Nonaqueous electrolyte secondary battery positive electrode active material and method for producing same, and nonaqueous electrolyte secondary battery which uses positive electrode active material

A positive electrode active material, secondary battery technology, applied in non-aqueous electrolyte batteries, active material electrodes, secondary batteries, etc., can solve the problems of crystallinity deterioration of positive electrode active materials, poor output characteristics, increased lithium, etc. Inhibition of the formation of lithium and the effect of high output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

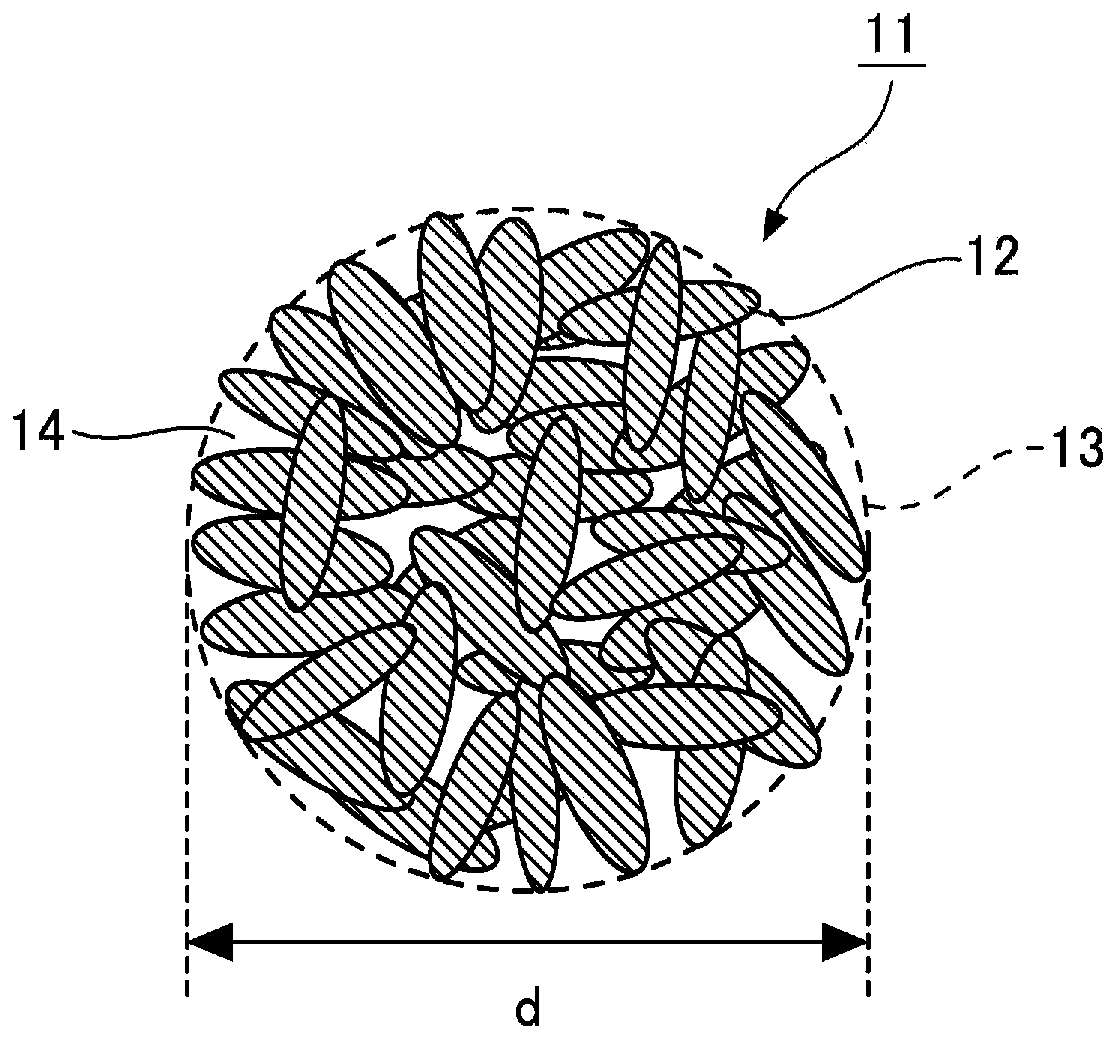

[0152] [Metal composite hydroxide]

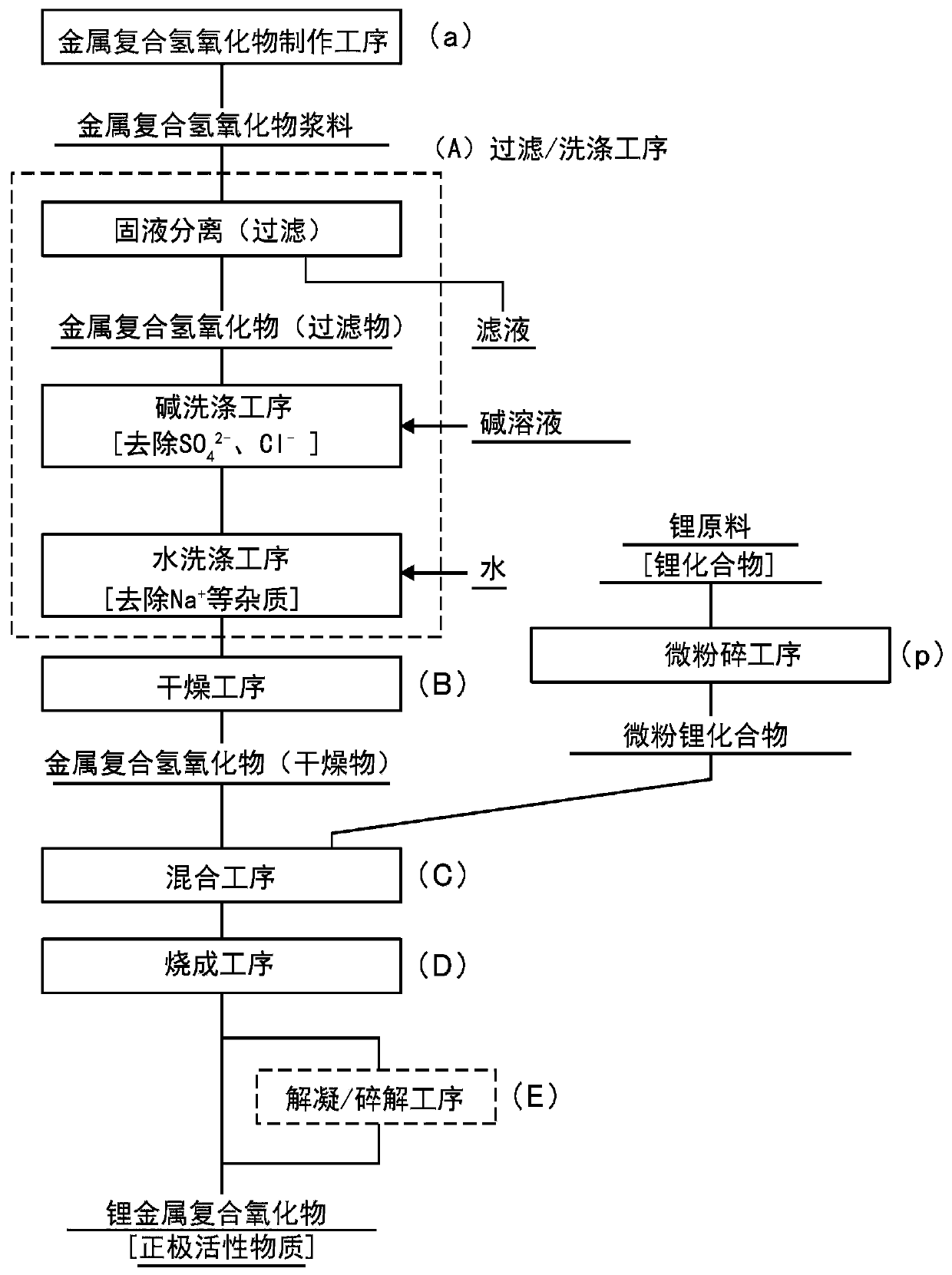

[0153] a) Manufacture of metal composite hydroxide powder

[0154] [(a) Manufacturing process of metal composite hydroxide]

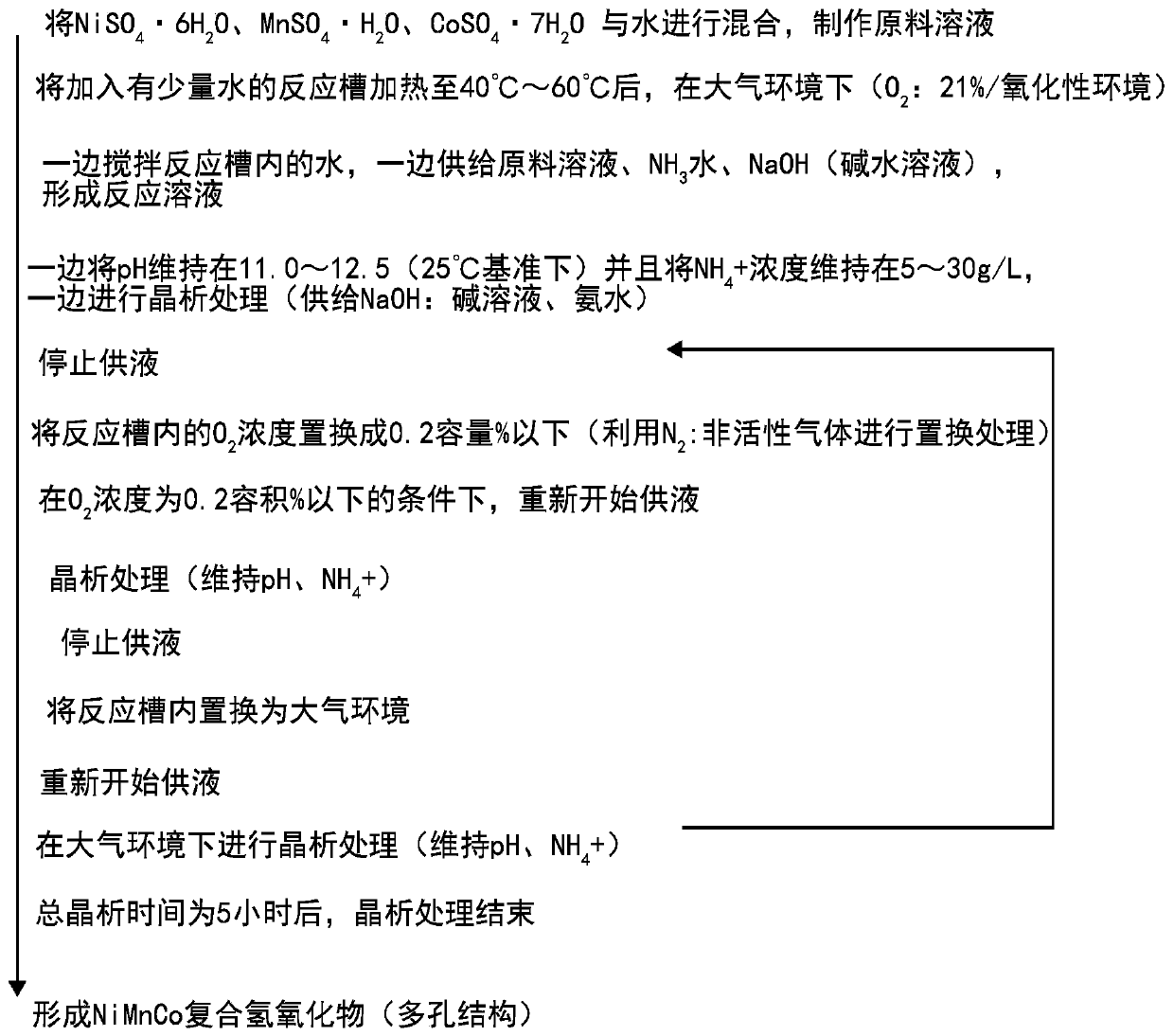

[0155] First, nickel sulfate hexahydrate, cobalt sulfate heptahydrate, and manganese sulfate monohydrate are dissolved in water so that the molar ratio of nickel, manganese, and cobalt becomes Ni:Mn:Co=35:30:35, and, The raw material solution was prepared so that the concentration of nickel, manganese, and cobalt became 2 mol / L. On the other hand, 900 ml of water was added to a reaction tank with a capacity of 6 L until it overflowed, and the temperature in the tank was heated to 40° C. using a water bath, and the reaction tank at this time was adjusted to an atmospheric environment (oxygen concentration: 21 volume %).

[0156] Then, while stirring the water in the reaction tank, the raw material solution, 25% by mass of ammonia water, and 25% by mass of sodium hydroxide solution were continuously supplied to form...

Embodiment 2

[0210] Lithium carbonate is finely pulverized using a jet mill until the maximum particle diameter in the particle size distribution is 8.0 μm or less and the average particle diameter is 4.0 μm or less. In addition, the same operation as in Example 1 was performed to obtain a positive electrode active material. and evaluate.

[0211] The evaluation results are shown in Table 1.

Embodiment 3

[0213] Lithium carbonate was finely pulverized using a jet mill until the maximum particle diameter in the particle size distribution was 4.1 μm or less and the average particle diameter was 2.5 μm or less. In addition, the same operation as in Example 1 was performed to obtain a positive electrode active material. and evaluate.

[0214] The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com