Method for preparing special high-strength tempered glass for high-speed train

A technology for tempered glass and high-speed trains, applied in glass manufacturing equipment, glass forming, glass tempering and other directions, can solve the problems of poor electric heating performance and low strength, and achieve good impact resistance, high strength and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

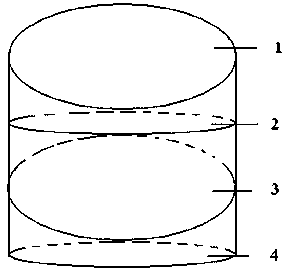

Image

Examples

Embodiment 1

[0028] (1) Cut and edge-grind ordinary flat glass, put it into the corresponding mold of the hot-bending forming furnace for hot-bending forming at 500°C;

[0029] (2) Mix 60% potassium nitrate, 5% sodium nitrate, and 35% cesium nitrate, preheat at 200°C for 1 hour, then raise it to 400°C, stir thoroughly to make the required molten salt;

[0030] (3) Put the formed glass into the molten salt tank of the exchange furnace, and perform ion exchange at 400°C for 24 hours to complete the chemical toughening;

[0031] (4) Put the chemically tempered glass into a heating furnace for heating, the heating time is 150 seconds, the furnace waiting time is 10 seconds, and the temperature in the furnace is 690°C, and then put it into a rapid cooling furnace for rapid cooling to strengthen the wind. The pressure is 650 mmAg, the cooling time is 80 seconds, and then it enters the secondary cooling furnace for cooling, and the slow cooling air pressure is 300mmAg, and finally a high-strength...

Embodiment 2

[0035] (1) Cut and edge-grind ordinary flat glass, put it into the corresponding mold of the hot bending forming furnace and perform hot bending at 600°C;

[0036] (2) Mix 50% potassium phosphate, 10% sodium phosphate, and 40% cesium sulfate, preheat at 300°C for 1 hour, then raise to 500°C, stir thoroughly to make the required molten salt;

[0037] (3) Put the formed glass into the molten salt tank of the exchange furnace, and perform ion exchange at 450°C for 12 hours to complete the chemical toughening;

[0038] (4) Put the chemically tempered glass into the heating furnace for heating, the heating time is 160 seconds, the furnace waiting time is 10 seconds, and the temperature in the furnace is 710°C, and then put it into the rapid cooling furnace for rapid cooling treatment to strengthen the wind. The pressure is 750 mmAg, the cooling time is 120 seconds, and then enters the secondary cooling furnace for slow cooling treatment, the slow cooling air pressure is 400 mmAg, a...

Embodiment 3

[0042] (1) Cut and grind the ordinary flat glass, put it into the corresponding mold of the hot bending forming furnace and perform hot bending at 700°C;

[0043] (2) Mix 60% potassium phosphate, 8% sodium phosphate, and 32% cesium sulfate, preheat at 250°C for 1 hour, then raise to 450°C, stir thoroughly to make the required molten salt;

[0044] (3) Put the formed glass into the molten salt tank of the exchange furnace, and perform ion exchange at 420°C for 20 hours to complete the chemical toughening;

[0045] (4) Put the chemically tempered glass into the heating furnace for heating, the heating time is 155 seconds, the furnace waiting time is 10 seconds, the temperature in the furnace is 700°C, and then put into the rapid cooling furnace for rapid cooling treatment, strengthen the wind The pressure is 700mmAg, the cooling time is 100 seconds, and then enters the secondary cooling furnace for cooling, the slow cooling air pressure is 350mmAg, and finally a high-strength si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com