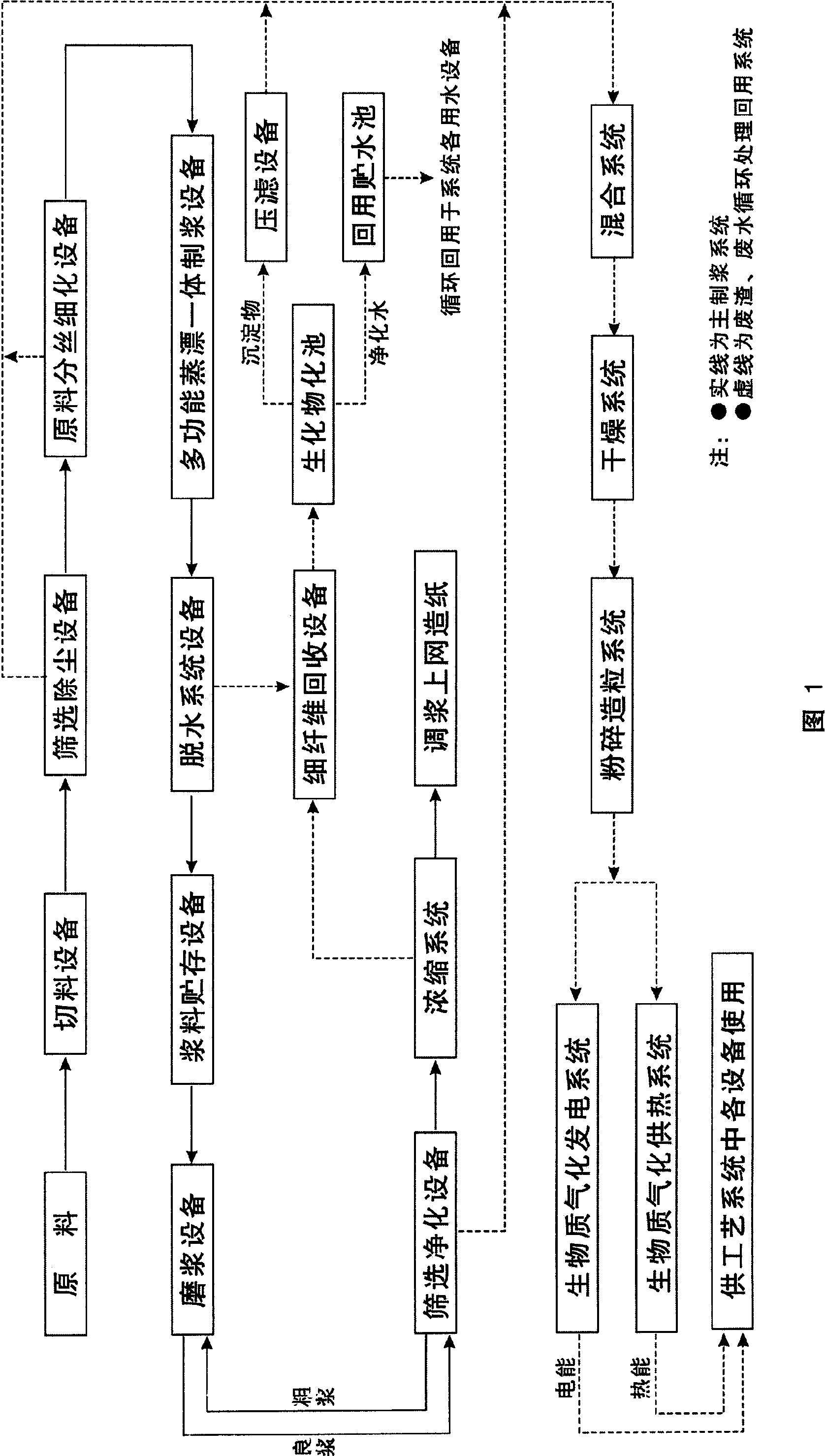

Environment friendly energy-saving circulation type non-pollution pulping process and its system apparatus

An environment-friendly, energy-saving and recycling technology, which can be used in the fields of pulping with inorganic alkali, pulping with cellulose raw materials, pulp bleaching, etc. The effect of sustainable development, protecting the ecological environment and solving high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material: wheat straw or straw

[0034] The raw materials are cut by the knife-roller grass cutter, screened and dedusted by the horn deduster, and then enter the spiral roller-type wire splitter for fine processing of raw materials, and then enter the multi-functional steaming and bleaching integrated pulping equipment. Add the presoaking agent into the multi-functional steaming and bleaching integrated pulping equipment, the presoaking time is 30min, the temperature is 50°C, after the presoaking is completed, the cooking agent and oxygen are introduced to keep the oxygen pressure at 0.1Mpa, the reaction time is 45min, and the reaction time is 45min. The temperature is 60°C, and the bleaching agent is continued to be introduced after the cooking is completed, the bleaching reaction time is 45min, the temperature is 60°C, and the bleaching end point is discharged. Among them, the presoaking agent contains 0.2% EDTA, 0.5% alkali; the cooking agent contains 2% alkali,...

Embodiment 2

[0038] Raw material: reed

[0039]Raw materials are cut by knife-roller reed cutter or disc reed cutter, screened and dedusted by double-cone dust collector, and then enter disc-type wire splitter for fine processing of raw materials, and then enter multi-functional steaming and bleaching integrated pulping equipment middle. Add the presoaking agent into the multi-functional steaming and bleaching integrated pulping equipment, the presoaking time is 60min, the temperature is 100°C, after the presoaking is completed, the cooking agent and oxygen are introduced to keep the oxygen pressure at 0.3Mpa, the reaction time is 90min, and the reaction time is 90min. The temperature is 100°C, and the bleaching agent is continued to be introduced after the cooking is completed, the bleaching reaction time is 120min, the temperature is 100°C, and the bleaching end point is discharged. Among them, the presoaking agent contains 1.0% of EDTA and 3.5% of alkali; the cooking agent contains 6% ...

Embodiment 3

[0043] Raw material: cotton stalk

[0044] The raw materials are cut by the knife-roller grass cutter, screened and dedusted by the roller-type dust collector, and then enter the flying blade-type wire splitter for fine processing of raw material filaments, and then enter the multi-functional steaming and bleaching integrated pulping equipment. Add the presoaking agent into the multi-functional steaming and bleaching integrated pulping equipment, the presoaking time is 45min, the temperature is 80°C, after the presoaking is completed, the cooking agent and oxygen are introduced to keep the oxygen pressure at 0.2Mpa, the reaction time is 70min, and the reaction time is 70min. The temperature is 80°C, and the bleaching agent is continued to be introduced after the cooking is completed, the bleaching reaction time is 80min, the temperature is 80°C, and the bleaching end point is discharged. Among them, the presoaking agent contains 0.6% of EDTA and 2% of alkali; the cooking agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com