Buckle strip and manufacturing method thereof

A manufacturing method and strip technology, which is applied in the field of binding tape, diaper closure system, and diapers, can solve the problems that buckle strips are prone to tearing and breaking, achieve simple equipment layout, improve production operability, and improve tear resistance cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

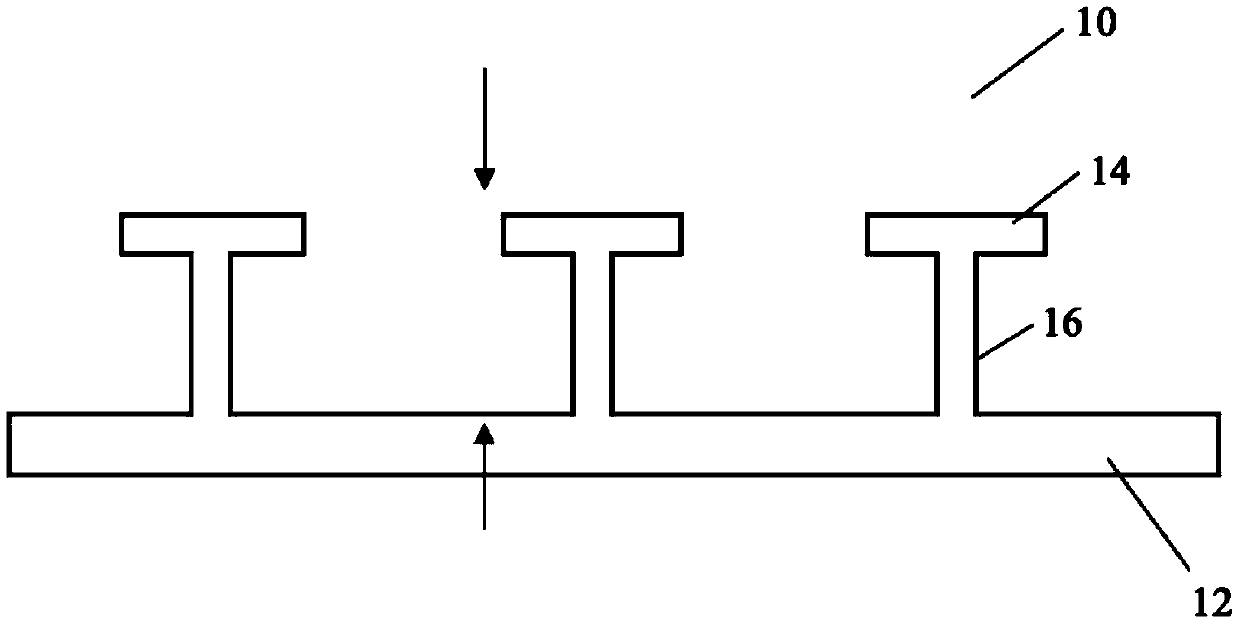

[0044] The first embodiment of the present invention proposes improvements based on the above-mentioned existing products. See Figure 4 , schematically illustrates a fastener strip 20 of the present invention, which is characterized by having a substantially continuous backing 17 of thermoplastic material, and an array of mushroom heads 14 integral with the backing, each mushroom head 14 There is a stem 16 (multiple protrusion configuration). The thermoplastic material backing 17 and the mushroom head 14 integral with the backing together constitute the first membrane. Furthermore, a reinforcement film 18 (second film material) is laminated on the back surface of the thermoplastic resin backing 17 .

[0045] In addition, please see attached Figure 4 , shows that the thickness of the thermoplastic resin backing 17 is relatively thin. The backing 17 has a thickness T2 and the reinforcement film 18 has a thickness T3. The sum of the thickness T2 and the thickness T3 prefer...

no. 2 approach

[0057] The buckle strip 20 provided by the second embodiment has the same configuration as that of the first embodiment, and therefore the same reference numerals are used. The difference is that the second embodiment provides a preferred combination of materials and an improvement on the reinforcement film 18 (second film material).

[0058] In the conventional technology, the buckle strip 10 made of polypropylene alone, and the array of mushroom heads 14 can provide better strength and realize a proper buckle interlocking closure system. However, thermoplastic backings 17 are generally not flexible enough. Attempts have been made to improve the composition of the material itself. For example, blending polypropylene with polyethylene is expected to provide suitable softness, however, this solution will reduce the rigidity of the product as a whole, thereby degrading the locking function of the buckle strip 10 . Likewise, simply reducing the thickness of the base layer of th...

no. 3 approach

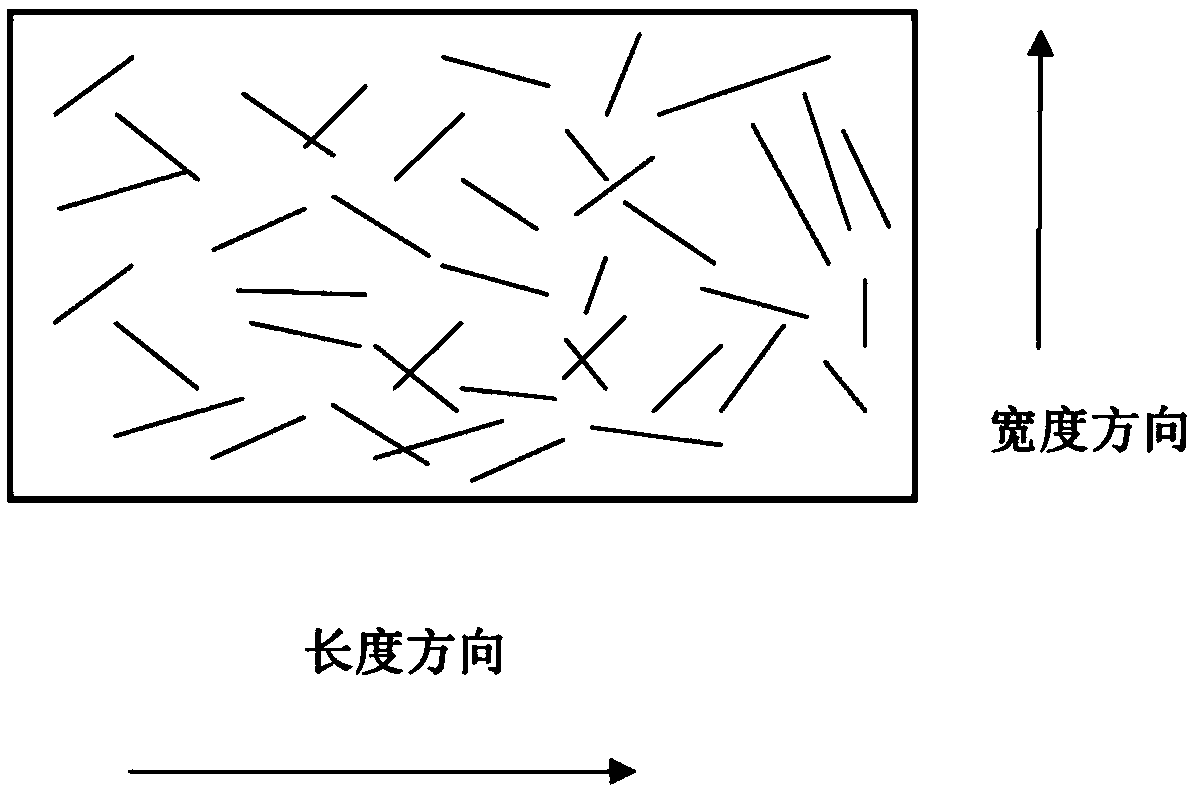

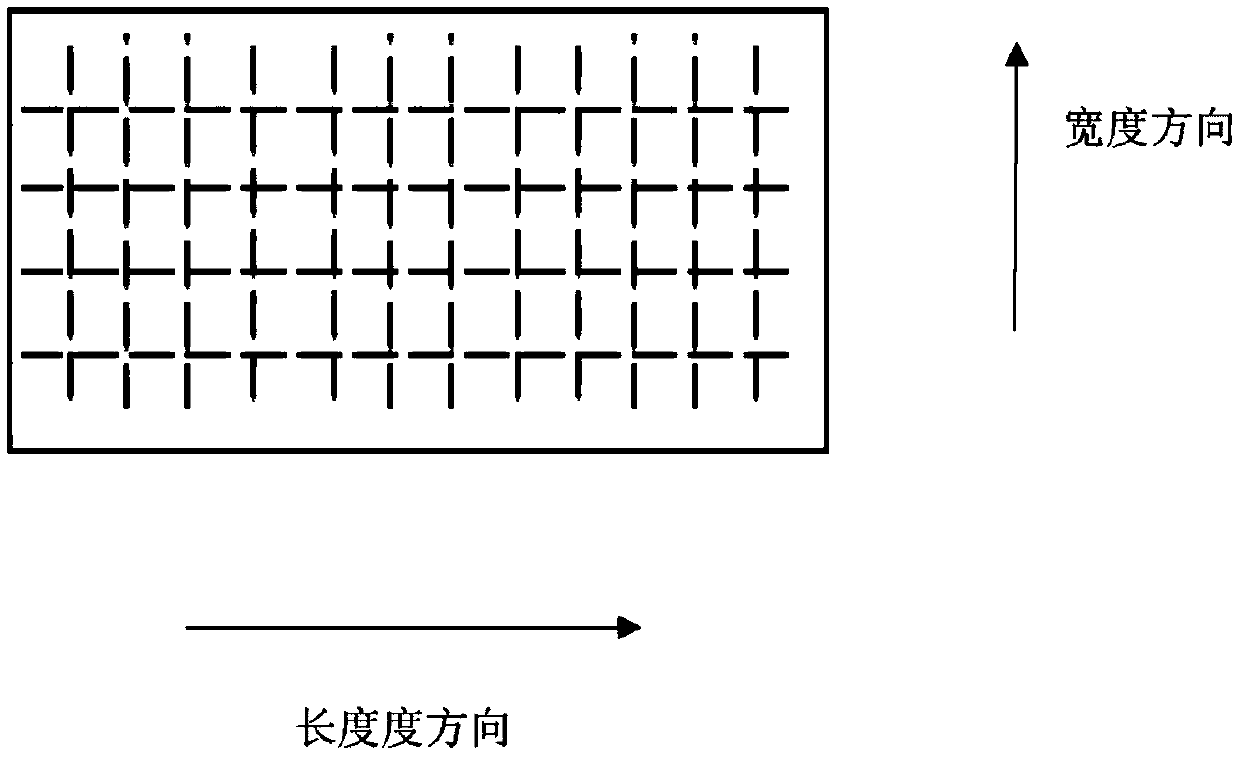

[0064] On the basis of the second embodiment, a further preferred solution is provided. The third embodiment employs a specially designed reinforcement film 18 which is a biaxially oriented polypropylene film (BOPP). see image 3 , which schematically shows that the polypropylene film has been stretched in the length direction and width direction, so that the polymer molecular chain has directionality. Biaxially oriented polypropylene film is softer and mechanically stronger than conventional base films for fastener tapes.

[0065] The third embodiment provides further advantages, the body of the first film material can be made thinner, the second film material has good flexibility and mechanical properties, and the sum of the thicknesses of the first film material and the second film material is substantially The thickness of the backing 12 of the prior art buckle strip 10 is not exceeded, but the softness and tear resistance can be significantly improved while maintaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com