Flame-retardant air filter paper, preparation method therefor and application thereof

A technology of air filter paper and filter paper, which is applied in the direction of combustion air/combustion-air treatment, paper, papermaking, etc. It can solve the problems that cannot meet the market demand, the mechanical properties of filter paper decrease, and the flame retardant effect cannot last, etc., so as to improve the quality of paper , Long service life, increase the effect of whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

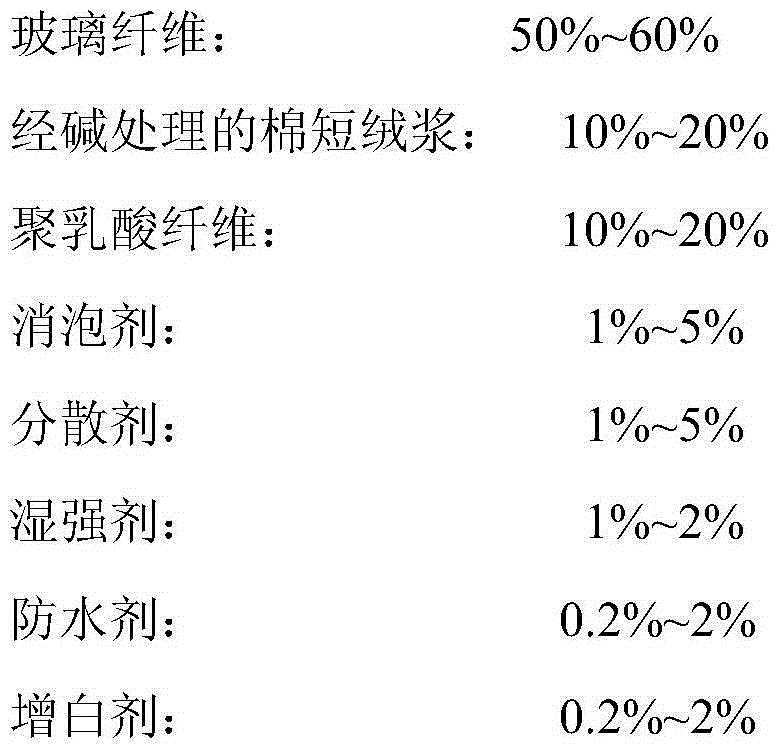

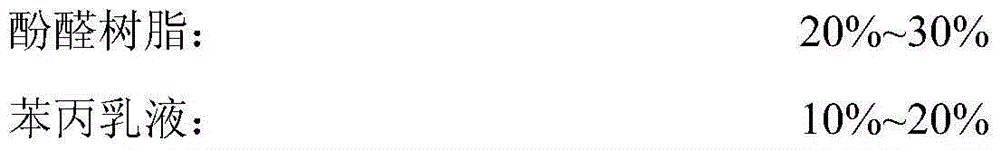

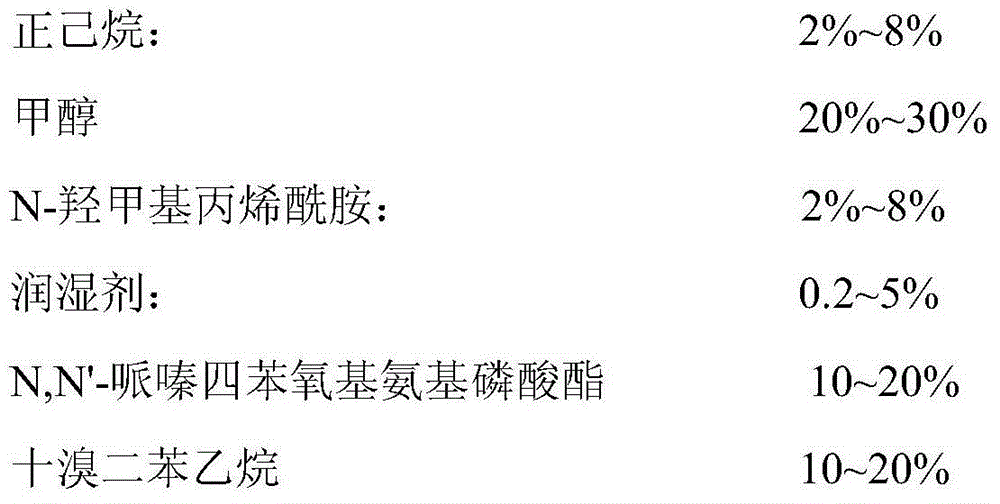

Method used

Image

Examples

Embodiment 1

[0042] A manufacturing process of flame-retardant air filter paper includes the following steps:

[0043] 1) Add 8% NaOH to 15 kg of cotton linters pulp, stir at 120°C for 4 hours to fully remove wax and soluble impurities in the cotton linters; the viscosity of the treated cotton linters is 300mPas, α-fiber 98% of element content, 0.2% of ash;

[0044] 2) Treat the cotton linter pulp obtained in 1) with 5% HCl at room temperature for 3 hours;

[0045] 3) Treat 60kg of glass fiber with 5% HCl at room temperature for 3hr;

[0046] 4) The glass fiber of step 3), the cotton linters pulp of step 2) and the polylactic acid fiber 15kg are beaten with a beating machine, and then the pulp slurry is obtained by on-line grinding with a double disc refiner. The beating concentration is 1.98%, respectively Beat to 50°SR, 16°SR and 22°SR;

[0047] 5) Dilute 2 kg of polyamide polyepichlorohydrin resin with water, stir evenly, and slowly add it to the pulp slurry;

[0048] 6) Add 3 kg of butanol, 3 k...

Embodiment 2

[0054] A manufacturing process of flame-retardant air filter paper includes the following steps:

[0055] 1) Add 12% NaOH to 18kg of cotton linters pulp, stir at 140°C for 4 hours to fully remove wax and soluble impurities in the cotton linters; the treated cotton linters have a viscosity of 290mPas, α-fiber The element content is 99%, and the ash content is 0.3%;

[0056] 2) Treat the cotton linter pulp obtained in 1) with 8% HCl at room temperature for 3 hours;

[0057] 3) Treat 55kg of glass fiber with 8% HCl at room temperature for 3hr;

[0058] 4) Use a beating machine to beat the glass fiber of step 3), the cotton linters pulp of step 2) and the polylactic acid fiber 14kg, and then use a double disc refiner to polish to obtain a pulp slurry with a beating concentration of 2.67%, respectively Beat to 42°SR, 15°SR and 26°SR;

[0059] 5) Dilute 2 kg of polyamide polyepichlorohydrin resin with water, stir evenly, and slowly add it to the pulp slurry;

[0060] 6) Add 4 kg of silicone ...

Embodiment 3

[0066] A manufacturing process of flame-retardant air filter paper includes the following steps:

[0067] 1) Add 10% NaOH to 12kg of cotton linters pulp, stir at 120°C for 4 hours to fully remove wax and soluble impurities in the cotton linters; the viscosity of the treated cotton linters is 280mPas, α-fiber Element content 98.5%, ash content 0.2%;

[0068] 2) Treat the cotton linter pulp obtained in 1) with 6% HCl at room temperature for 3 hours;

[0069] 3) Treat 60 kg of glass fiber with 6% HCl at room temperature for 3 hours;

[0070] 4) The glass fiber of step 3), the cotton linters pulp of step 2) and 18 kg of polylactic acid fiber are beaten with a beater, and then polished on-line by a double-disc refiner to obtain a pulp slurry with a beating concentration of 2.08%, respectively Beat to 58°SR, 18°SR and 20°SR;

[0071] 5) Dilute 2 kg of polyamide polyepichlorohydrin resin with water, stir evenly, and slowly add it to the pulp slurry;

[0072] 6) Add 3kg of pine oil, 3kg of sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com