Washing machine

A washing machine and detergent technology, applied in the field of washing machines, can solve the problems that the performance of liquid detergent can no longer be fully utilized, the liquid detergent is difficult to put in, and the liquid outlet is narrowed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below with reference to the accompanying drawings. Wherein, for the parts whose structures are the same as those in the background art, only the same symbols are assigned, and text descriptions are omitted. At the same time, it should be pointed out that the scope of the present invention is not limited to the embodiment described below.

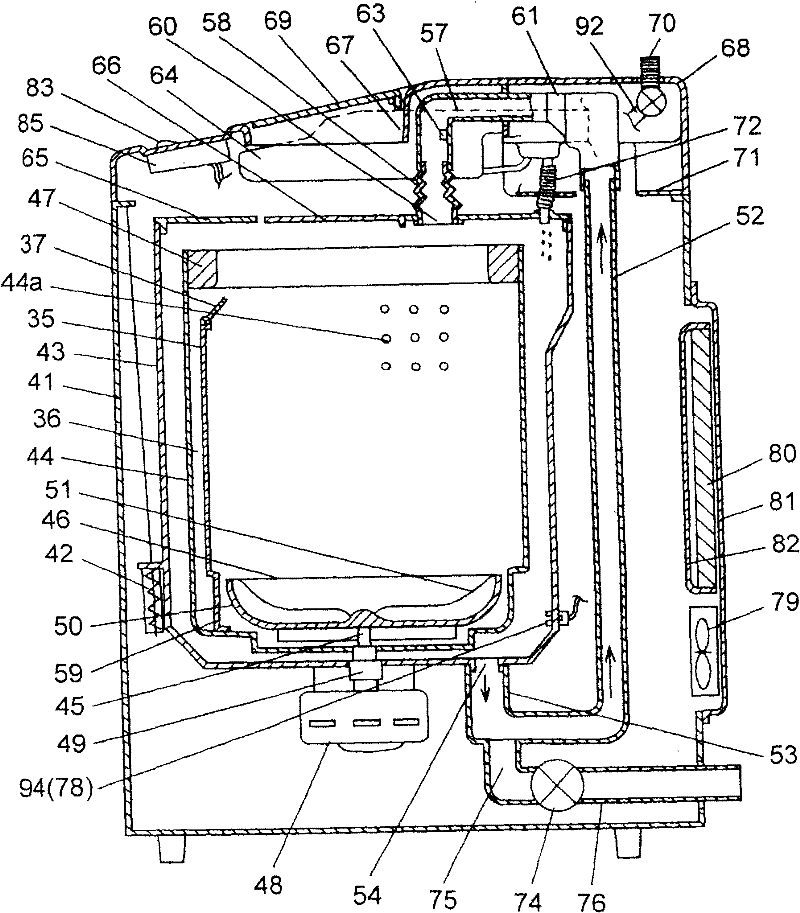

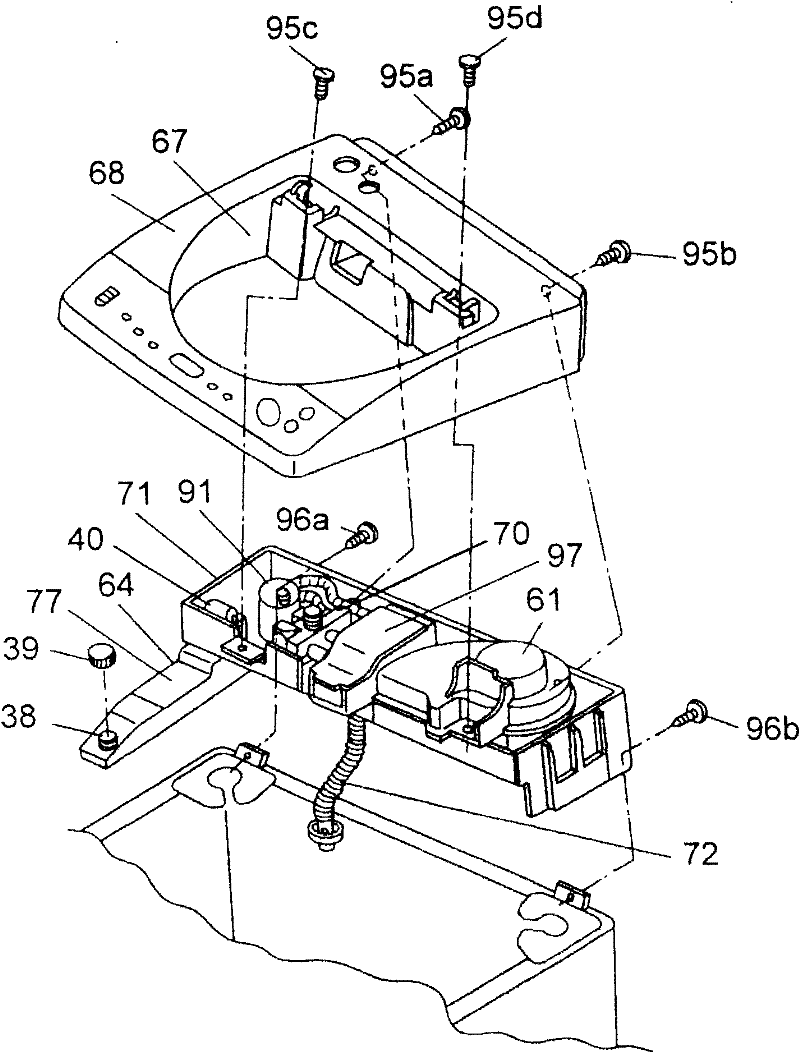

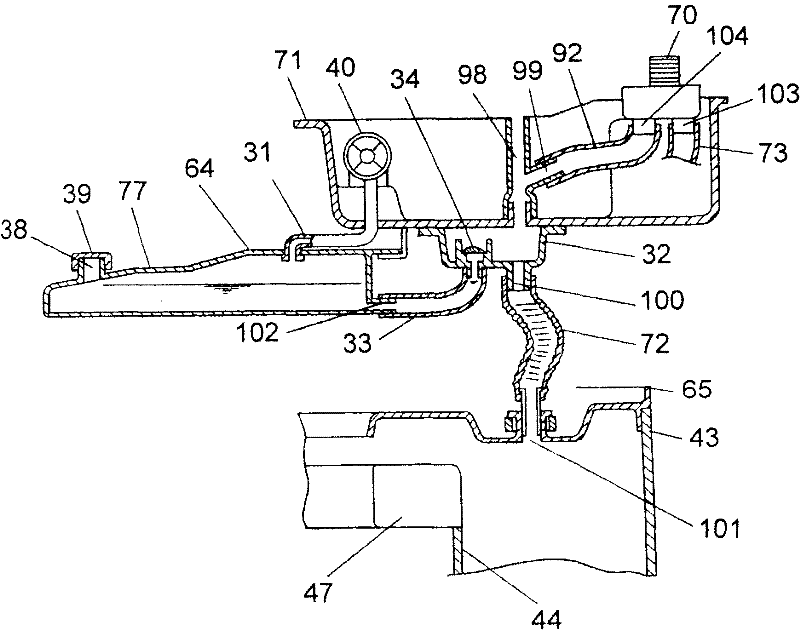

[0025] figure 1 is a longitudinal sectional view of the washing machine in an embodiment of the present invention, and figure 2 It is a partially exploded oblique view of the washing machine in the embodiment of the present invention, image 3 It is a sectional view of main parts of the washing machine in the embodiment of the present invention.

[0026] exist figure 1 Among them, the inside of casing 41 is provided with an outer bucket 43, and outer bucket 43 utilizes a plurality of suspending parts 42 to carry out elastic hoisting, forms the structure that can absorb the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com