High-performance flexible fire-resistant cable

A fire-resistant cable, high-performance technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of high equipment investment, increased copper consumption, and high cable costs, and achieve simple production process conditions, improved fire resistance, and excellent fire resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

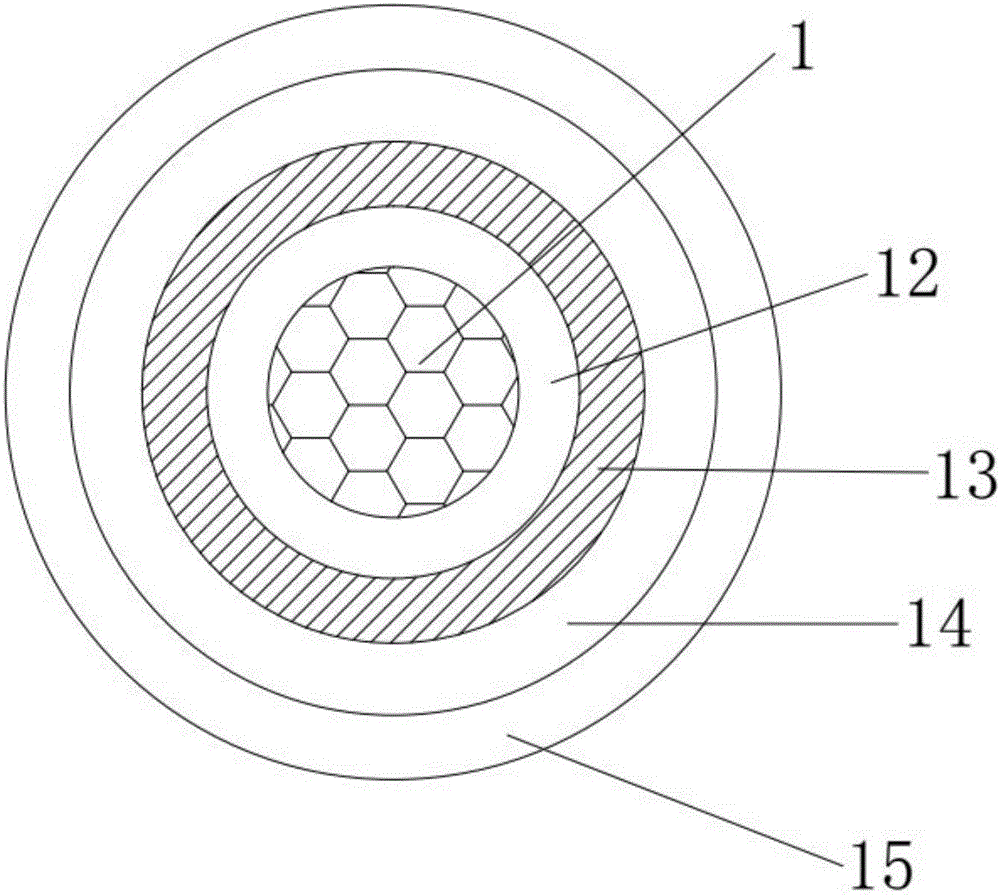

[0042] Such as figure 1 as shown,

[0043] A high-performance flexible fire-resistant cable, including a conductor 1, the conductor 1 includes a copper conductor, which is tinned or not tinned, and can be formed by a single copper wire or twisted into a single strand by no less than two copper wires ; The inner conductor 1 of the cable is a single strand;

[0044] The conductor 1 is covered with a mica tape refractory layer 12, a special polymer material insulation layer 13, an aluminum foil mica paper layer 14, and an outer sheath layer 15 sequentially from the inner layer to the outer layer.

[0045] The mica tape refractory layer 12 is any one of synthetic mica tape, muscovite tape, or phlogopite mica tape, and the synthetic mica tape is the best. The wrapping thickness of the mica tape refractory layer 12 is 0.2-0.5mm, with 2-3 layers of wrapping.

[0046] The special polymer material insulation layer 13 is a polymer material with a residue of more than 75% after burnin...

Embodiment 2

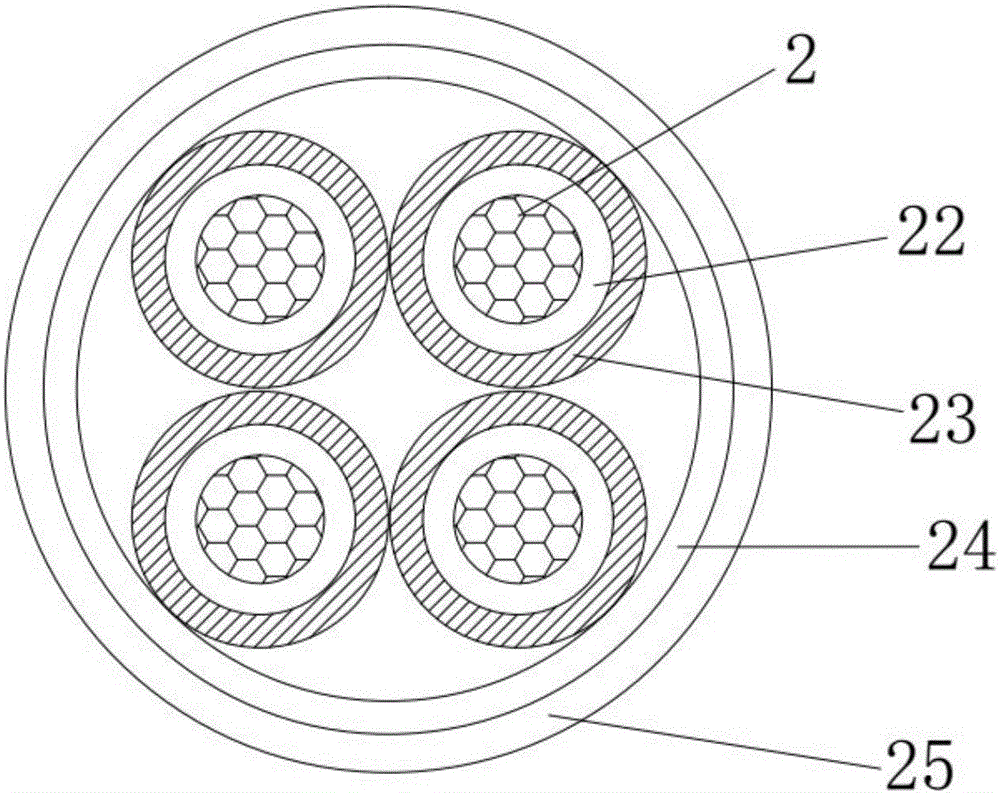

[0051] Such as figure 2 as shown,

[0052] A high-performance flexible fire-resistant cable, the cable includes a conductor 2, the conductor 2 includes a copper conductor, tinned or not tinned, the inner conductor 2 of the cable is not less than 2 strands, and this embodiment uses 4 strands.

[0053] Each strand of conductor 2 is coated with a mica tape refractory layer 22 and a special polymer material insulation layer 23 from the inside to the outside in sequence, and then is covered with an aluminum foil mica paper layer 24 and an outer sheath layer 25 in sequence. The conductor of the mica tape refractory layer 22 and the insulating layer 23 of special polymer material.

[0054] The material selection and thickness of the mica tape refractory layer 22, the special polymer material insulation layer 23, the aluminum foil mica paper layer 24, and the outer sheath layer 25 refer to the first embodiment.

Embodiment 3

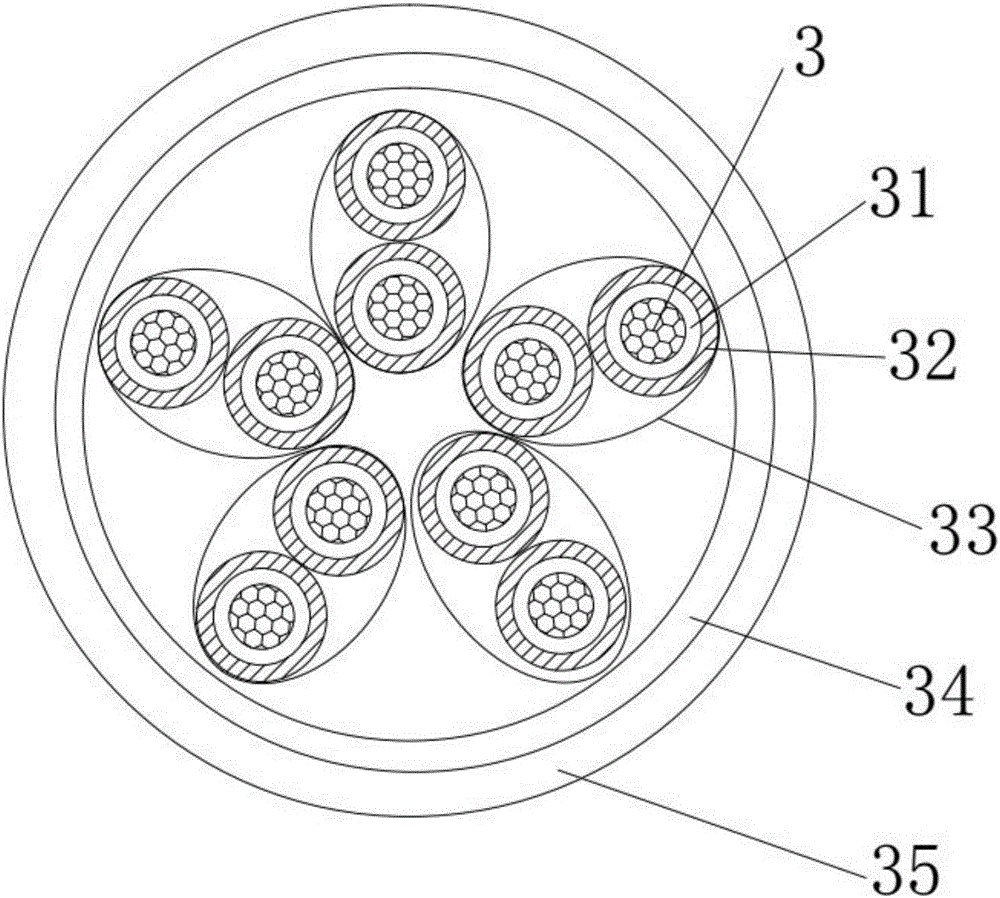

[0056] Such as image 3 As shown, a high-performance flexible fire-resistant cable, the cable includes a conductor 3, the conductor 3 includes a copper conductor, tinned or not tinned, and the inner conductor 3 of the cable is not less than 2 strands.

[0057]Each strand of conductor 3 is covered with mica tape refractory layer 31 and special polymer material insulation layer 32 in sequence from inside to outside, and then two strands of conductor 3 are set as a group and covered with isolation layer 33. There are no less than 2 strands in the cable. The conductors 3 can be divided into no less than 2 groups. In this embodiment, 5 groups are used, and then the aluminum foil mica paper layer 34 and the outer sheath layer 35 cover all the conductor groups outward in sequence;

[0058] The material of the isolation layer 33 includes aluminum foil mica paper.

[0059] The material selection and thickness of mica tape refractory layer 31 , special polymer material insulation layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com