Composite macromolecular waterproof board and preparation method thereof

A technology of composite polymer and waterproof board, applied in the field of material chemistry, can solve the problems of inability to balance mechanical strength and construction performance, and achieve the effect of adapting to a wide temperature range, high tensile strength, and improving tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

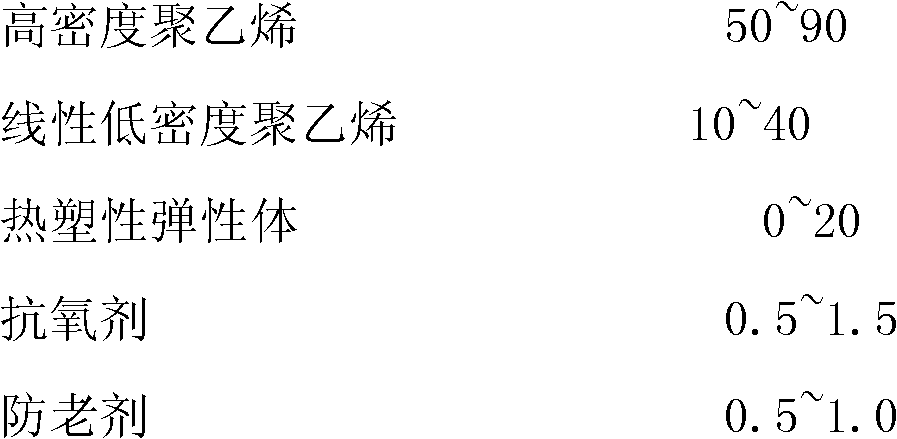

[0030] In the following examples, each raw material is a common type purchased from the market, and there is no special limitation. Embodiment 1: Transparent composite polymer waterproof board, made of the following raw materials in parts by weight:

[0031]

[0032] The manufacturing process includes the following steps:

[0033] (1) Ingredients: take the raw material components respectively according to the formula;

[0034] (2) Mixing: put the raw materials into the high-speed mixer, the temperature is 80°C, and the mixing time is 10-15 minutes;

[0035] (3) Blending extrusion: blending extrusion adopts a single-screw extruder, and the temperatures of the feeding section, melting section, and metering section of the single-screw are 120°C, 180°C, and 220°C, respectively;

[0036] (4) Molding: After the material is extruded, it is filtered through a mesh filter, the melt metering pump is boosted and pumped, passed through a T-shaped die to form a sheet, and then calende...

Embodiment 2

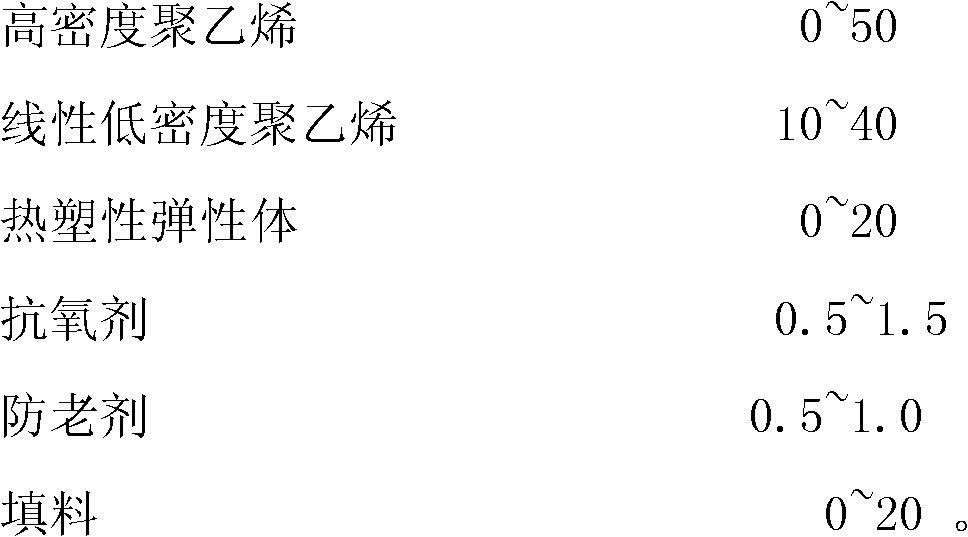

[0040] Embodiment 2: Non-transparent composite polymer waterproof board, made of the following raw materials in parts by weight:

[0041]

[0042] The manufacturing process includes the following steps:

[0043] (1) Ingredients: take the raw material components respectively according to the formula;

[0044] (2) Mixing: put the raw materials into the high-speed mixer, the temperature is 80°C, and the mixing time is 10-15 minutes;

[0045] (3) Blending extrusion: blending extrusion adopts a single-screw extruder, and the temperatures of the feeding section, melting section, and metering section of the single-screw are 120°C, 180°C, and 220°C, respectively;

[0046] (4) Molding: After the material is extruded, it is filtered through a mesh filter, the melt metering pump is boosted and pumped, passed through a T-shaped die to form a sheet, and then calendered by a three-roller calender;

[0047] (5) Cooling: air cooling is used;

[0048] (6) Rewinding.

[0049] The thermop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com