Decorative film and method for producing decorative molded body using same

A technology for decorative films and resin moldings, applied in the direction of chemical instruments and methods, decorations, applications, etc., can solve the problem of insufficient solvent resistance and heat resistance, the inability to fully obtain the bonding strength of decorative films and moldings, wrinkles Disappearance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

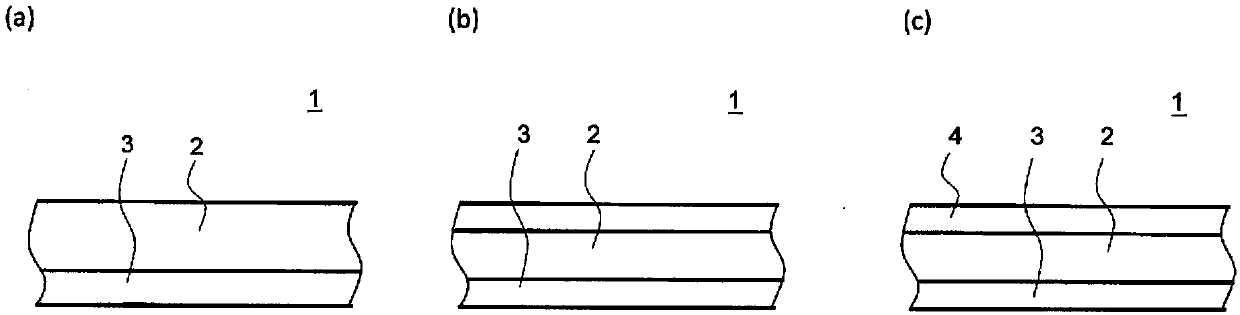

[0147] In the basic embodiment, the sealing layer (I) contains a polypropylene-based resin (A). In the basic embodiment, the polypropylene-based resin (A) is preferably a resin that is easily relaxed. By providing the sealing layer (I) containing such a polypropylene-based resin (A), it is possible to suppress the occurrence of voids, wrinkles, and air entrapment on the surface of the decorative molded body, and it is possible to prevent scratches formed on the surface of the substrate. The marks are not obvious.

[0148] >

[0149] 1. Melt flow rate (MFR(A)): (a1)

[0150] In the basic embodiment, the melt flow rate (230°C, 2.16 kg load) MFR (A) of the polypropylene-based resin (A) needs to exceed 0.5 g / 10 minutes, preferably 1 g / 10 minutes or more, more preferably 2 g / 10 minutes More than 10 minutes. Within the above range, relaxation at the time of three-dimensional decorative thermoforming proceeds sufficiently and sufficient adhesive strength can be exhibited. The up...

no. 1 approach

[0155] In the first embodiment, the sealing layer (I) is composed of a resin composition (X1) containing a polypropylene-based resin (A). In the first embodiment, the polypropylene-based resin (A) is preferably a resin that is easy to melt and relax. By providing the sealing layer (I) composed of the resin composition (X1) containing such a polypropylene-based resin (A), the occurrence of voids, wrinkles, and air entrapment, etc., on the surface of the decorative molded body can be suppressed, and Scratches formed on the surface of the substrate can be made inconspicuous.

[0156] >

[0157] 1. Melt flow rate (MFR(A)): (a1)

[0158] In the first embodiment, the melt flow rate (230°C, 2.16 kg load) MFR (A) of the polypropylene-based resin (A) needs to exceed 0.5 g / 10 minutes, preferably 1 g / 10 minutes or more, more preferably 2 g / more than 10 minutes. Within the above range, relaxation at the time of three-dimensional decorative thermoforming proceeds sufficiently, and su...

no. 2 approach

[0169] In the second embodiment, the sealing layer (I) is composed of a resin composition (X2) containing a polypropylene-based resin (A). In the second embodiment, the polypropylene-based resin (A) is preferably a resin whose crystallization starts late. By providing the sealing layer (I) composed of the resin composition (X2) containing such a polypropylene-based resin (A), the occurrence of voids, wrinkles, and air entrapment, etc., on the surface of the decorative molded body can be suppressed, and Scratches formed on the surface of the substrate can be made inconspicuous.

[0170] >

[0171] 1. Melt flow rate (MFR(A)): (a1)

[0172] In the second embodiment, the melt flow rate (230°C, 2.16 kg load) MFR (A) of the polypropylene-based resin (A) needs to exceed 0.5 g / 10 minutes, and preferably 1 g / 10 minutes or more, more preferably 2g / 10 minutes or more. Within the above range, relaxation at the time of three-dimensional decorative thermoforming proceeds sufficiently, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com