Wiper blade, wiper arm and connection arrangement for a windscreen wiper system of a vehicle

A technology of wiper arm and wiper blade, which is applied in the fields of joint elements and connecting mechanisms, can solve the problems of maintenance, complicated removal of wiper blades, and unreliable wiper blades, and achieves the effect of simplifying removal and replacement operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

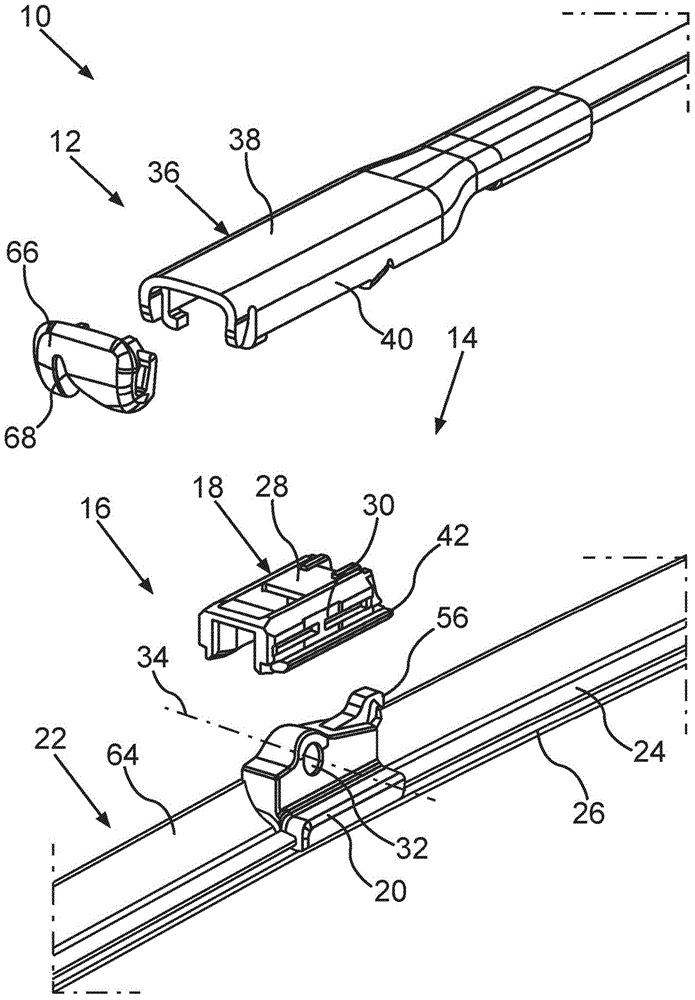

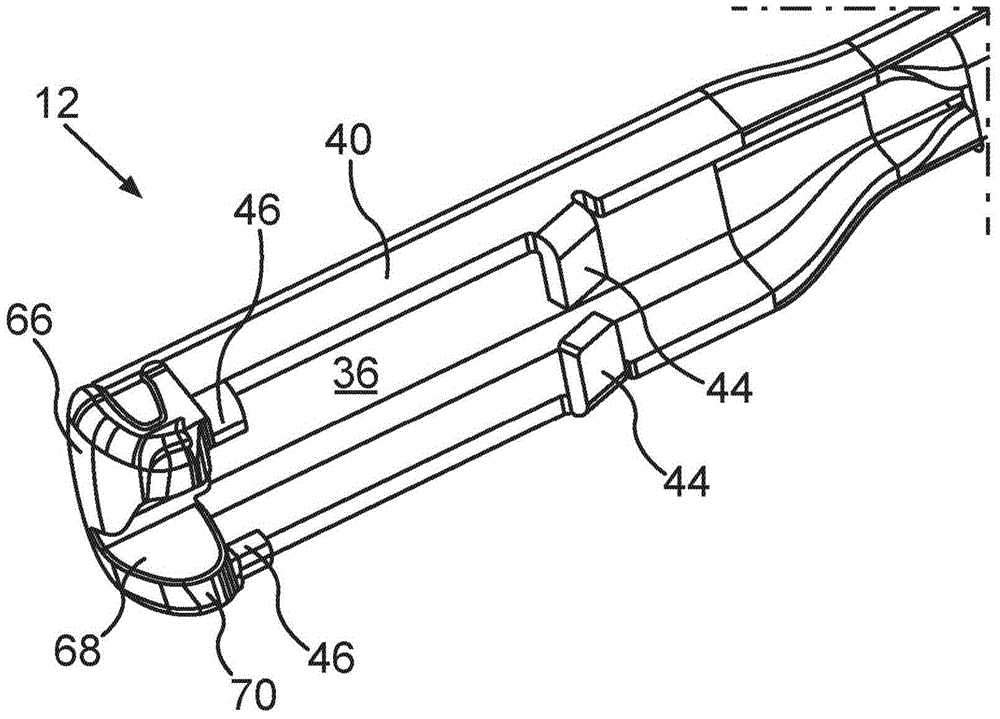

[0036] figure 1 The assembly of a wiper arm 12 and a wiper blade 14 of a connection mechanism 10 of a vehicle wiper system is shown in perspective. A coupling element in the form of an adapter 16 serves to fasten the wiper blade 14 on the wiper arm 12 .

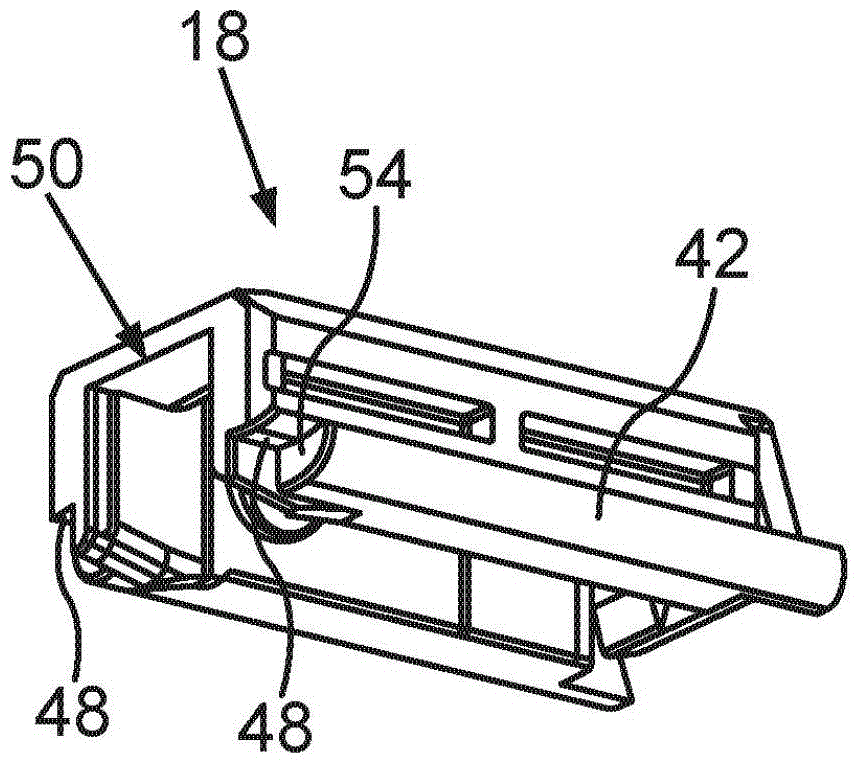

[0037] The adapter 16 comprises an upper part 18 with a U-shaped cross-section and a lower part in the form of a slider 20 holding a body 22 of the wiper blade 14 . In this case, the body 22 comprises a spring rail 24 and a wiper lip 26 of the wiper blade 14 . The upper part 18 of the adapter 16 includes a back 28 and lateral sides 30 connected to the back 28 . A (not shown) metal pin is held on the side edge 30 of the upper part 18, and on the upper part 18 fixed on the slider 20 (see Figure 5 ), the metal pin runs through a through-hole 32 formed in the sheet-like region of the slider 20 . By means of the metal pin supported in the through-hole 32, an axis of rotation 34 is provided.

[0038] In this way, the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com