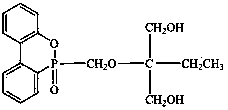

Phosphorus-containing dihydric alcohol and preparation method thereof

A dihydric alcohol and dihydrogen technology, applied in the field of phosphorus-containing dihydric alcohol and its preparation, can solve the problems of poor compatibility of matrix resin, deteriorated mechanical properties, difficult to reflect flame retardant performance, etc. The effect of simple processing, high product purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

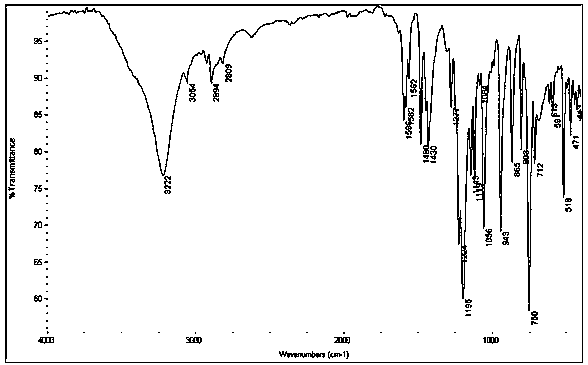

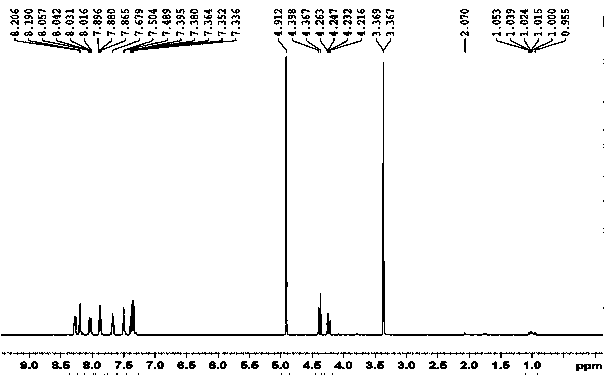

Image

Examples

Embodiment 1

[0025] Step 1: Add 72.83g of n-butyraldehyde and 202.7g of formaldehyde solution to a 500ml three-neck flask equipped with a reflux condenser, a thermometer and a magnet, using a mass fraction of 3% NaCO 3 solution and a mass fraction of 2% NaOH solution to adjust the pH of the reaction solution to 9, and react at 30°C for 2 hours. After the reaction is finished, neutralize to PH=5 with HCl solution with a mass fraction of 5%, evaporate most of the solvent under reduced pressure, put the transparent liquid into a large amount of ethyl acetate, filter out the precipitated inorganic salt solid, and spin the filtrate Dry to obtain a transparent viscous liquid, which is 2,2-dimethylolbutyraldehyde.

[0026] Step 2: Add 13.34 grams of 2,2-dimethylolbutyraldehyde, 32.75 grams of DOPO and 150 ml of absolute ethanol to a 250 ml three-neck flask equipped with a reflux condenser, a thermometer and a magnet, and react at 80° C. for 6 hours. After the reaction was completed, most of the ...

Embodiment 2

[0028] The first step: the synthetic method of intermediate 2,2-dimethylolbutyraldehyde is the same as Example 1.

[0029] Step 2: Add 13.34 grams of 2,2-dimethylolbutyraldehyde and 32.75 grams of DOPO into a 100 ml three-necked flask equipped with a reflux condenser, a thermometer and an electric stirrer, and react at 120° C. for 4 hours. After the reaction, it was recrystallized with absolute ethanol and dried under vacuum at 80°C to obtain 31.7 g of phosphorus-containing diol in the form of white powder, with a yield of 91.0%. The melting point of the product is 170.3°C-172.1°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com