Burley tobacco extract for heat-not-burn cigarettes and preparation method thereof

A heat-not-burn, burley tobacco technology, applied in application, tobacco, food science, etc., to achieve the effect of high efficiency, reduced purification cost, and increased natural complexity of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

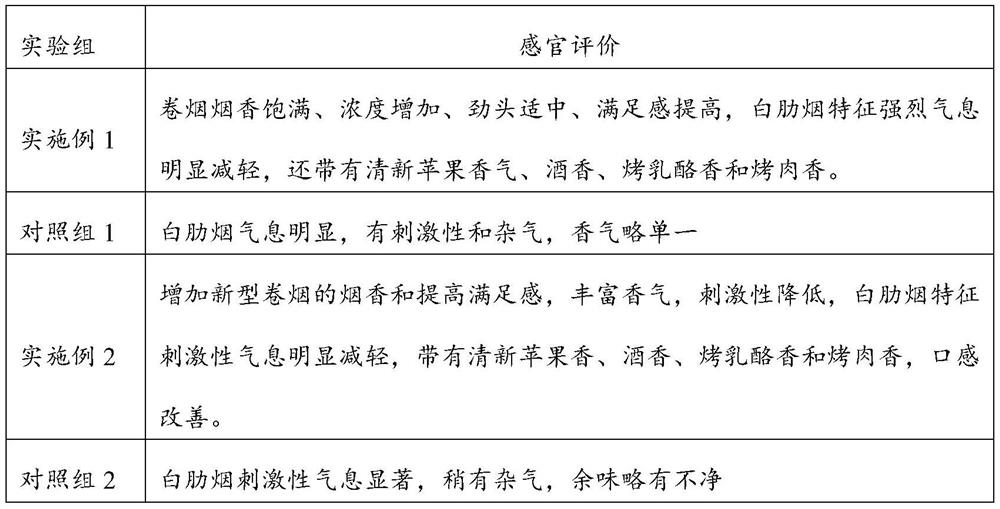

Examples

Embodiment 1

[0032] A method for preparing a Burley tobacco extract for heat-not-burn cigarettes, comprising the steps of:

[0033] (1) Pretreatment: Burley tobacco leaves are pulverized to 40 mesh powder through a pulverizer;

[0034] (2) Activation of microbial strains: the active lyophilized powder of Saccharomycopsis fibuligera is added to the mass concentration of 5 times of mass sterilization treatment and is 5% glucose solution, and succinic acid is added to adjust The pH value is 1, placed in a water bath at 10°C for 10 minutes to activate, and the strain activation solution is obtained;

[0035] (3) Preparation of immobilized carrier: Wash and dry Burley tobacco stems and bagasse, process the tobacco stems into pieces about 1 cm long, mix them with bagasse, and dry them after autoclaving to obtain a mixed biological material Immobilized carrier;

[0036] (4) Immobilization treatment of microbial strains: put a certain amount of mixed immobilized carrier after sterilization and d...

Embodiment 2

[0047] A method for preparing a Burley tobacco extract for heat-not-burn cigarettes, comprising the steps of:

[0048] (3) Pretreatment: Burley tobacco leaf is pulverized to 100 mesh powder through pulverizer;

[0049] (2) Activation of microbial strains: the active freeze-dried powder of Saccharomycopsis fibuligera is added to 12 times the mass concentration of sterilization treatment in 15% glucose solution, and succinic acid is added to adjust The pH value is 3, placed in a water bath at 18°C for 20 minutes to activate, and the strain activation solution is obtained;

[0050] (3) Preparation of immobilized carrier: Wash and dry Burley tobacco stems and bagasse, process the tobacco stems into pieces about 1 cm long, mix them with bagasse, and dry them after autoclaving to obtain a mixed biological material Immobilized carrier;

[0051] (4) Immobilization treatment of microbial strains: put a certain amount of mixed immobilized carrier after sterilization and drying in th...

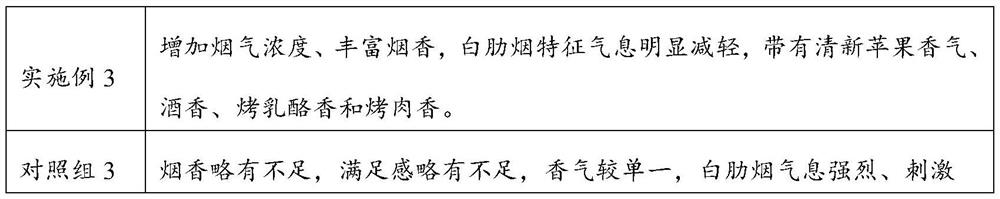

Embodiment 3

[0062] A method for preparing a Burley tobacco extract for heat-not-burn cigarettes, comprising the steps of:

[0063] (1) Pretreatment: Burley tobacco leaves are pulverized to 200 mesh powder through a pulverizer;

[0064] (2) Activation of microbial strains: the active lyophilized powder of Saccharomycopsis fibuligera is added to the sterilized mass concentration of 20 times of mass in 30% glucose solution, and succinic acid is added to adjust The pH value is 6, placed in a water bath at 25°C for 30 minutes, and the strain activation solution is obtained;

[0065] (3) Preparation of immobilized carrier: Wash and dry Burley tobacco stems and bagasse, process the tobacco stems into pieces about 1 cm long, mix them with bagasse, and dry them after autoclaving to obtain a mixed biological material immobilized carrier;

[0066] (4) Immobilization treatment of microbial strains: put a certain amount of mixed immobilized carrier after sterilization and drying in the above step (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com