Thermosetting resin composition and printed circuit board filled with the resin composition

A technology of resin composition and printed circuit board, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of reduced workability and short usable time, so as to prevent the reduction of workability, prolong the storage period, Excellent grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

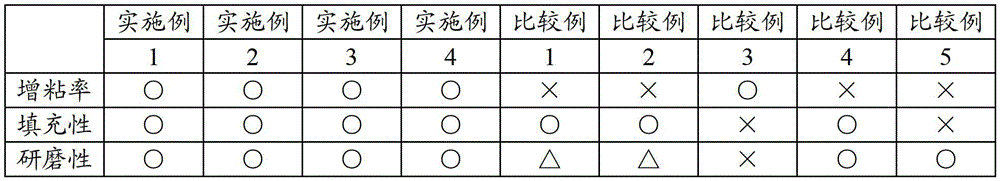

[0048] Although this invention is demonstrated in more detail based on an Example and a comparative example, the technical scope of this invention and its embodiment are not limited to these. The "part" or "%" in an Example and a comparative example is a basis of weight unless otherwise indicated. The property value test of the composition of this Example was performed by the method described below.

[0049] (preparation of paste)

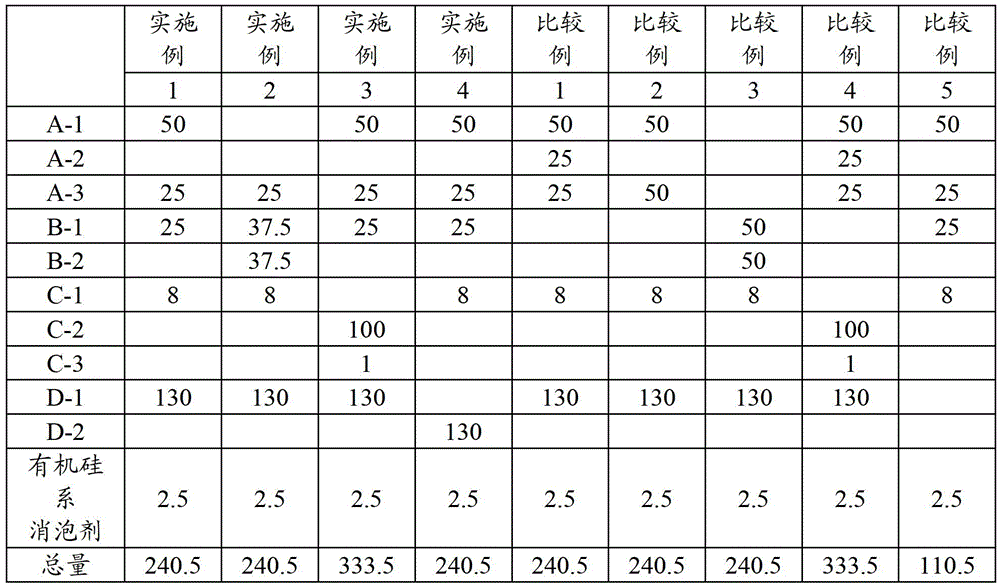

[0050] The components shown in Table 1 were pre-mixed by a mixer according to their respective compounding ratios (parts by mass), and then dispersed by a three-roll mill to prepare the thermosetting resin compositions of Examples 1-2 and Comparative Examples 1-3.

[0051] Table 1

[0052]

[0053] Epoxy resin A-1 not having an alicyclic skeleton: Bisphenol A type epoxy resin (manufactured by Mitsubishi Chemical Corporation, "jER-828")

[0054] Epoxy resin A-2 not having an alicyclic skeleton: bisphenol F type epoxy resin (manufactured by M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com