Adsorption and fermentation preparation method and application of sun-cured yellow tobacco extract

A technology of sun-cured tobacco and extract, which is applied in the field of adsorption and fermentation preparation of sun-cured tobacco extract, which can solve problems such as unfavorable taste, increased irritation, miscellaneous gas and residual feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

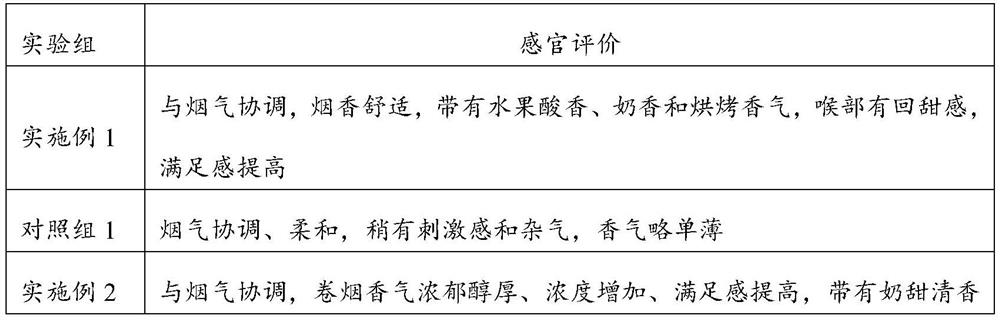

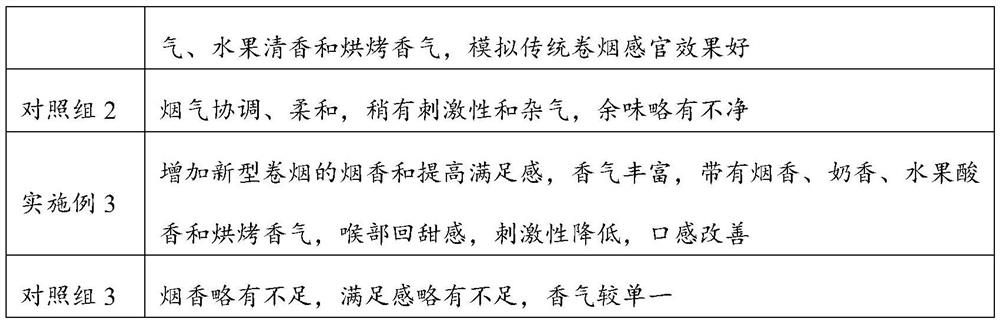

Examples

Embodiment 1

[0027] A preparation method for adsorption and fermentation of sun-cured tobacco extract, comprising the following steps:

[0028] (1) Raw material pretreatment: sun-cured yellow tobacco leaves are pulverized into 40-mesh powder by a pulverizer;

[0029] (2) Activation of microbial strains: the active solid freeze-dried bacterial powder (food grade, activity of 10u / mg) of Saccharomycopsis fibuligera and Bacillus methylotrophicus (VJ4-1) was added to The mass concentration of 5 times the mass of sterilization treatment is 5% glucose solution, placed in a 35 ° C water bath for activation for 30 minutes, to obtain a microbial strain activation solution, wherein the preservation number of Bacillus methylotrophicus (VJ4-1) is CCTCC NO: 2012004, preserved in the Chinese Type Culture Collection Center of Wuhan University on January 11, 2012;

[0030] (3) Preparation of immobilized carrier: Wash and dry the tobacco rods and beetroots of sun-cured tobacco, cut them into small pieces a...

Embodiment 2

[0039] A preparation method for adsorption and fermentation of sun-cured tobacco extract, comprising the following steps:

[0040] (1) Raw material pretreatment: sun-cured yellow tobacco leaves are pulverized into 80-mesh powder by a pulverizer;

[0041] (2) Activation of microbial strains: the active solid freeze-dried bacterial powder (food grade, activity of 25u / mg) of Saccharomycopsis fibuligera and Bacillus methylotrophicus (VJ4-1) was added to The mass concentration of 8 times the mass of sterilization treatment is 15% glucose solution, placed in a 42 ° C water bath for activation for 40 minutes, to obtain a microbial strain activation solution, wherein the preservation number of Bacillus methylotrophicus (VJ4-1) is CCTCC NO: 2012004, preserved in the Chinese Type Culture Collection Center of Wuhan University on January 11, 2012;

[0042] (3) Preparation of immobilized carrier: wash and dry the tobacco rods and beetroots of sun-cured tobacco, cut them into small pieces ...

Embodiment 3

[0051] A preparation method for adsorption and fermentation of sun-cured tobacco extract, comprising the following steps:

[0052] (1) Raw material pre-treatment: sun-cured yellow tobacco leaves are pulverized into 120-mesh powder by a pulverizer;

[0053] (2) Activation of microbial strains: the active solid freeze-dried bacterial powder (food grade, activity of 30u / mg) of Saccharomycopsis fibuligera and Bacillus methylotrophicus (VJ4-1) was added to The mass concentration of 10 times the mass of sterilization treatment is 30% glucose solution, placed in a 55 ° C water bath for activation for 60 minutes, to obtain a microbial strain activation solution, wherein the preservation number of Bacillus methylotrophicus (VJ4-1) is CCTCC NO: 2012004, preserved in the Chinese Type Culture Collection Center of Wuhan University on January 11, 2012;

[0054] (3) Preparation of immobilized carrier: Wash and dry the tobacco rods and beetroots of sun-cured tobacco, cut them into small piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com