Nano organic solvent silicasol and preparation method thereof

A technology of organic solvent and silica sol, applied in the field of nanomaterials, can solve the problem that organic silica sol cannot be absolutely water repellent and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

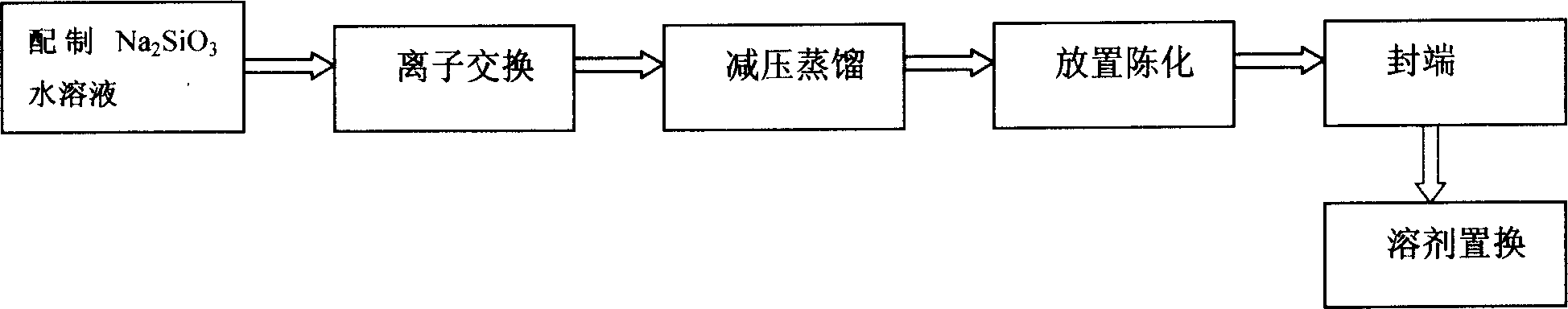

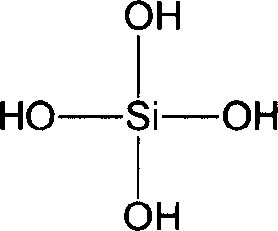

[0039] (1). Weigh analytically pure sodium silicate reagent (Na 2 SiO 3 ·9H 2 O) 116.25 grams were dissolved in 383.75 milliliters of high-purity deionized water to prepare a 10% aqueous solution of sodium silicate.

[0040] (2). The Na 2 SiO 3 The aqueous solution is introduced from the ion exchange upper port, and the outlet piston of the ion exchange column equipped with the hydrogen-type cation exchange resin is opened to collect the exchange liquid. And constantly detect the pH value of the exchange liquid at the outlet, and replenish Na in time 2 SiO 3 solution. When the pH value of the exchange liquid became 4-5, the effluent exchange liquid was collected as a silica sol sample. When all Na 2 SiO 3 After adding the solution, continue to inject high-purity deionized water into the tube to replace the silica sol retained in the exchange column and collect all the products. When the pH value of the exchange liquid returned to 6-7, the collection was stopped. Rin...

specific Embodiment approach 2

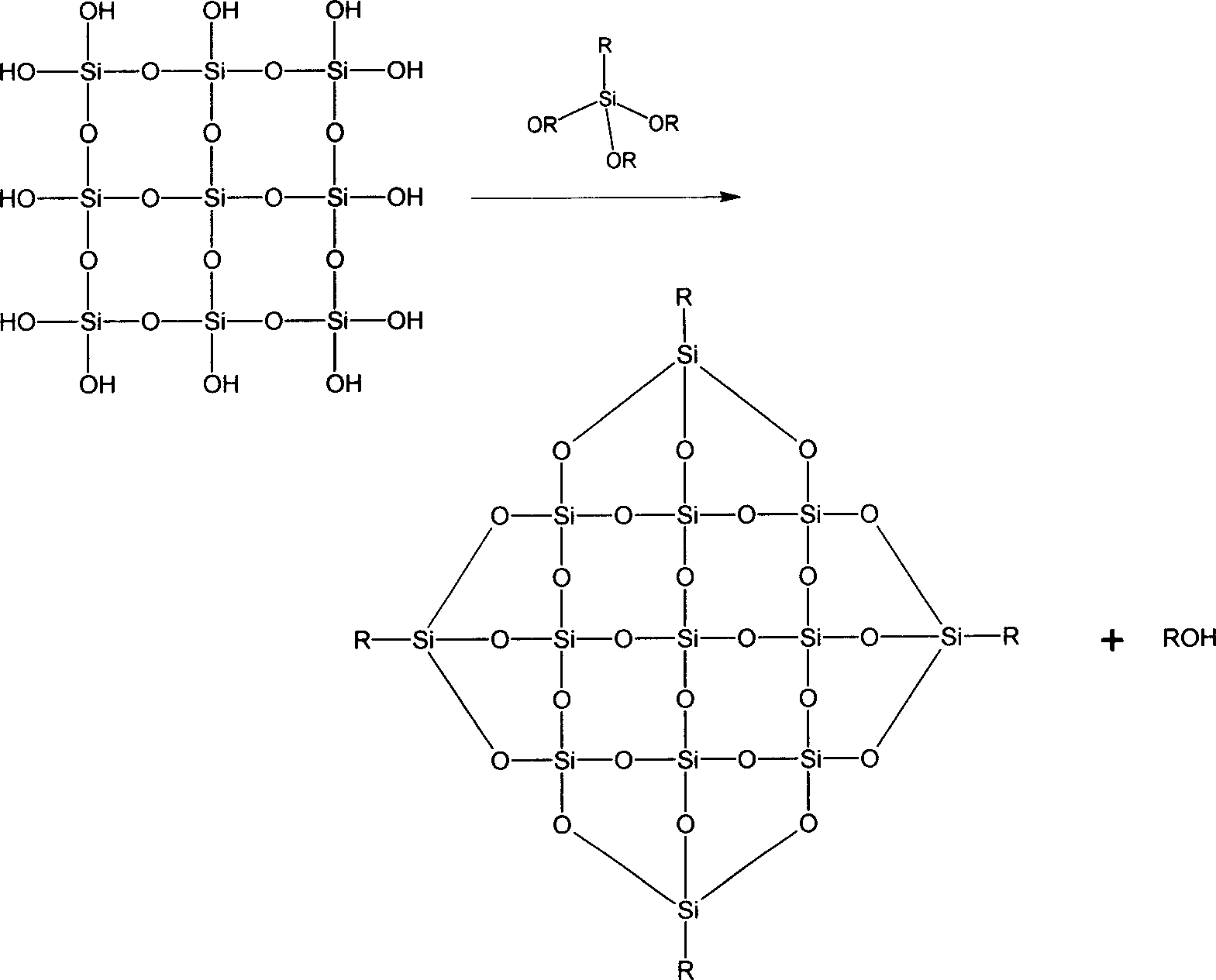

[0045] According to the steps of Example 1, weigh the analytically pure sodium silicate reagent (Na 2 SiO 3 ·9H 2 O) 232.5 grams, dissolved in 267.5 milliliters of high-purity deionized water to prepare a 20% aqueous solution of sodium silicate. After ion exchange, excess water was distilled off by vacuum distillation to obtain 10% SiO 2 Hydrosol. will get H 4 SiO 4 After the solution was placed and aged at 70 °C for 2 hours, a certain amount of end-capping agent, such as triethoxysilane [CH 3 Si(OC 2 H 5 ) 3 ], so that the mass percentage concentration in the solution is 1.0%. Mix well and then age at room temperature for 24 hours. Mix SiO in a volume ratio of 10:9 2 Hydrosol and high-boiling ethylene glycol solvent, the mixture is loaded into a distillation apparatus for underpressure distillation, the pH of the mixed solution is controlled to be 9, all water is removed, and ethylene glycol silica sol is prepared. Its appearance is colorless, clear and transparen...

specific Embodiment approach 3

[0046] According to the steps of Example 1, take by weighing the analytically pure sodium silicate reagent (Na 2 SiO 3 ·9H 2 O) 384.8 grams, dissolved in 151.2 milliliters of deionized high-purity water to prepare a 30% aqueous solution of sodium silicate. After ion exchange, excess water was distilled off by vacuum distillation to obtain 15% SiO 2 Hydrosol. will get H 4 SiO 4 After the solution was placed and aged at 70 °C for 2 hours, a certain amount of end-capping agent, such as monomethyltriethoxysilane [CH 3 Si(OC 2 H 5 ) 3 ], so that the percentage concentration in the solution is 1.5%. Mix well and then age at room temperature for 24 hours. Mix SiO in a volume ratio of 10:9 2 Hydrosol and high-boiling ethylene glycol solvent, the mixture is loaded into a distillation apparatus for underpressure distillation, and the pH of the controlled mixed solution is 9 to prepare ethylene glycol silica sol. Its appearance is colorless, clear and transparent. Silica sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com