Method for producing positive electrode active material for nonaqueous electrolyte secondary batteries, positive electrode active material for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

A positive active material and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, active material electrodes, electrode manufacturing, etc., can solve the problems of unexplained manufacturing methods of positive active materials, achieve less surface damage, and suppress the increase of internal resistance , The effect of water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

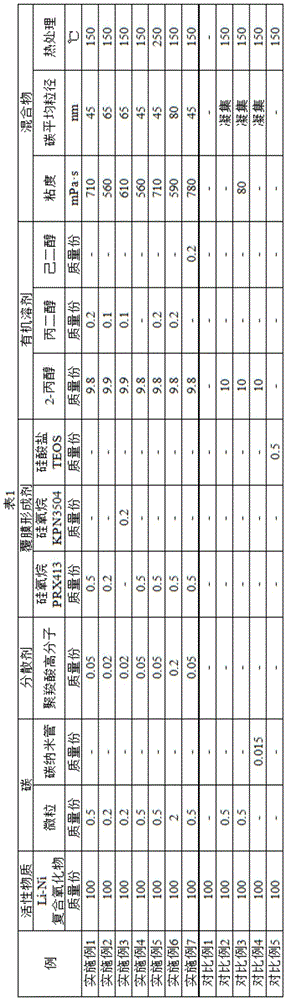

[0055] The preparation method of the mixture in the mixing step is not particularly limited as long as it is a method capable of sufficiently mixing the materials, and known methods can be used, but among them, it is preferable to use a kneading mixer of a self-rotation and revolution system for mixing. The above-mentioned kneading mixer can apply moderate shear force to the mixture to achieve uniform mixing, and can mix in a short time. For example, if the processing capacity is 20-50g, the mixing time is preferably 1-5 minutes. According to the processing capacity Just make adjustments. The short-time mixing by the kneading and agitating machine of the self-rotating and revolving system can also suppress damage to the surface of the particles. On the other hand, if a device such as a bead mill, a ball mill, a rod mill, a homogenizer, etc. is used to directly apply a large force to the positive electrode active material particles, sometimes the positive electrode active mater...

Embodiment 1

[0136] (lithium-nickel composite compound LiNiCoAlO 2 )

[0137] A lithium-nickel composite oxide powder obtained by a known technique was used as the positive electrode active material. That is, by mixing and firing nickel oxide powder mainly composed of Ni and lithium hydroxide, Li 1.06 Ni 0.76 co 0.14 Al 0.10 o 2 Represented lithium-nickel composite oxide powder. The lithium-nickel composite oxide powder has an average particle size of 7.6 μm and a specific surface area of 0.82 m 2 / g.

[0138] (Preparation of positive electrode active material)

[0139] First, 10 parts by mass of carbon fine particles (manufactured by Denka, trade name "HS100") and 1 part by mass of a polycarboxylate polymer dispersant (manufactured by Kao, trade name "HOMOGENOLL18") were added in advance to 2-propanol. A carbon-containing composition (2) (hereinafter referred to as "dispersion liquid") was prepared.

[0140] Next, 20 g of the lithium-nickel composite oxide powder was taken out...

Embodiment 2

[0143] Add 0.2 parts by mass of polydimethylsiloxane containing hydroxyl groups, 0.1 parts by mass of propylene glycol, 0.2 parts by mass of carbon particles from the dispersion, 0.02 parts by mass of polycarboxylic acid polymer dispersant, and 4.9 parts by mass of 2-propanol to obtain Except for the mixture, a positive electrode active material was obtained in the same manner as in Example 1, and evaluation was performed at the same time. The viscosity of the mixture was 560 mPa·s.

[0144] The initial discharge capacity of the obtained positive electrode active material was 201 mAh / g, and the positive electrode resistance value was 1.2. Furthermore, the evaluation results of water resistance were pH=10.3, the electrical conductivity was 120 μS / cm, and the evaluation results of moisture resistance were a mass increase rate of 0.7%. According to the evaluation of gelation, the positive electrode composite material paste did not gel even after being left at room temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com