Phosphorus-containing spiro-compound and preparation method thereof

A technology of spiro compounds and compounds, applied in the field of phosphorus-containing spiro compounds and their preparation, can solve problems such as performance failure, composite material cracking, and strength decline, and achieve high product purity and yield, and production process conditions Simple, easy post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

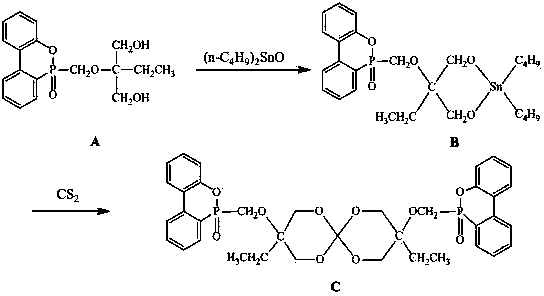

Method used

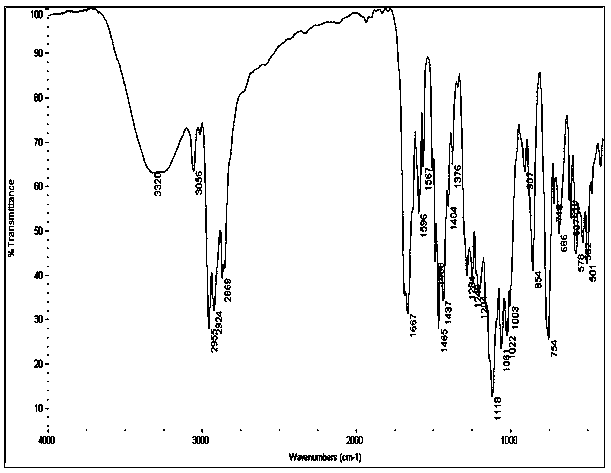

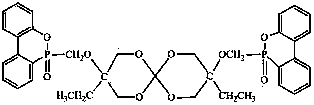

Image

Examples

Embodiment 1

[0021] Add 0.1 mol of phosphorus-containing glycol and 0.1 mol of di-n-butyltin oxide into a 500ml three-necked flask equipped with a water separator, reflux condenser, thermometer and magnet, add 200ml of toluene, and react at 130°C for 8 hours. After the reaction, cool down to room temperature, and slowly add 0.05mol of CS 2 , then reacted at 100°C for 12 hours, evaporated the solvent under reduced pressure, washed the viscous liquid at the bottom several times with n-hexane, recrystallized with toluene, filtered with suction, and dried to obtain 53.5 g of light yellow crystals with a yield of 75.7%.

Embodiment 2

[0023] Add 0.1 mol of phosphorus-containing glycol and 0.1 mol of di-n-butyltin oxide into a 500ml three-neck flask equipped with a water separator, reflux condenser, thermometer and magnet, add 200ml of benzene, and react at 100°C for 12 hours. After the reaction, cool down to room temperature, and slowly add 0.06mol of CS to the reaction flask dropwise. 2 , then reacted at 80°C for 12 hours, evaporated the solvent under reduced pressure, washed the viscous liquid at the bottom several times with n-hexane, recrystallized with benzene, filtered with suction, and dried to obtain 50.3 g of light yellow crystals, with a yield of 71.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com