Biodegradable filling type foam and production process thereof

A biodegradable and filling technology, applied in the field of foam, can solve the problems of weak compressive strength and resilience, different mechanical properties, poor weather resistance, etc., and achieve the effects of convenient operation, easy implementation, good flexibility, resilience and weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

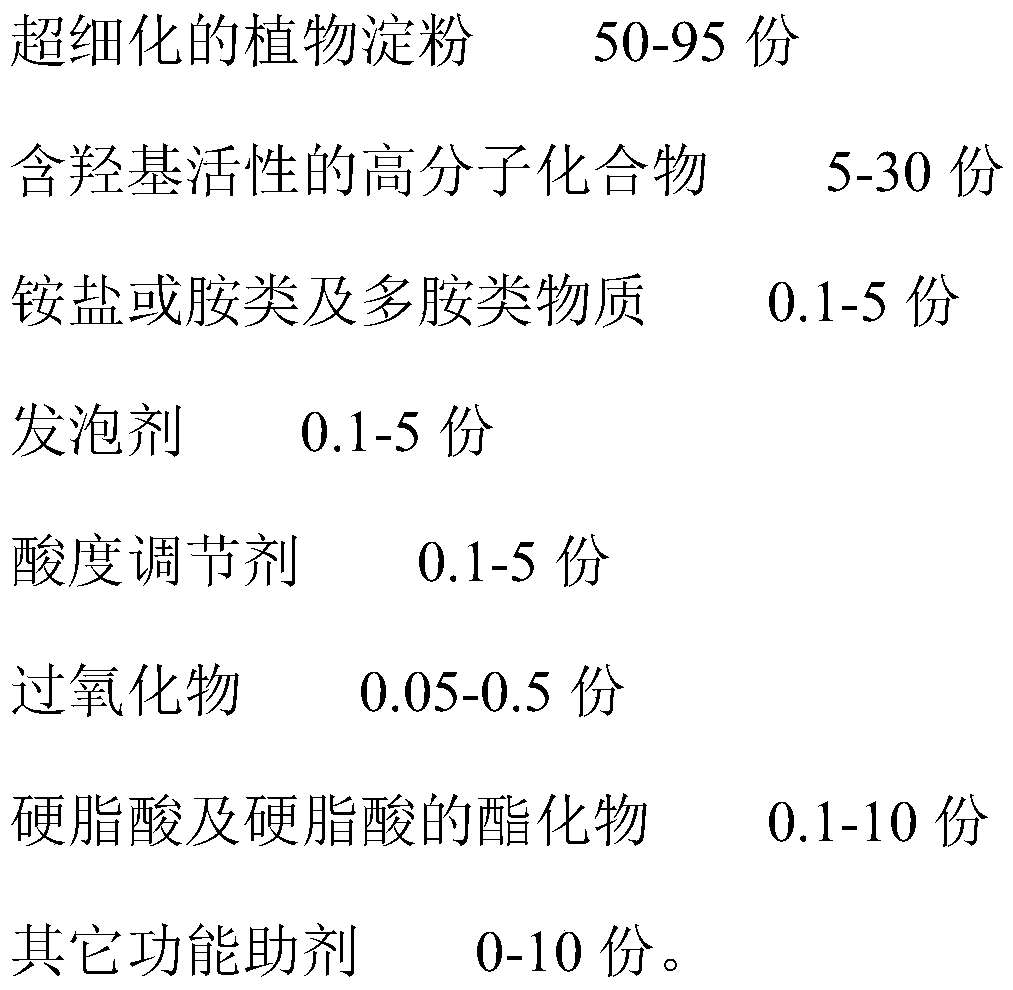

[0043] A biodegradable filling foam, comprising the following raw materials in parts by weight:

[0044] Superfine vegetable starch 50 parts

[0045] 5 parts of hydroxyl-containing active polymer compound

[0046] Ammonium salt or amines and polyamines 0.1 parts

[0047] Foaming agent 0.1 parts

[0048] Acidity regulator 0.1 parts

[0049] Peroxide 0.05 parts

[0050] 0.1 parts of stearic acid and stearic acid esters

[0051] 1 part of other functional additives.

[0052] The hydroxyl-containing active polymer compound is modified cellulose.

[0053] The ammonium salt is ammonium chloride; the amine is methylamine; and the polyamine is ethylenediamine.

[0054] The foaming agent is calcium carbonate.

[0055] The acidity regulator is oxalic acid.

[0056] The peroxide is hydrogen peroxide.

[0057] Described stearic acid and the esterification product of stearic acid are stearic acid.

[0058]The other functional additives are plasticizers and nucleating agents.

...

Embodiment 2

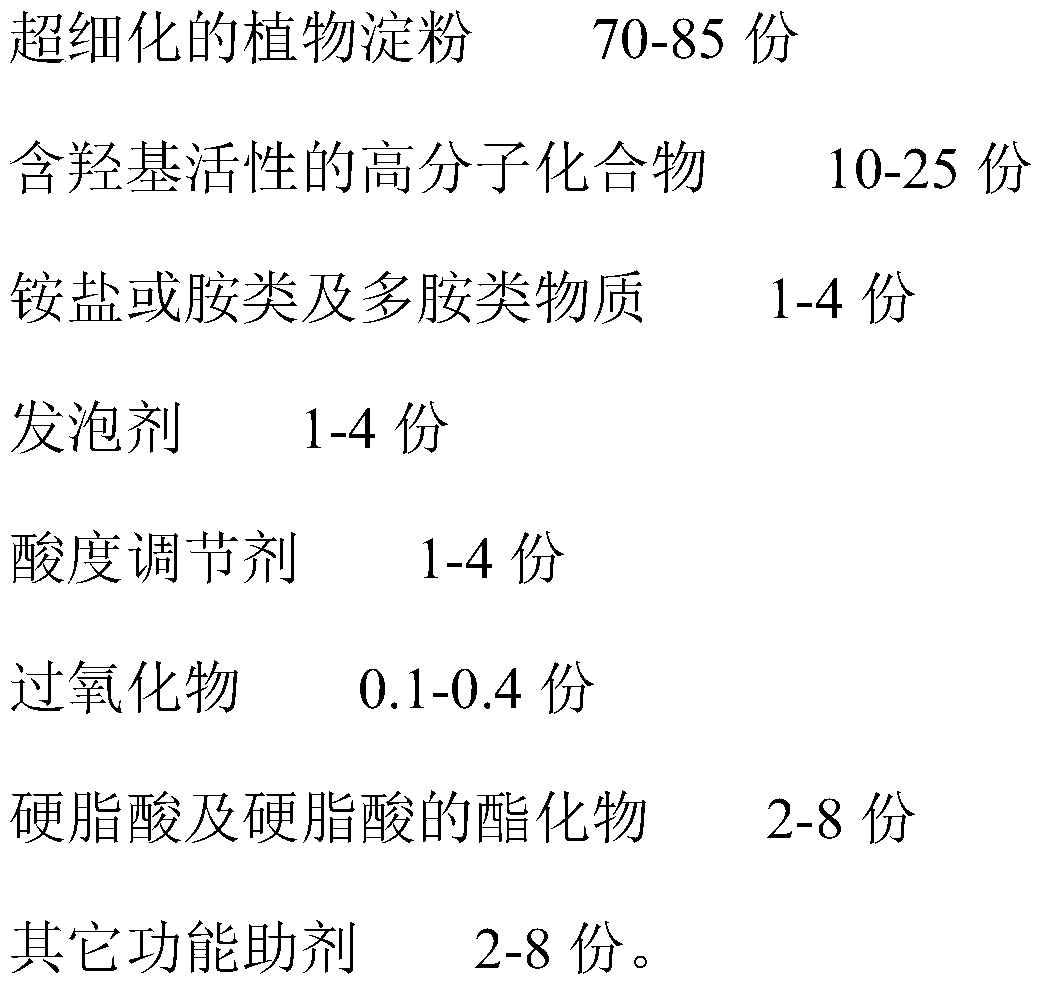

[0066] A biodegradable filling foam, comprising the following raw materials in parts by weight:

[0067] Superfine vegetable starch 70 parts

[0068] 10 parts of polymer compound containing hydroxyl activity

[0069] Ammonium salt or amines and polyamines 1 part

[0070] Foaming agent 1 part

[0071] 1 part acidity regulator

[0072] Peroxide 0.1 parts

[0073] Stearic acid and stearic acid esters 2 parts

[0074] 2 parts of other functional additives.

[0075] The active polymer compound containing hydroxyl is polyvinyl alcohol.

[0076] The ammonium salt is ammonium nitrate; the amines are monoethanolamine; and the polyamines are propylenediamine.

[0077] The blowing agent is magnesium carbonate.

[0078] The acidity regulator is malic acid.

[0079] The peroxide is peracetic acid.

[0080] Described stearic acid and the esterification product of stearic acid are glycerol monostearate.

[0081] The other functional additives are plasticizers and nucleating agents...

Embodiment 3

[0089] A biodegradable filling foam, comprising the following raw materials in parts by weight:

[0090] Superfine vegetable starch 75 parts

[0091] 15 parts of polymer compound containing hydroxyl activity

[0092] Ammonium salt or amines and polyamines 2.5 parts

[0093] Foaming agent 2.5 parts

[0094] Acidity regulator 2.5 parts

[0095] Peroxide 0.25 parts

[0096] Stearic acid and stearic acid esters 5 parts

[0097] 5 parts of other functional additives.

[0098] The active polymer compound containing hydroxyl group is ethylene-vinyl alcohol copolymer.

[0099] The ammonium salt is ammonium sulfate; the amines are diethanolamine; and the polyamines are diethylenetriamine.

[0100] Described whipping agent is sodium bicarbonate.

[0101] The acidity regulator is tartaric acid.

[0102] The peroxide is benzoyl peroxide or lauroyl peroxide.

[0103] The stearic acid and the esterified product of stearic acid are glyceryl distearate.

[0104] The other functiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com