High temperature resistant resin, its preparation method and application, high temperature resistant coating containing the high temperature resistant resin, its preparation method and coating

A high-temperature-resistant resin and high-temperature-resistant coating technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as easy discoloration, poor high-temperature resistance, yellowing or falling off, and achieve color retention and good adhesion , Good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

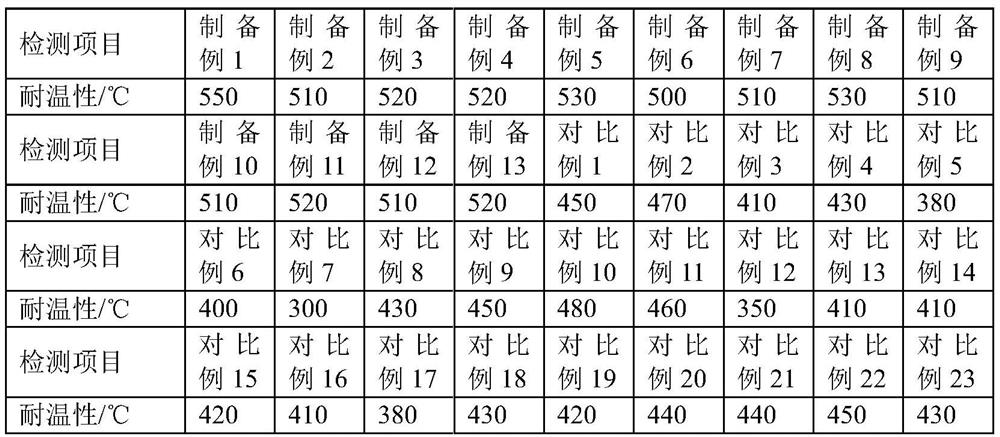

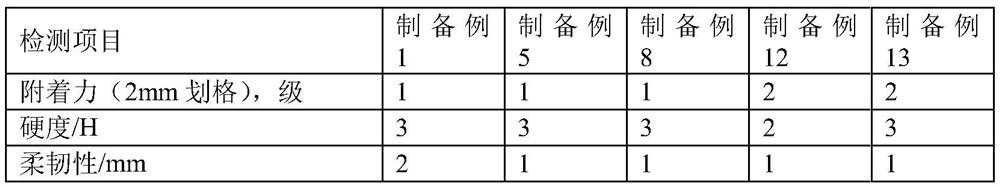

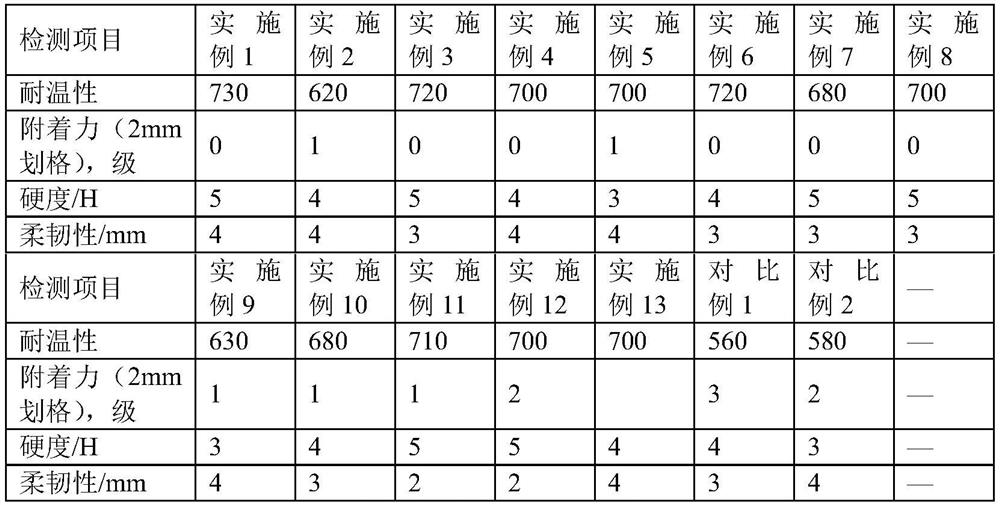

Examples

preparation example Construction

[0046] A preparation method of high temperature resistant resin, comprising the following steps:

[0047] Monomer Mixing: Combine the Three C's 1 -C 5 Alkylethoxysilane, two C 1 -C 5 Alkyldiethoxysilane and C 1 -C 5 Alkyl triethoxysilane is mixed with ethyl orthosilicate, stirred and heated to obtain composition A;

[0048] Polymerization: Slowly add the acid solution to the composition A, dropwise within 50-70min, after the dropwise addition, the pH of the solution is 4-5, and stir for 4-5h;

[0049] Wherein, in the monomer mixing step, three C 1 -C 5 Alkylethoxysilane, two C 1 -C 5 Alkyldiethoxysilane and C 1 -C 5 The mass ratio of alkyl triethoxysilane to be added is 1: (4-6): (8-12), and the mass ratio of tri-C1-C5 alkylethoxysilane to ethyl orthosilicate is 1: (1.5-2.5);

[0050] Preferably, the triple C 1 -C 5 Alkylethoxysilane, two C 1 -C 5 Alkyldiethoxysilane and C 1 -C 5 Alkyltriethoxysilanes are selected from trimethylethoxysilane, dimethyldiethoxy...

preparation example 1

[0067] A preparation method of high temperature resistant resin, comprising the following steps:

[0068] Monomer mixing: Mix 5g of trimethylethoxysilane, 25g of dimethyldiethoxysilane, 50g of methyltriethoxysilane and 10g of ethyl orthosilicate, stir, and heat to 40°C to obtain a combination Object A;

[0069] Polymerization: Slowly add the acid solution to the composition A, dropwise within 60 minutes, the pH of the solution is 4 after the dropwise addition, keep stirring and reacting at 40°C for 4-5h after the dropwise addition, to obtain a high temperature resistant silicone resin.

preparation example 2

[0071] A method for preparing a high-temperature-resistant resin is carried out according to the method in Preparation Example 1, except that in the monomer mixing step, the amount of dimethyldiethoxysilane added is 20 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com