Water insulator and electric water heater using the water insulator

A technology for electric water heaters and water insulation, applied in lighting and heating equipment, fluid heaters, energy-saving heating/cooling, etc., can solve problems such as large space occupied by pipes, overheating of water tanks, and damage to plastic water pipes that cannot be detected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

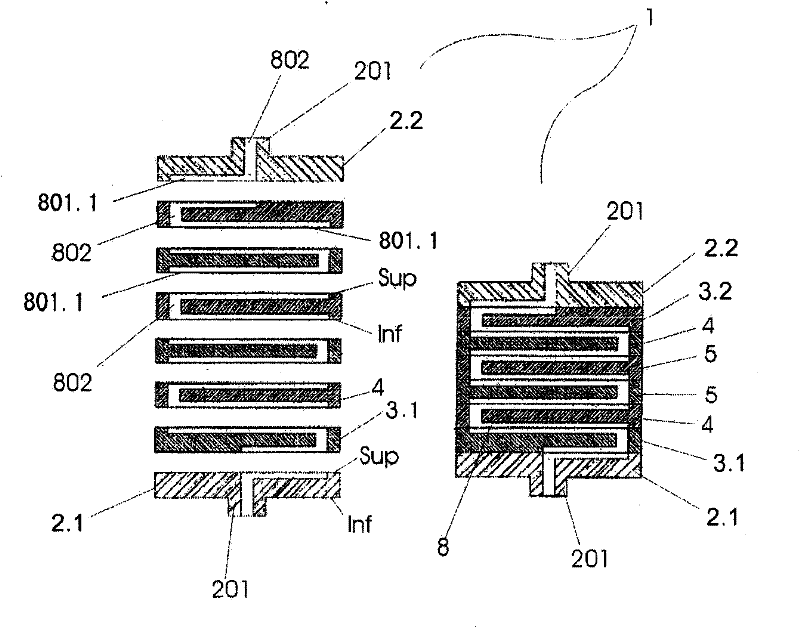

[0050] From a brief inspection of the drawings, the water insulator of the invention is conceived as follows:

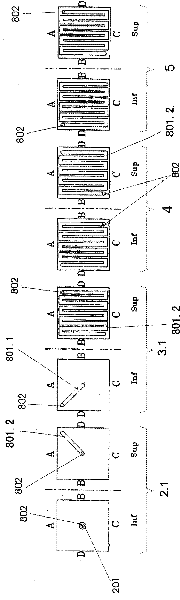

[0051] - the establishment of a set of elements made of insulating material, between their opposite faces provided with coiled linear conduits for the flow of water;

[0052] - Some elements made of insulating material are modular and can be added arbitrarily repeatedly in order to adjust the length of the waterway according to the required resistance.

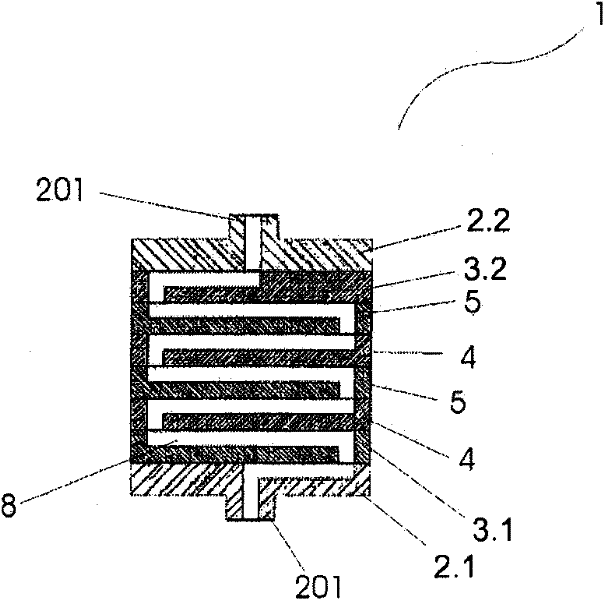

[0053] According to two examples, figure 1 and figure 2 The shown water insulator 1 consists of a set of elements ( 2.1 and 2.2 ), ( 3.1 and 3.2 ), 4 and 5 .

[0054]Shown in more detail in the figure is the first joint 2.1, which is provided with means 201 for hydraulic connection to the water heater or to the pipes. The top surface Sup of said joint 2.1 is in contact with the bottom surface Inf of the first distributor 3.1, and the top surface Sup of the distributor 3.1 is in turn in contact with the bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com