A kind of preparation method and application of Maryland tobacco leaf fermented extract

A technology of extract and tobacco leaf, applied in the field of preparation of Maryland tobacco leaf fermented extract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

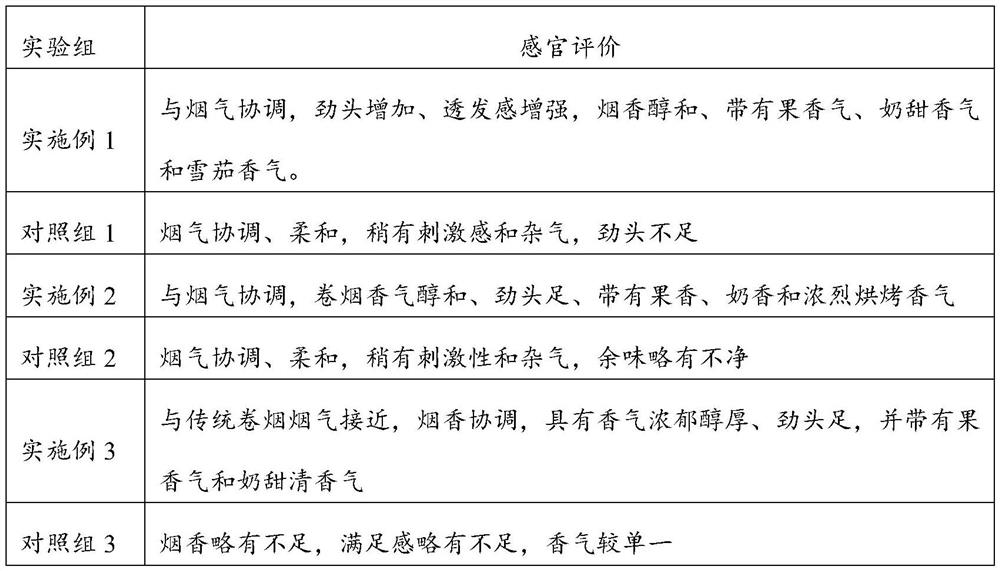

Examples

Embodiment 1

[0027] A preparation method for immobilized fermented extract of Maryland tobacco leaves, comprising the steps of:

[0028] (1) Pre-treatment of raw materials: Maryland tobacco leaves are pulverized into 40-mesh coarse powder through a pulverizer;

[0029] (2) Activation of microbial strains: add the active solid freeze-dried bacterial powder (food grade, activity 10u / mg) of Saccharomycopsis fibuligera and Enterobacter moriVL4-3 to 10 times the mass In the sterilized 5% glucose solution, place it in a 38°C water bath for activation for 30 minutes to obtain a microbial strain activation solution;

[0030] (3) Preparation of immobilized carrier: wash and dry the immobilized carrier (the tobacco rod of Maryland tobacco) and cut it into small pieces about 1 cm long with scissors, and dry it after autoclaving;

[0031] (4) Immobilization treatment of microbial strains: Weigh the sterilized and dried Maryland tobacco stem fragments in the above step 3) into a 20L barrel, add a cert...

Embodiment 2

[0037] A preparation method for immobilized fermented extract of Maryland tobacco leaves, comprising the steps of:

[0038] (1) Pre-treatment of raw materials: Maryland tobacco leaves are pulverized into 60-mesh coarse powder through a pulverizer;

[0039] (2) Activation of microbial strains: add the active solid freeze-dried bacterial powder (food grade, activity 15u / mg) of Saccharomycopsis fibuligera and Enterobacter moriVL4-3 to 15 times the mass In the sterilized 12% glucose solution, place it in a 45°C water bath for activation for 45 minutes to obtain a microbial strain activation solution;

[0040] (3) Preparation of immobilized carrier: wash and dry the immobilized carrier (the tobacco rod of Maryland tobacco) and cut it into small pieces about 1 cm long with scissors, and dry it after autoclaving;

[0041] (4) Immobilization treatment of microbial strains: Weigh the sterilized and dried Maryland tobacco rod fragments in the above step 3) into a 20L barrel, add a cert...

Embodiment 3

[0047] A preparation method for immobilized fermented extract of Maryland tobacco leaves, comprising the steps of:

[0048] (1) Pre-treatment of raw materials: Maryland tobacco leaves are pulverized to 100 mesh powder by a pulverizer;

[0049] (2) Activation of microbial strains: add the active solid freeze-dried bacterial powder (food grade, activity 20u / mg) of Saccharomycopsis fibuligera and Enterobacter moriVL4-3 to 20 times the mass In the sterilized 20% glucose solution, place it in a 50°C water bath for activation for 60 minutes to obtain a microbial strain activation solution;

[0050] (3) Preparation of immobilized carrier: wash and dry the immobilized carrier (the tobacco rod of Maryland tobacco) and cut it into small pieces about 1 cm long with scissors, and dry it after autoclaving;

[0051] (4) Immobilization treatment of microbial strains: Weigh the sterilized and dried Maryland tobacco rod fragments in the above step 3) into a 20L barrel, add a certain amount (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com