Pulp composition

a technology of composition and pulp, applied in the field of new pulp composition, can solve the problems of low pulp strength, insufficient reduction of kappa in existing pulping processes, and insufficient strength of arf pulp currently available on the market, and achieve the effect of sufficient strength parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

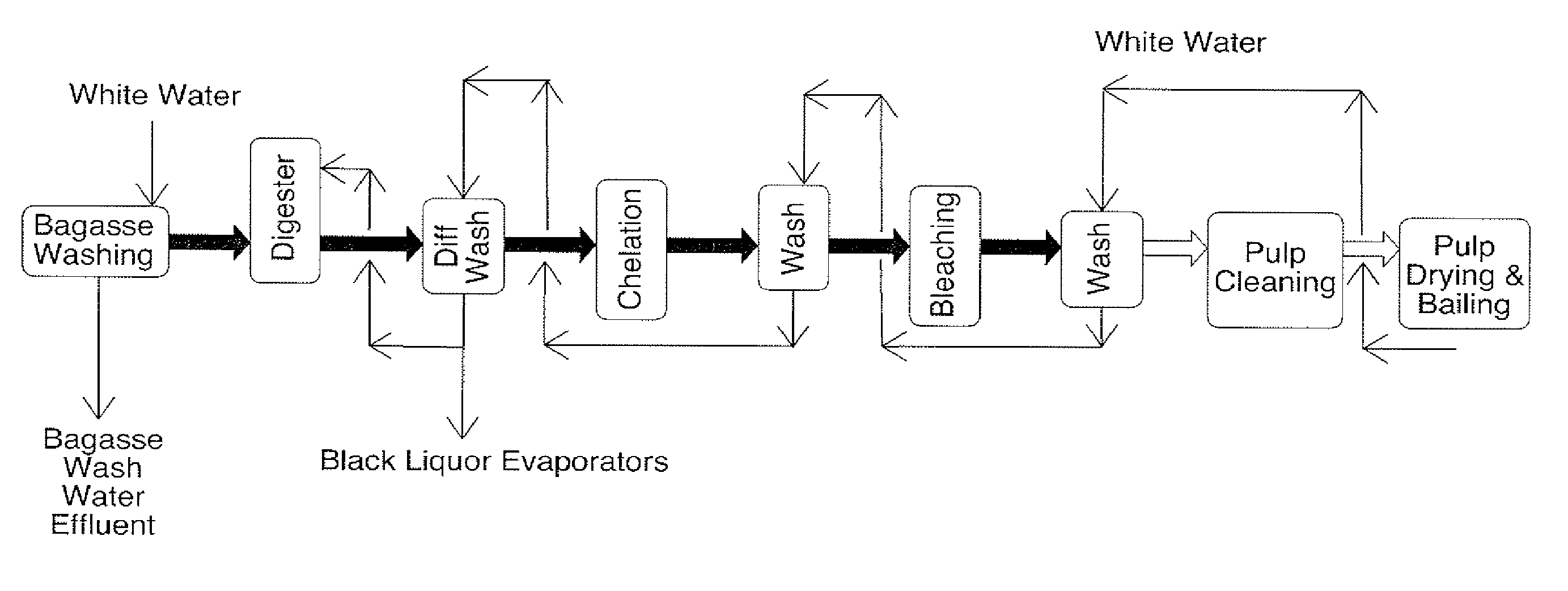

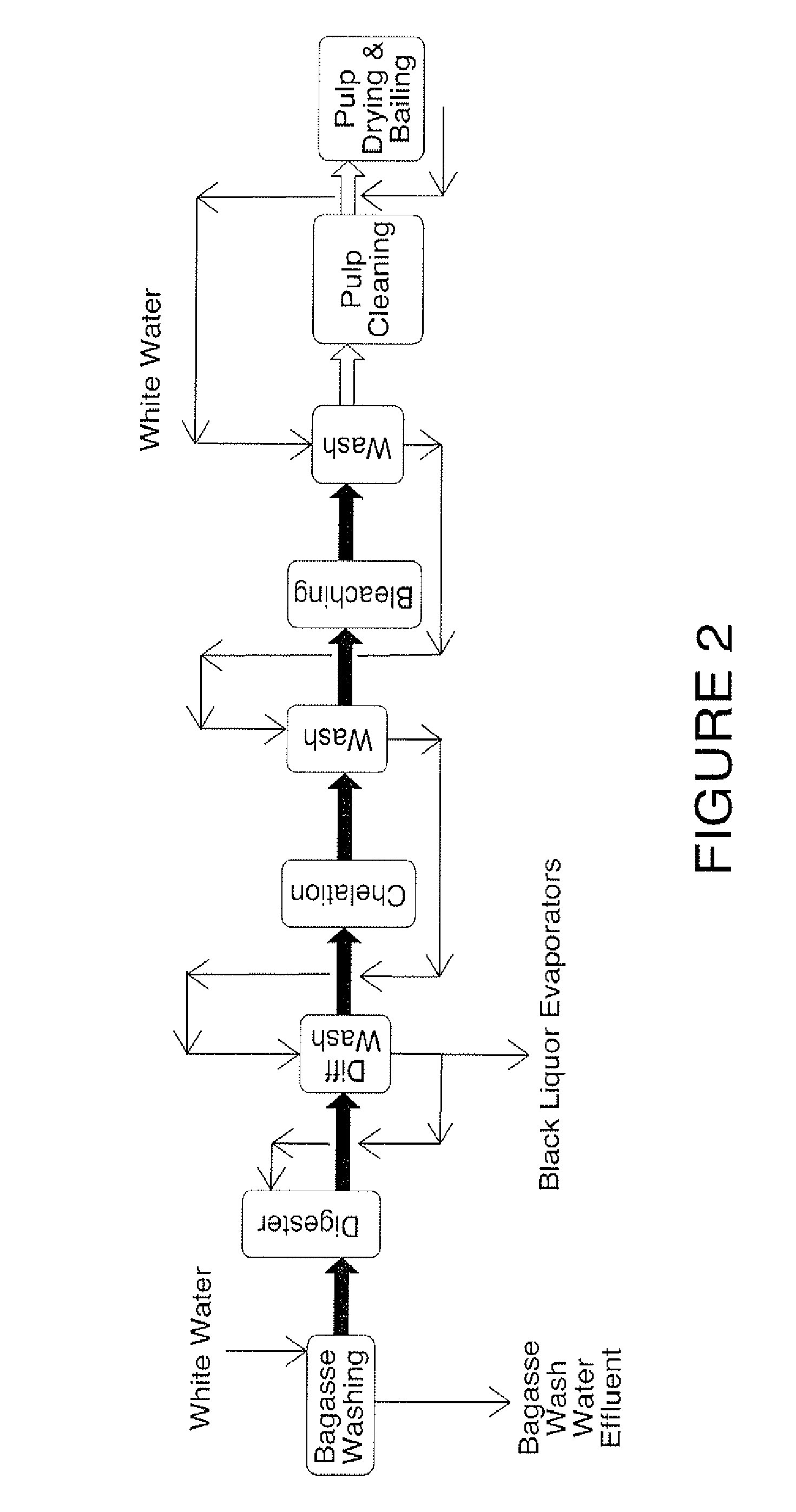

Cleaning of Raw Fibers

[0071]Bagasse was used as an example of raw fibers. Bagasse was first hydrated for 10 minutes with hot clean water (temperature of water was above room temperature, about 40° C., or 60° C.), under moderate agitation, at a consistency of 0.5% to 2.0%. Pith and sand were separated from the fibers in a Trammel Screen, which was a rotating drum that lifted and dropped the material and accepted water and pith through ⅛th inch holes up to ½″ holes. The rejected material was collected and removed from the screen to prevent accumulation, and disposed. The washing yield was about 80% or higher, or about 85.9%, depending on quality of the bagasse starting material.

example 2

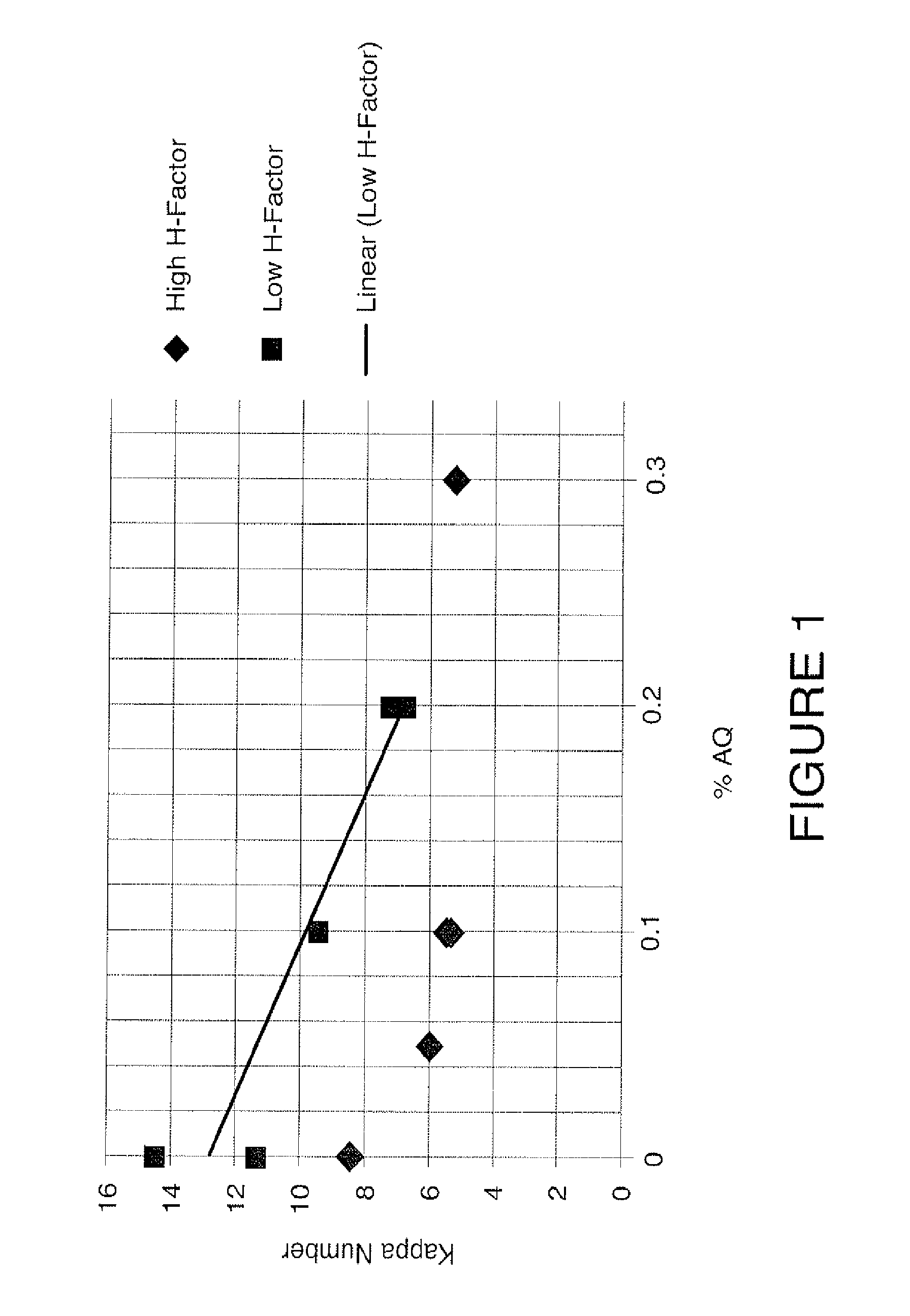

Soda AQ Pulping of Bagasse

[0072]OD bagasse (cleaned as described in Example 1, Kappa number was 89) was treated with sodium hydroxide (20% by weight of the OD bagasse) and AQ (0.3% by weight to the dry weight of OD bagasse) at a liquid to dry fiber ratio of 7 (consistency of about 12.5%), at maximum temperature of about 175° C. for 35 or 40 minutes. Time to the maximum temperature was 60 minutes.

[0073]The target H-factor was 1060, as low as 20, and as high as 3000, and the temperature of the pulping reaction was 120° C. to 185° C. The Kappa number of the obtained pulp was 4.5.

example 3

Washing of Pulp

[0074]A pulp obtained from Example 2 was washed in a pressure diffuser washer designed specifically to accomplish all washing with a single unit without introducing undesired modifications to the pulp. The temperature of the wash water was chosen to cool the pulp temperature to about 100° C., 95° C., 90° C., 85° C., 80° C. or lower. The output went to a bleaching step and was cooled to 100° C. or less to prevent flashing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kappa number | aaaaa | aaaaa |

| Kappa number | aaaaa | aaaaa |

| initial Kappa number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com