Method for recovering protein in shrimp heads and shrimp shells by enzyme hydrolysis method

A protein and enzymatic hydrolysis technology, applied in the field of protein recovery, can solve problems such as low added value and adverse environmental impact, and achieve the effects of convenient operation, good taste and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

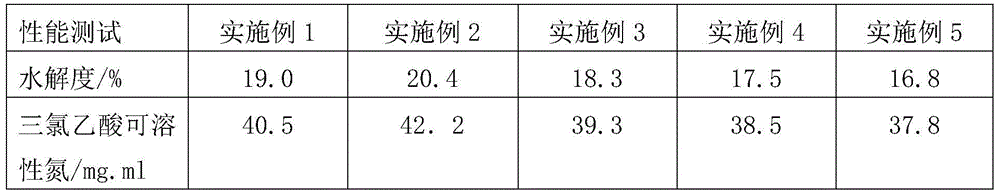

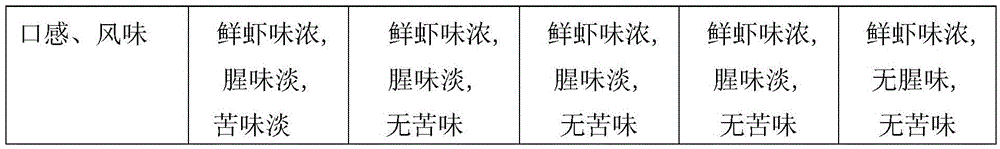

Examples

Embodiment 1

[0021] (1) After the heads and shells of the collected prawns are selected, removed, cleaned and dried, they are pulverized and mixed, and set aside;

[0022] (2) Take 5g of crushed shrimp shells and shrimp heads, put them into a triangular flask, add 40g of water, heat to 55°C in a water bath, add 3IU / g alkaline protease to hydrolyze after constant temperature, seal with plastic wrap, and hydrolyze for 2 hours Add 15IU / g flavored protease, continue the hydrolysis reaction for 3 hours, then heat up to 100°C in a water bath for 3 minutes to inactivate the enzyme, and obtain the protein hydrolyzate after cooling;

[0023] (3) The obtained hydrolyzate can be further formulated into shrimp oil or made into protein powder through spray drying.

Embodiment 2

[0025] (1) After the heads and shells of the collected prawns are selected, removed, cleaned and dried, they are pulverized and mixed, and set aside;

[0026] (2) Take 6g of crushed shrimp shells and shrimp heads, put them into a triangular flask, add 60g of water, heat to 60°C in a water bath, add 4IU / g alkaline protease to hydrolyze after constant temperature, seal with plastic wrap, and hydrolyze for 2 hours Add 25IU / g flavored protease, continue the hydrolysis reaction for 4 hours, then heat up to 100°C in a water bath for 4 minutes to inactivate the enzyme, and obtain the protein hydrolyzate after cooling;

[0027] (3) The obtained hydrolyzate can be further formulated into shrimp oil or made into protein powder through spray drying.

Embodiment 3

[0029] (1) After the heads and shells of the collected prawns are selected, removed, cleaned and dried, they are pulverized and mixed, and set aside;

[0030] (2) Take 7g of crushed shrimp shells and shrimp heads, put them into a triangular flask, add 84g of water, heat to 65°C in a water bath, add 3.5IU / g alkaline protease to hydrolyze after constant temperature, seal with plastic wrap, and hydrolyze for 2h Then add 38IU / g flavored protease, continue the hydrolysis reaction for 5 hours, then heat up to 100°C in a water bath for 5 minutes to inactivate the enzyme, and obtain the protein hydrolyzate after cooling;

[0031] (3) The obtained hydrolyzate can be further formulated into shrimp oil or made into protein powder through spray drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com