Fatty alcohol emulsion defoamer stabilized by water-soluble homopolymer and preparation method thereof

A technology of water-soluble alcohol and fatty alcohol, which is applied in the preparation of fatty alcohol emulsion defoamer and in the field of fatty alcohol emulsion defoamer, which can solve the problems of less emulsion phase separation, less viscosity increase and gelling, and higher stability, and achieve Inhibition of gelation and thickening, excellent stability, and mild use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

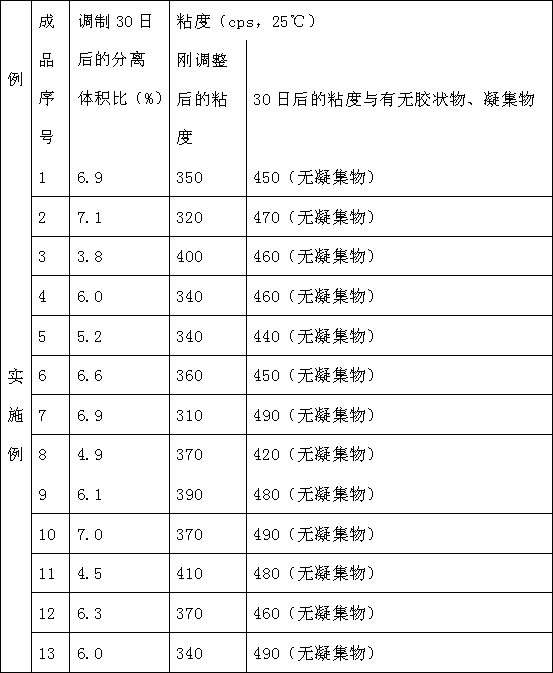

Examples

Embodiment 1

[0031] The preparation method of the stable fatty alcohol emulsion defoamer of water-soluble homopolymer comprises the following steps:

[0032] (1) Prepare the oil phase:

[0033] Take an appropriate amount of fatty alcohol and organic hydrocarbons and mix them into the reaction vessel, heat and stir at a temperature t1 until an oil phase is formed, the temperature t1 is higher than the higher melting point of the fatty alcohol and organic hydrocarbons, and the temperature t1 is at least is 110°C.

[0034] in:

[0035] Fatty alcohol is selected lauryl alcohol, and its weight is 10g;

[0036] Organic hydrocarbons are diesel oil, the weight of which is 1g;

[0037] t1=100°C.

[0038] (2) Prepare the water phase:

[0039] Take an appropriate amount of water-soluble 2-acrylamide-2-methylpropanesulfonic acid homopolymer and / or its salt, water-soluble alcohols, and non-cationic surfactants, mix them, add them to the reaction kettle, heat and stir at temperature t2 Uniform unt...

Embodiment 2

[0048] The preparation method of the stable fatty alcohol emulsion defoamer of water-soluble homopolymer comprises the following steps:

[0049] (1) Prepare the oil phase:

[0050] Take an appropriate amount of fatty alcohol and organic hydrocarbons and mix them into the reaction vessel, heat and stir at a temperature t1 until an oil phase is formed, the temperature t1 is higher than the higher melting point of the fatty alcohol and organic hydrocarbons, and the temperature t1 is at least is 110°C.

[0051] in:

[0052] Fatty alcohol selects stearyl alcohol for use, and its weight is 15g;

[0053] Organic hydrocarbons select paraffin for use, and its weight is 2g;

[0054] t1=110°C.

[0055] (2) Prepare the water phase:

[0056] Take an appropriate amount of water-soluble 2-acrylamide-2-methylpropanesulfonic acid homopolymer and / or its salt, water-soluble alcohols, and non-cationic surfactants, mix them, add them to the reaction kettle, heat and stir at temperature t2 Un...

Embodiment 3

[0065] The preparation method of the stable fatty alcohol emulsion defoamer of water-soluble homopolymer comprises the following steps:

[0066] (1) Prepare the oil phase:

[0067] Take an appropriate amount of fatty alcohol and organic hydrocarbons and mix them into the reaction vessel, heat and stir at a temperature t1 until an oil phase is formed, the temperature t1 is higher than the higher melting point of the fatty alcohol and organic hydrocarbons, and the temperature t1 is at least is 110°C.

[0068] in:

[0069] Fatty alcohol selects C22 alcohol for use, and its weight is 90g;

[0070] Organic hydrocarbons select microcrystalline wax for use, and its weight is 6g;

[0071] t1=110°C.

[0072] (2) Prepare the water phase:

[0073] Take an appropriate amount of water-soluble 2-acrylamide-2-methylpropanesulfonic acid homopolymer and / or its salt, water-soluble alcohols, and non-cationic surfactants, mix them, add them to the reaction kettle, heat and stir at temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com