. When the cleaning composition is used for cleaning skin and hairs, a satisfactory thick appearance can be achieved and stable viscosity can be kept under different temperature conditions. When used by consumers, the cleaning composition is easy to smear, forms foams easily and has good foam quality.

Owner:SUZHOU ELECO CHEM IND

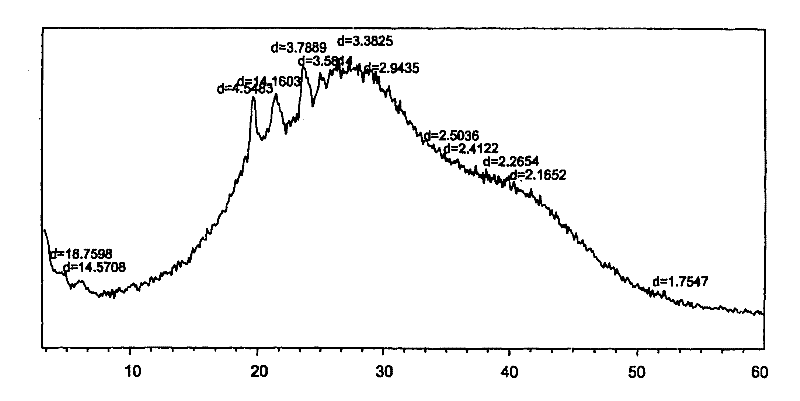

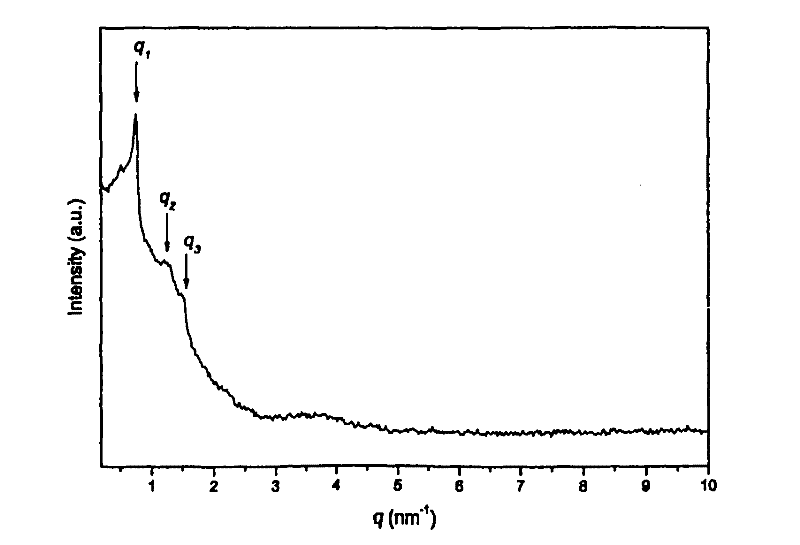

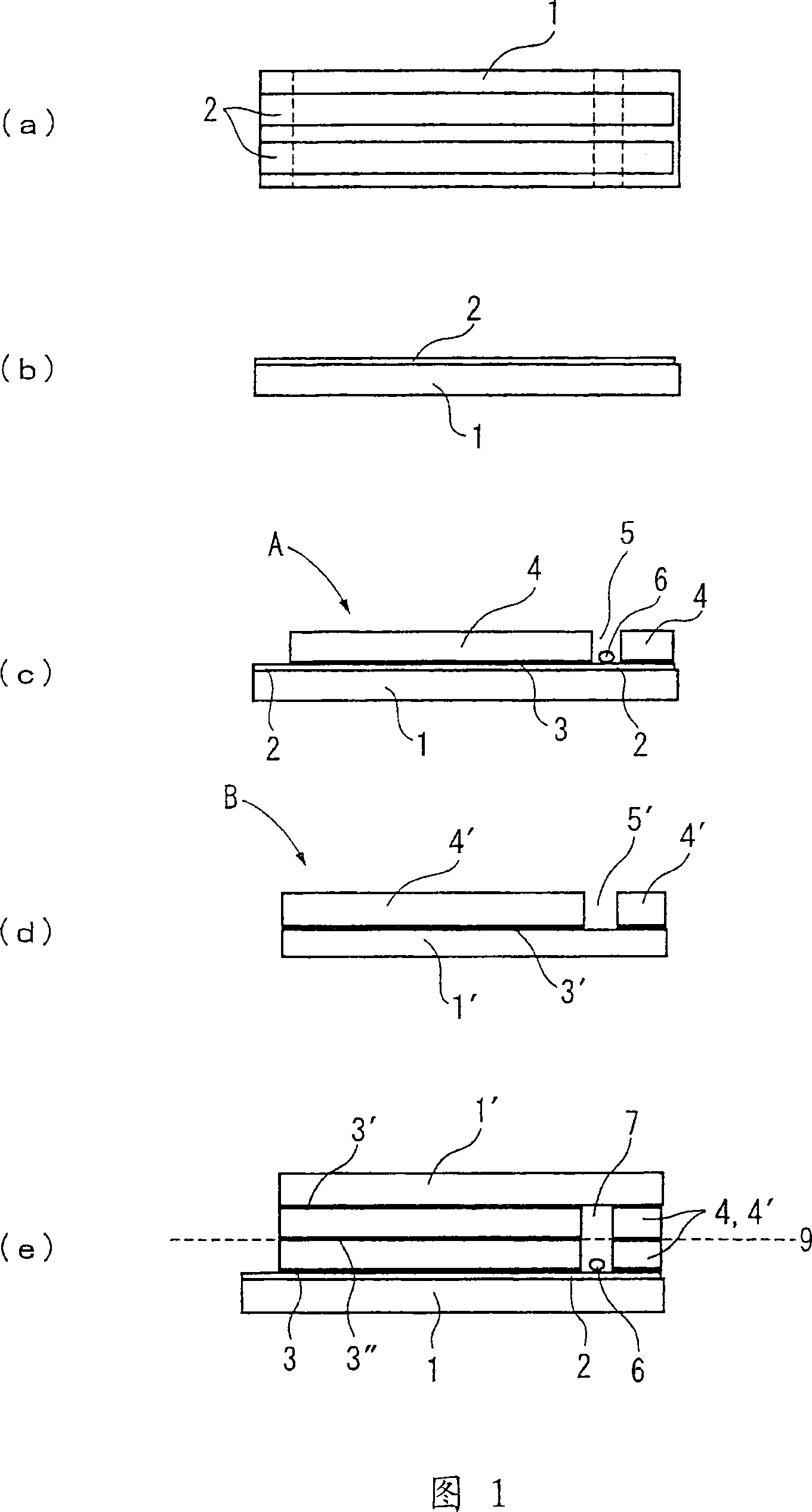

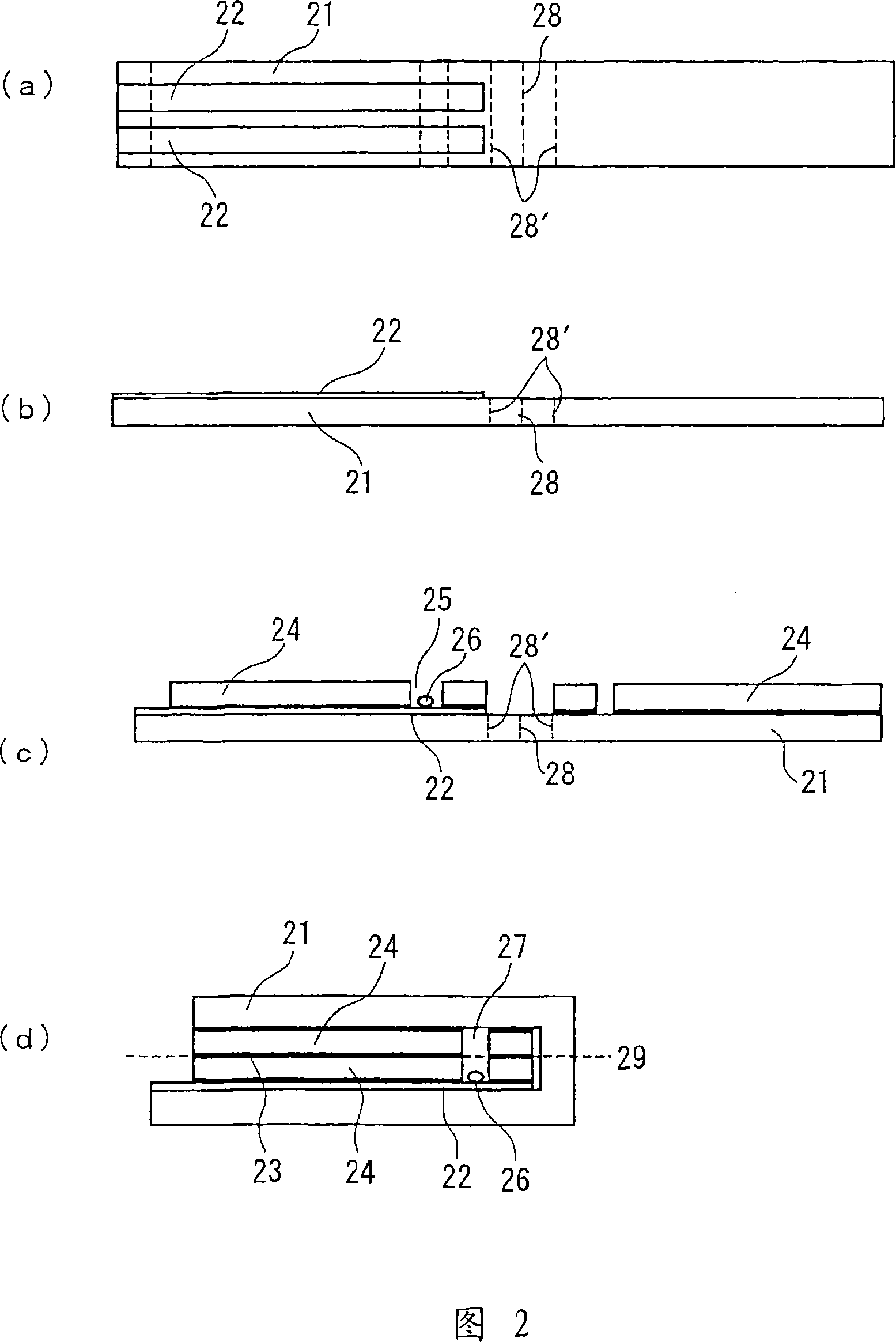

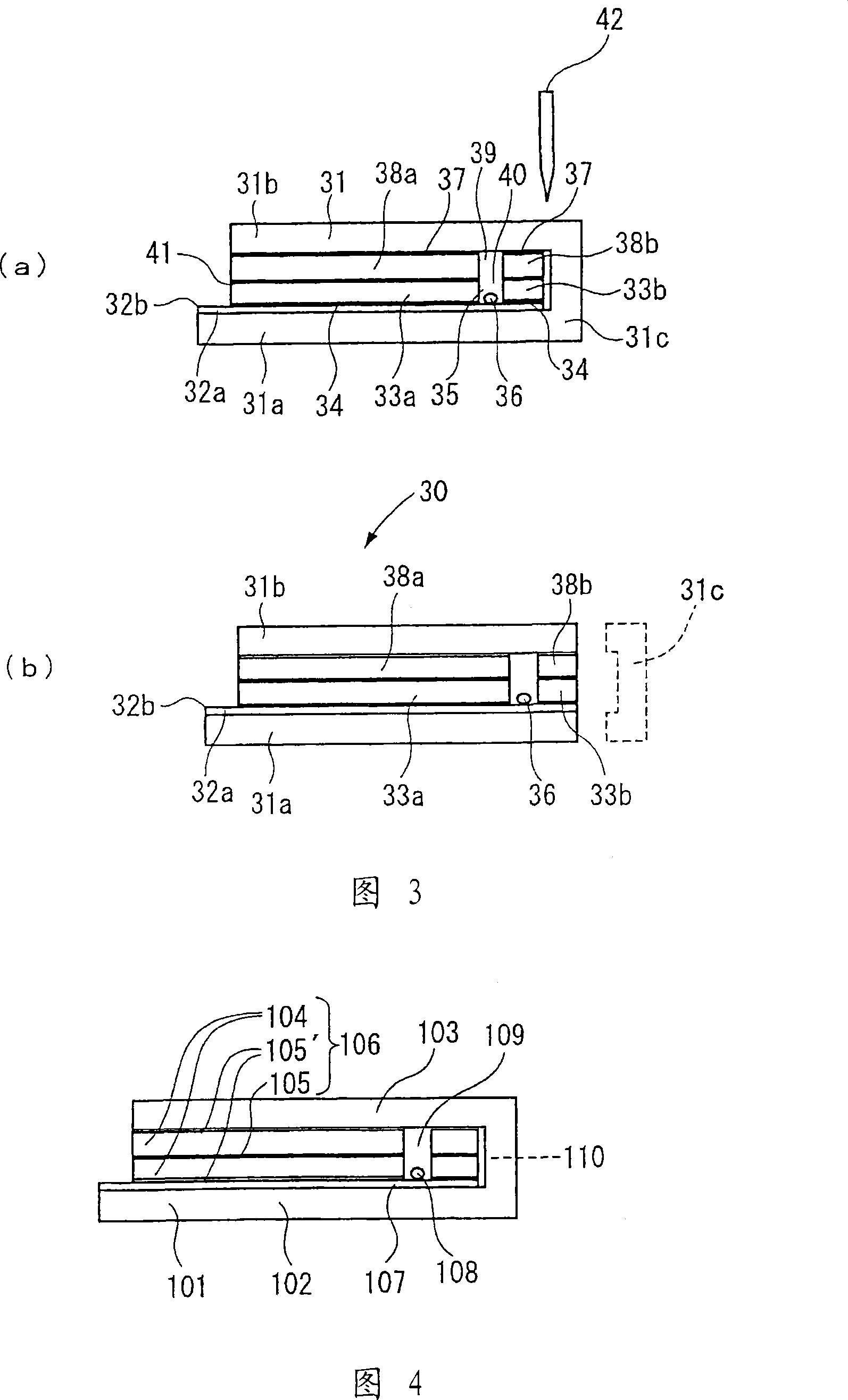

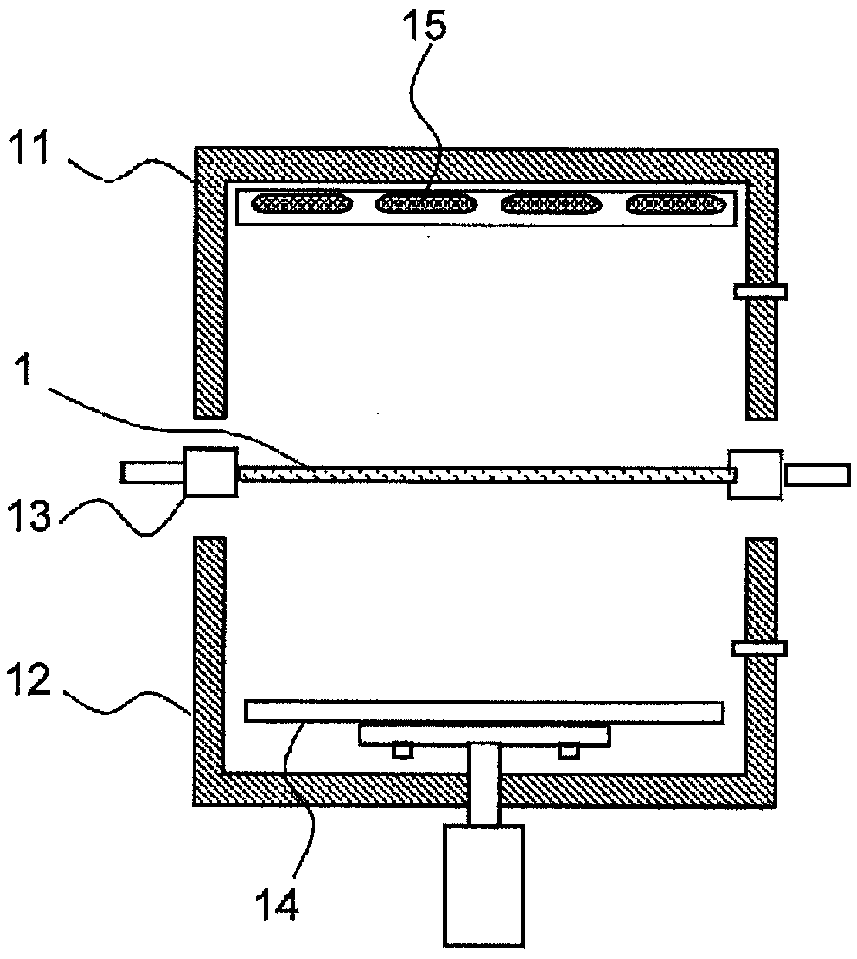

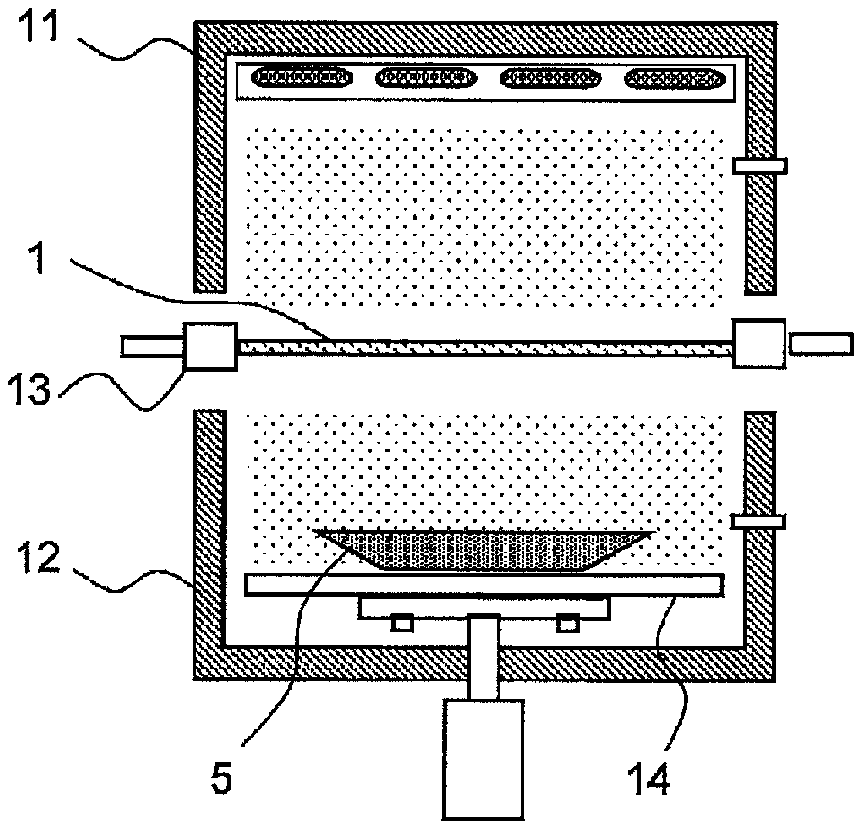

Sensor chip and production method therefor

InactiveCN101006337ANo warpingSatisfied with the appearanceMaterial analysis by electric/magnetic meansElectrical and Electronics engineeringHumidity

A sensor chip is provided. The sensor chip is provided with the board, the cover layer, the spacer layer sandwiched between the board and the cover layer, the hollow reacting part between the board and the cover layer, and a detecting means in the hollow reacting part. The board and the cover layer are made of the same material and have the same thickness. The material and the shape of the spacer layer are symmetric to a flat plane which is parallel to the board at equal distances from the board and the cover layer. The sensor chip does not warp due to changes of temperature and humidity in the environment. A method for manufacturing such sensor chip is also provided.

Owner:SUMITOMO ELECTRIC IND LTD +1

Connection apparatus for a wiping arm

InactiveCN101331040AClear affiliationPrevent installationVehicle cleaningElectrical and Electronics engineering

The invention relates to a connection apparatus (10) for a wiper arm (14) and a wiper blade (12). The connection apparatus comprises a first and a second connection part. According to the invention, provision is made for the first connection part to have a first identification means and for the second connection part to have a second identification means which corresponds to the first identification means. The invention also comprises a system with two flat-bar wiper blades, with at least one first identification means being provided on at least one flat-bar wiper blade in order to distinguish between the two wiper blades.

Owner:ROBERT BOSCH GMBH

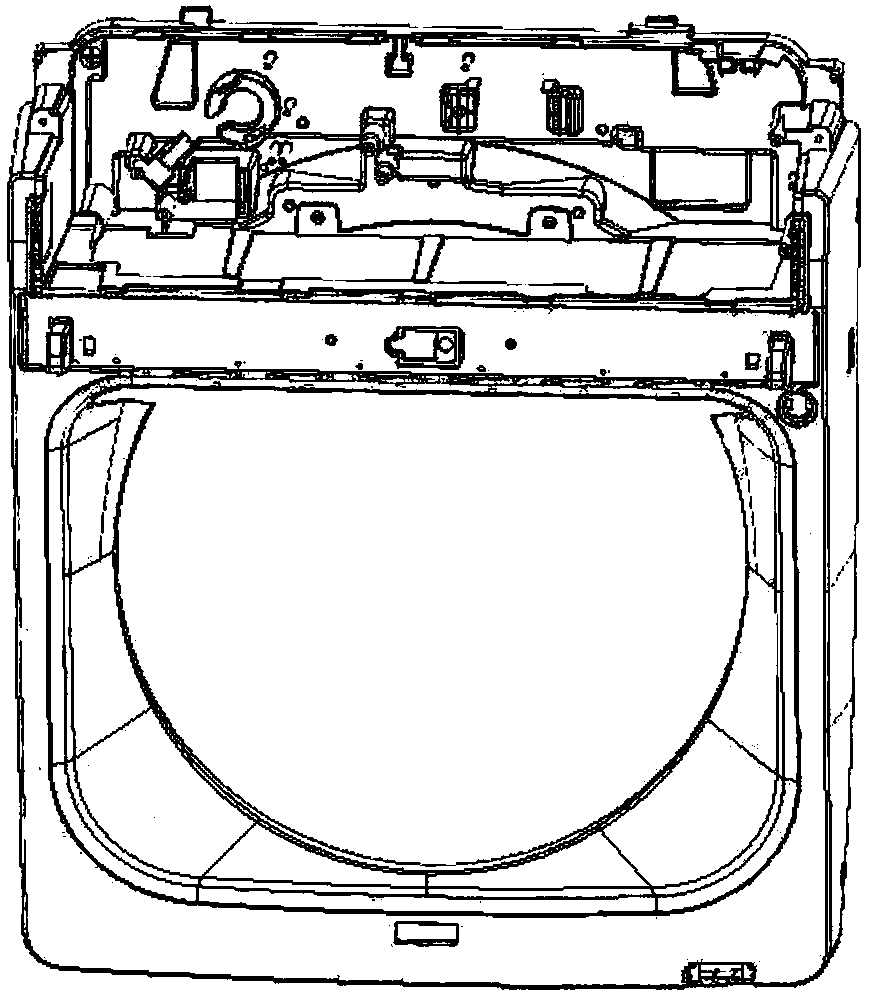

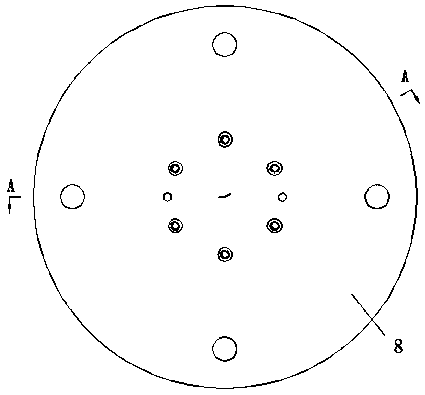

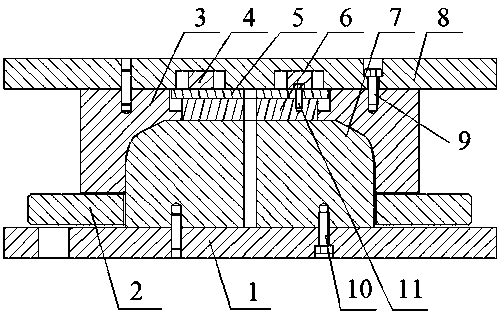

Washing machine upper frame mold

The invention relates to a washing machine upper frame mold for moulding of a washing machine upper frame. Gate inserts are employed for two connection (point gates and submarine gates) switching andthrottle valves are added, each throttle valve can ensure smooth cavity filling and balanced dissolution flow through adjustment, and the product can be free of mottle. Ejector blocks adopting ejectorpins are added with polyurethane elastomer cushions, during mold closing, the ejector blocks and parting surfaces cooperate consistently, during mold opening, the ejector blocks and a shrinkage product cooperate consistently under the action of the polyurethane elastomer cushions, therefore the problem of product surface stress mark can be well solved. Compared with the prior art, through point gate and submarine gate switching, the mold provided by the invention can solve the problem of accelerated solution flow in the mold so as to shorten the product moulding cycle and better achieve saturation pressure, improve the product injection moulding stability and reduce the follow-up de-gating process, and by improving the ejection system, the previous process of heating treatment with a hairdryer can be reduced subsequently, the produce quality is guaranteed, and the appearance can satisfy customers.

Owner:SHANGHAI YONGXING PLASTICS

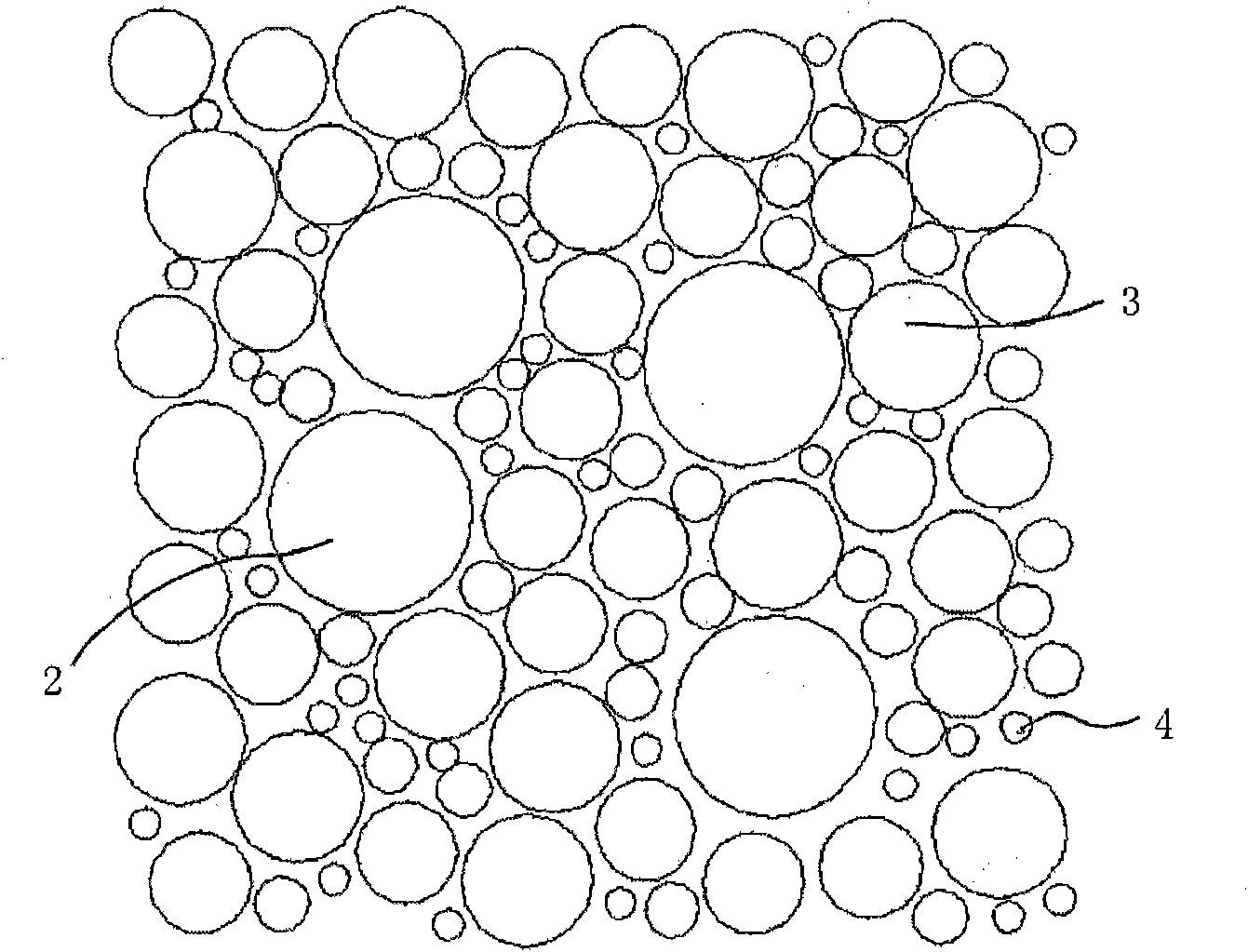

Mosaic brick

InactiveCN102251645AGood decorative effectLow manufacturing costCovering/liningsMaterials scienceBrick

The invention relates to a decorative material and in particular relates to a decorative mosaic brick. The mosaic brick comprises a meshy bearing layer, wherein brick bodies are clung onto the bearing layer at intervals. The mosaic brick is low in manufacturing cost, and can generate satisfying appearance visually, thus being a mosaic brick with changeable patterns and colors.

Owner:EVERSTONE BUILDING MATERIALS QINGDAO

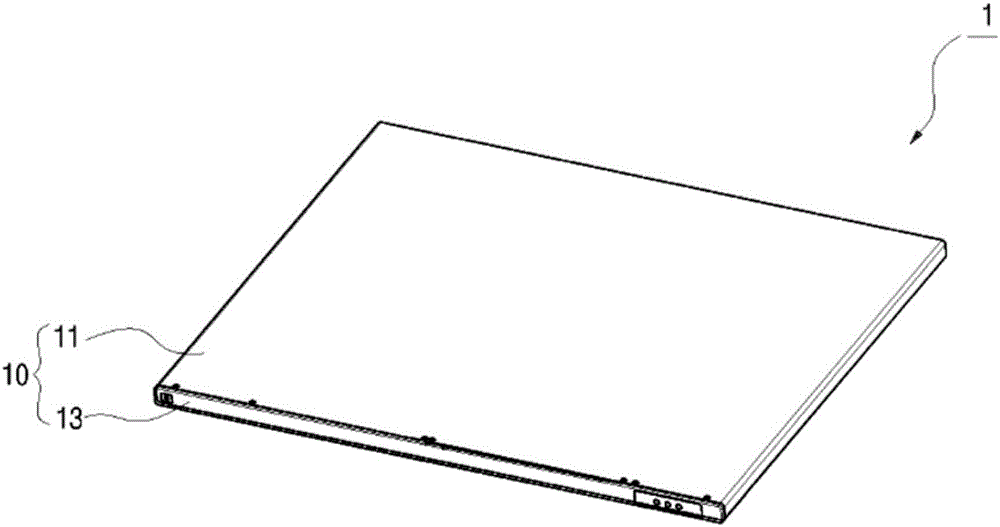

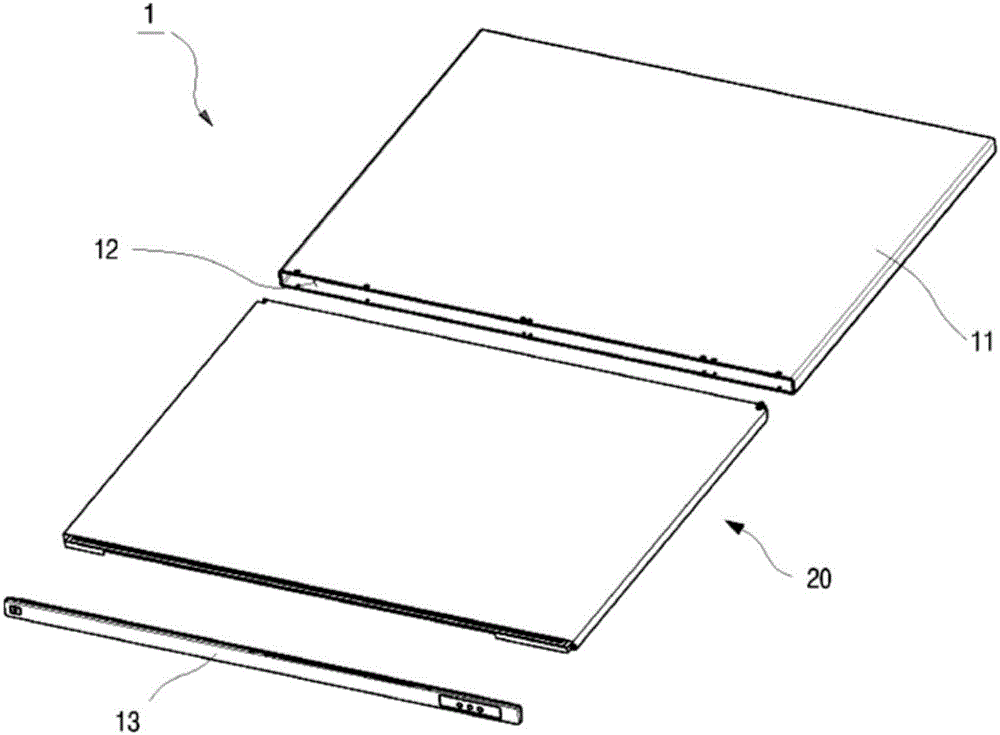

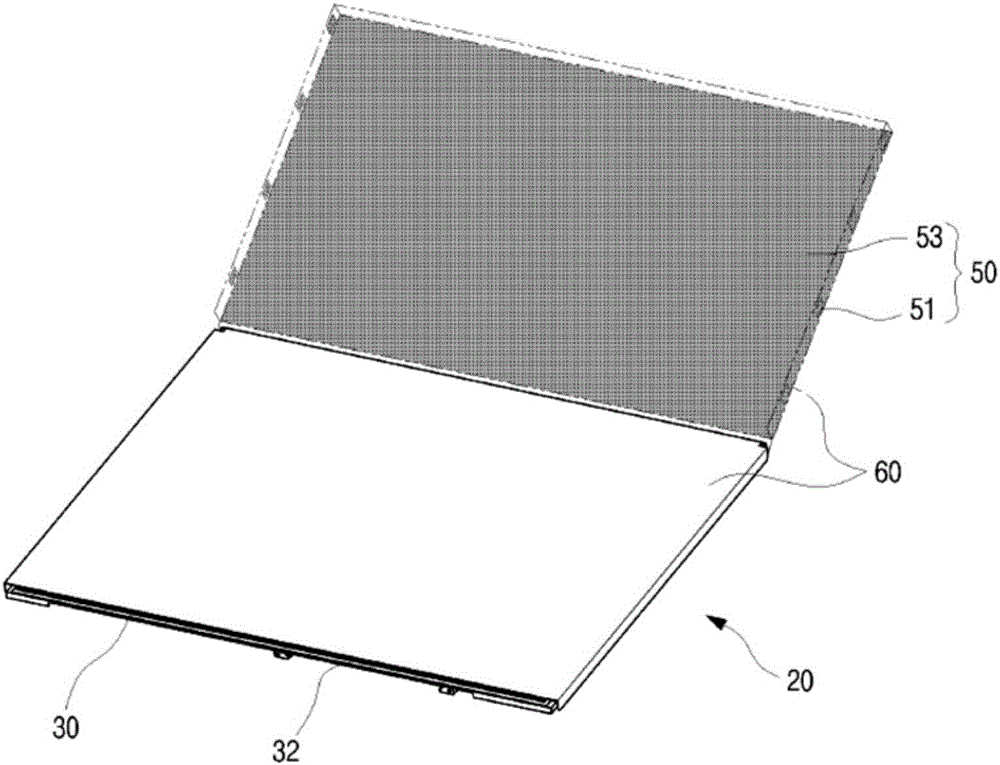

Radiation Image Detector, And Housing For Radiation Image Detector

InactiveCN106456079ASimple and slim structureReduce weightRadiation diagnosticsPhotographyFiberComing out

The present invention relates to a radiation image detector and a housing for a radiation image detector, comprising: a plate type detector assembly for detecting a radiation image; a housing main body, which is a plate type hollow body, produced in a seamless form using carbon fiber so as to form, only on one side of the perimeter thereof, a detector entrance to and from which the detector assembly goes in and comes out; and a housing cover for opening and closing the detector entrance. Accordingly, it is possible to provide a radiation image detector and a housing for a radiation image detector which are simpler, slimmer and lighter. In addition, the present invention provides a radiation image detector and a housing for a radiation image detector being excellent in convenience in use and having excellent appearance.

Owner:RAYENCE +1

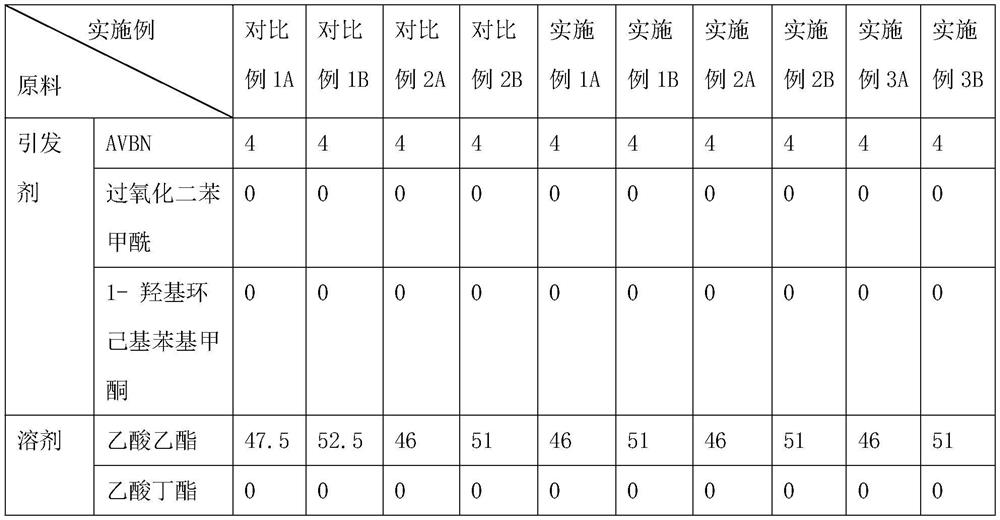

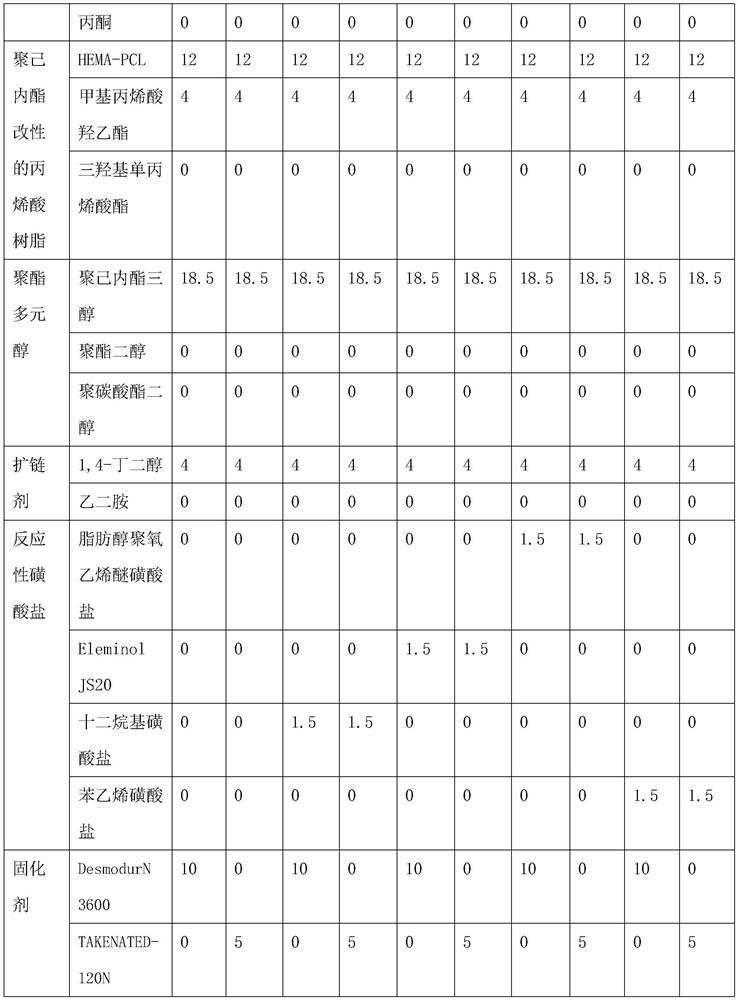

Super-hydrophilic anti-dirt self-repairing coating, preparation method of coating and coating

ActiveCN114806392AImprove hydrophilicityAvoid breakingPolyurea/polyurethane coatingsPolyesterPolymer science

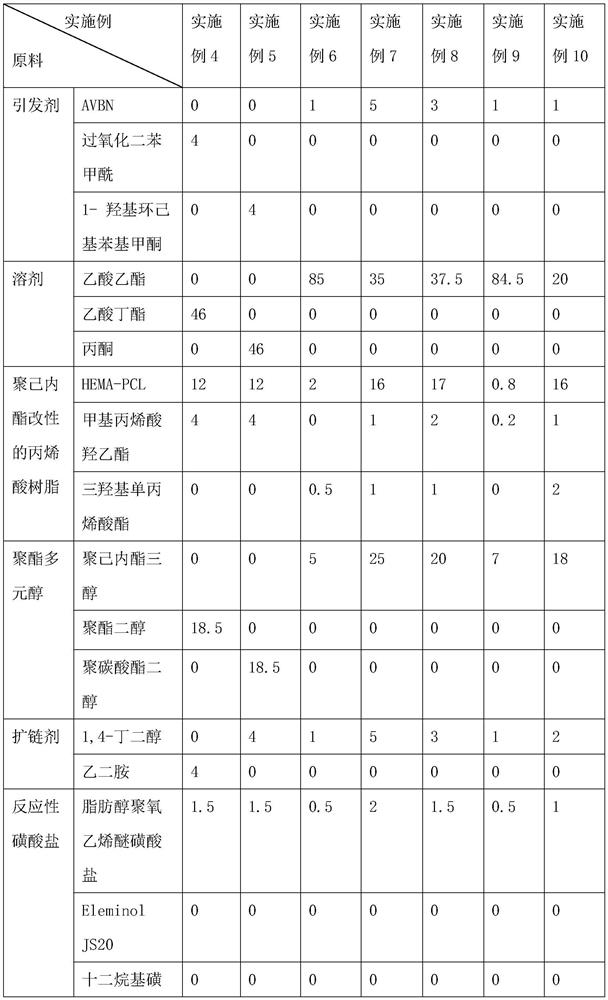

The invention provides a super-hydrophilic anti-smudginess self-repairing coating, a preparation method of the coating and the coating, and the preparation method of the coating comprises the following steps: step 1, adding a solvent into a reaction container, adding an initiator, polycaprolactone modified acrylic resin, reactive sulfonate, polyester polyol and a chain extender into the reactor under the protection of inert gas, and stirring to obtain a mixture; reacting for 8-48 hours at the temperature of 85-100 DEG C to obtain synthetic resin containing carbon-carbon double bonds, and reactive functional groups of the reactive sulfonate at least comprise the carbon-carbon double bonds; and step 2, under the protection of inert gas, adding an isocyanate curing agent into the reaction container, continuously stirring for 10-30 minutes, filtering, removing bubbles, blade-coating and drying to prepare the super-hydrophilic anti-smudginess self-repairing coating, coating the surface of an object with the coating, and forming a coating after curing and film forming to obtain the super-hydrophilic anti-smudginess self-repairing coating. The coating provided by the invention has the advantages of super hydrophilicity, smudginess resistance, low haze, high light transmittance and high glossiness.

Owner:江苏易米新材料科技有限公司

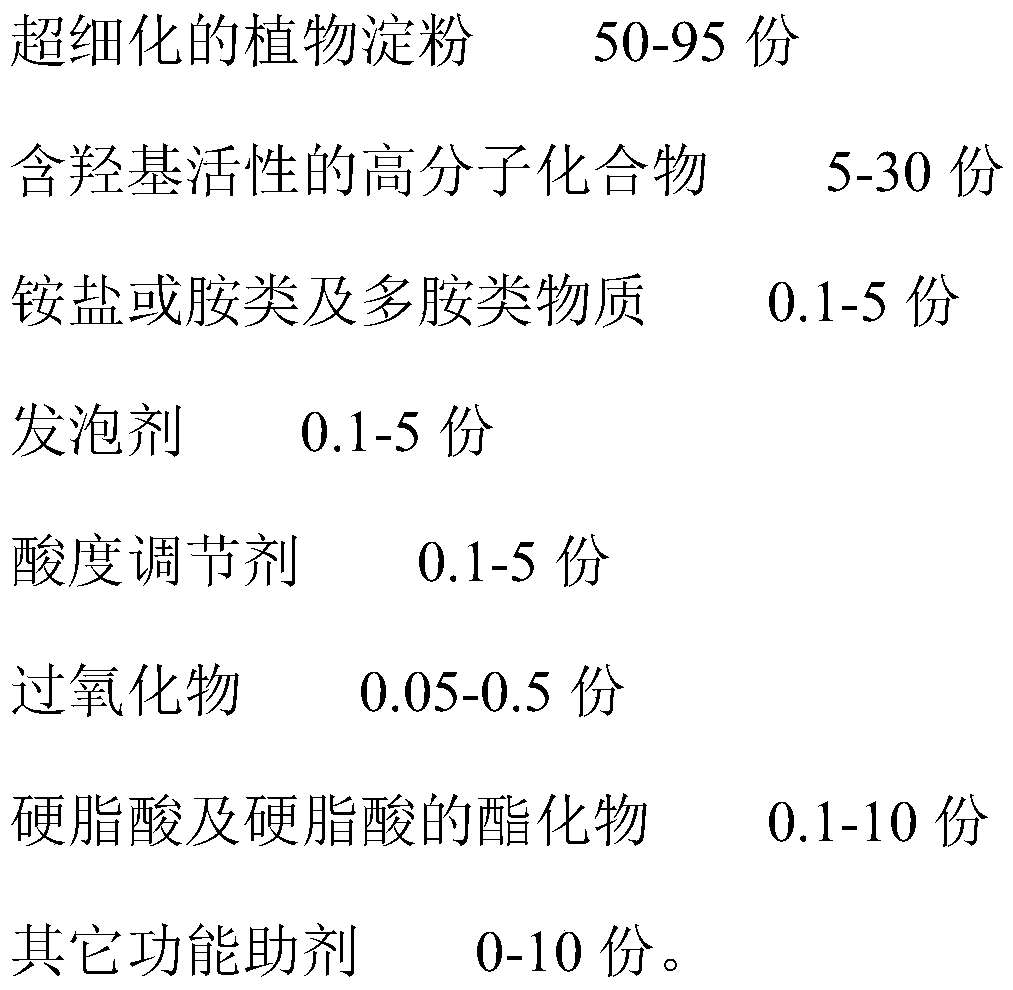

Biodegradable filling type foam and production process thereof

PendingCN111423624AImprove rheological properties of granular structureEvenly distributedPolymer scienceFoaming agent

The invention relates to the technical field of foam. The invention relates biodegradable filling type foam and a production process thereof. The biodegradable filling type foam comprises the following raw materials in parts by weight: 50 to 95 parts of ultrafine plant starch, 5 to 30 parts of a hydroxyl-containing active high-molecular compound, 0.1 to 5 parts of ammonium salt or amine and polyamine substance, 0.1 to 5 parts of a foaming agent, 0.1 to 5 parts of an acidity regulator, 0.05 to 0.5 part of a peroxide, 0.1 to 10 parts of stearic acid and ester of stearic acid, and 0 to 10 parts of other functional additives. According to the biodegradable filling type foam, the raw materials are adopted, the weight ratio of the raw materials is strictly controlled, and the prepared biodegradable filling type foam particles are smooth and fine in appearance, fine and uniform in internal foam pore structure and good in pressure resistance, resilience, weather resistance and cold resistance.

Owner:中山市淀堂环保科技有限公司

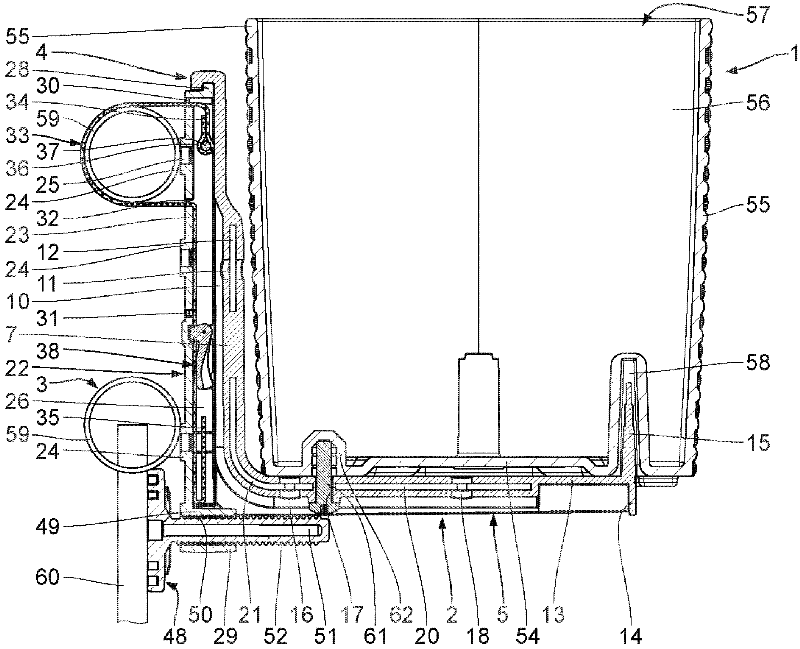

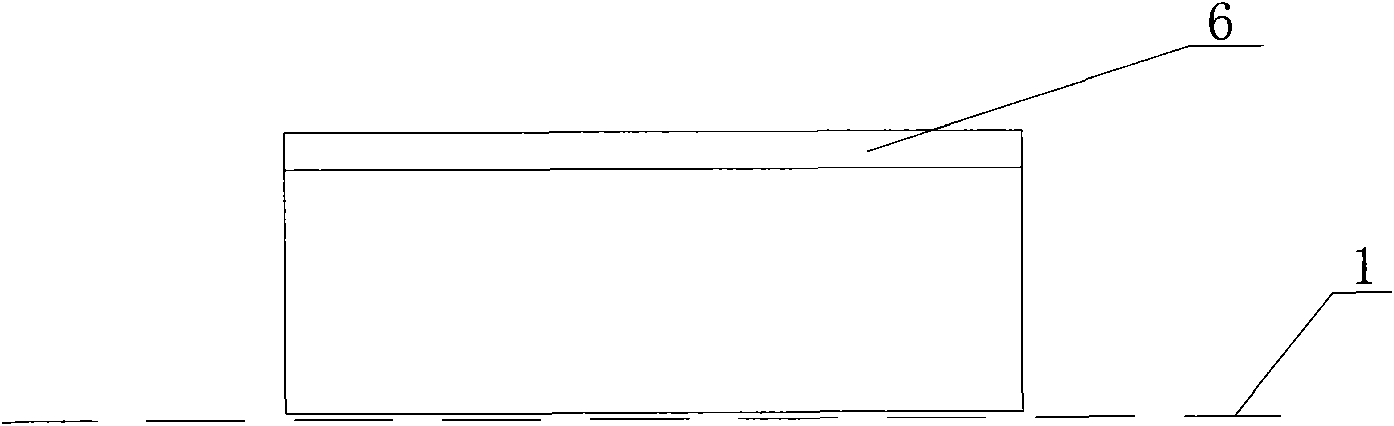

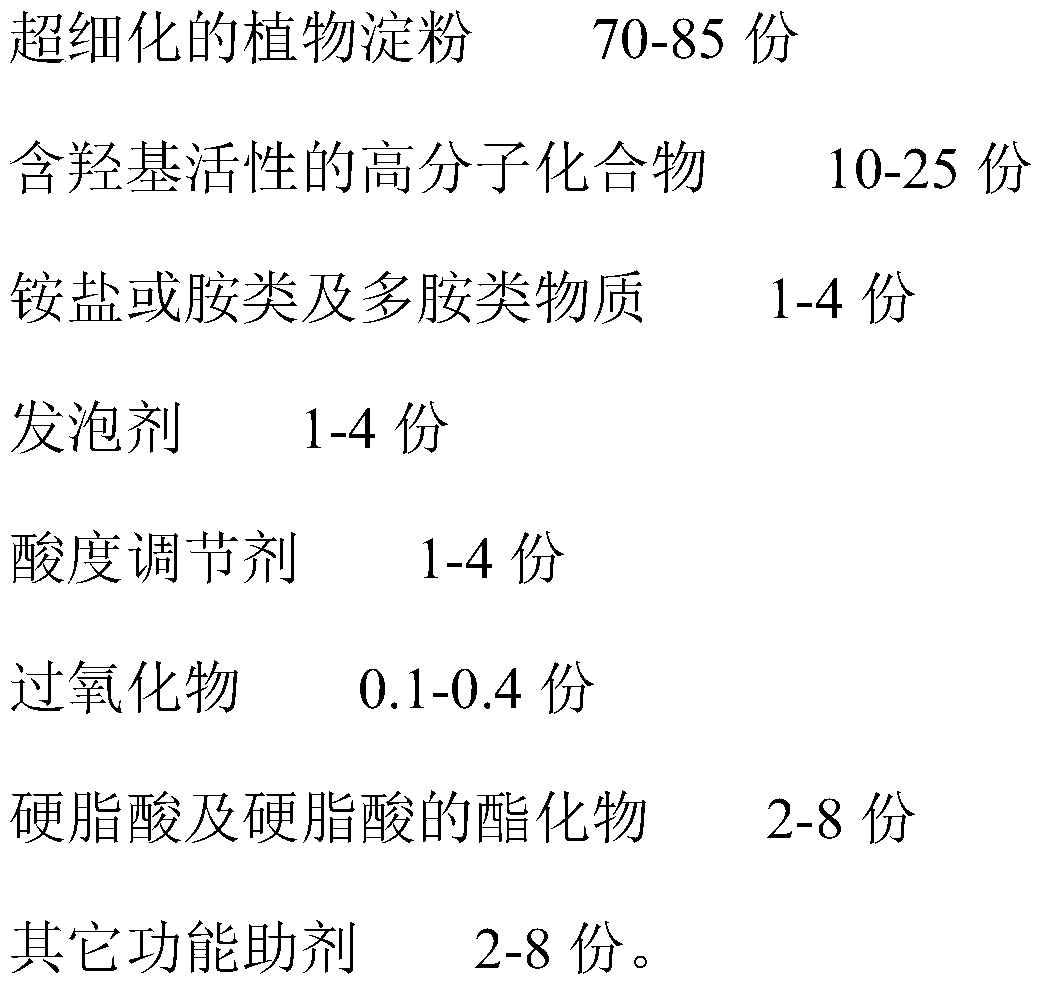

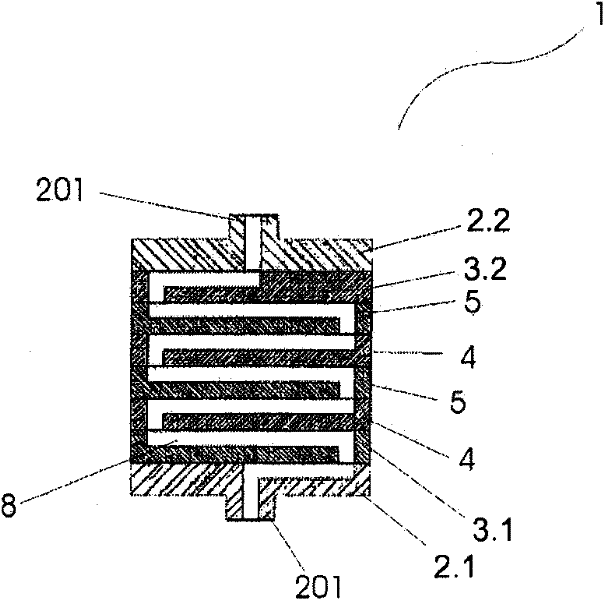

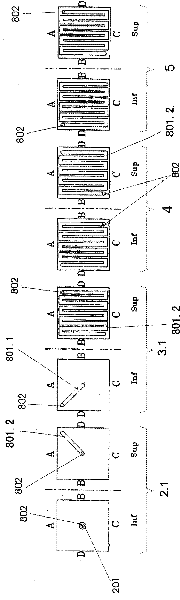

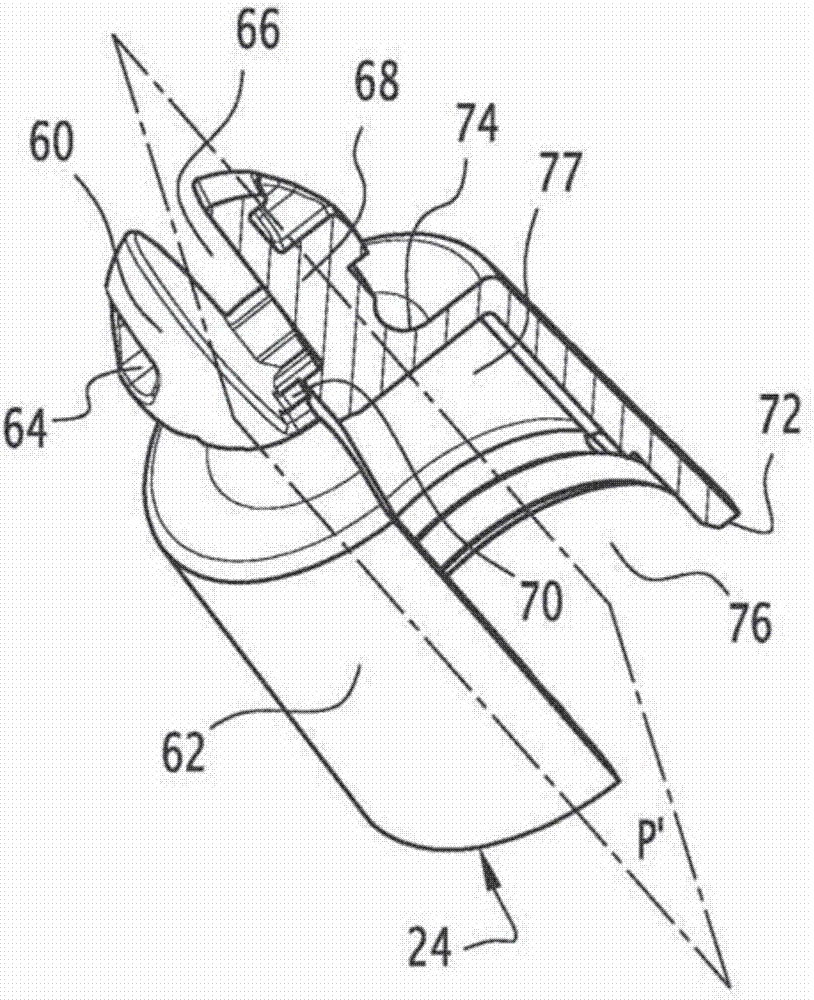

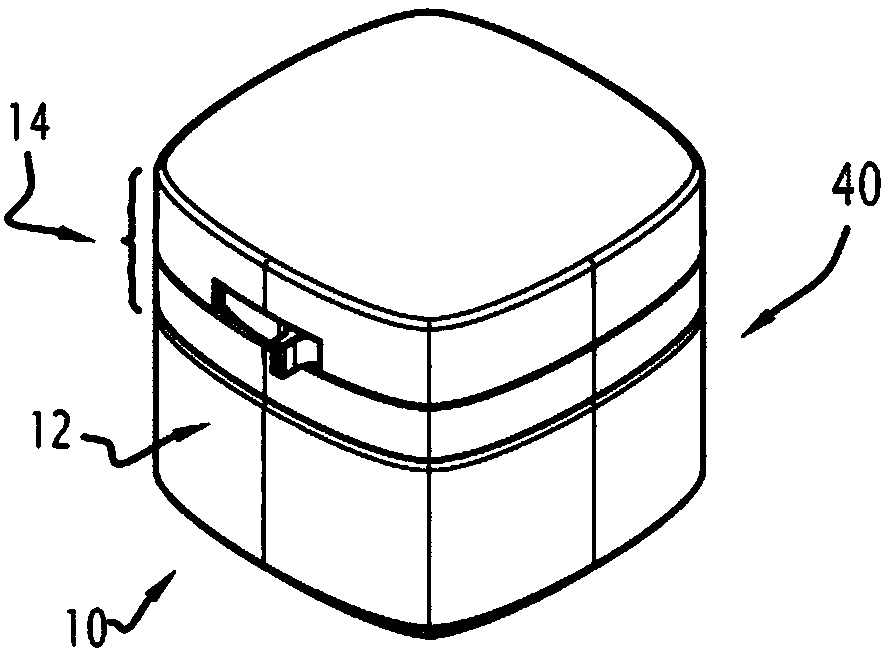

Water insulator and electric water heater using the water insulator

InactiveCN101460786BReduce volumeSatisfied with the appearanceFluid heatersEnergy efficient heating/coolingElectrical resistance and conductanceEngineering

A device called water insulator (1) is described, for limiting the transmission of current through the water in pipes, in particular for the electrical insulation of water inlet and outlet pipes (1102; 1103) in electrical storage or instant water heaters (11). The water insulator (1) comprises a pile of elements of insulating material (2.1, 2.2, 3.1, 3.2; 23.1, 23.2; 4, 5) on whose faces channels (801) are obtained, in communication with each other by passages (802), so as to form a continuous duct (8) from a first connector (2.1) up to a second connector (2.2). The channels (801.1; 801.2) have a winding path, in order to maximise the length of the duct (8); the use of a variable number of first and second type modular elements (4, 5) alternating to each other in the pile, allows obtaining a duct (8) of variable length and sufficient for ensuring the desired electrical resistance whatever the water conductivity.

Owner:ARISTON THERMO SPA

Thick cleaning composition

The invention relates to a thick cleaning composite, in particular to a thick cleaning composite used for cleaning skin, eyes, teeth and hair in the field of personal care products. The cleaning composite comprises long-chain fatty acyl basic amino acid ester, fatty compound of fatty acid, fatty alcohol, fatty alcohol ether or polyalcohol fatty acid ester, surfactant, solvent composed of water, lower alcohol, polyalcohol and polyalcohol ether as well as auxiliary reagent used for beautifying and cleaning skin, eyes, teeth and hair. The cleaning composite is used for cleaning skin and hair, can obtain satisfactory thick appearance and ensures viscosity to be stable at different temperatures, thus being easy for a consumer to smear when in use and realizing rapid foaming and good foam quality.

Owner:SUZHOU ELECO CHEM IND

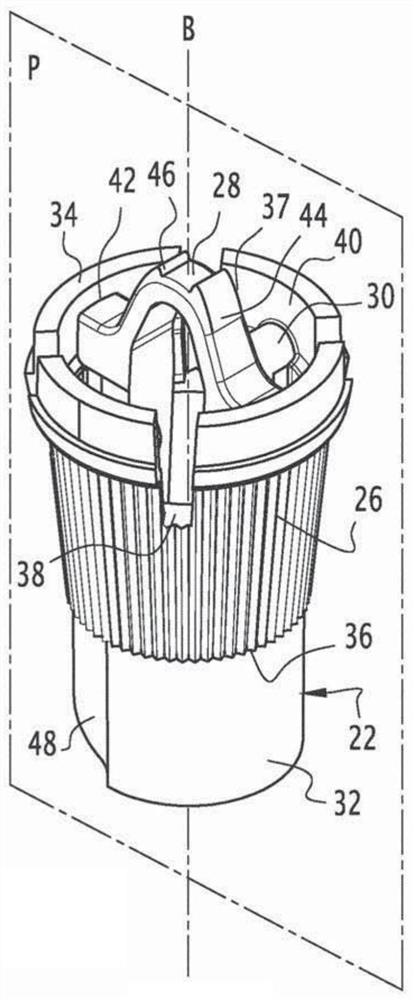

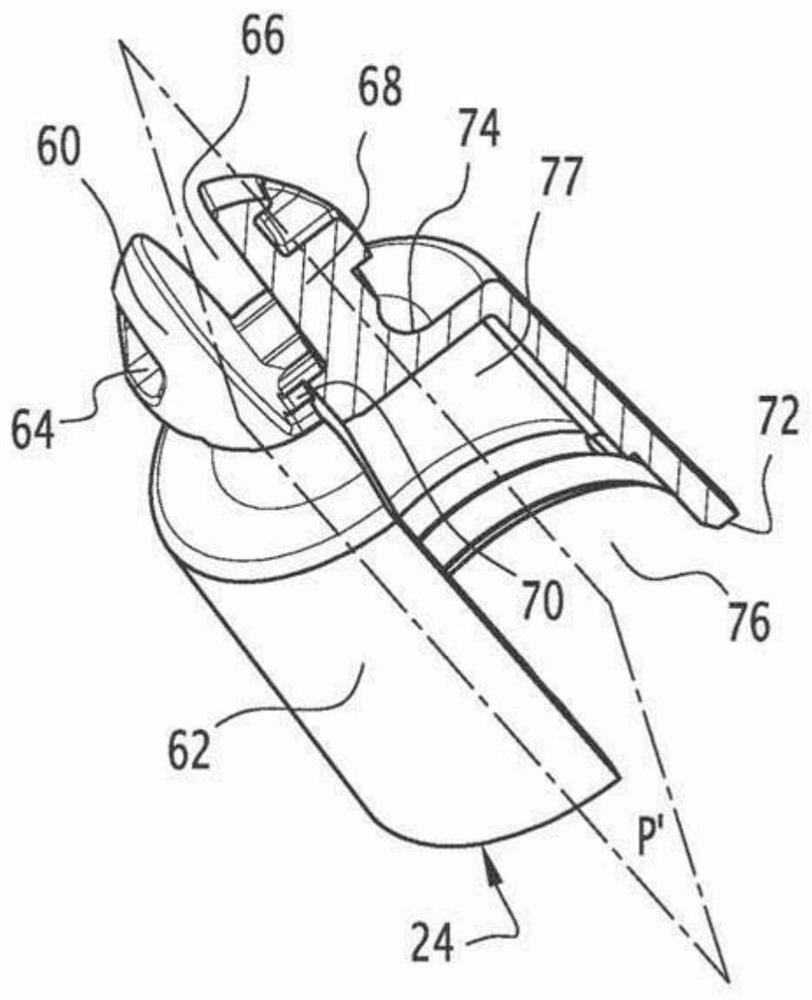

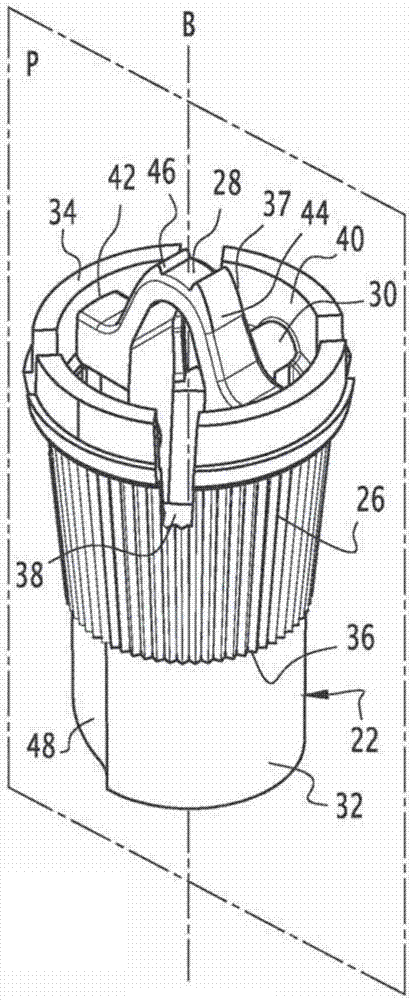

Engagement mechanism of cosmetics application device, related device, application method and manufacturing method

ActiveCN107529870BEasy to useSatisfied with the appearancePackaging toiletriesPackaging cosmeticsMechanical engineeringIndustrial engineering

Owner:LOREAL SA

Chemical plating method for Mg and its alloy

InactiveCN100462479CSatisfied with the appearanceLiquid/solution decomposition chemical coatingNickel saltChemical plating

The chemical plating process for magnesium-base material includes the following steps: 1. alkaline dewaxing the magnesium-base material; 2. activating with acid solution containing fluoric salt and no chlorine ion and in pH 2.0-5.0, and treating with alkaline neutralizing solution containing alkali metal salt of pyrophosphoric acid, fluoric salt and hypophosphite in pH 8.0-12.0; 3. chemical nickel pre-plating with the plating solution containing nickel salt in 10-80 g / L concentration, fluoric salt in 5-50 g / L concentration, pyrophosphite in 20-100 g / L concentration and no chlorine ion and in pH 5.0-9.0; 4. chemical nickel plating with the plating solution containing nickel salt in 10-100 g / L concentration, pyrophosphite in 10-80 g / L concentration and no chlorine ion and in pH 3-7; and 5. optional heat treatment. The said process can form homogeneous compact nickel layer with sufficient binding force on magnesium-base material.

Owner:李克清

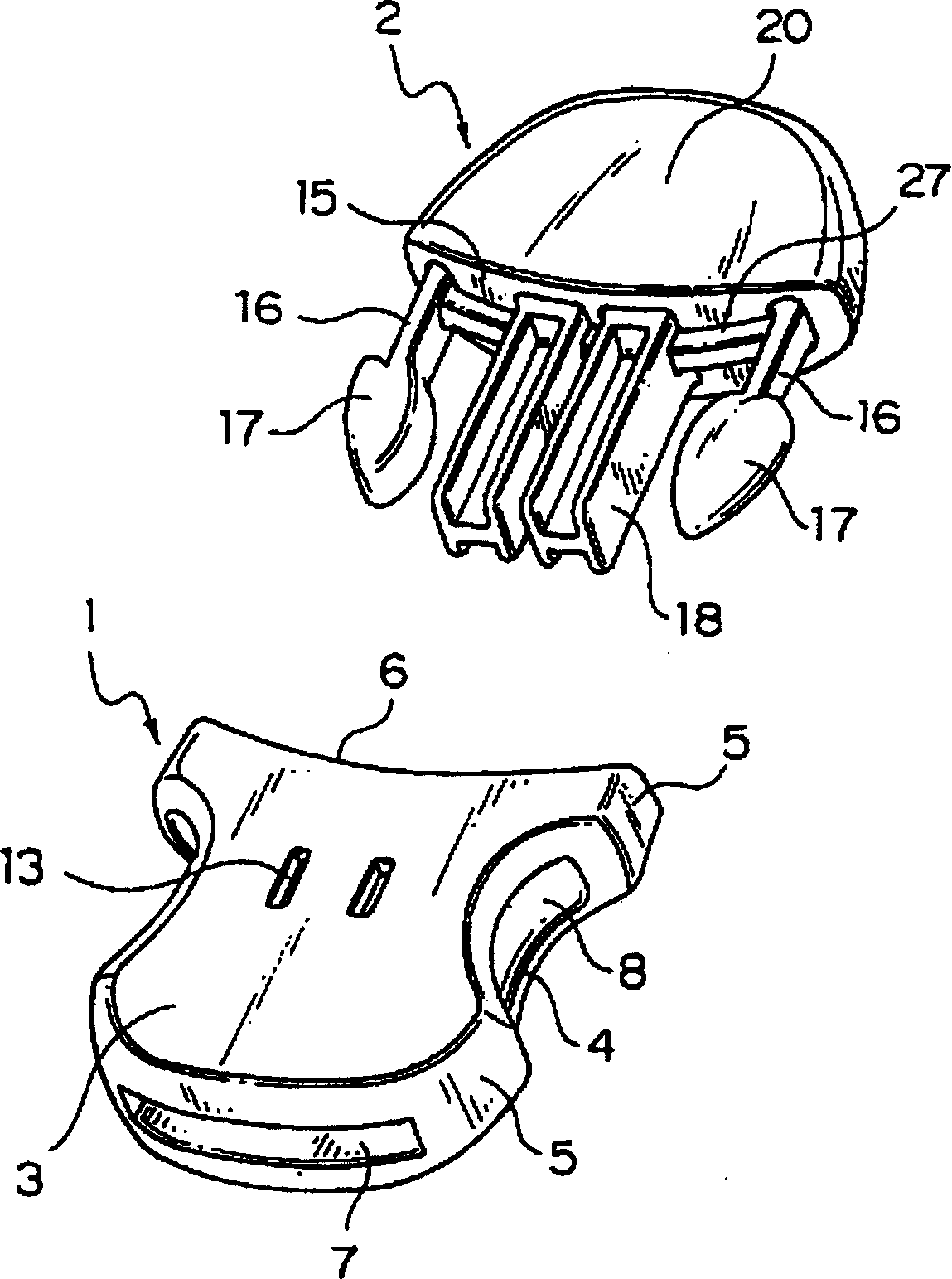

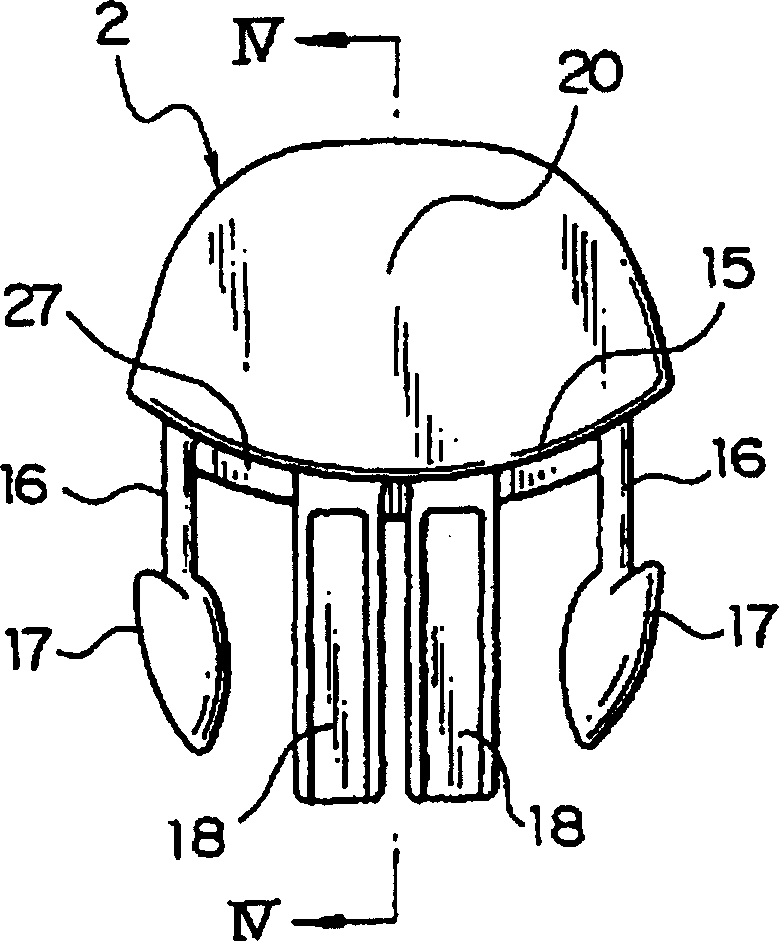

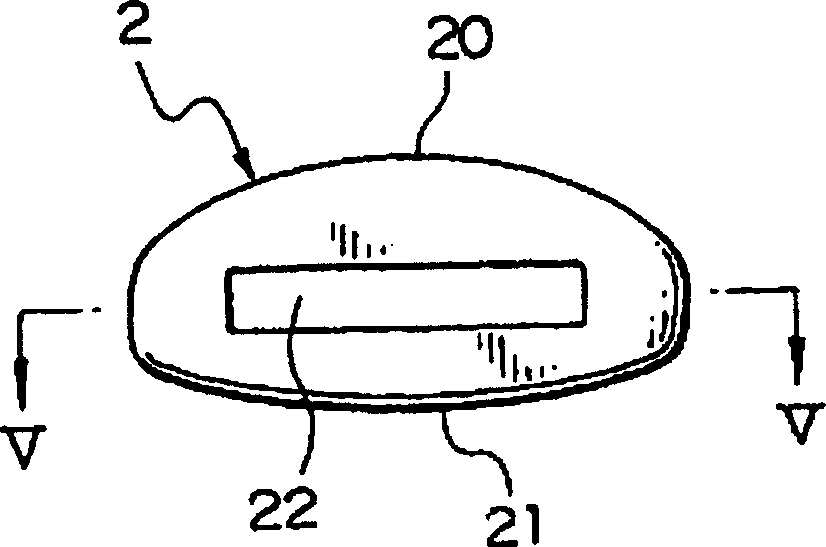

Buckle

The invention provides a buckle which is formed from a buckle main body and an insert-in body, and which has a good appearance in which a belt attaching portion is hidden from view. The buckle is formed from a buckle main body and an insert-in body. The insert-in body is provided with engaging rods and a guide rod. The engaging rods are provided at both sides of a base portion of the insert-in body and have engaging portions. The guide rod is provided at a center of the base portion and can be inserted into an insert-in hole of the buckle main body. At an opposite surface of the base portion are provided a lower surface plate having a belt attaching portion, and an upper surface plate which covers a surface of the lower surface plate. The buckle main body is formed from an upper surface plate, a lower surface plate and side walls. At another end of the buckle main body, a belt insertion hole is provided. An attaching portion to which the belt is attached is provided at an end portion of the lower surface plate. Through holes, for passage of the belt being inserted through the insertion hole, are provided at the belt attaching portions.

Owner:YKK CORP

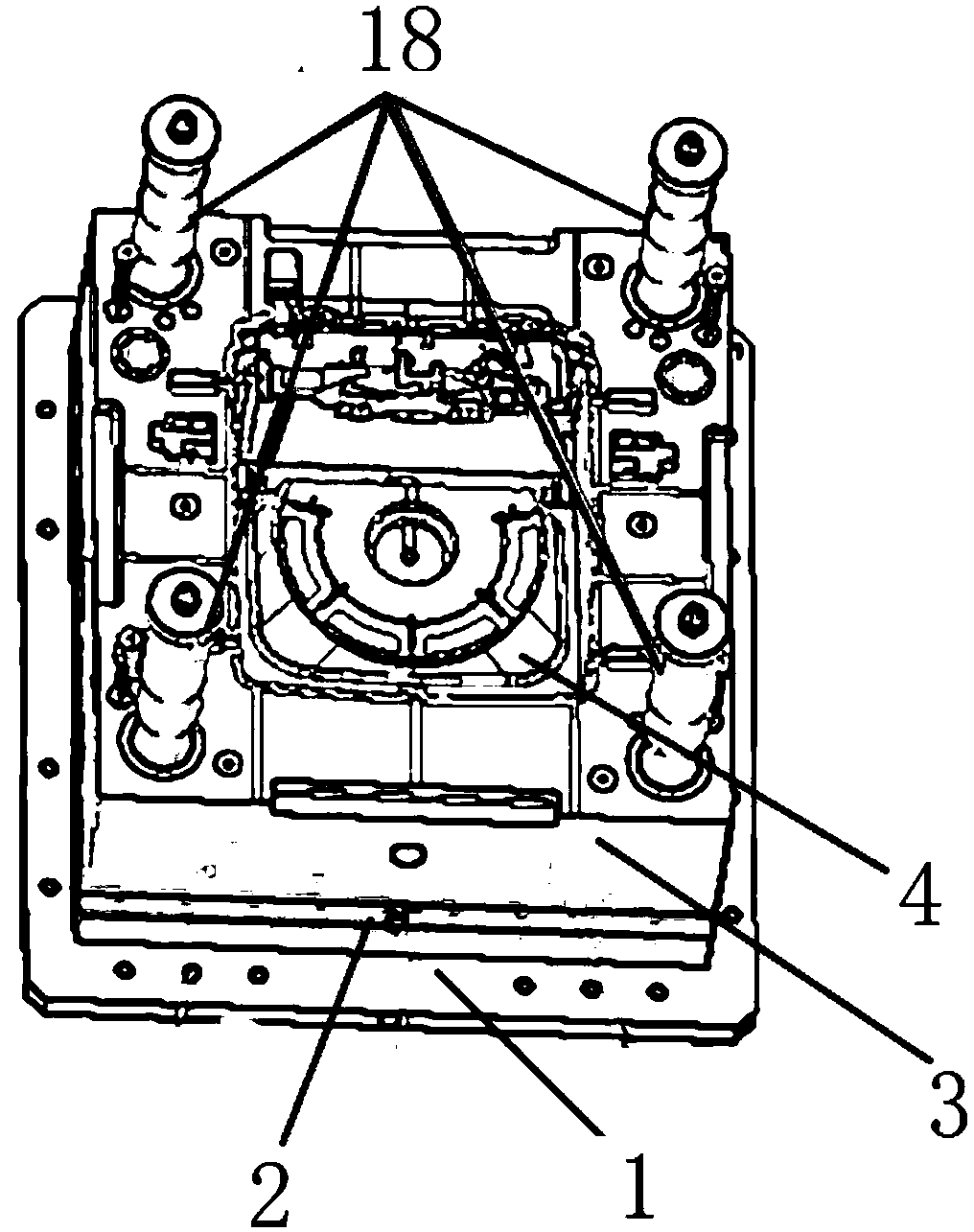

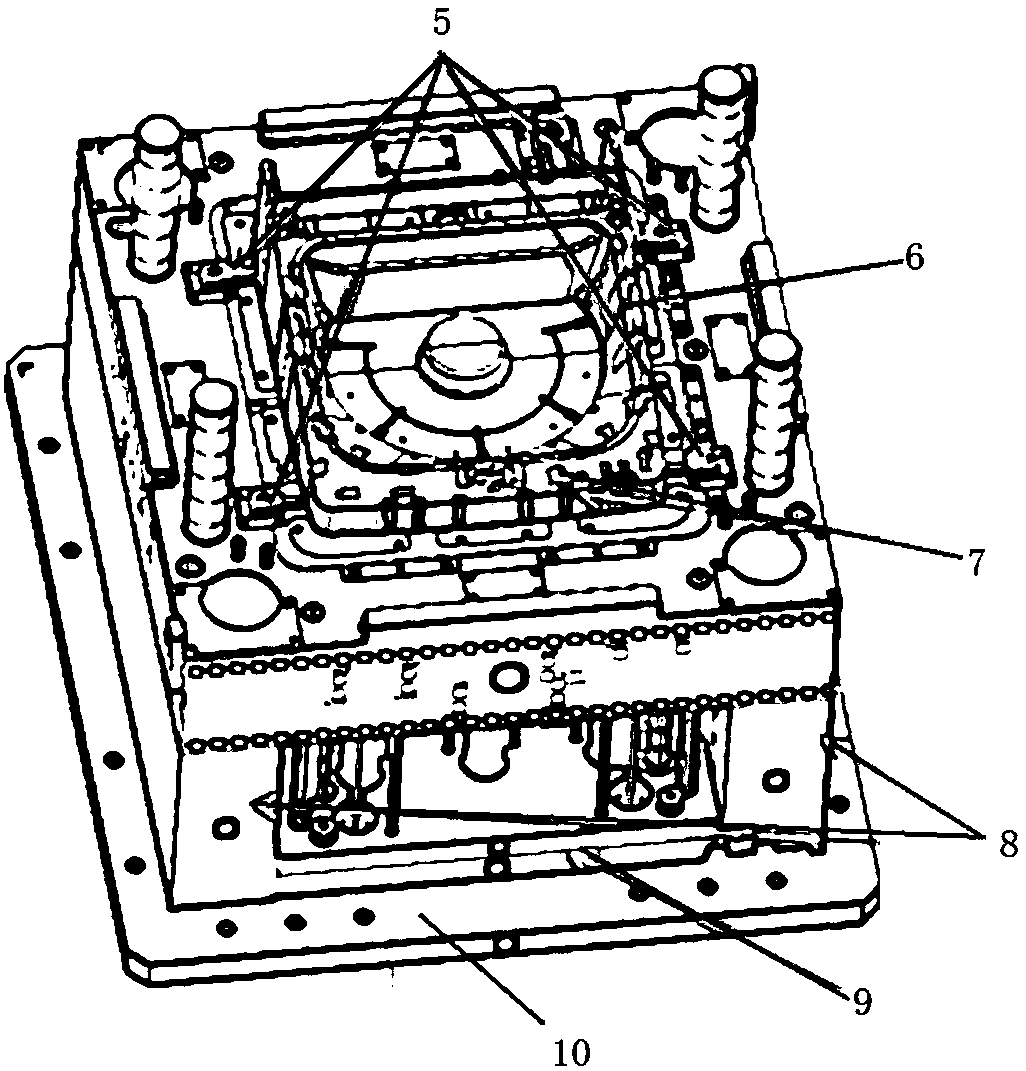

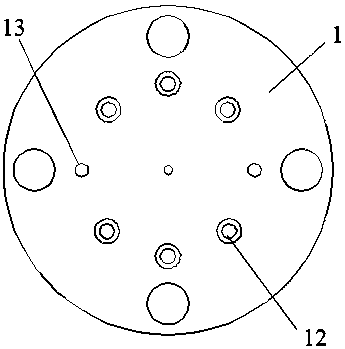

Mould used for stretching long cone body

InactiveCN111496055AEven by forceGuaranteed forming accuracyShaping toolsHollow articlesCompression moldingEngineering

The invention discloses a mould used for stretching a long cone body. The mould comprises a lower mould plate (1), an upper cover plate (8), a concave die (3) and a terrace die (7), wherein the terrace die (7) is connected to the top of the lower mould plate (1) through first bolts (10); the concave die (3) covers the top of the terrace die (7); the upper cover plate (8) is connected to the upperpart of the concave die (3) through second bolts (9); the lower part of the outer side of the terrace die (7) is also provided with an edge pressing ring (2); and the edge pressing ring (2) is positioned on the bottom of the concave die (3). According to the mould, a shaping surface and the taper-shaped terrace die are cooperated to realize compression molding. In a shaping process, a part is evenly stressed, accuracy is higher after shaping, the surface of the shaped part is free from damage by pulling, so that the shaping accuracy of the shaped part can be more favorably guaranteed to achieve a satisfactory appearance state of the shaped part, and the part with better quality can be formed. In addition, a long cone does not need to be subjected to secondary shaping, but is shaped properly in one time, the appearance state of the part is better, and a good use effect is obtained.

Owner:贵州红湖发动机零部件有限公司

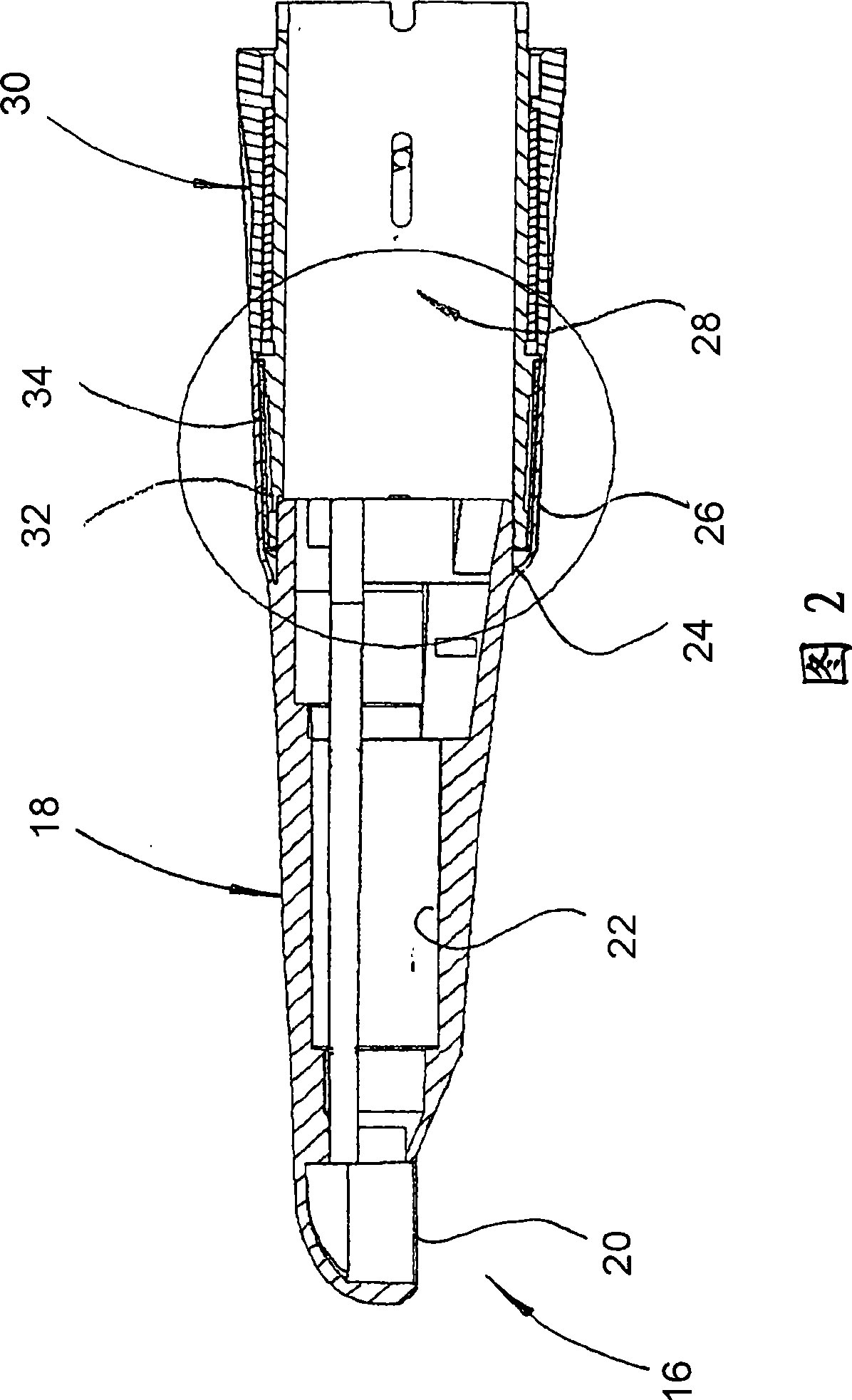

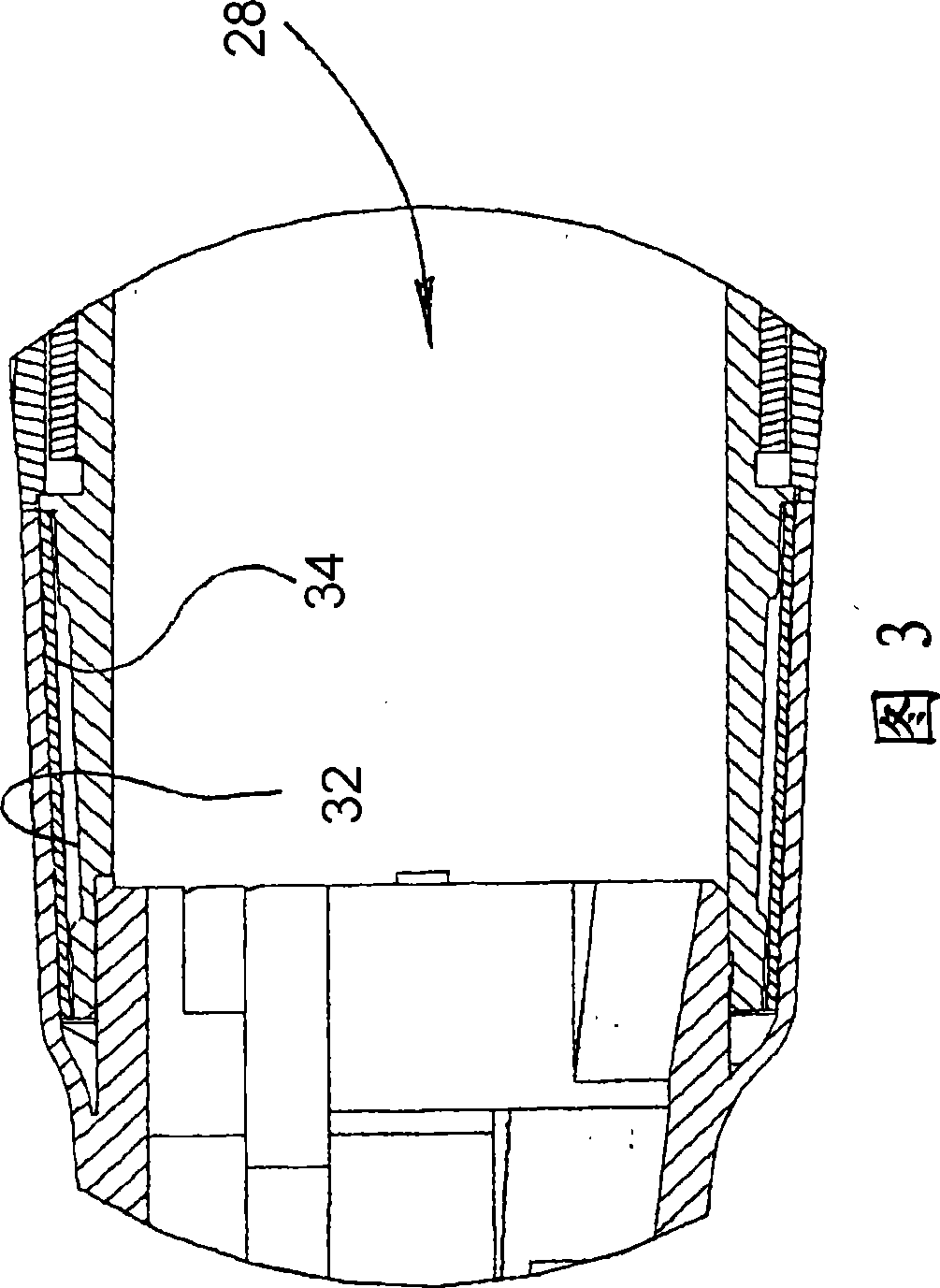

Dental handpiece

InactiveCN101389262ANo danger of entryImprove surface qualityEndoscopesSomatoscopeBiomedical engineering

A dental handpiece, in particular a camera handpiece, has a housing (16), which is provided with a deformable wall portion (26) extending in the circumferential direction. Lying behind the deformable wall portion (26) there is a deformation sensor (34), which can be formed by a piezo film. The output signal of the deformation sensor (34) is monitored by a discriminator in such a way as to trigger the recording of an image when a predetermined deformation of the deformable wall portion (26) is reached.

Owner:DURR DENTAL GMBH & CO KG

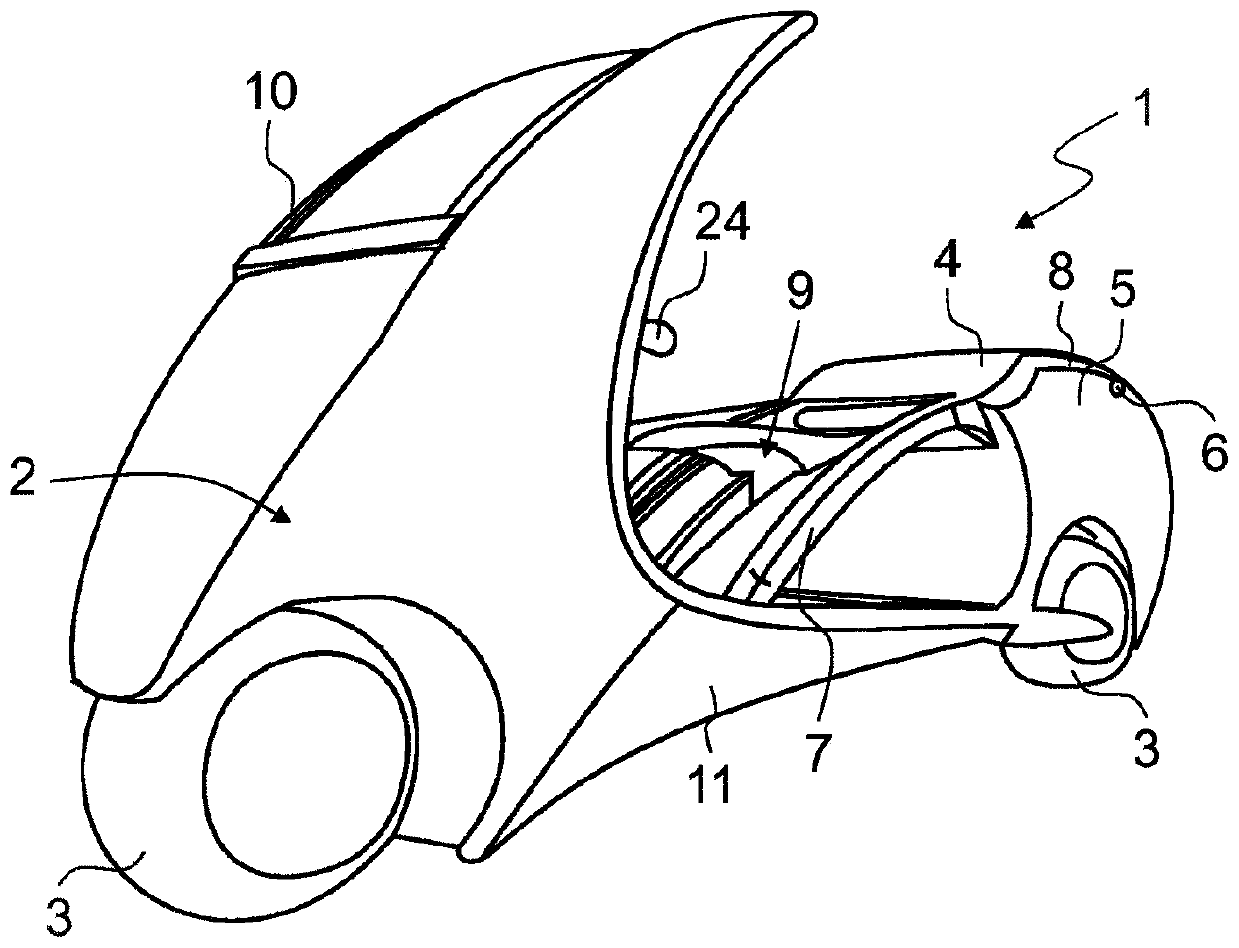

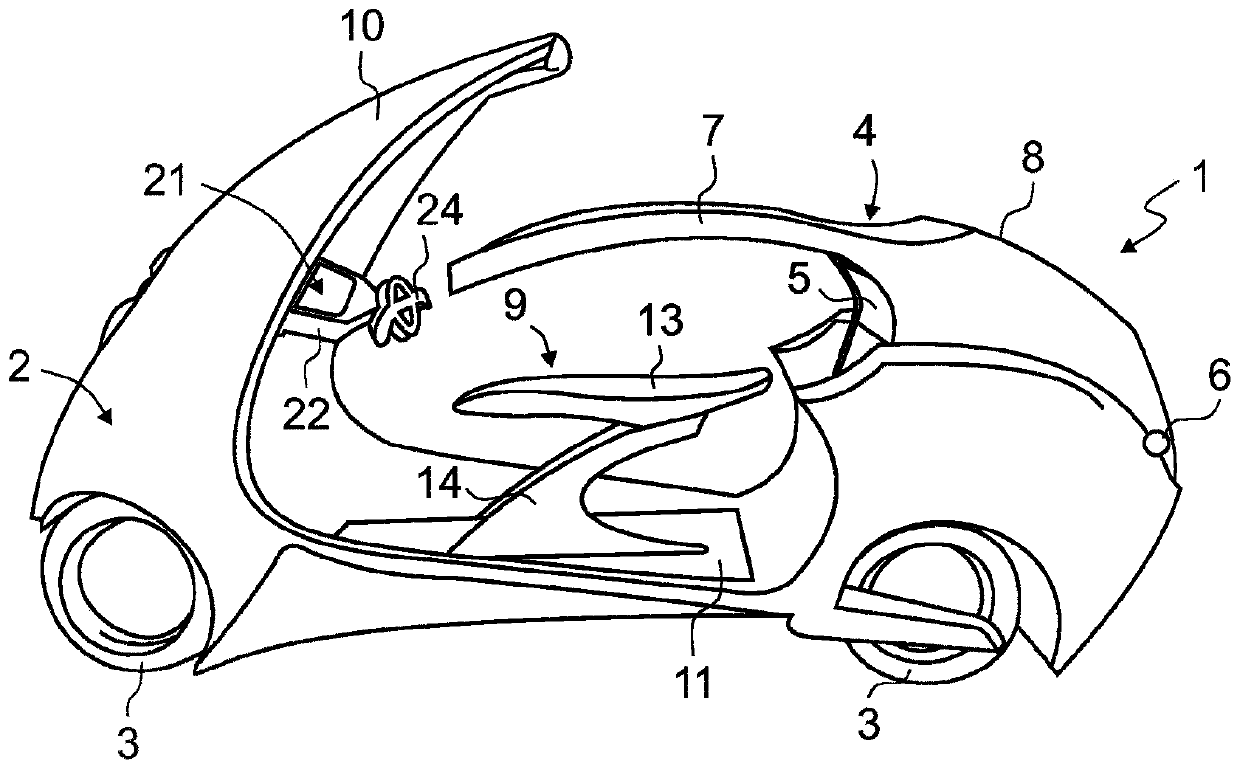

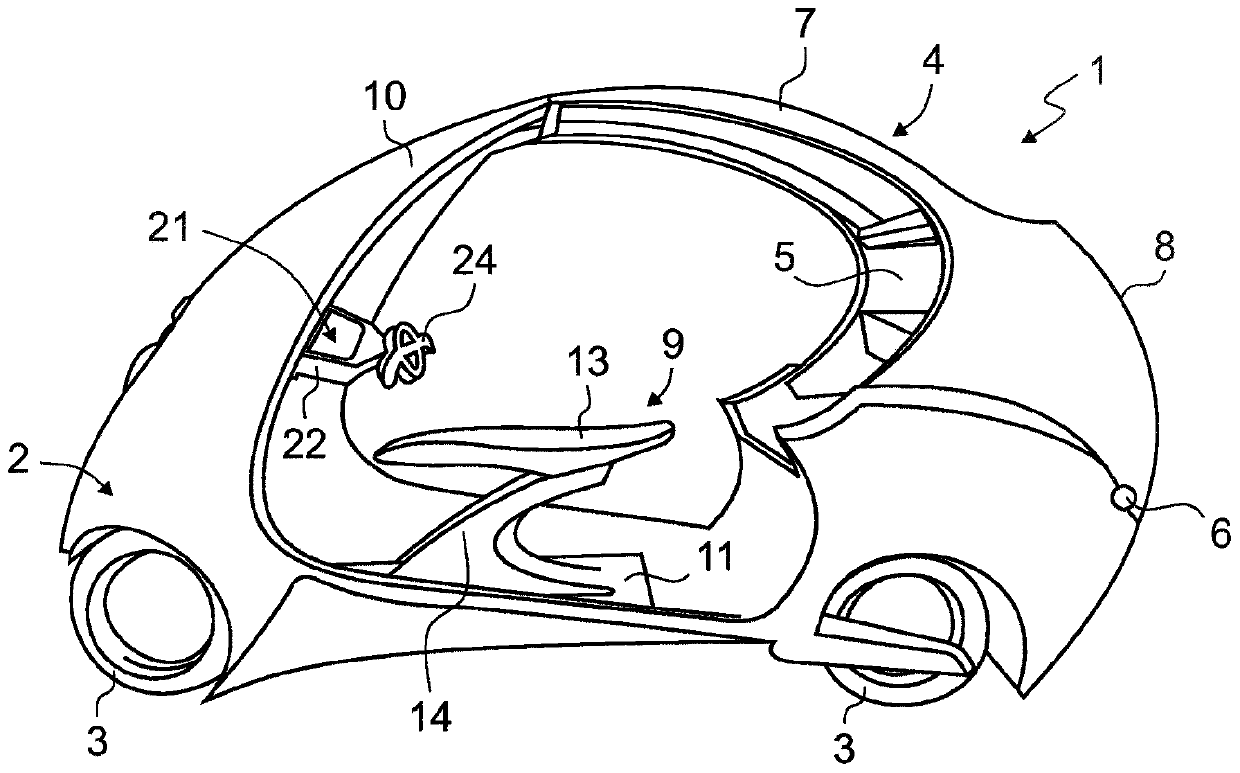

Rider's seat for two-wheeled vehicle

ActiveCN110505997AGuaranteed uptimeImprove adaptabilityMovable seatsMotorcyclesEngineeringMechanical engineering

Owner:AUDI AG

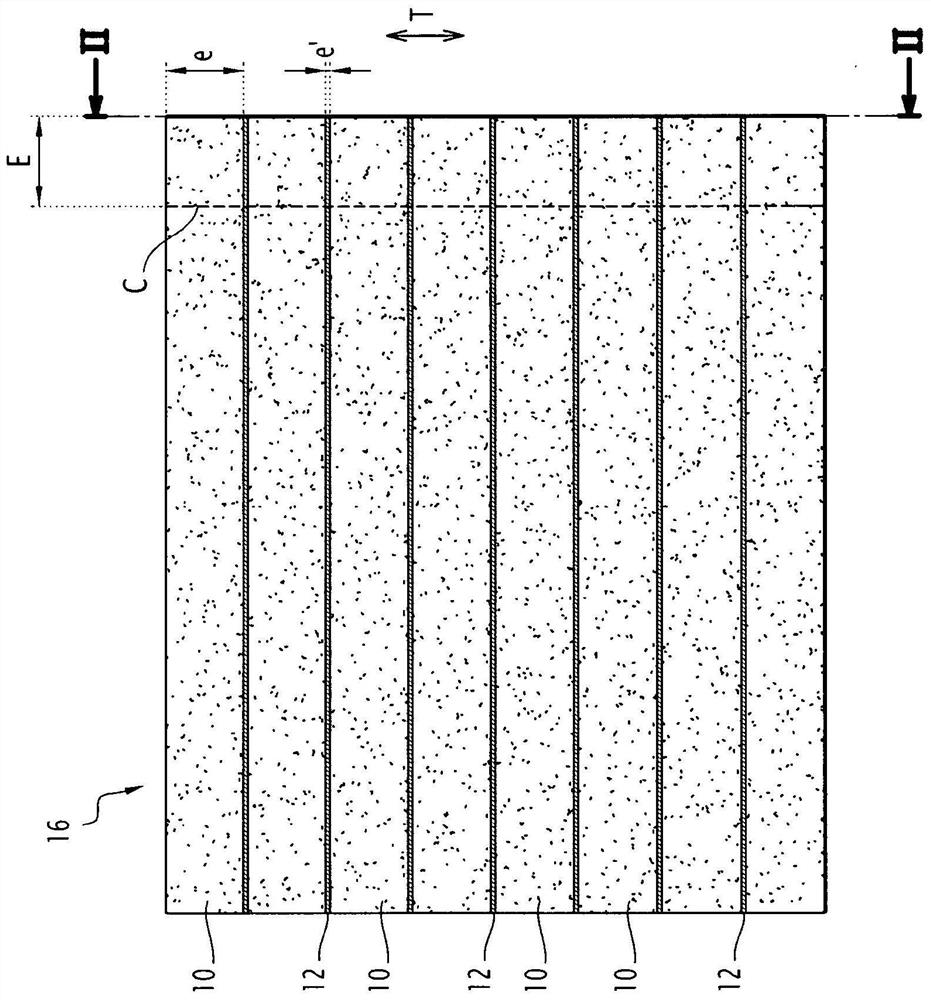

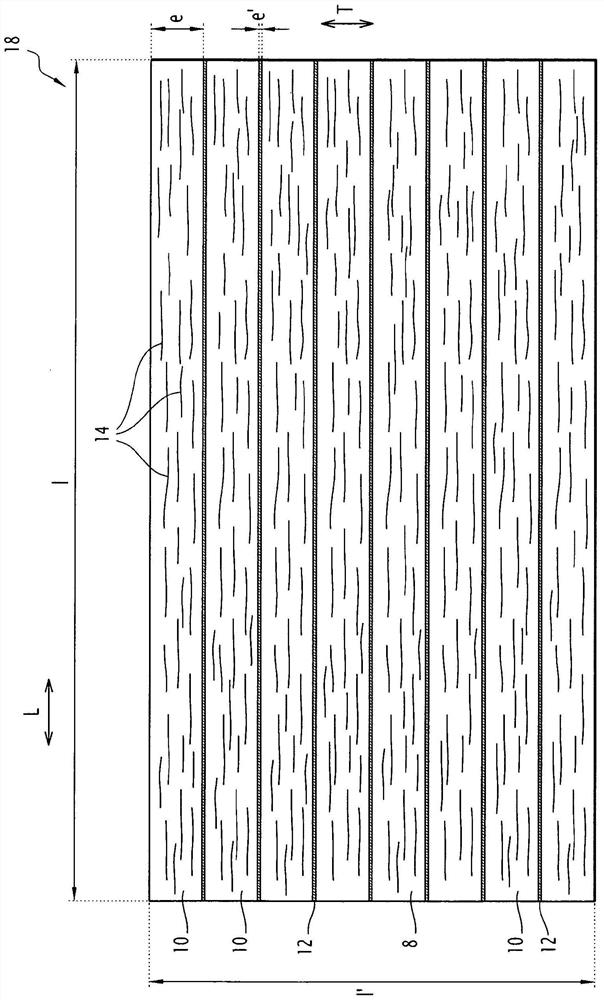

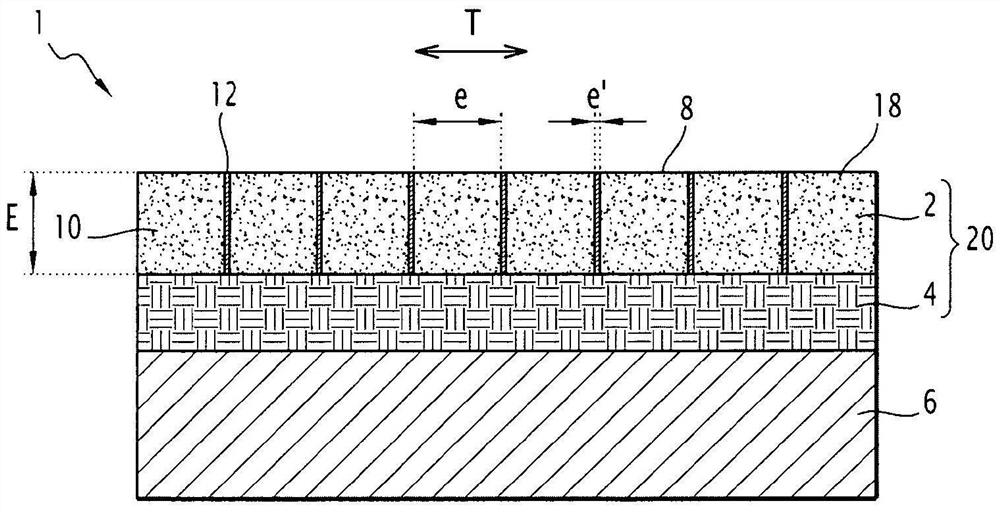

Method for implementing a trim comprising an appearance layer with a strip of wood material

ActiveCN105365000BSatisfactory appearanceSatisfied with the appearanceWood veneer joiningVehicle componentsMechanical engineeringComposite material

The method comprises the following steps: - provision of two wood material layers (10), substantially plane and each extending in a first plane, one on another in a stacking direction (T) perpendicular to the first plane, a layer of viscoelastic material (12) being arranged between the two wood material layers (10), - assembly of the wood material layers (10) by means of the layer of viscoelastic material (12) so as to obtain a complex intermediate (16). The method further comprises the steps of: - cutting the intermediate complex (16) along a cutting plane (C) perpendicular to the first plane so as to obtain a cut blank (18), - forming a decorative element (1) from the cut blank (18) forming an appearance layer (2) of said packing element.

Owner:FAURECIA INTERIEUR IND

Joint mechanism of application device of cosmetic product, associated device, application method and manufacturing method

ActiveCN107529870AEasy to useSatisfied with the appearancePackaging toiletriesPackaging cosmeticsBiomedical engineering

Owner:LOREAL SA

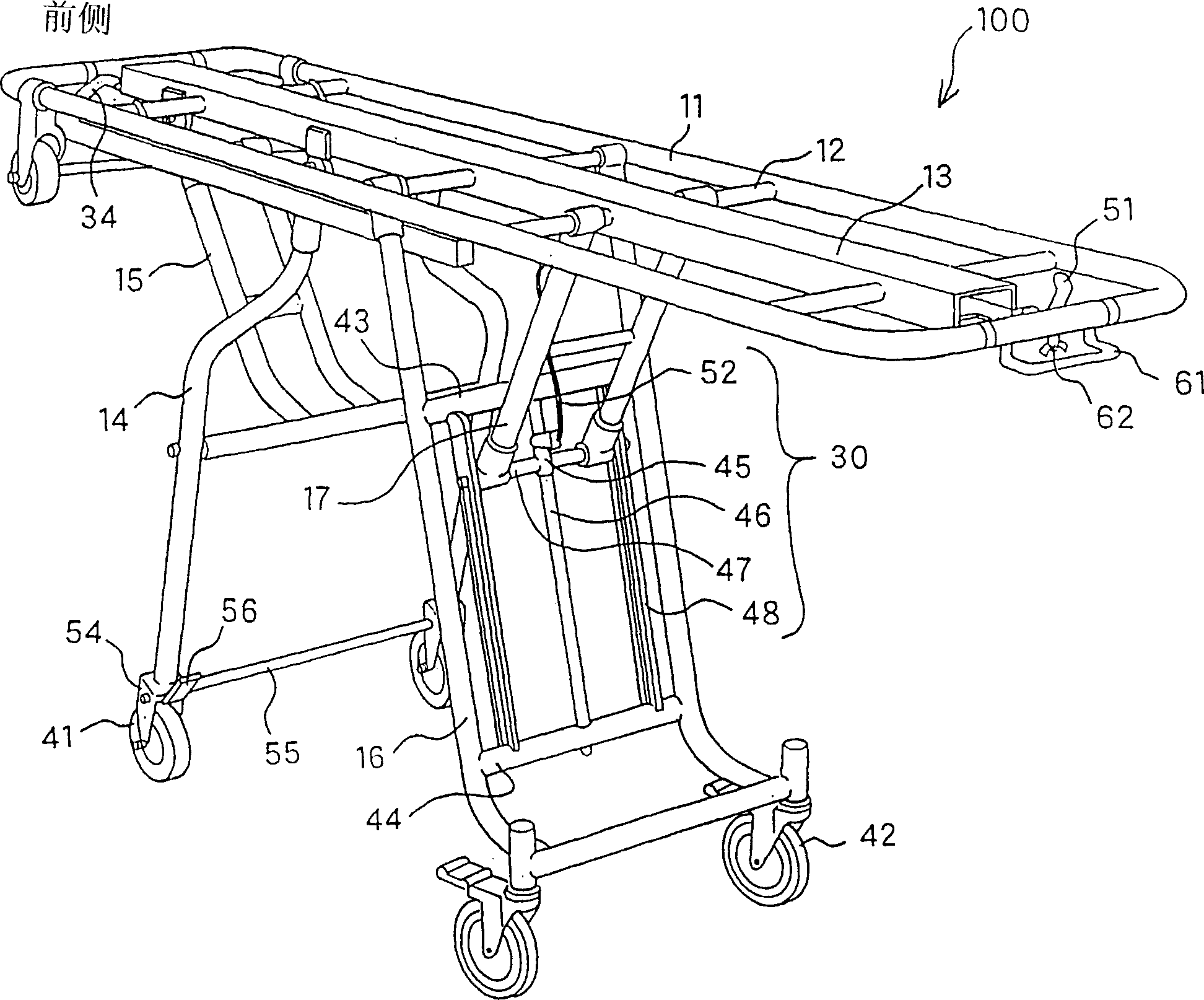

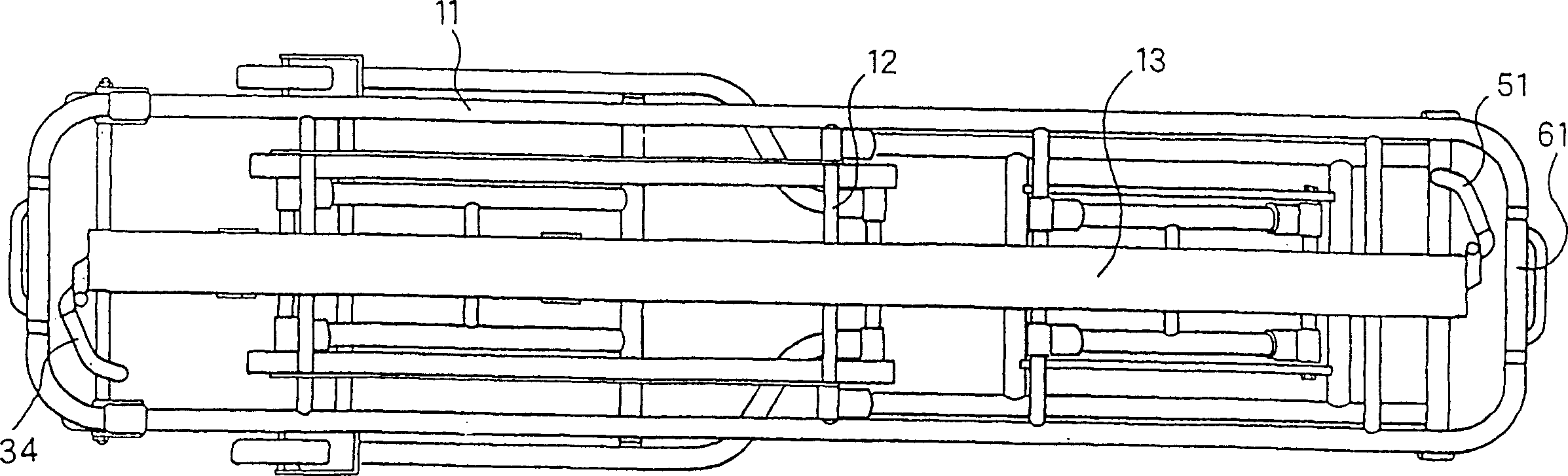

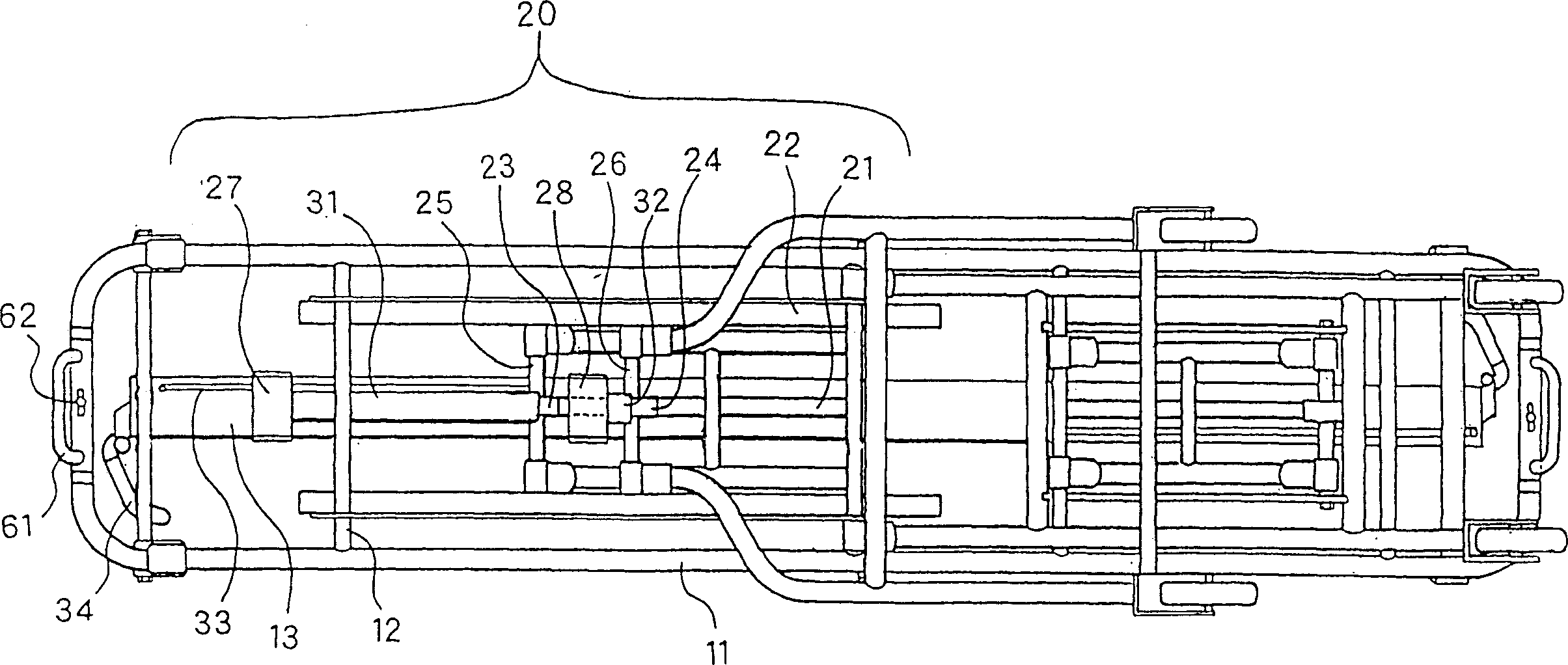

Stretcher

In a stretcher (100) comprising an upper frame (11) for placing a litter on an upper portion thereof having casters (41) and (42) in the front and rear portions, and a slide mechanism for changing up / down the position ofthe upper frame (11), the stretcher (100) is provided with a non-step stopper mechanism for stopping the sliding in the slide mechanism in a non-step manner. As a result, the height of the stretcher (100) can be changed up / down smoothly without rendering pain or uneasiness to a patient.

Owner:MATUNAGA MANUFACTORY

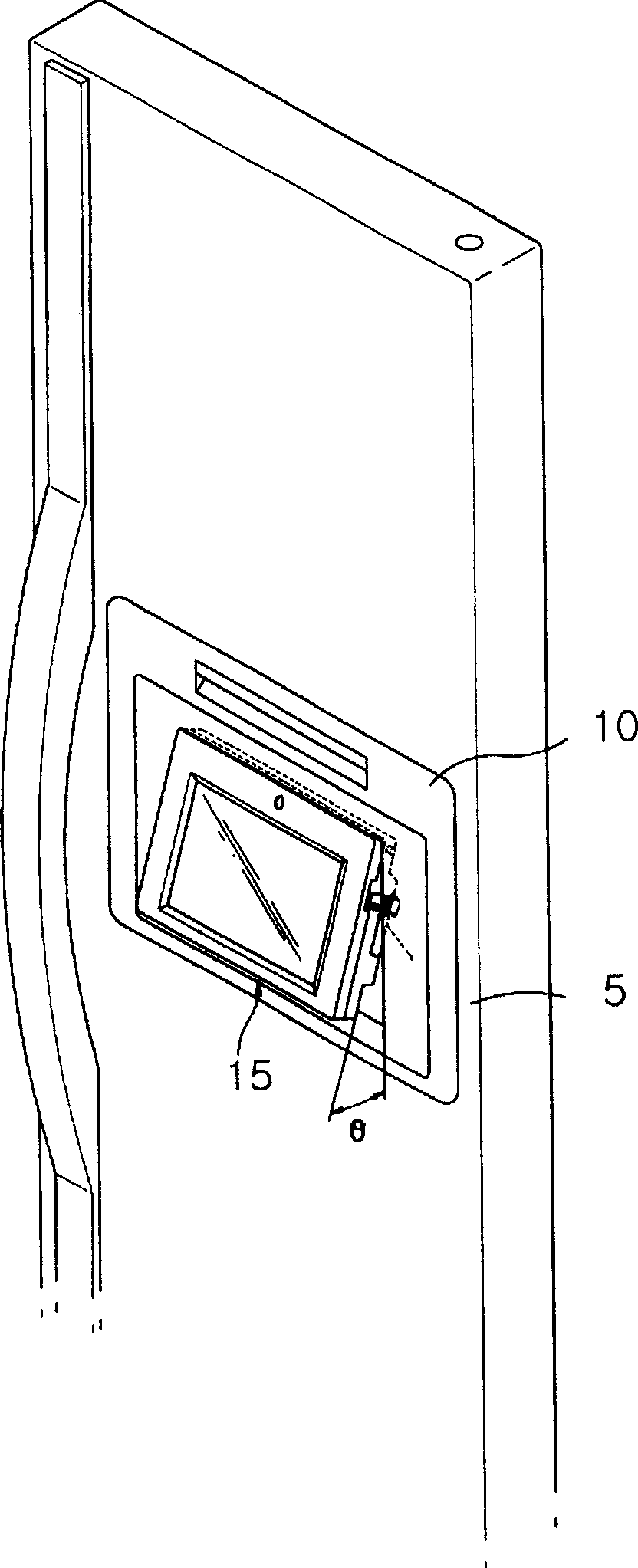

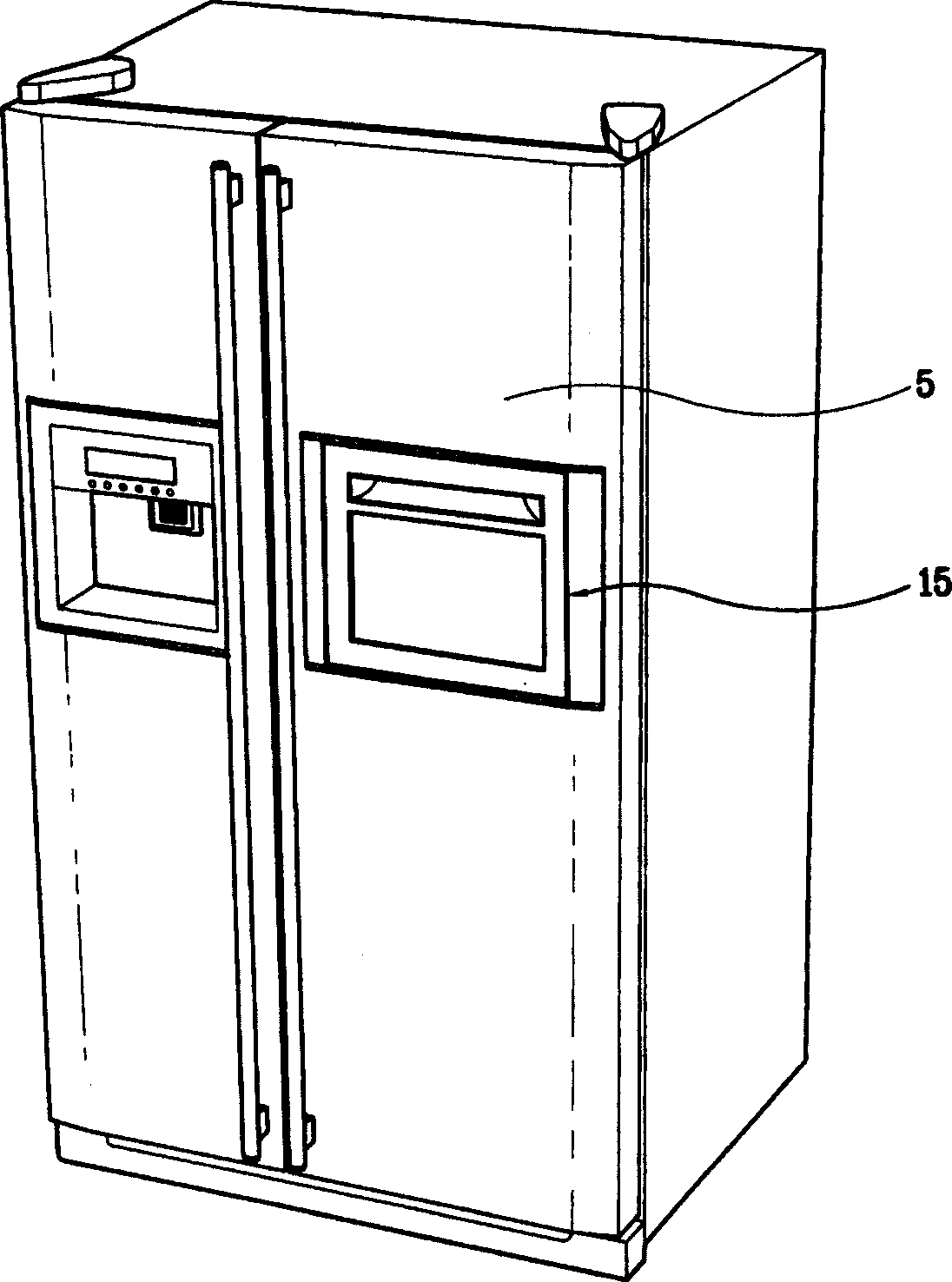

Electric refrigerator with display part

InactiveCN1683853AAvoid enteringSatisfied with the appearanceLighting and heating apparatusDomestic refrigeratorsForeign matterDisplay device

The electric refrigerator display includes refrigerator door, display and covering unit. The display set in the seat on the refrigerator door includes holding casing and display panel, the openable holding casing is set on the seat and the display panel may be set in and detached from the holding casing. After the display panel is set inside the holding casing, the covering unit has its hood in the initial position behind the display panel; and when the display panel is detached from the holding casing, the hood is made to forward shift to cover the detached space. The electric refrigerator display can avoid foreign matter from entering the display parts and has beautiful outer appearance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

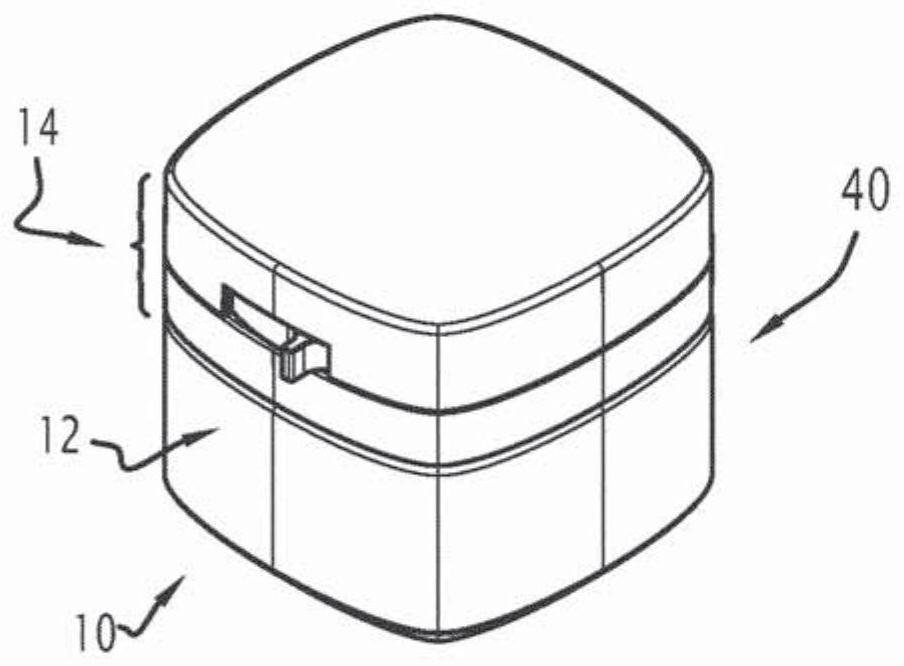

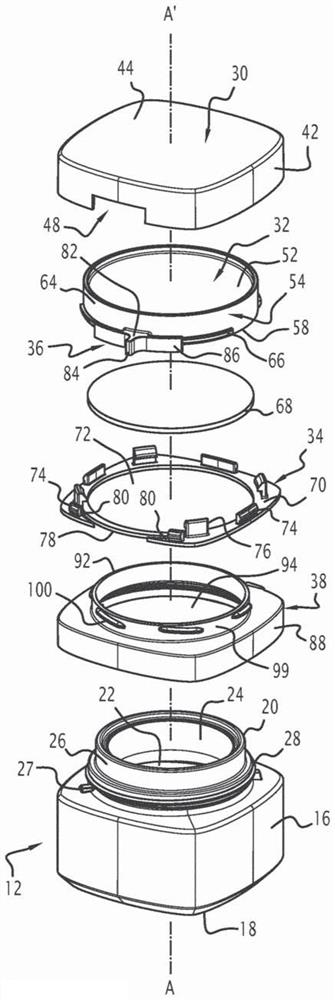

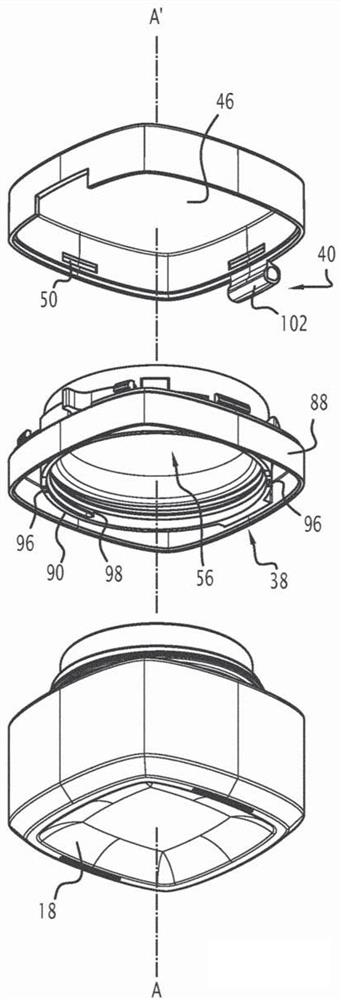

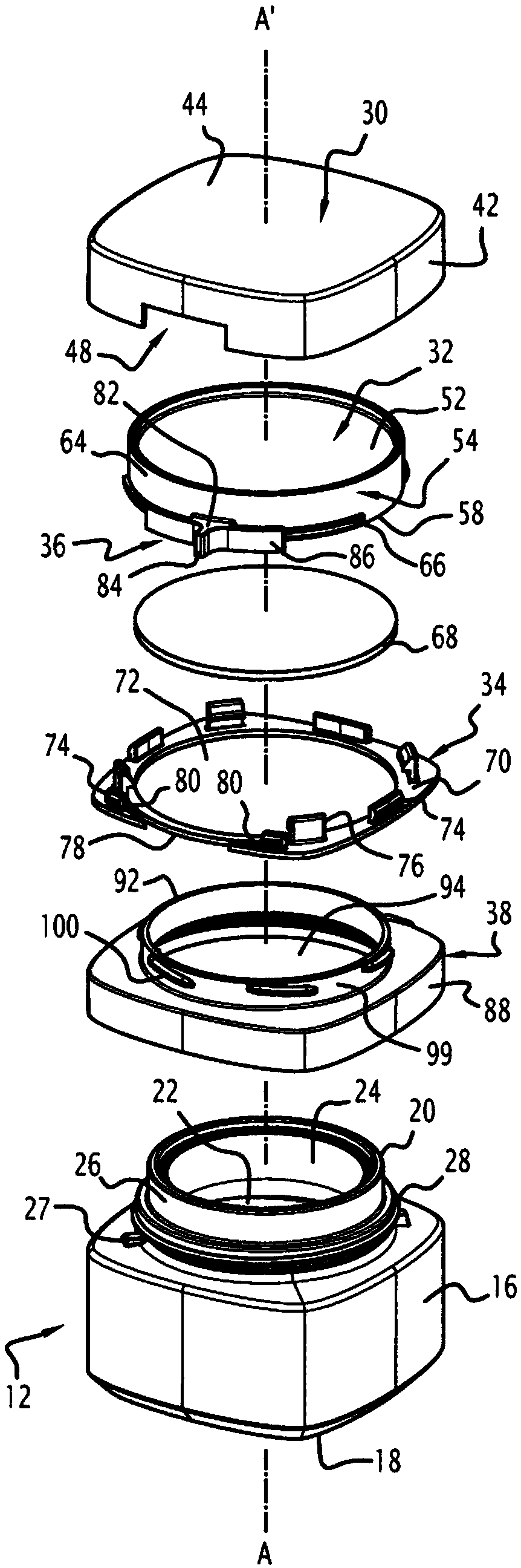

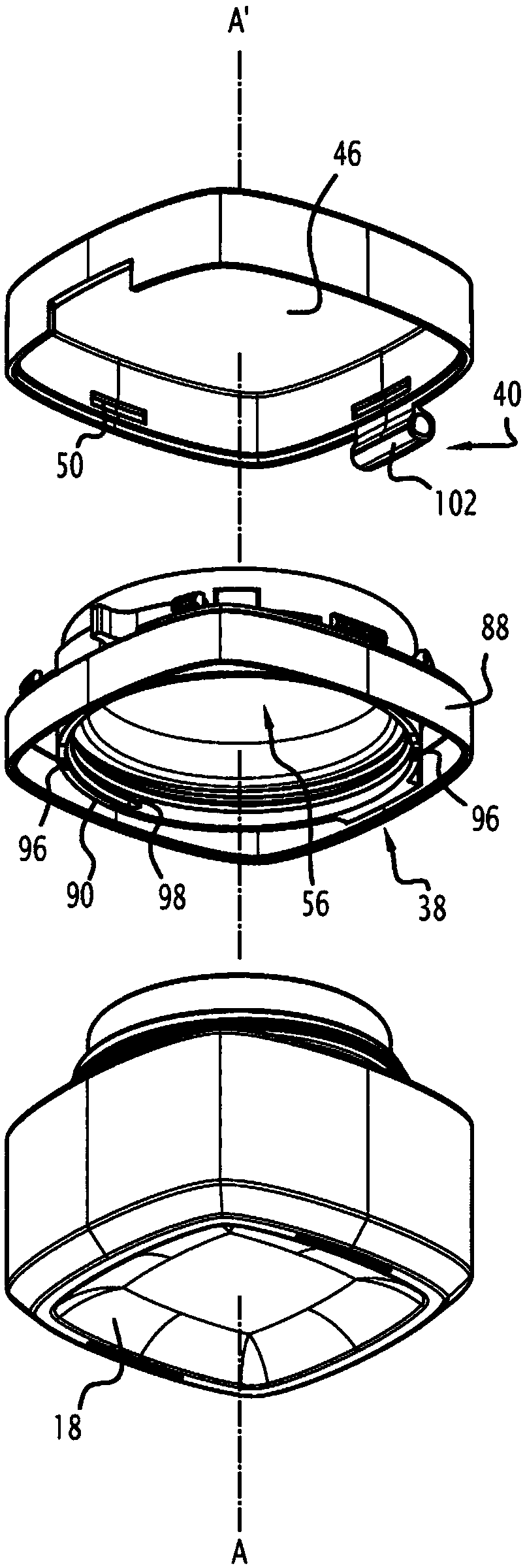

Closure assembly for container containing product, related packaging device and method

ActiveCN108471861BLong term storageEasy to useCapsClosure capsStructural engineeringMechanical engineering

The assembly comprises a cover (30) defining a cavity, a movable part (32) rotatably mounted in the cavity of the cover (30) and having a space defining an insertion space of the part to be closed An inner surface comprising at least one selective fastening element for engagement with a corresponding complementary fastening element secured to the portion to be closed. The closure assembly includes an actuating member (36) connected to the movable part (32) via the cover (30), the actuating member (36) being adapted to be operated from the outside of the cover (30) to move the movable part (32) Changing from a locked position of the container (12) to an unlocked position.

Owner:LOREAL SA

Decorative film and method for producing decorative molded body using same

ActiveCN109562611AAchieve recyclabilitySatisfied with the appearanceAdhesive articlesSynthetic resin layered productsPolymer scienceThermoforming

A decorative film is to be bonded to a resin molded body by means of thermoforming, and comprises a sealing layer (I) that contains a polypropylene resin (A) and a layer (II) that contains a polypropylene resin (B). The polypropylene resin (A) satisfies the requirement (a1), while the polypropylene resin (B) satisfies the requirement (b1). (a1) The melt flow rate (MFR (A)) (at 230 DEG C under a load of 2.16 kg) is more than 0.5 g / 10 minutes. (b1) The melt flow rate (MFR (B)) (at 230 DEG C under a load of 2.16 kg) and the MFR (A) satisfy relational expression (b-1). MFR (B) < MFR (A) (b-1).

Owner:JAPAN POLYPROPYLENE CORP

Closing assembly for a container intended for containing a product, related packaging device and process

This assembly comprising a cap (30) defining a cavity, a movable portion (32), movably mounted in rotation in the cavity of the cap (30), the movable portion (32) having an inner surface defining an insertion space of a portion to be closed, said inner surface comprising at least one selective fastening element intended to engage with a corresponding complementary fastening element secured to theportion to be closed, The closing assembly comprises an actuation member (36) connected to the movable portion (32) via the cap (30), the actuation member (36) being suitable for being operated from the outside of the cap (30) to change the movable portion (32) from a locking position of the container (12) to an unlocked position.

Owner:LOREAL SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com