Patents

Literature

32results about How to "Simple production process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

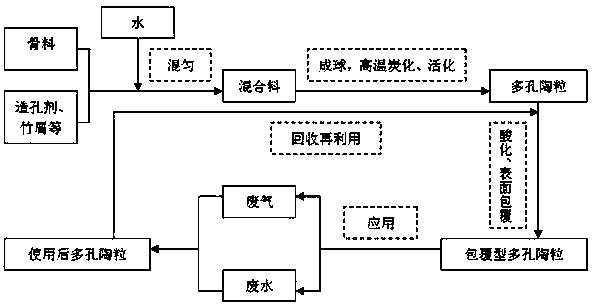

Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

ActiveCN104291797AImprove physical strengthGood processing effectCeramicwareExpanded clay aggregateHoneycomb

The invention provides bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as a preparation method and application of the bamboo-charcoal-shaped porous ceramsite. The preparation method of the bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron comprises the following steps: taking alpha-Al2O3 powder as ceramsite primary aggregate, clay and bentonite as auxiliary aggregates and surface-activated bamboo bits as bamboo charcoal preparation materials to combine with a pore forming agent to prepare pores without adding a sintering aid or a binder; adopting graded sintering at 400-600 DEG C to obtain bamboo-charcoal-shaped porous ceramsite by once molding; then, preparing the product bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron by virtue of a reducing coating process of the coating material, wherein the product bamboo-charcoal-shaped porous ceramsite is a deep dark small ball with a grain size of 2-10 mm, internally a porous honeycomb spherical structure with a surface pore size of 15-25 mu m, has water absorption of 20-35% and a specific surface area of 40-60m<2> / g. The preparation method disclosed by the invention is environmentally friendly simple and energy-saving in preparation process, various in treated pollutants, and suitable for treating non-biodegradable wastewater such as flue gas wastewater, heavy metal wastewater, phenol-containing wastewater, emulsified oil wastewater, note printing and printing and dyeing wastewater, and raw material are easily available.

Owner:FUZHOU UNIV

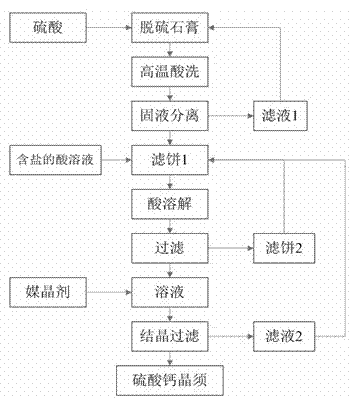

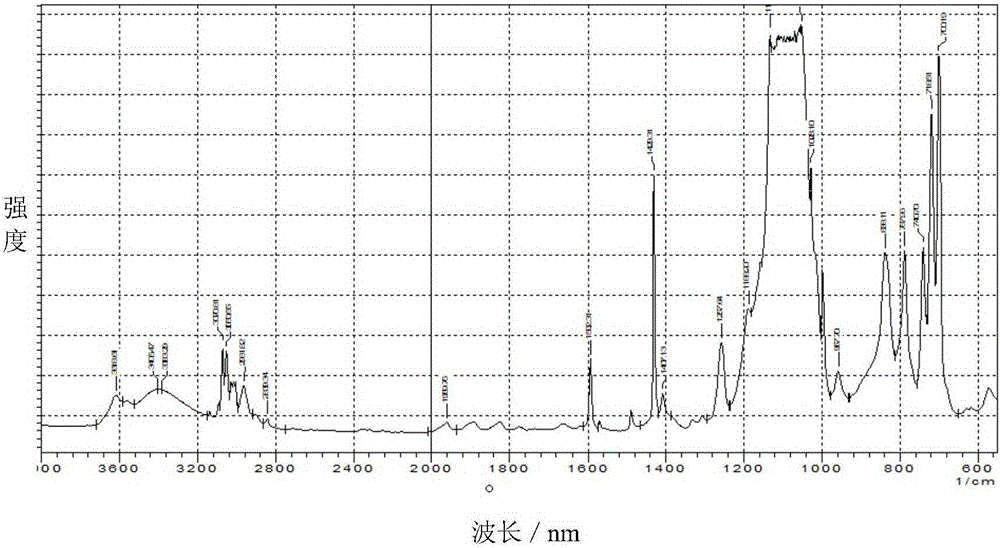

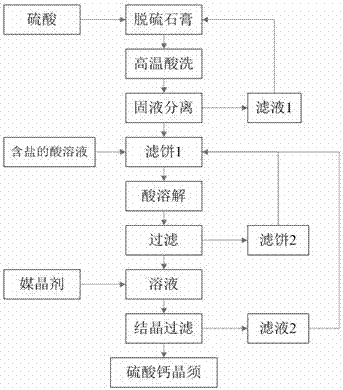

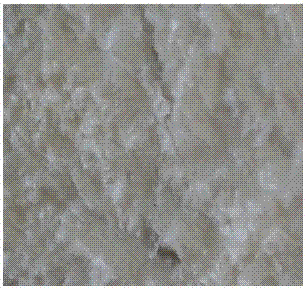

Method for preparing high-purity calcium sulfate dihydrate crystal whisker by using metallurgic flue gas desulfurization gypsum recrystallization process

ActiveCN104846440APromote conversionImprove Calcium UtilizationPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryCalcium Sulfate Dihydrate

The invention discloses a method for preparing a high-purity calcium sulfate dihydrate crystal whisker by using a metallurgic flue gas desulfurization gypsum recrystallization process. The method comprises the steps of pickling metallurgic flue gas desulfurization gypsum to remove a small deal of calcium carbonate or calcium oxide and soluble impurities; dissolving the gypsum by using a salt-containing acid solution to obtain a product used as a raw material for preparing the high-purity calcium sulfate dihydrate crystal whisker; adding a medium crystal agent to control the controllable growth of a calcium sulfate crystal whisker to form a calcium sulfate crystal whisker with controllable length-to-diameter ratio and complete crystal appearance, filtering and drying to obtain the calcium sulfate dehydrate crystal whisker. The recycling of the high-added-value calcium sulfate crystal whisker prepared from the metallurgic flue gas desulfurization gypsum is realized under normal-pressure and mild conditions according to the recrystallization principle. The raw material adopted in the method is available, the production process condition is simple, the added value of the high-purity crystal whisker is high, and the produced calcium sulfate dihydrate crystal whisker has the characteristics of small diameter, high length-to-diameter ratio, complete and uniform appearance and stable performance, can be used as a reinforcing material to be applied to an additive for industries such as plastics, rubber, papermaking, ceramics and the like and has a wide application prospect.

Owner:KUNMING METALLURGY INST

Plastic-bamboo composite tube coiled forming technology method

InactiveCN101143453AEasy to produceSimple production process conditionsWood treatment detailsVeneer manufactureFilling materialsRoom temperature

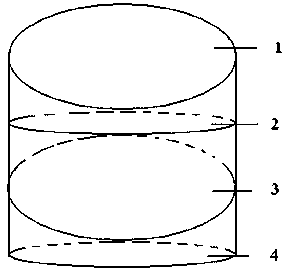

The invention relates to a bamboo-plastic composite pipe rolling forming technique, which solves a problem that present bamboo-plastic composite pipe centrifugal casting has the defects of easy offset and exposure, loose bamboo filling materials, low content, etc. The specific processing steps are to cut bamboo materials into bamboo long strips, on which degreasing, dehydration and surface active agent activation treatments are implemented. A mat bamboo weaved object are precast. Resin mortars are evenly coated on the mat bamboo weaved object. Silicon oil demould agent is coated on the outer surface of the mould pipe. More than one layer of the mat bamboo weaved object is helicoidally tensioned and winded on the mould pipe and is heated and solidified for forming. Then, the object is cooled to the room temperature and is demoulded to obtain the bamboo-plastic composite pipe. The manufacturing process condition requirements of the invention are relative simple. The compactness of the bamboo filling materials is greatly improved. The strength and the rigidity of the pipe are improved. And the content of the bamboo materials reaches to 50-70 percentage, which is beneficial to the further lowering of the cost. The invention is especially applied to the production of pipe products with large diameter.

Owner:HEFEI UNIV OF TECH +1

Method for preparing special high-strength tempered glass for high-speed train

InactiveCN103553306AIncrease the surface compressive stressHigh speedGlass/slag layered productsGlass reforming apparatusToughened glassMaterials science

The invention relates to the field of tempered glass preparation, in particular relates to a method for preparing special high-strength tempered glass for a high-speed train, and provides a method for preparing special high-strength tempered glass for a high-speed train aiming at the defects of the prior art. The method is characterized in that high-strength single glass is prepared by using a method that a thermal tempering technique is taken as a main method and a chemical tempering technique is taken as an auxiliary method, and furthermore a glass conductive heating film and an anti-splashing film are added by using an interlay technique and a precision forming technique, so as to finally produce multi-layer high-speed train windproof glass with high strength and demisting and defrosting effectiveness. The high-speed train windproof glass prepared by using the method has the characteristics of high strength, good light translucency, uniform electrical heating and the like.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD +1

Biomass coal adhesive and biomass coal prepared by the same

InactiveCN101134920ASimple processRaw materials are easy to getSolid fuelsWaste based fuelChemistryBiomass

The present invention is one kind of biomass briquette adhesive and corresponding biomass briquette producing process. The pale yellow ropy biomass briquette adhesive is produced with crop stalk and through air drying, crushing, soaking in water, adding slaked lime and steaming while stirring. The biomass briquette adhesive has facile cheap material, high efficiency, simple production process and simple composition. The biomass briquette with high biomass adding amount and best utilization of biomass energy of crop stalk is produced through mixing the biomass briquette adhesive and powdered coal in certain ratio and extruding formation. The biomass briquette has high strength, high waterproofing performance, low burning point, high heat value and excellent sulfur fixing effect.

Owner:HENAN POLYTECHNIC UNIV

Preparation method for lithium cobalt oxide with high pole piece compaction density

ActiveCN103022475AEasy to processIncrease compaction densityCell electrodesCobalt compoundsZirconium hydrideLithium carbonate

The invention relates to a preparation method for lithium cobalt oxide with high pole piece compaction density. The preparation method is characterized by comprising the following steps: (1) weighing battery grade lithium carbonate, cobaltosic oxide with the particle size of 2.5-5 mu m and a doped raw material-magnesium oxide, aluminum oxide, titanium oxide or zirconium oxide; and sintering a mixed raw material for the first time; (2) carrying out ball milling and mixing on the battery grade lithium carbonate and the cobaltosic oxide with the particle size of 2.5-5 mu m; and sintering a mixed raw material for the first time; and (3) weighing powder prepared in the steps (1) and (2) respectively, carrying out ball milling and mixing, and sintering for the second time. The preparation method has the advantages of capability of remarkably enhancing the pole piece compaction density, excellent pole piece processing performance, high commonality of a slurry formula, long cyclic life and the like, and particularly has the advantages of simple required production equipment and simplicity for change of production process conditions.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

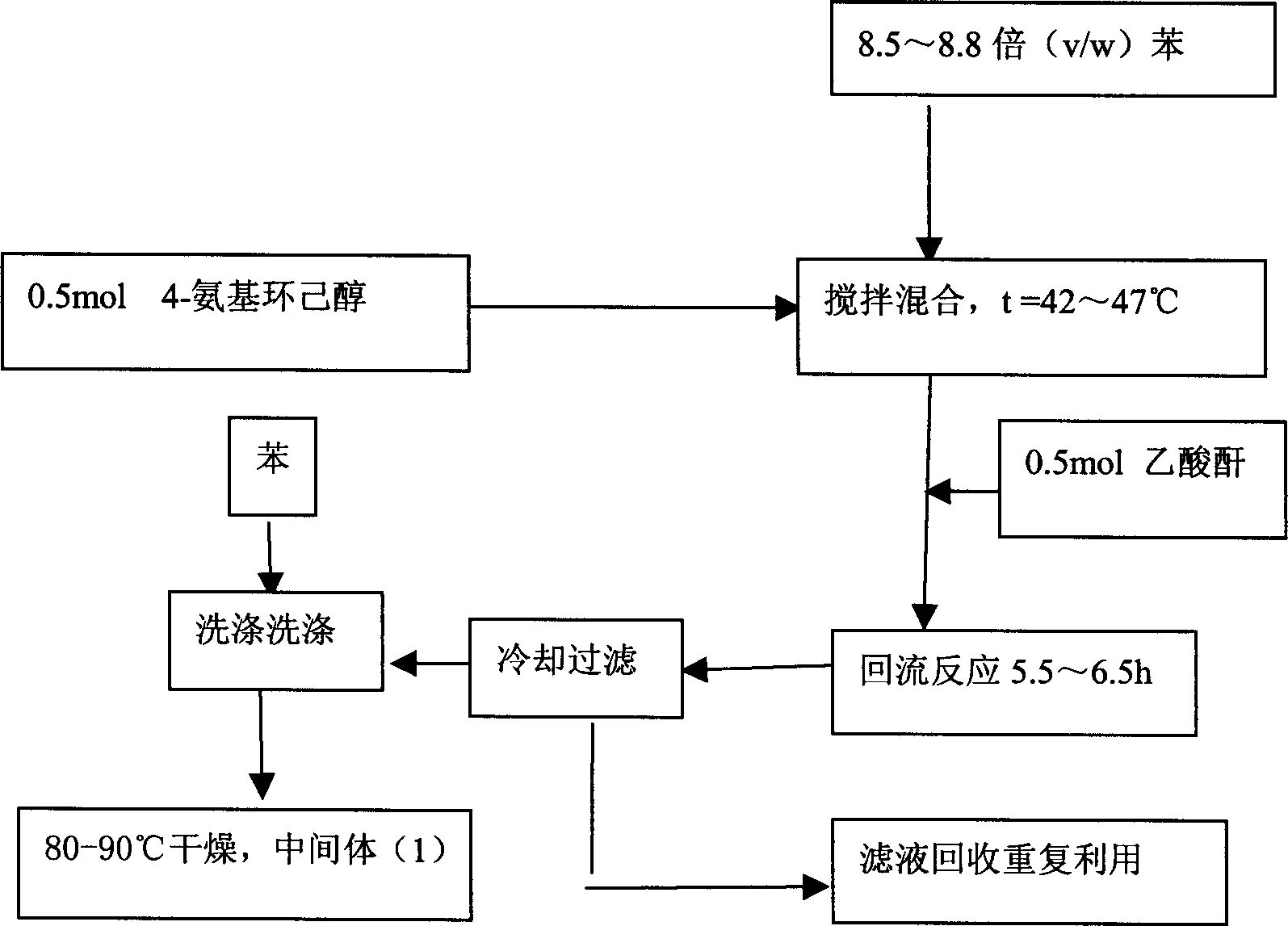

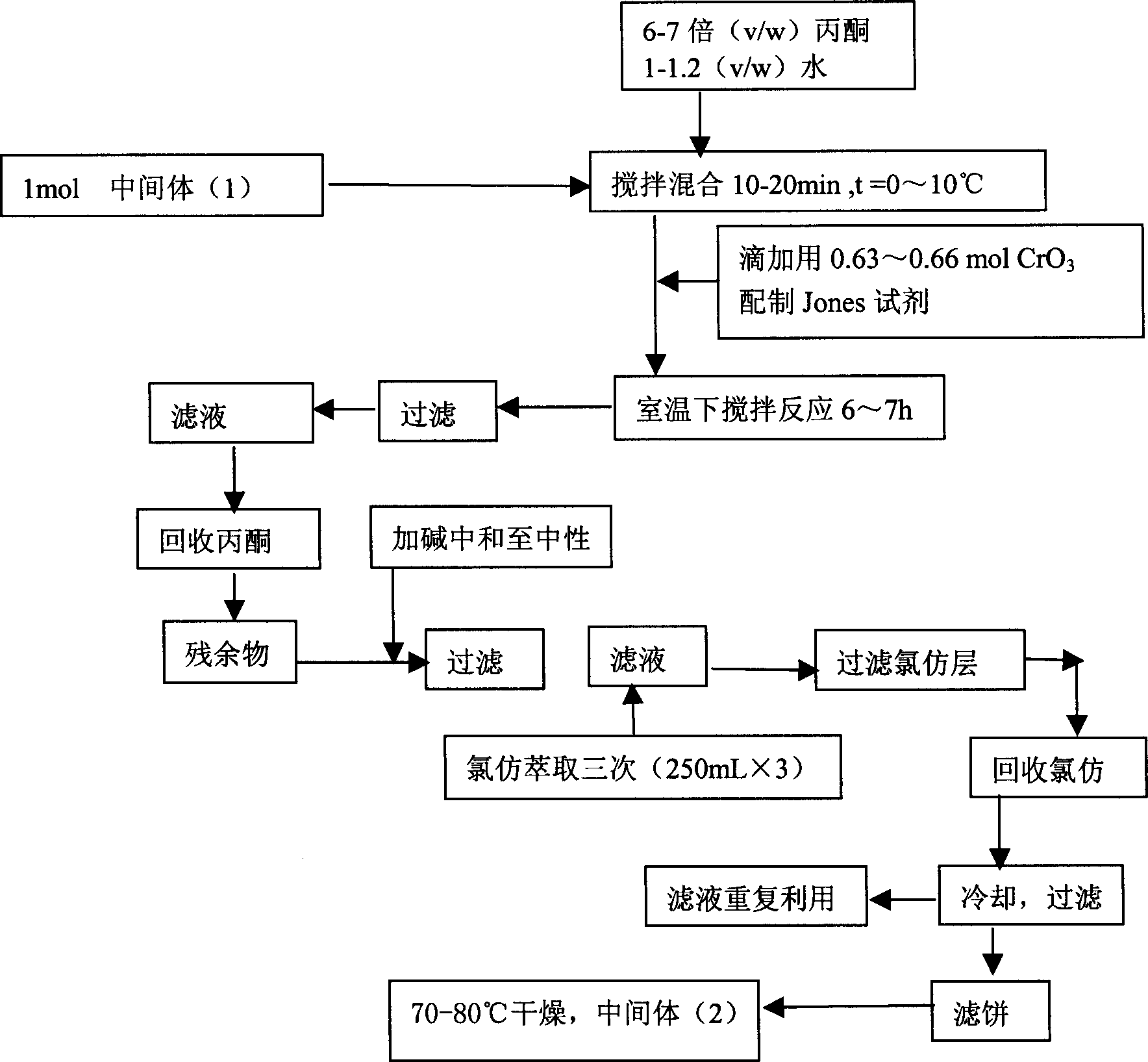

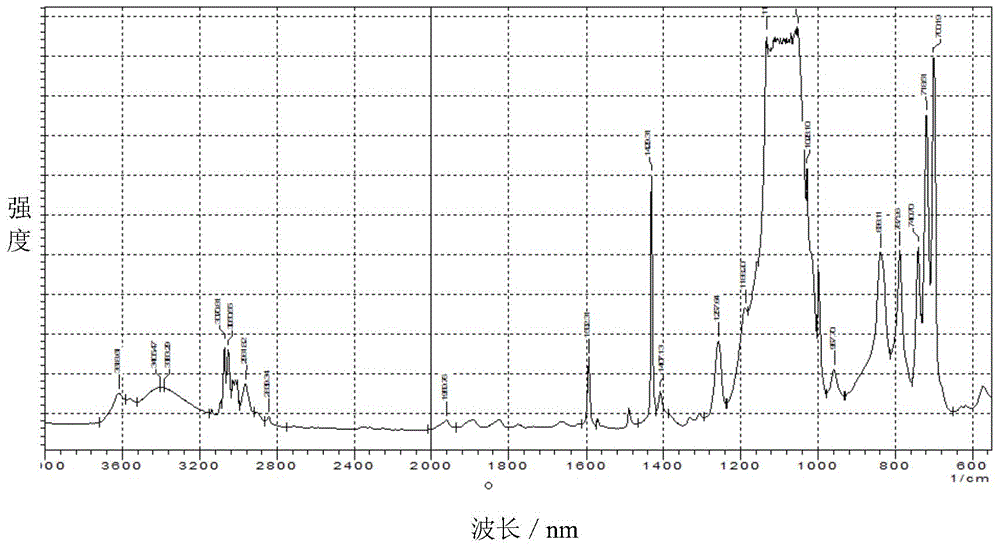

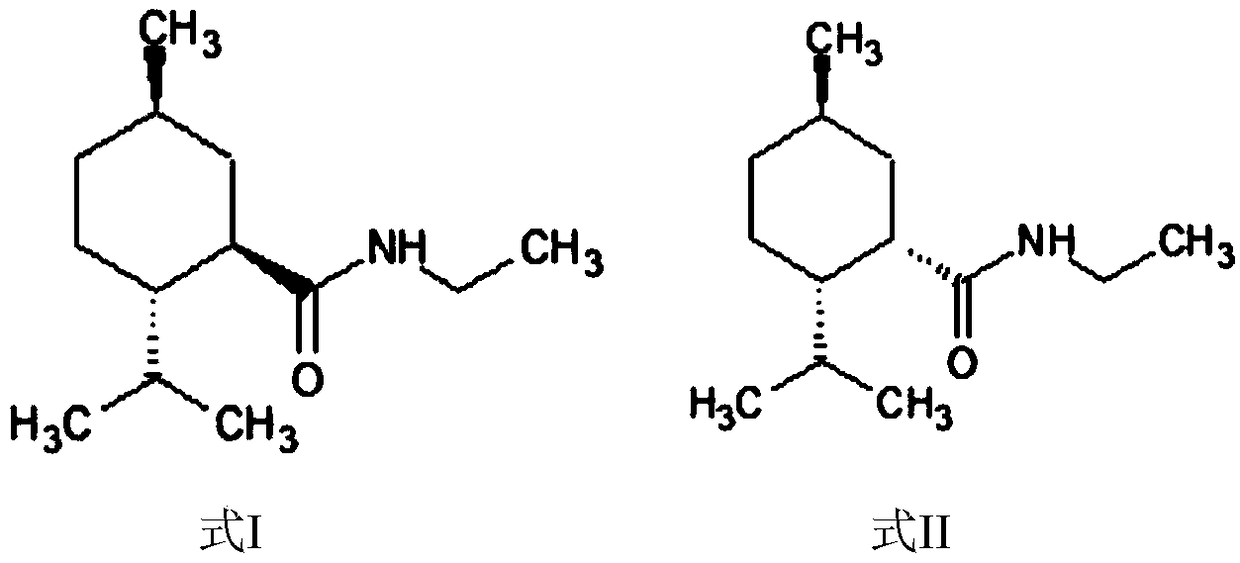

Synthesis of (-)-2-amino-6-propionamido tetrahydro benzothiazole

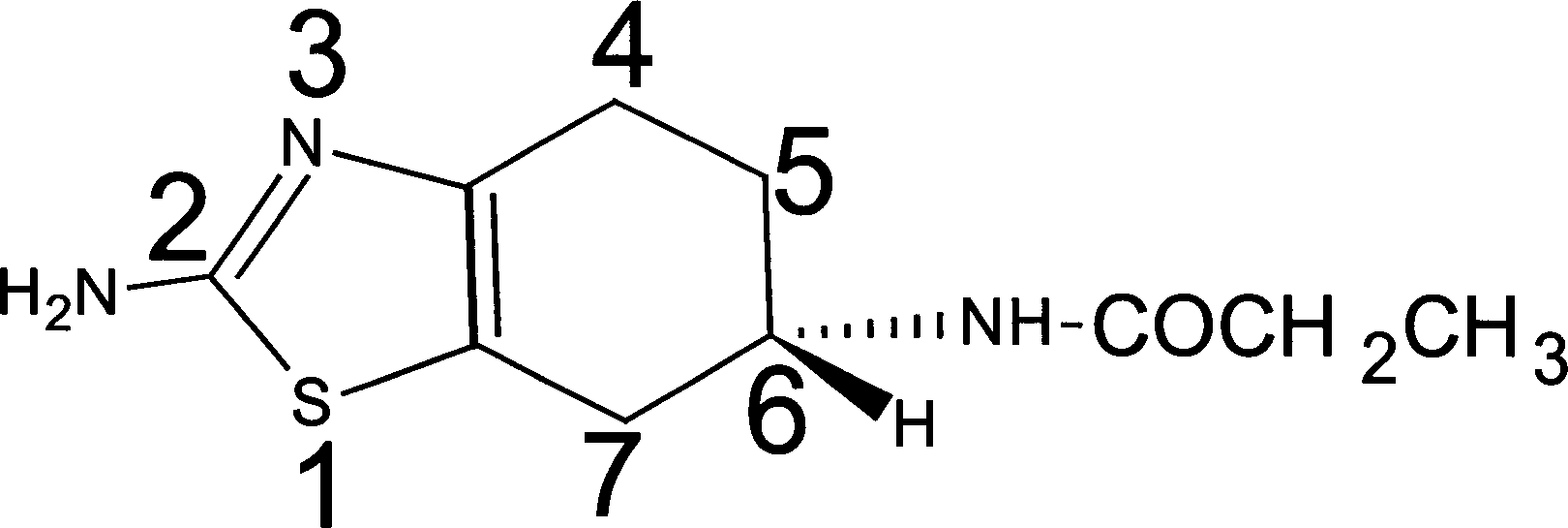

InactiveCN1772744AMild reaction conditionsEasy to controlOrganic chemistryCyclohexanoneChemical reaction

The syntyesis of (-)-2-amino-6-propionamido tetrahydro benzothiazole features the adopting common chemical material 4-amin cyclohexanol as initial material, and the six-step process including N-acetylating reaction for protecting amino radical, oxidation with Jones reagent to prepare 4-acetamido cyclohexanone, thiazole annelation, HBr hydrolysis, tartaric acid chiral compound resolution, propionic anhydride acylation. The present invention has mild reaction condition, easy control, simple production process, low production cost, high reaction yield and easy industrial application.

Owner:YANGTZE UNIVERSITY

MDQ phenyl vinyl silicone resin and preparation method thereof

The invention relates to MDQ phenyl vinyl silicone resin. The MDQ phenyl vinyl silicone resin has the structure shown in the following general formula: (Ph2SiO)a(ViMe2SiO0.5)b(Me3SiO0.5)c(SiO2)d, wherein Ph is phenyl, Me is methyl and Vi is vinyl; the a value ranges from 0.1 to 1, the (b+c) value ranges from 0 to 0.1, and b is larger than 0; the d value ranges from 0 to 0.8, and the sum of a, b, c and d is larger than 0; the value of (a / d) ranges from 1.6 to 2.5; and the value of [(b+c) / d] ranges from 1.6 to 2.5. The invention further provides a preparation method of the MDQ phenyl vinyl silicone resin. According to the method, the viscosity, the refractive index and the vinyl content of a product are controlled through conditions of monomer raw material ratio, the reaction time, temperature and pH value and the like, the manufacturing conditions are mild, simple and feasible, the raw material source is wide, and the repeatability is good.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

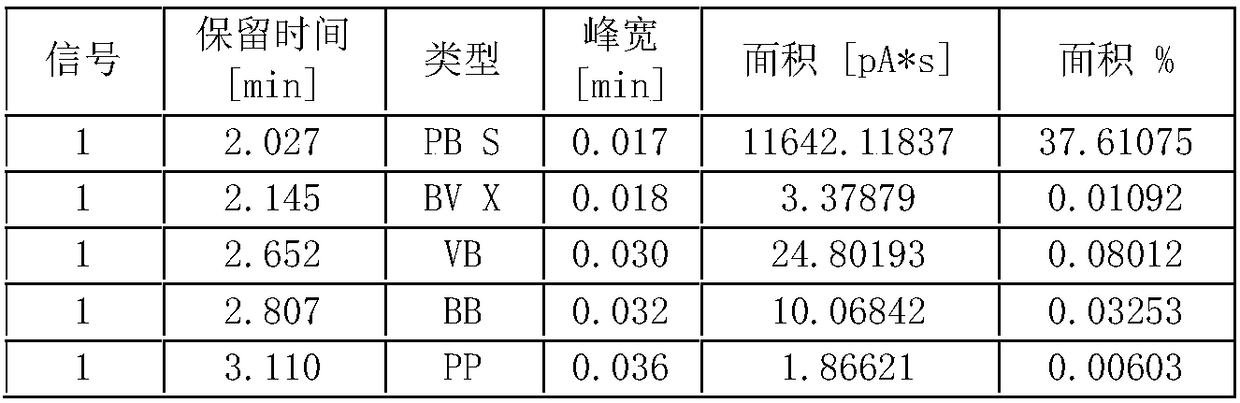

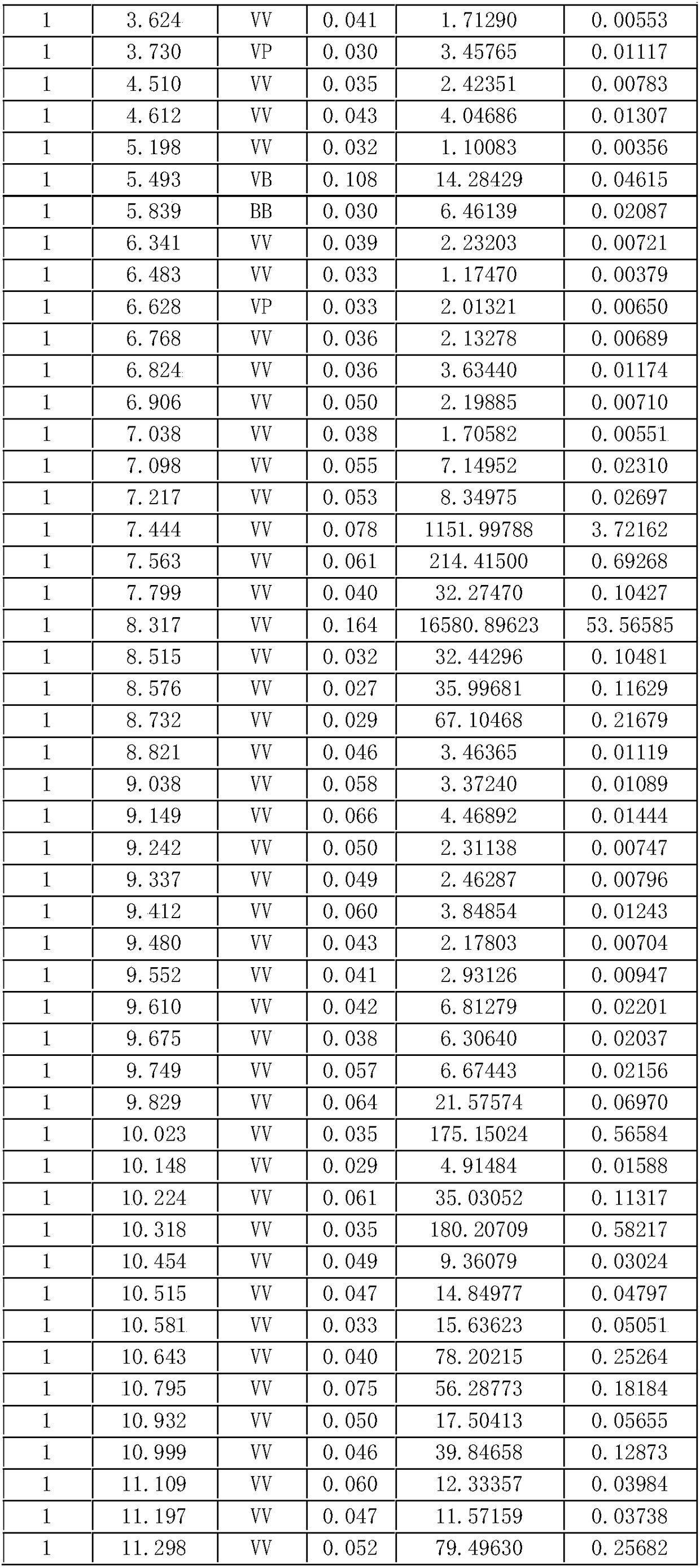

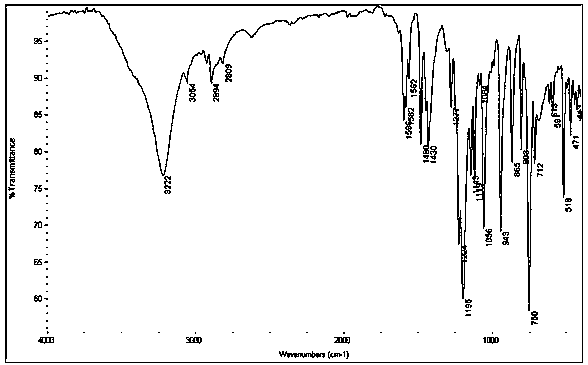

Method of removing chiral dextroisomer in cooling agent WS-3 synthesized based on raw material natural menthol

ActiveCN108358810ADifficult to handleHigh energy consumptionOrganic chemistry methodsCarboxylic acid amides optical isomer preparationMentholNational standard

The invention relates to a method of removing chiral dextroisomer in cooling agent WS-3 synthesized based on a raw material natural menthol. The method is based on purification of dextroisomer in thecooling agent WS-3 and other impurities in the reaction product, purification comprises steps of distilling, crystalizing, recrystallizing, centrifuging, drying and post-treatment, and levo-cooling agent WS-3 in the final product reaches national standards and commercial requirements.

Owner:HENAN HUALONG SPICE

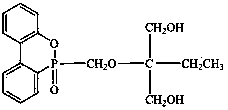

Phosphorus-containing dihydric alcohol and preparation method thereof

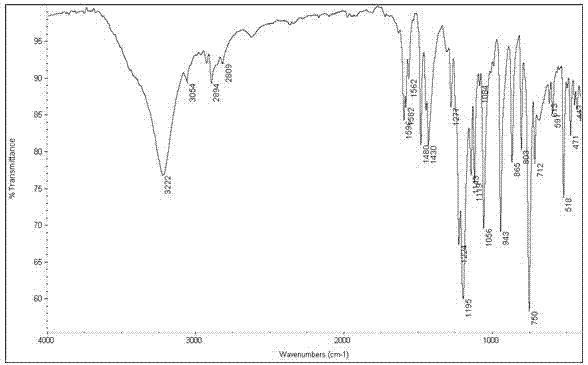

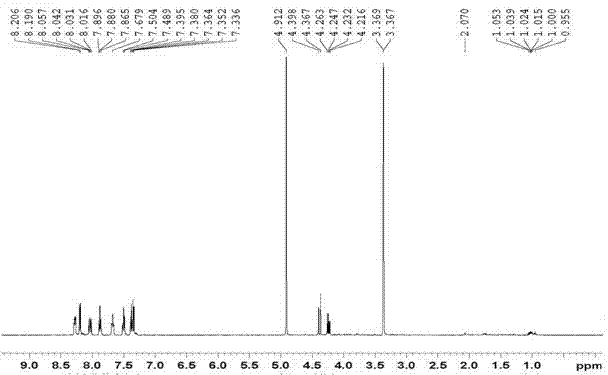

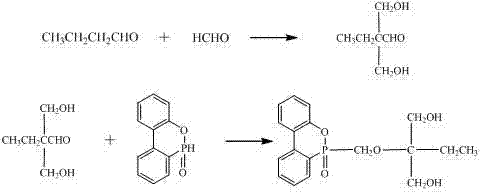

InactiveCN103387591AImprove flame retardant performanceSimple production process conditionsGroup 5/15 element organic compoundsEpoxyChemical synthesis

The invention discloses a phosphorus-containing dihydric alcohol and a preparation method thereof. The phosphorus-containing dihydric alcohol is a synthetic dihydric alcohol. The preparation method comprises the following steps that 1, n-butyraldehyde and a formaldehyde solution undergo a reaction under a certain condition to produce 2,2-dimethylolbutyraldehyde; and 2, DOPO and 2,2-dimethylolbutyraldehyde undergo a reaction under a certain condition; and the reaction products are subjected to pumping filtration, washing, recrystallization and drying to form the phosphorus-containing dihydric alcohol product. The phosphorus-containing dihydric alcohol can be used as a reactive flame retardant used in polymers such as epoxy resins, phenolic resins, plastic and rubber to improve the flame resistance of the polymers, and can also be used as a phosphorus-containing intermediate for preparation of other high-performance materials. The preparation method has the advantages of simple processes, high product purity, high yield and simple aftertreatment.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

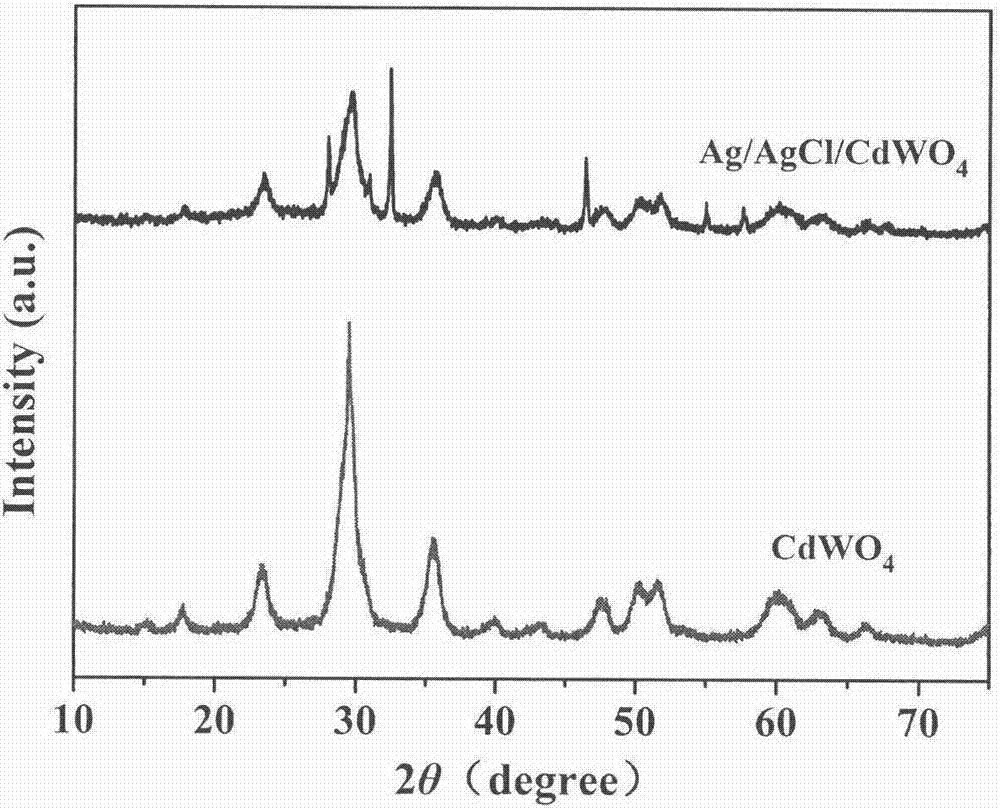

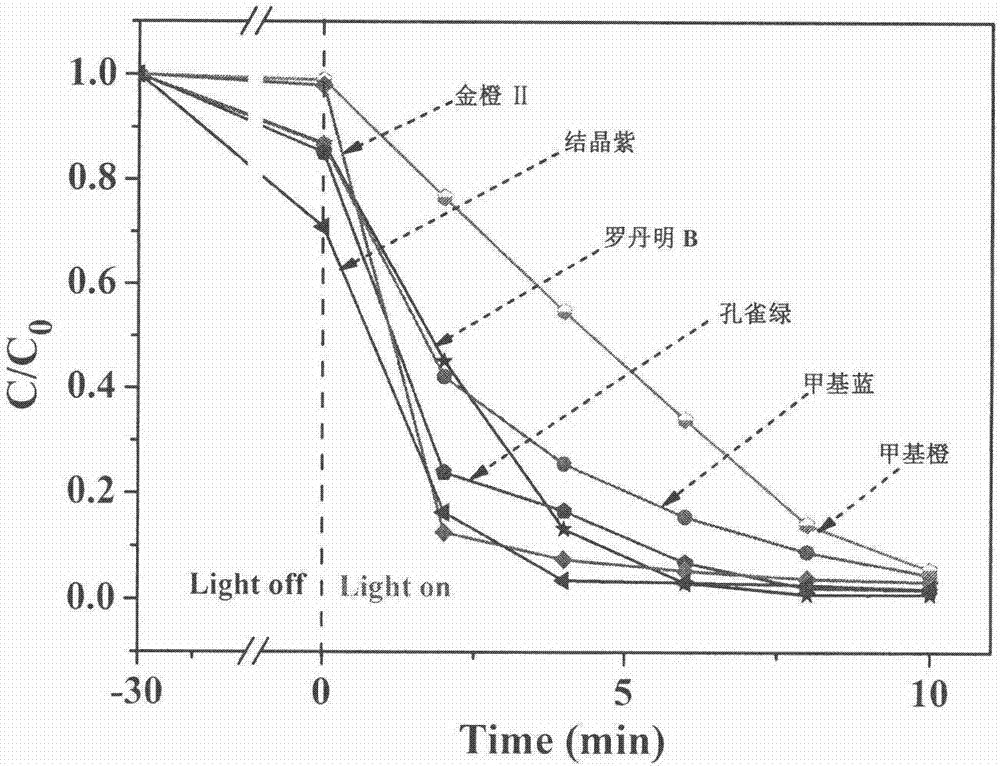

Ag/AgCl/CdWO4 catalyst with efficient visible-light catalytic activity

InactiveCN106890655AImprove photocatalytic degradation performanceHigh mineralization rateWater/sewage treatment by irradiationWater contaminantsMethyl blueSolvent

The invention provides a preparation method for an Ag / AgCl / CdWO4 catalyst with an efficient visible-light catalytic activity and an application in various dyes capable of catalytically degrading under visible light. The method comprises the following steps: by taking sodium tungstate and chromic nitrate as main raw materials and taking water and glycol as a mixed solvent, adopting a hydrothermal method for preparing a CdWO4 material, and then adopting a dipping and photo-reduction method for preparing the Ag / AgCl / CdWO4 photocatalyst with a plasma resonance effect. The catalyst prepared according to the method has excellent photocatalytic degradation property to various dyes, such as gold orange II, methyl orange, methyl blue, peacock green, crystal violet and rhodamine B under the irradiation of visible light; the degradation rate within 10 minutes can reach up to 95% or above; the mineralization rate is high; the catalyst is reusable. The production process conditions are simple, the raw materials are easily acquired and the acquired material has efficient photo-response and wide industrial application prospect.

Owner:NANJING UNIV OF TECH

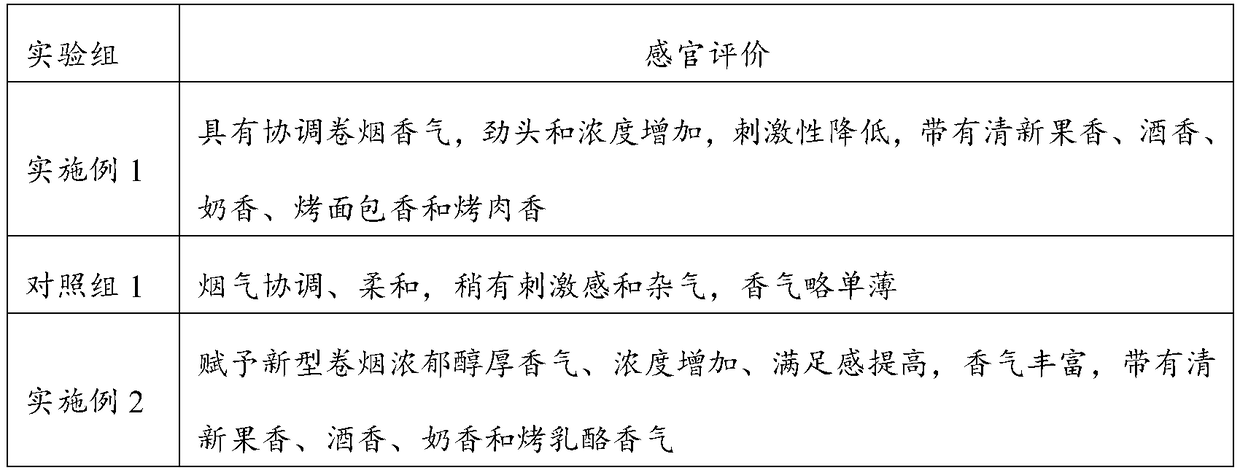

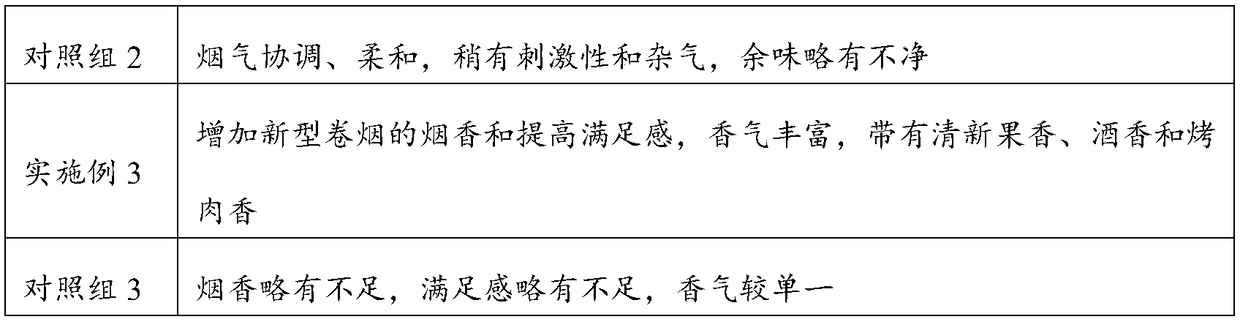

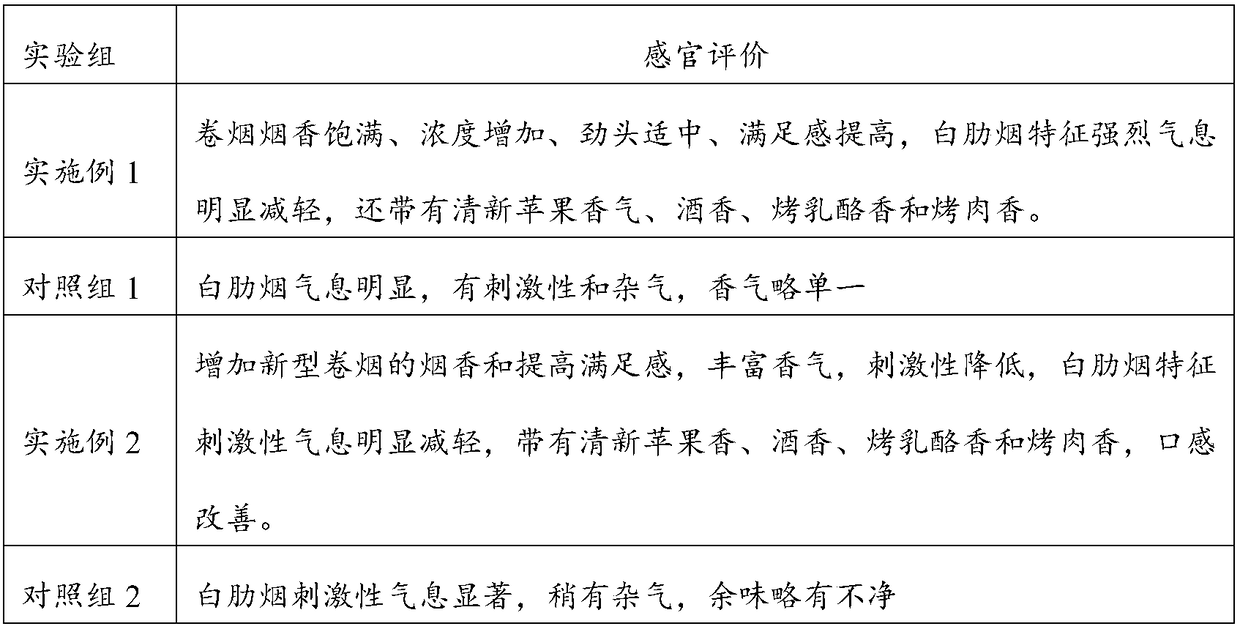

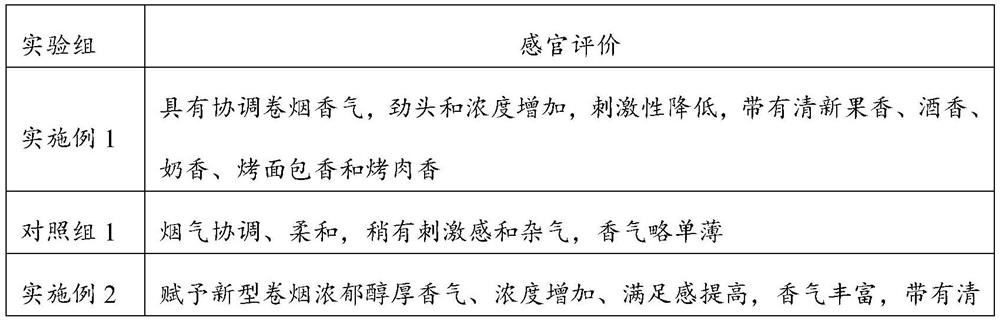

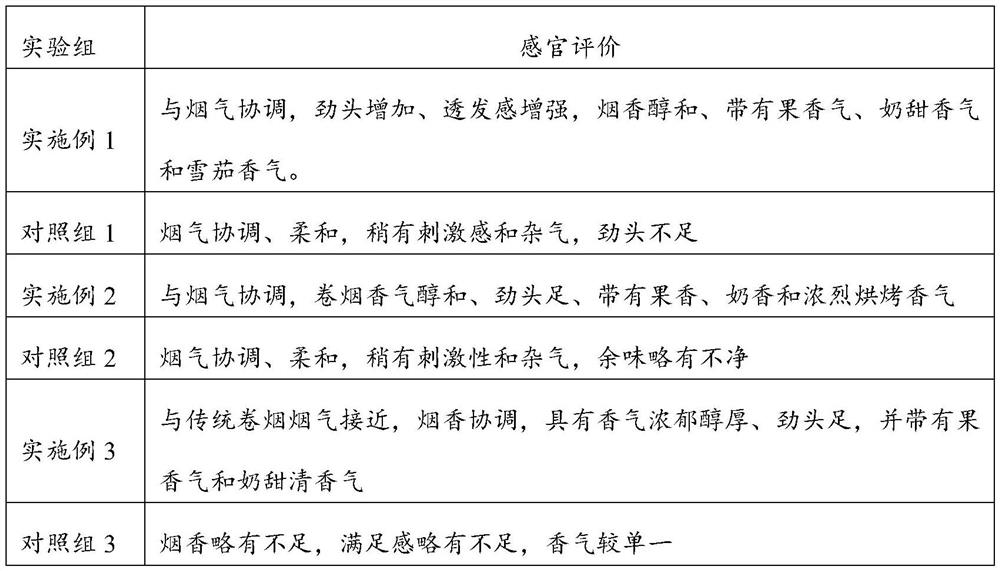

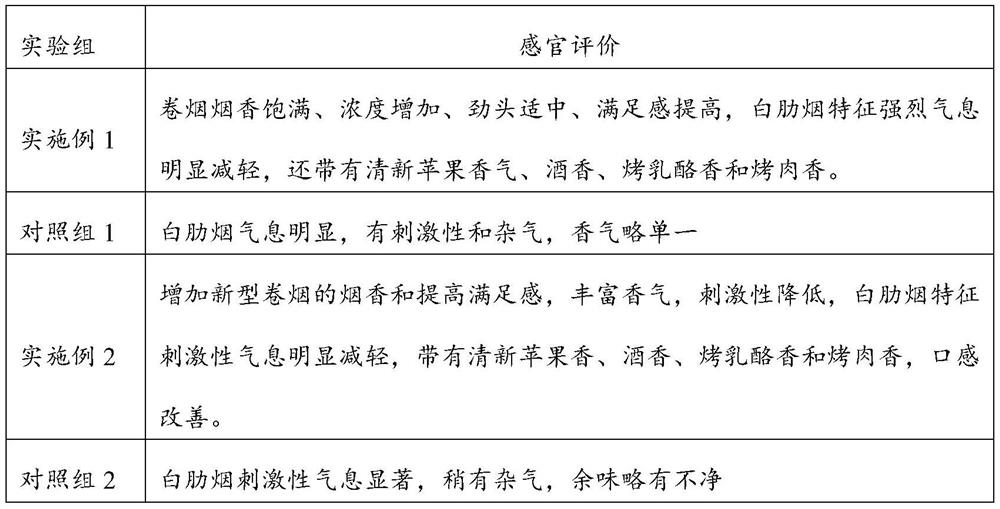

Preparation method and application of composite tobacco leaf extract

ActiveCN109349678AImprove adsorption capacityEasy to separate by filtrationTobacco preparationFungiFlavorHeat not burn

The invention provides a preparation method and application of a composite tobacco leaf extract. Aired tobacco stems, corn cobs and a rice bran composite biological material are adopted as immobilization carriers for adsorbing microbial aroma-producing strains, compounded and aired tobacco leaf raw materials are subjected to incubated hydrolysis fermentation, and then in combination with a continuous countercurrent ultrasonic extraction technology, the composite tobacco leaf extract is prepared. The composite tobacco leaf extract has rich natural tobacco fragrance and has a fresh fruit aroma,a wine aroma, a milk aroma, a barbecue meat aroma, a baked bread aroma, a roasted cheese aroma and other rich natural complex aromas, the irritating property is reduced, the quality of the spices is improved, the purification and separation steps are simple, the process conditions are mild, the extraction rate is increased, and the production efficiency is improved; the composite tobacco leaf extract is applied to traditional cigarettes and novel heat-not-burn cigarettes and is harmony with cigarette fragrance and uniform in style, the concentration of the smoke is increased, the satisfactionfeeling is improved, the cigarette fragrance is enhanced, the irritating property is reduced, and the taste is improved.

Owner:HUBEI CHINA TOBACCO IND

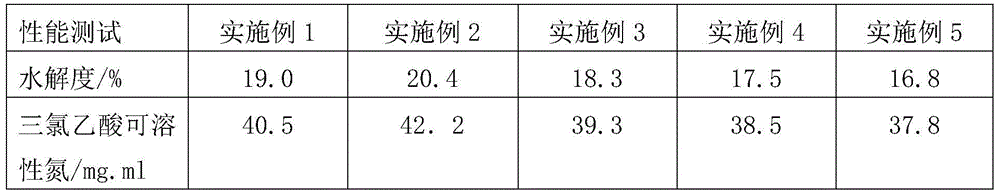

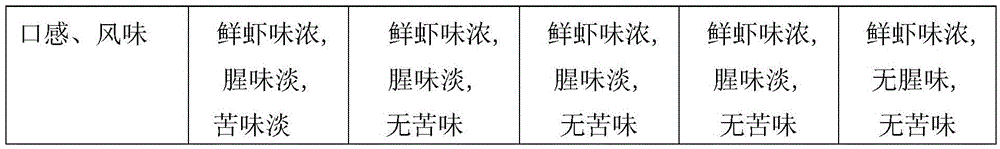

Method for recovering protein in shrimp heads and shrimp shells by enzyme hydrolysis method

A method for recovering protein in shrimp heads and shrimp shells by an enzyme hydrolysis method is disclosed. According to the invention, shrimp product leftovers, namely shrimp heads and shrimp shells, are used as raw materials, and undergo artificial enzymolysis process to obtain a hydrolysate which has no bitter taste or fishy smell and has an excellent taste; and the hydrolysate is further made into shrimp oil or dried to prepare protein. On one hand, precious resources such as shrimp heads and shrimp shells, etc. can be fully utilized so as to change waste materials into valuable things; and on the other hand, the environmental pollution problem caused by shrimp shells and shrimp heads also can be solved. The production technology has simple conditions, is convenient to operate, and can be adopted to realize industrial production.

Owner:广西钦州市绿源天然食品加工有限公司

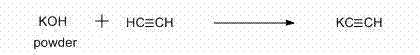

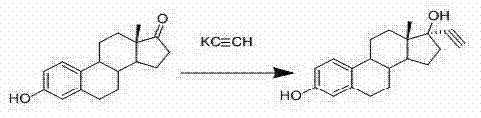

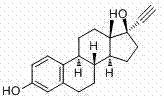

High-purity ethinyloestradiol synthesis method

InactiveCN103204891AReduce consumptionSimple production process conditionsSteroidsEconomic benefitsPotassium

A high-purity ethinyloestradiol synthesis method relates to a synthesis method of estrogen ethinyloestradiol, and in particular relates to a synthesis method for synthesizing high-purity ethinyloestradiol by using estrone and acetylene potassium. The synthesis method comprises two steps as follows:1, reacting potassium hydroxide powder with an acetylene gas to obtain acetylene potassium; and 2, reacting the estrone with the acetylene potassium so as to obtain the ethinyloestradiol at a high content. The high-purity ethinyloestradiol synthesis method has a simple technical condition, no need of expensive reagents, low production cost, easily controlled industrial generation condition, fast reaction speed, high production efficiency, high yield, high content and good product quality, meets the standard of European pharmacopoeia, achieves obvious comprehensive economic benefits, solves the problems that reagents used in the conventional production technology are expensive, the reaction time is long, the consumption amount of acetylene, is great, the proportion of epimers in an ethynylation product cannot be controlled efficiently, the yield and content are low, and the demands on industrial production of the ethinyloestradiol cannot be satisfied, and can be popularized and applied to all the ethinyloestradiol production enterprises.

Owner:湖北三晶生物科技股份有限公司

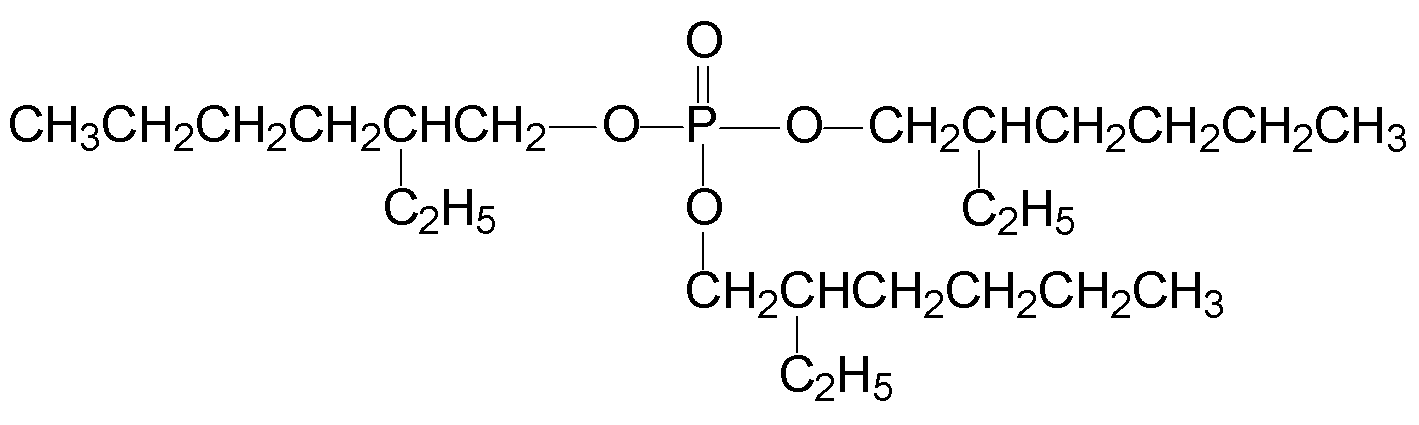

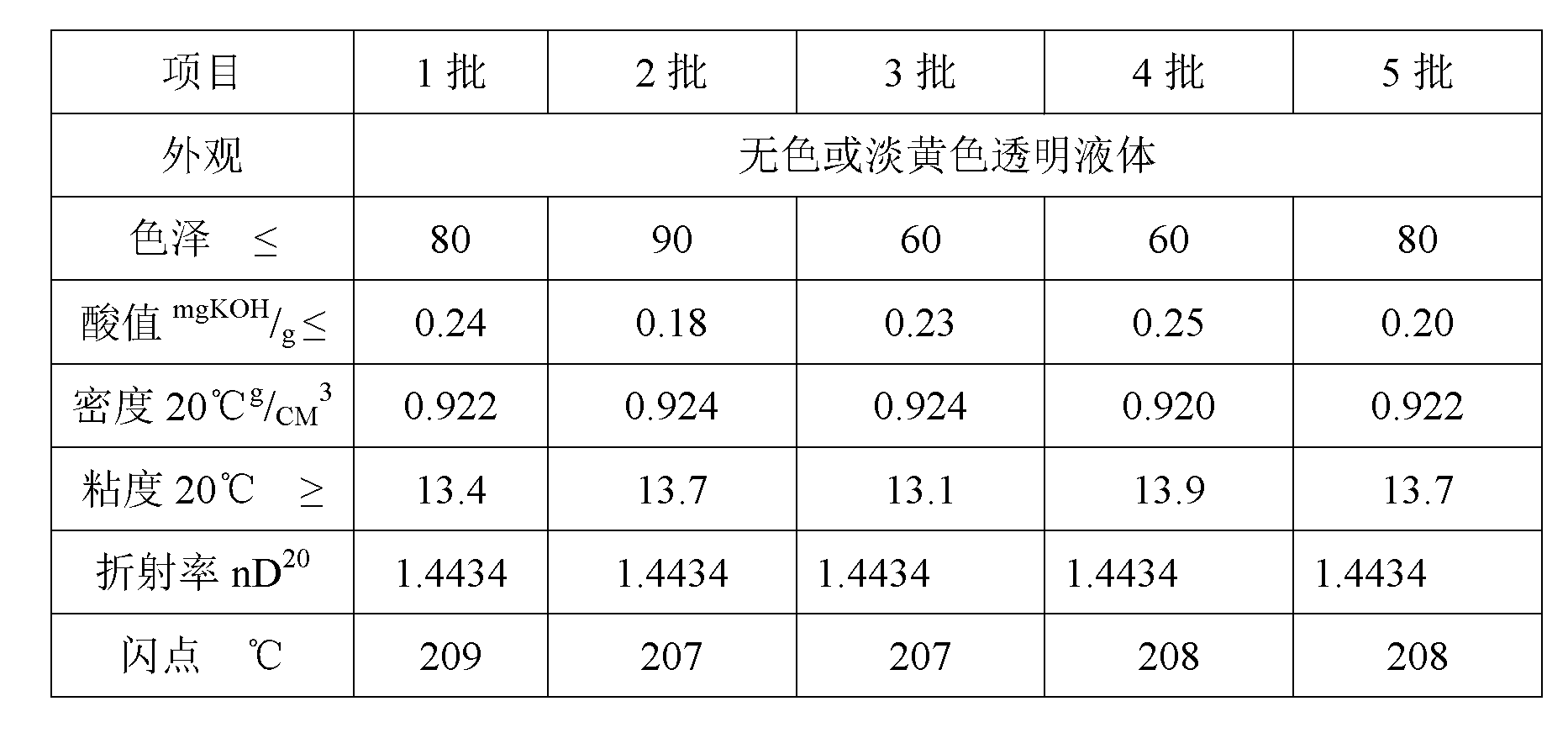

Synthesis method of trioctyl phosphate

PendingCN103224516AReaction conditions are easy to controlReaction condition controlGroup 5/15 element organic compoundsSynthesis methodsPhosphate

The present invention relates to a synthesis method of trioctyl phosphate, and the method comprises the following steps of heating isooctanol to 47-53 DEG C, and adding phosphorus oxychloride in 4 to 6 hours while stirring, and the temperature is controlled at 65 + / - 2 DEG C; balancing for 4 to 6 hours and removing acid generated from reaction to obtain a crude ester; adding the crude ester into an alkaline solution, mixing for neutralization, and balancing for 1 to 1.5 hours at the temperature of 70 + / - 3 DEG C and the pH value is controlled between 8 and 9; separating and transferring the sediments into hot water of 80 + / - 2 DEG C, rinsing for 2 to 3 times, controlling the pH value of between 6.5 and 7.5, removing impurities to obtain qualified wet crude ester; pressure-reducing, distilling and separating the wet crude ester to get thefraction, and then cooling to obtain trioctyl phosphate. According to the invention, the condition of the production process can be easily controlled, the method is simple, the operation is convenient, the raw materials can be easily got, the reaction condition is controllable, the transportation and storage are convenient and safe, and the reaction period is short. The yield of trioctyl phosphate obtained by the method is increased from 72% to 81-83%, therefore the yield is significantly raised, the consumption is reduced and the economic benefits of enterprise are improved.

Owner:天津市联瑞阻燃材料有限公司

Burley tobacco extract applied to heated-non-combustible cigarette and preparation method of burley tobacco extract

ActiveCN109393568AImprove adsorption capacityEasy to separate by filtrationTobacco devicesNicotiana tabacumIrritation

The invention provides a burley tobacco extract applied to a heated-non-combustible cigarette and an application of the burley tobacco extract. With a composite biological material of burley tobacco stems and bagasse as an immobilized carrier, biological preparations, including a microbial aroma-producing strain and enzyme, are adsorbed; burley tobacco powder is incubated, hydrolyzed and fermented; and in combination with a continuous counter-current ultrasonic solvent extracting technology, the burley tobacco extract is prepared, and the burley tobacco extract can be combined with propylene glycol; intrinsic intense fragrance of natural tobacco is reserved; characteristic smell of burley tobacco is relieved and irritation is reduced; the burley tobacco has natural composite fragrance of fresh fruity aroma, smell of caramel, smell of being roasted and the like; the preparation method of gentle in process conditions, high in extracting rate and high in production efficiency; the burleytobacco extract is applied to a novel heated-non-combustible cigarette material; the burley tobacco extract is coordinate with cigarette fragrance and uniform in style, and the burley tobacco extractcan increase smoke concentration, enhance feeling of being satisfied and enrich cigarette aroma; and irritant smell of burley tobacco is obviously reduced, and taste is improved.

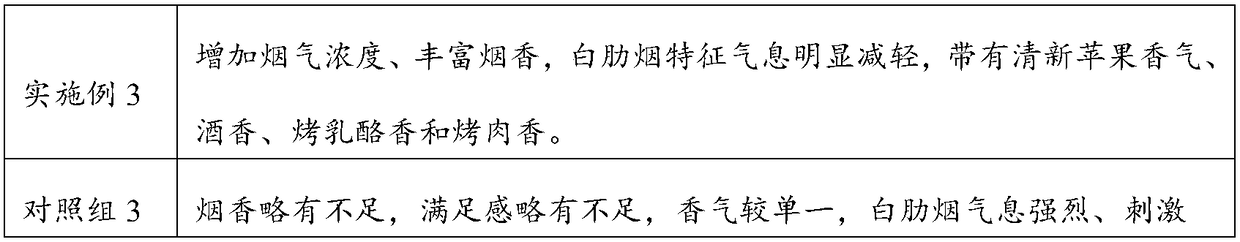

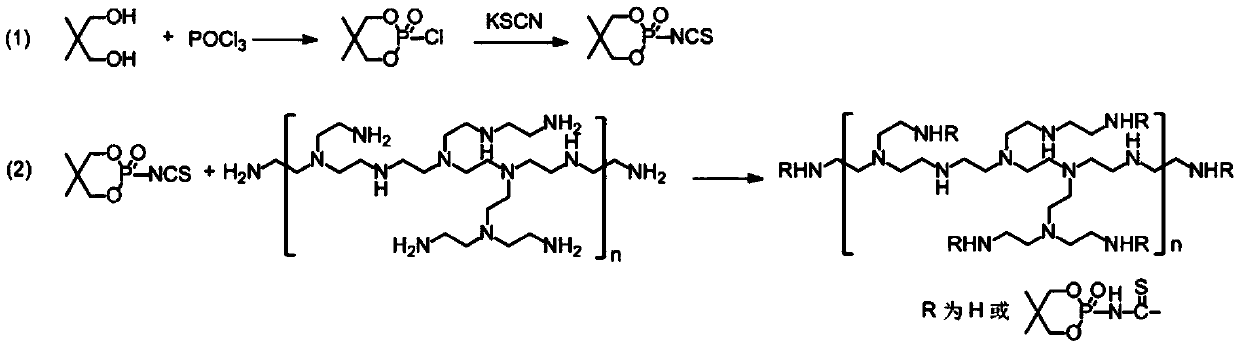

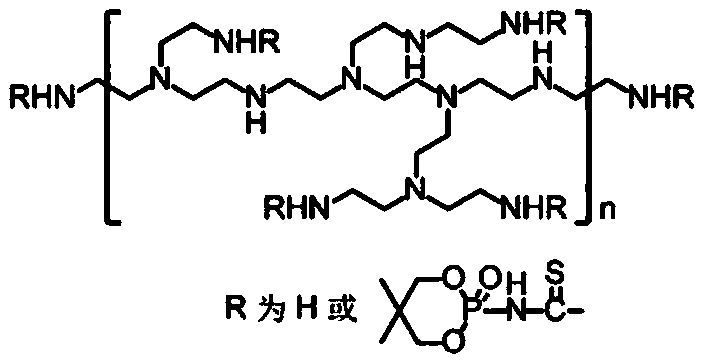

A kind of preparation method of phosphorus and nitrogen synergistic water-soluble polymer flame retardant

ActiveCN107474247BImprove flame retardant performanceDifficult to migrate and precipitatePolymer sciencePotassium thiocyanate

The invention belongs to the field of applications of functional polymer materials and particularly relates to a preparation method of a phosphorous and nitrogen synergistic type water-soluble polymer flame retardant. According to the method, a phosphorous-containing intermediate is prepared from raw materials including neopentyl glycol and phosphorous oxychloride and then activated with potassium thiocyanate, the activated phosphorous-containing intermediate reacts with macromolecular nitrogen-containing intermediate polyethyleneimine, and the tawny powdery phosphorous and nitrogen synergistic type polymer flame retardant is obtained. The flame retardant is water-soluble and can be well compatible with a polymer material, the molecular weight is adjustable as required, and the flame retardance of the material can be improved. The flame retardant can effectively solve the problem that common phosphorous and nitrogen synergistic type flame retardants are insoluble in water, can be effectively dispersed when applied to preparation of water foam polyurethane materials and the like and cannot migrate and separate out of the materials and the problem of the poor mechanical performance of the materials is solved. The production technology condition is convenient, and the product is high in purity and convenient to use.

Owner:JIANGNAN UNIV +1

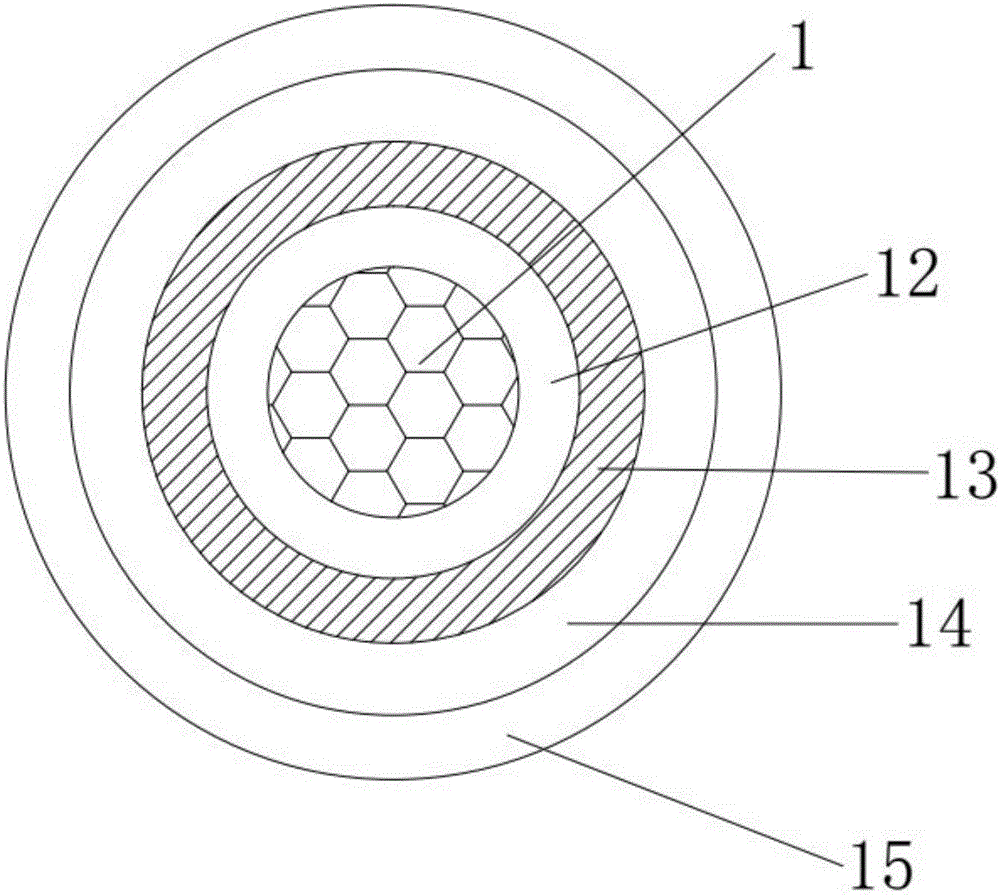

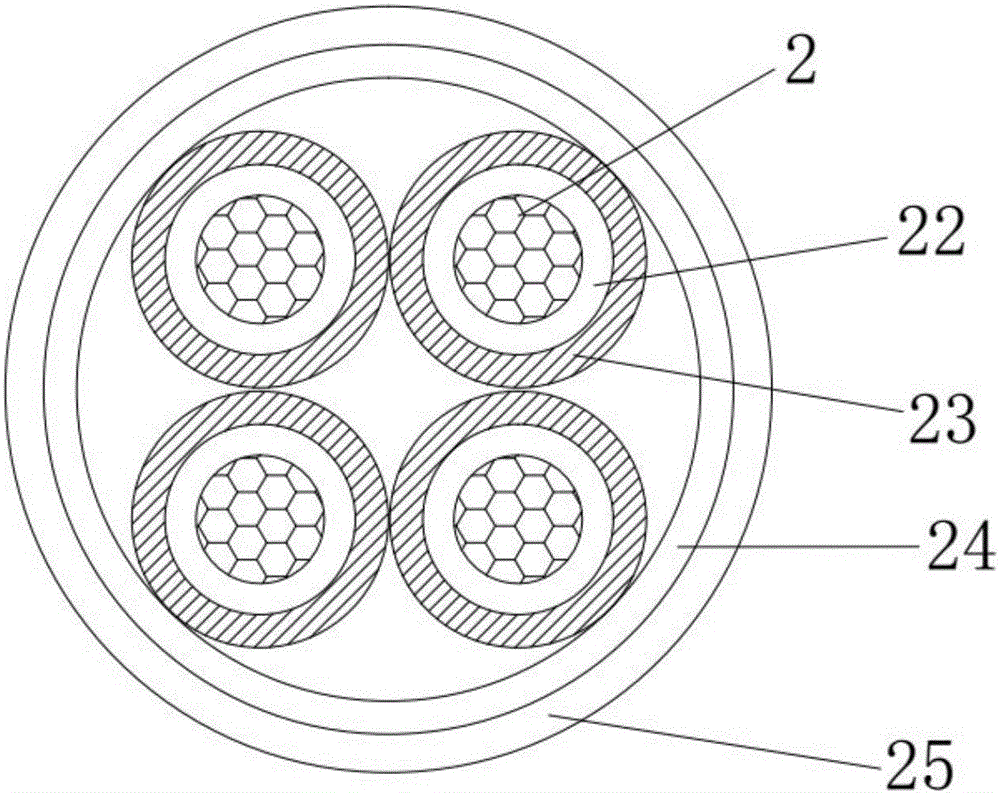

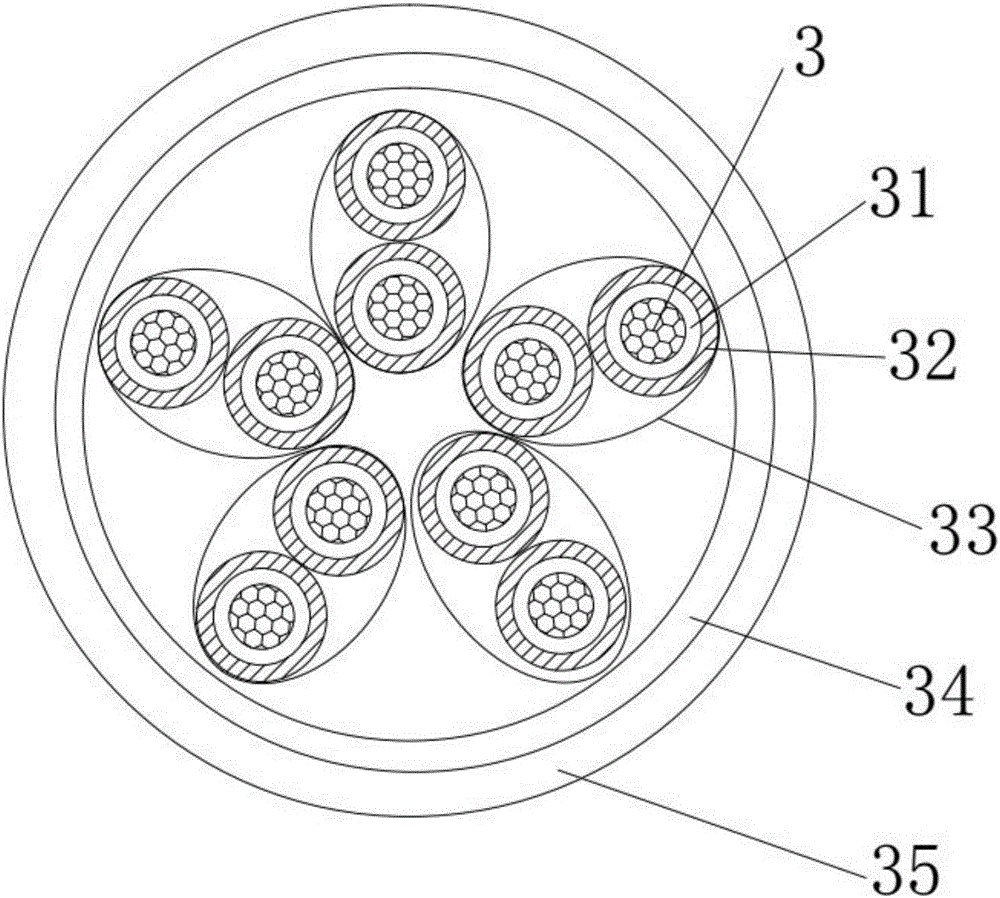

High-performance flexible fire-resistant cable

InactiveCN106448890APlay a protective effectSo as not to damageInsulated cablesInsulated conductorsLow smoke zero halogenElectrical conductor

The invention discloses a high-performance flexible fire-resistant cable, which comprises a conductor, wherein the conductor is sequentially coated with a mica tape refractory layer, a special polymer material insulating layer, an aluminum foil mica paper layer and an outer sheath layer from inside to outside. The high-performance flexible fire-resistant cable has the advantages that a low-smoke halogen-free sheath material is taken as the outer sheath layer, aluminum foil mica paper is taken as a first refractory layer, the special polymer material insulating layer with the flame retardant property is taken as a second refractory layer and a mica tape is taken as a third fireproof layer, so that the fire resistance of the cable is greatly improved due to presence of protection of the three refractory layers; the condition that the cable can tolerate 950 DEG C for 3 hours is ensured; the high-performance flexible fire-resistant cable has spraying and vibrating fire-resistant conditions; the production process condition is simple and easy to control; and the produced cable is a flexible cable and a special device or process is not needed for laying and installation.

Owner:龙川秀康威达新型材料有限公司

Preparation method for lithium cobalt oxide with high pole piece compaction density

ActiveCN103022475BEasy to processIncrease compaction densityCell electrodesCobalt compoundsZirconium hydrideLithium carbonate

The invention relates to a preparation method for lithium cobalt oxide with high pole piece compaction density. The preparation method is characterized by comprising the following steps: (1) weighing battery grade lithium carbonate, cobaltosic oxide with the particle size of 2.5-5 mu m and a doped raw material-magnesium oxide, aluminum oxide, titanium oxide or zirconium oxide; and sintering a mixed raw material for the first time; (2) carrying out ball milling and mixing on the battery grade lithium carbonate and the cobaltosic oxide with the particle size of 2.5-5 mu m; and sintering a mixed raw material for the first time; and (3) weighing powder prepared in the steps (1) and (2) respectively, carrying out ball milling and mixing, and sintering for the second time. The preparation method has the advantages of capability of remarkably enhancing the pole piece compaction density, excellent pole piece processing performance, high commonality of a slurry formula, long cyclic life and the like, and particularly has the advantages of simple required production equipment and simplicity for change of production process conditions.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

A kind of mdq type phenyl vinyl silicone resin and preparation method thereof

The present invention relates to MDQ phenyl vinyl silicone resin. The MDQ phenyl vinyl silicone resin has a structure represented by the following general formula: (Ph2SiO)a(ViMe2SiO0.5)b(Me3SiO0.5)c(SiO2)d, wherein Ph is phenyl, Me is methyl and Vi is vinyl; the value of a ranges from 0.1 to 1; the value of b+c ranges from 0 to 0.1, and b>0; the value of d ranges from 0 to 0.8, and a+b+c+d>0; the value of a / d ranges from 1.6 to 2.5; and the value of (b+c) / d ranges from 1.6 to 2.5. The present invention also provides a method for preparing the MDQ phenyl vinyl silicone resin. According to the method, the viscosity, the refractive index and the vinyl content of a product are controlled through conditions such as the monomer raw material ratio, the reaction time, the temperature and the pH value, the manufacturing conditions are mild, simple and feasible, the raw material source is wide, and the repeatability is good.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

A method for preparing high-purity calcium sulfate dihydrate whiskers by metallurgical flue gas desulfurization gypsum recrystallization method

ActiveCN104846440BPromote conversionImprove Calcium UtilizationPolycrystalline material growthFrom normal temperature solutionsResource utilizationImpurity

The invention discloses a method for preparing high-purity calcium sulfate dihydrate crystal whiskers by metallurgical flue gas desulfurization gypsum recrystallization method. The method comprises: metallurgical flue gas desulfurization gypsum pickling to remove a small amount of calcium carbonate or calcium oxide and soluble impurities; The acid solution of salt dissolves gypsum, which is used as the raw material for the preparation of high-purity calcium sulfate dihydrate whiskers; the addition of mediators controls the controllable growth of calcium sulfate whiskers, so as to form calcium sulfate whiskers with controllable aspect ratio and complete crystal morphology, Filter and dry to obtain calcium sulfate dihydrate whiskers. Under normal pressure and mild conditions, the invention utilizes the principle of recrystallization to realize resource utilization of high value-added calcium sulfate whiskers prepared from metallurgical flue gas desulfurization gypsum. The raw materials used in the invention are easy to obtain, the production process conditions are simple, the high-purity whiskers have high added value, and the produced calcium sulfate dihydrate whiskers have the characteristics of small diameter, high aspect ratio, complete and uniform appearance and stable performance, and can be used as reinforcing materials It is used as an additive in industries such as plastics, rubber, paper and ceramics, and has broad application prospects.

Owner:KUNMING METALLURGY INST

A kind of phosphorus-containing dihydric alcohol and preparation method thereof

InactiveCN103387591BImprove flame retardant performanceSimple production process conditionsGroup 5/15 element organic compoundsChemical synthesisEpoxy

The invention discloses a phosphorus-containing dihydric alcohol and a preparation method thereof. The phosphorus-containing dihydric alcohol is a synthetic dihydric alcohol. The preparation method comprises the following steps that 1, n-butyraldehyde and a formaldehyde solution undergo a reaction under a certain condition to produce 2,2-dimethylolbutyraldehyde; and 2, DOPO and 2,2-dimethylolbutyraldehyde undergo a reaction under a certain condition; and the reaction products are subjected to pumping filtration, washing, recrystallization and drying to form the phosphorus-containing dihydric alcohol product. The phosphorus-containing dihydric alcohol can be used as a reactive flame retardant used in polymers such as epoxy resins, phenolic resins, plastic and rubber to improve the flame resistance of the polymers, and can also be used as a phosphorus-containing intermediate for preparation of other high-performance materials. The preparation method has the advantages of simple processes, high product purity, high yield and simple aftertreatment.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

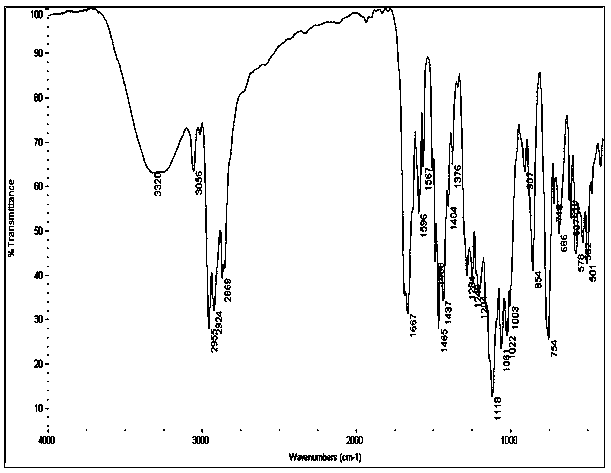

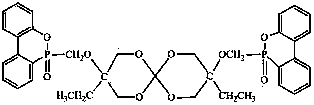

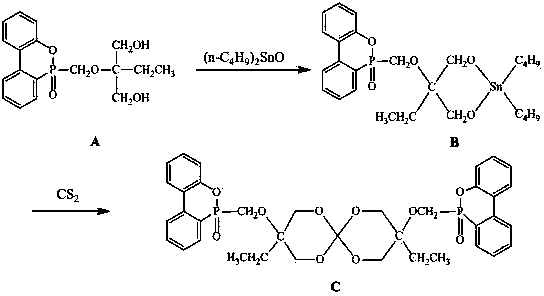

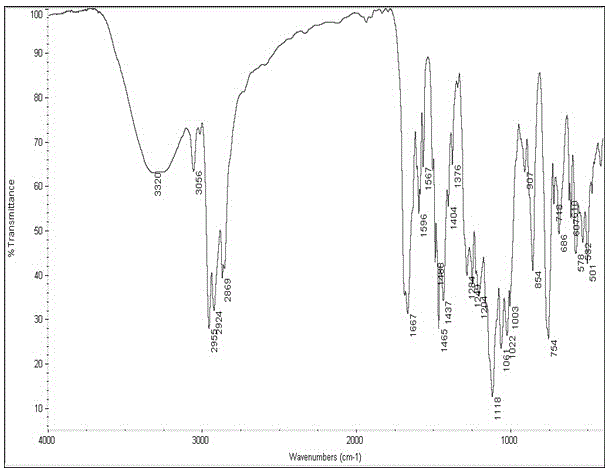

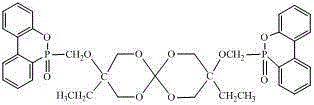

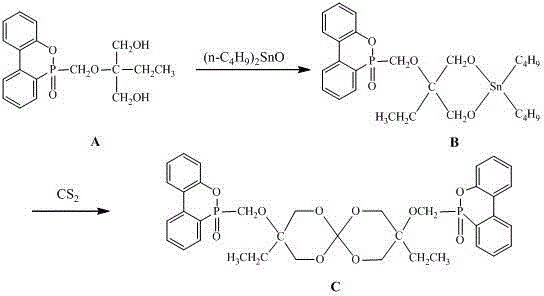

Phosphorus-containing spiro-compound and preparation method thereof

InactiveCN103408596AImprove mechanical propertiesImprove flame retardant performanceGroup 5/15 element organic compoundsEpoxyCombinatorial chemistry

Relating to a preparation method of spiro-compounds, the invention provides a phosphorus-containing spiro-compound and a preparation method thereof. The preparation method comprises the steps of: 1. reacting phosphorus-containing diol with di-n-butyltin oxide under certain conditions to generate an intermediate; 2. reacting the intermediate with carbon disulfide under certain conditions, carrying out pump filtration, washing, recrystallization and drying treatment, thus obtaining a phosphorus-containing spiro-compound product. The phosphorus-containing spiro-compound prepared in the invention can be used in epoxy resin, phenolic resin and other high polymer materials to improve the mechanical properties of polymer materials, and also can enhance the flame retardant property of the materials, thus being a multifunctional modification additive. The method adopted in the invention has the advantages of simple production process conditions, high product purity and yield, and easy aftertreatment process, etc.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

A kind of preparation method and application of compound tobacco leaf extract

ActiveCN109349678BImprove adsorption capacityEasy to separate by filtrationTobacco preparationFungiBurn cigaretteTobacco leaf extract

The present invention provides a preparation method and application of composite tobacco leaf extract, which uses air-dried tobacco stems, corncobs, and rice bran composite biological materials as immobilized carriers, absorbs microbial aroma-producing strains, incubates, hydrolyzes and ferments composite air-dried tobacco leaf raw materials, and then Combined with the continuous countercurrent ultrasonic extraction technology, the compound tobacco leaf extract is prepared, which has a strong natural tobacco aroma, with rich natural compound aromas such as fresh fruit, wine, milk, barbecue, toasted bread and grilled cheese, etc., irritating reduced, the quality of spices is improved, the purification and separation steps are simple, the process conditions are mild, the extraction rate and production efficiency are improved; it is used in traditional cigarettes and new heat-not-burn cigarettes, and it is coordinated with cigarette aroma and style, increasing smoke concentration and improving satisfaction The taste is rich, the aroma is rich, the irritation is reduced, and the taste is improved.

Owner:HUBEI CHINA TOBACCO IND

Plastic-bamboo composite tube coiled forming technology method

InactiveCN100500403CEasy to produceSimple production process conditionsWood treatment detailsVeneer manufactureFilling materialsRoom temperature

Owner:HEFEI UNIV OF TECH +1

A kind of phosphorus-containing spiro compound and preparation method thereof

InactiveCN103408596BImprove mechanical propertiesImprove flame retardant performanceGroup 5/15 element organic compoundsEpoxyCombinatorial chemistry

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

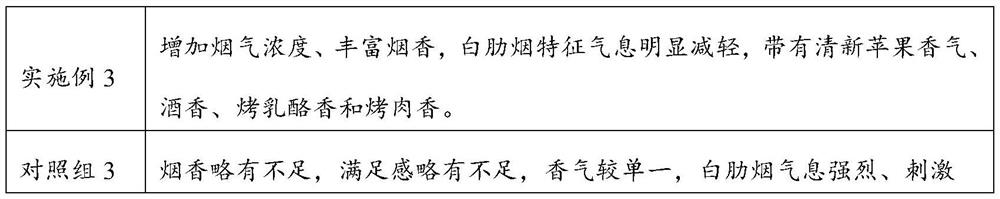

A kind of preparation method and application of Maryland tobacco leaf fermented extract

ActiveCN109536393BAdd natural complexityEasy to purifyTobacco preparationFungiBiotechnologyNicotiana tabacum

The present invention provides a preparation method and application of Maryland tobacco leaves fermented extracts. After the Maryland tobacco leaves are crushed, Maryland tobacco rods are used to immobilize and adsorb microbial strains, and the Maryland tobacco powder is incubated, hydrolyzed and fermented, combined with continuous countercurrent ultrasonic Extraction and preparation of Maryland tobacco leaf extract, the extract has strong natural tobacco aroma, reduced irritation, simple purification and separation steps, mild process conditions, improved extraction rate and production efficiency; adding ingredients to traditional cigarettes and new heat-not-burn cigarettes For incense application, it has natural tobacco aroma, full of strength, strong sense of hair penetration, with fruity and milky sweet aroma, which is in harmony with cigarette smoke and has the same style.

Owner:HUBEI CHINA TOBACCO IND

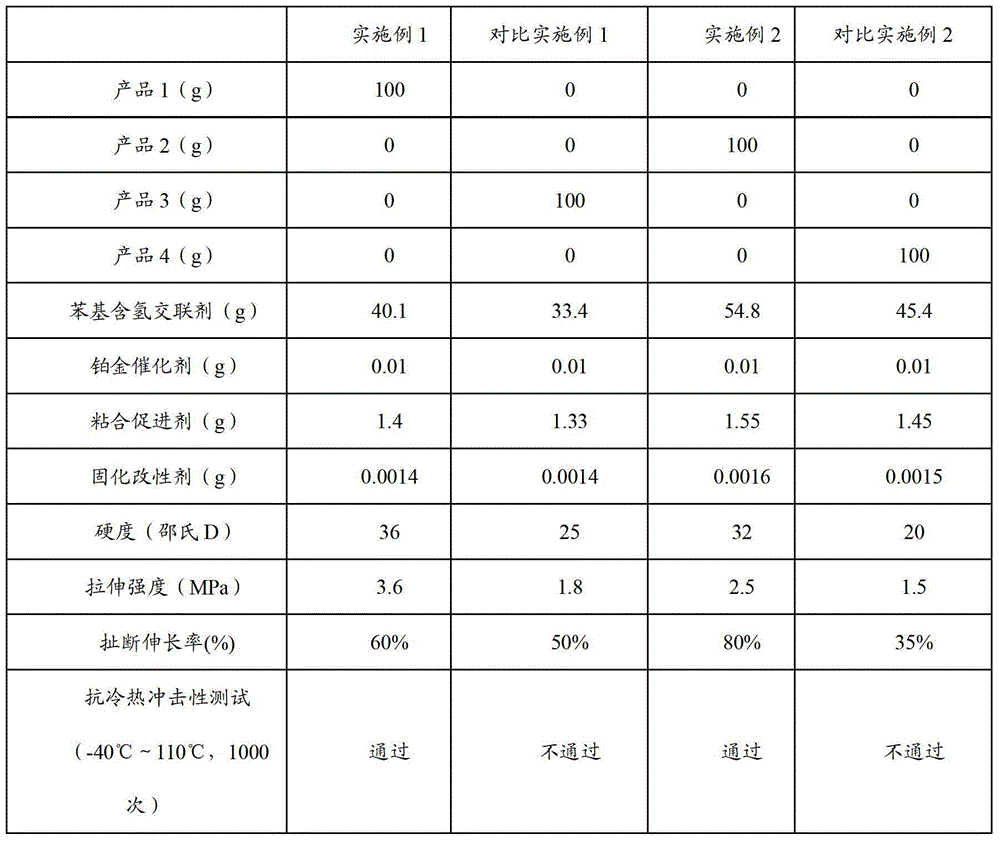

A kind of phenyl vinyl silicone resin for LED encapsulation and preparation method thereof

ActiveCN103360603BHigh refractive indexWide variety of sourcesSemiconductor devicesCross-linkLight-emitting diode

The invention relates to the technical field of polymer materials and provides phenyl vinyl silicone resin for packaging an LED (light-emitting diode). The phenyl vinyl silicone resin comprises an inner core and a flexible chain segment which is cross-linked outside the inner core, wherein the inner core is a phenyl alkoxysilane polymer, and the flexible chain segment is at least one of vinyl-terminated polydimethylsiloxane, vinyl-terminated poly(methyl phenyl siloxane) and vinyl-terminated polydimethyl diphenyl siloxane. The invention further provides a preparation method of the phenyl vinyl silicone resin for packaging the LED. The method has the advantages of mild process conditions, simplicity and easiness in operation, wide range of sources of raw materials and good repeatability, and a product obtained after curing of the prepared phenyl vinyl silicone resin has the advantages of better tensile strength, hardness and other mechanical properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Burley tobacco extract for heat-not-burn cigarettes and preparation method thereof

ActiveCN109393568BImprove adsorption capacityEasy to separate by filtrationTobacco devicesTobaccoHeat not burnPropylene glycol

The invention provides a burley tobacco extract applied to a heated-non-combustible cigarette and an application of the burley tobacco extract. With a composite biological material of burley tobacco stems and bagasse as an immobilized carrier, biological preparations, including a microbial aroma-producing strain and enzyme, are adsorbed; burley tobacco powder is incubated, hydrolyzed and fermented; and in combination with a continuous counter-current ultrasonic solvent extracting technology, the burley tobacco extract is prepared, and the burley tobacco extract can be combined with propylene glycol; intrinsic intense fragrance of natural tobacco is reserved; characteristic smell of burley tobacco is relieved and irritation is reduced; the burley tobacco has natural composite fragrance of fresh fruity aroma, smell of caramel, smell of being roasted and the like; the preparation method of gentle in process conditions, high in extracting rate and high in production efficiency; the burleytobacco extract is applied to a novel heated-non-combustible cigarette material; the burley tobacco extract is coordinate with cigarette fragrance and uniform in style, and the burley tobacco extractcan increase smoke concentration, enhance feeling of being satisfied and enrich cigarette aroma; and irritant smell of burley tobacco is obviously reduced, and taste is improved.

Owner:HUBEI CHINA TOBACCO IND

Liquor-saturated gingko fruit leisure food and production method thereof

Owner:徐州绿之野生物食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com