MDQ phenyl vinyl silicone resin and preparation method thereof

A phenyl vinyl silicon and vinyl technology, which is applied in the field of MDQ type phenyl vinyl silicone resin and its preparation, can solve the problems of difficult phenyl monomer to continue to react, cannot be encapsulated with LED, and affects the transparency of products, etc. The effect of stable quality, mild production process conditions and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

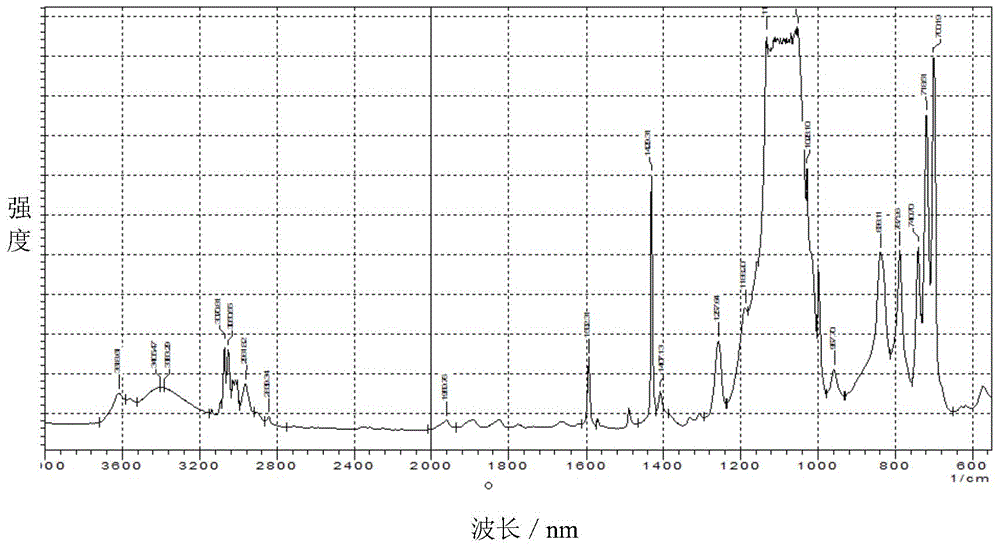

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention also provides a preparation method of the above-mentioned MDQ type phenyl vinyl silicone resin, which includes the following steps:

[0025] S01: Mix 100-1000 parts by mass of diphenyldimethoxysilane and / or diphenyldiethoxysilane, 10-300 parts by mass of tetraethyl orthosilicate, and 50-500 parts by mass of organic solvent , stirred at room temperature to obtain a mixed solution;

[0026] S02: Add dropwise 20-300 parts by mass of an acidic aqueous solution to the mixed solution, heat up to 60°C-70°C for 4-6 hours after the dropwise addition, and then add 20-200 parts of vinyl capping agent and / or methyl capping agent, the temperature is maintained at 60°C-70°C for 6-8 hours to obtain a reaction solution, wherein the mass concentration of the acidic catalyst solution is 5%-15%;

[0027] S03: the reaction solution is left to stand for stratification, after removing the acid solution in the upper layer, adding alkali to adjust the ...

Embodiment 1

[0035] In a 2L three-necked flask filled with 200 parts by mass of methanol, add 444 parts by mass of diphenyldimethoxysilane and 189 parts by mass of ethyl orthosilicate, and dropwise add 45 parts by mass of A mixed solution composed of 25% hydrochloric acid and 150 parts by mass of deionized water was stirred thoroughly, and the dropwise addition was completed within half an hour, then the temperature was raised to 60-80°C and reacted for 5 hours, and then 111.6g of divinyltetramethyldisilica was added Oxygen capping agent, keep the temperature at 60-80°C, stop the reaction after 7 hours, cool to room temperature and then separate layers, add 5g sodium hydroxide to neutralize, wash to neutral, at 150°C, vacuum degree 0.9MPa~ Distilled under the condition of 1.0MPa for 3 hours to remove low-boiling point substances to obtain 512.0g of colorless and transparent MDQ type phenylvinyl silicone resin, with a viscosity of 7800mPa·s / 25°C, a refractive index of 1.5495 / 25°C, and a viny...

Embodiment 2

[0037] In a 1L three-neck flask containing 100 parts by mass of methanol, add 148 parts by mass of diphenyldimethoxysilane and 63 parts by mass of ethyl orthosilicate, and dropwise add a mass fraction of 30 parts by mass at 30°C. It is a mixed solution of 25% hydrochloric acid and 100 parts by mass of deionized water, fully stirred, and the dropwise addition is completed within half an hour, then the temperature is raised to 60-80°C for 5 hours, and 56.5g of divinyltetramethyldisiloxane is added Alkane head-capping agent, keep the temperature at 60-80°C, stop the reaction after 7 hours, cool to room temperature and then separate layers, remove the upper acid solution, add 2.5g sodium hydroxide to neutralize, wash with water until neutral, at 150°C, Distill for 3 hours under the condition of vacuum degree 0.9MPa~1.0MPa, remove low boiling point substances, and obtain 186g of colorless and transparent MDQ type phenylvinyl silicone resin, viscosity is 20000mPa·s / 25℃, refractive in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com