Preparation method and application of composite tobacco leaf extract

A technology of tobacco leaf extract and tobacco leaf, which is applied in the field of preparation of compound tobacco leaf extract, to achieve the effect of increasing the natural complexity of aroma, strong adsorption performance and strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

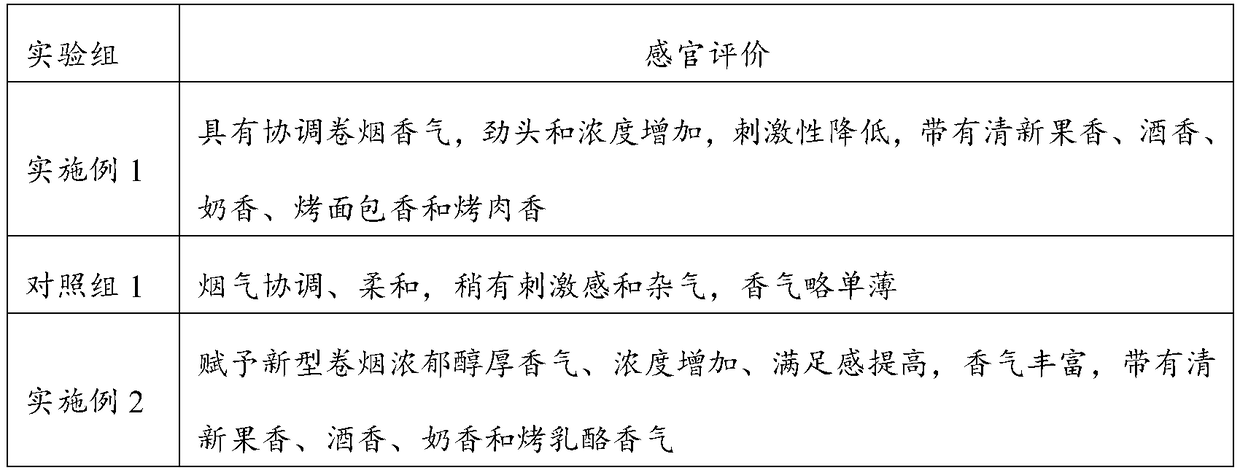

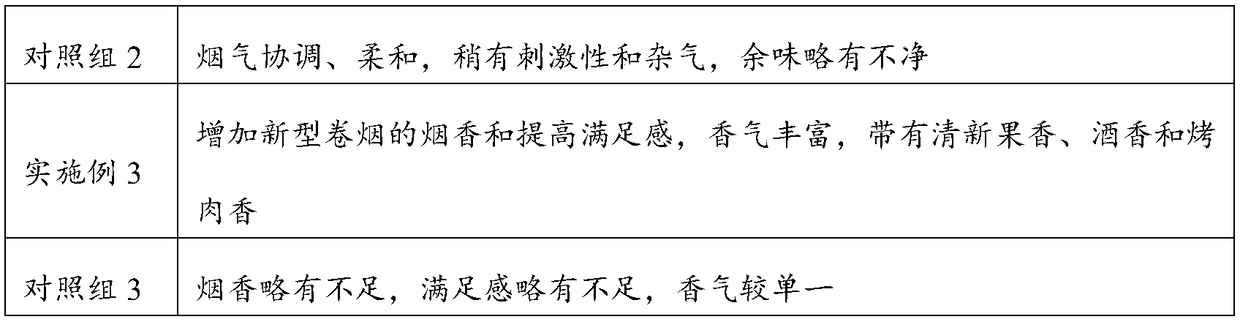

Examples

Embodiment 1

[0031] A preparation method of compound tobacco leaf extract, comprising the steps of:

[0032] (1) Raw material pretreatment: the composite tobacco leaves are pulverized into 40-mesh powder by a pulverizer, and the composite tobacco leaves are a mixture of sun-cured red tobacco, sun-cured yellow tobacco and burley tobacco, with a mass ratio of 1:1:2.

[0033] (2) Activation of microbial strains: the active solid freeze-dried bacterial powder (food grade, activity of 10u / mg) of Saccharomycopsis fibuligera and Raoultella planticola VP4-4, The mass concentration that is added to the sterilization treatment of 5 times of mass is in the solution of 5% fructose (food grade), is placed in 35 ℃ of water baths and activated 30min, obtains microbial strain activation solution, wherein said Raoultella planticola (Raoultella planticola ) The VP4-4 collection number is CCTCC M 2012005, which was deposited in the Chinese Type Culture Collection Center of Wuhan University on January 11, 201...

Embodiment 2

[0041] A preparation method of compound tobacco leaf extract, comprising the steps of:

[0042] (1) Raw material pretreatment: the composite tobacco leaves are pulverized into 80-mesh powder by a pulverizer, and the composite tobacco leaves are a mixture of sun-cured red tobacco, sun-cured yellow tobacco and burley tobacco, with a mass ratio of 1:1.2:1.2;

[0043] (2) Activation of microbial strains: the active solid freeze-dried bacterial powder (food grade, activity of 15u / mg) of Saccharomycopsis fibuligera and Raoultella planticola VP4-4, The mass concentration that joins 12 times of mass sterilization treatment is in the solution of 12% glucose (food grade), is placed in 42 ℃ of water baths and activated 45min, obtains microbial strain activation solution, wherein said Raoultella planticola (Raoultella planticola) The VP4-4 collection number is CCTCC M 2012005, and it was deposited in the Chinese Type Culture Collection Center of Wuhan University on January 11, 2012;

[0...

Embodiment 3

[0052] A preparation method of compound tobacco leaf extract, comprising the steps of:

[0053] (1) Pre-treatment of raw materials: the composite tobacco leaves are pulverized into 120-mesh powder by a pulverizer, and the composite tobacco leaves are a mixture of sun-cured red tobacco, sun-cured yellow tobacco and Burley tobacco, with a mass ratio of 1:1:0.5;

[0054] (2) Activation of microbial strains: the active solid freeze-dried bacterial powder (food grade, active 30u / mg) of Saccharomycopsis fibuligera and Raoultella planticola VP4-4 was added to The mass concentration of sterilization treatment to 20 times the mass is 30% glucose (food grade) solution, placed in a 50 ° C water bath for activation for 60 min, to obtain a microbial strain activation solution, wherein the plant Raoultella planticola (Raoultella planticola) The VP4-4 collection number is CCTCC M 2012005, and it was deposited in the Chinese Type Culture Collection Center of Wuhan University on January 11, 2012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com