High-whiteness bleaching method for high-yield bamboo wood pulp

A high-yield pulp and high-brightness technology, which is applied in the field of pulp and papermaking, can solve the problems of poor liquid penetration, difficulty in achieving high-brightness bleaching goals, and low reaction efficiency, so as to increase the limit of bleaching brightness and waste water. Easy to manage and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

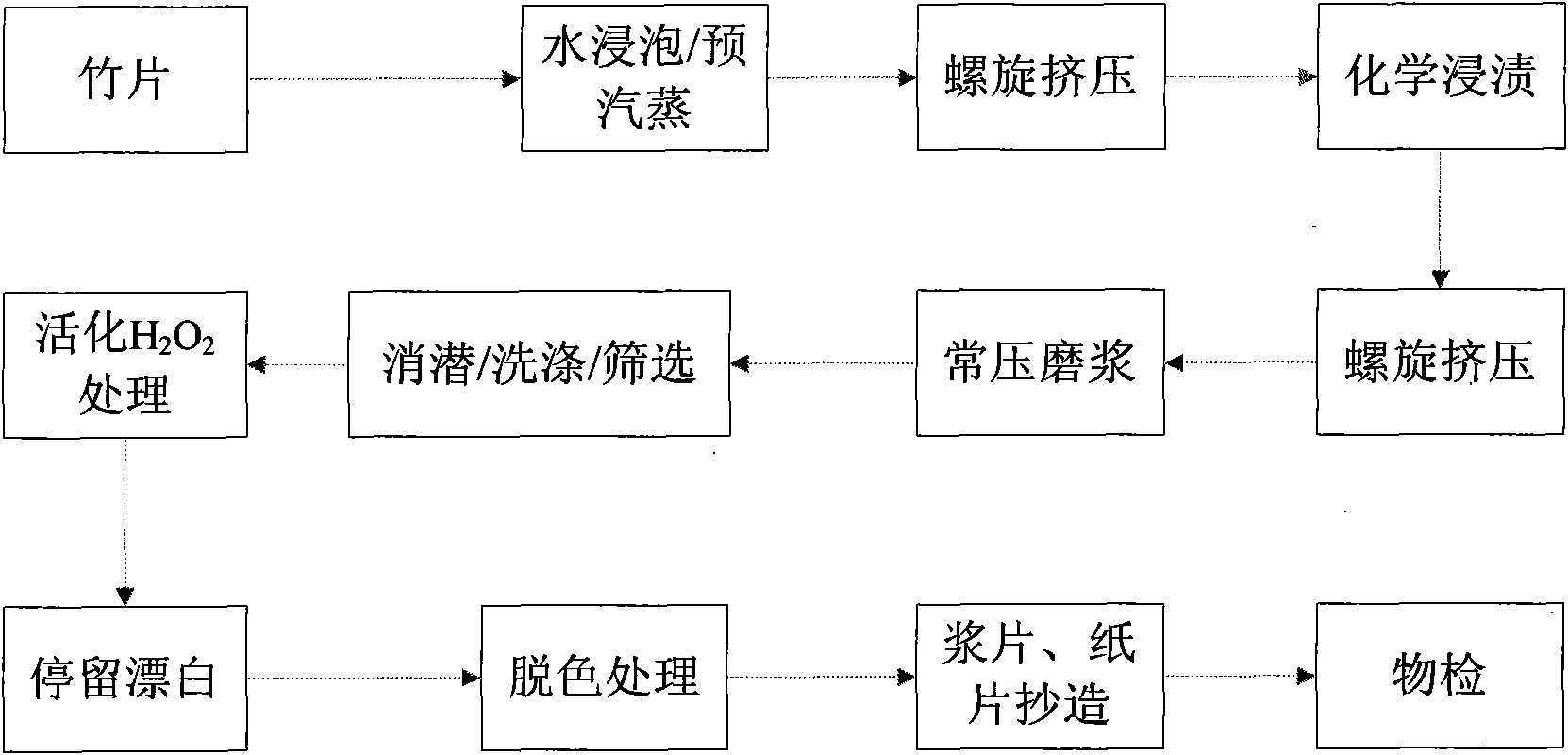

Image

Examples

Embodiment 1

[0026] The specific bleaching implementation method is as follows:

[0027] 1. Intensified mechanical and chemical treatment Cizhu is taken from Guangxi Zhuang Autonomous Region. After slicing and removing impurities, it is soaked in water at room temperature. After pre-steaming in a steam chamber with a pressure of 1 atmosphere and a temperature of 105°C for 10 to 15 minutes, use a compression ratio of 1. : 4 screw extruders extrude, the Cizhu material uses 2%NaOH, 1.6%Na relative to the absolute dry material quality after extrusion 2 SO 3 Carry out chemical impregnation treatment with 0.2% DTPA, the treatment temperature is 50°C, the treatment time is 30min, and the slurry concentration is 30%wt, followed by secondary screw extrusion, and then the high-consistency refiner is used for refining, and the concentration of the slurry is 30%wt, control different refining energy inputs, and adjust pulp freeness to 260-280mlCSF. The yield of natural-color bamboo high-yield pulp is...

Embodiment 2

[0034] Cizhu (taken from Guangxi), sliced and removed, soaked in water at room temperature, sent to the steaming chamber, pre-steamed at normal pressure for 10-15 minutes, and extruded in a screw extruder (compression ratio is 1: 4). After extrusion, the bamboo material uses 2% NaOH, 2% H 2 o 2 , 0.2% DTPA dosage for chemical treatment, the material concentration is 30%, the treatment temperature is 50°C, and the treatment time is 30min. Then use a screw extruder to extrude and send it to a high-consistency atmospheric pressure refiner for refining, control different refining energy inputs, and adjust the pulp freeness to 260-280mlCSF. The yield of natural-color bamboo high-yield pulp is 87.2%. The ground slurry is depotentialized and screened, and the depotentialization conditions are: 3% slurry concentration, 90° C. for 15 minutes. Bamboo high yield pulp is used for bleaching. For the implementation process of pulping, bleaching, copying and testing, see figure 1 . ...

Embodiment 3

[0044] The specific bleaching implementation method is as follows:

[0045] 1. Intensified mechanical and chemical treatment Cizhu is taken from Guangxi Zhuang Autonomous Region. After slicing and removing impurities, it is soaked in water at room temperature. After pre-steaming in a steam chamber with a pressure of 1 atmosphere and a temperature of 105°C for 10 to 15 minutes, use a compression ratio of 1. : 4 screw extruders are extruded to make the bamboo chip material reach liquid: material=2.5~3.5: 1 liquid absorption ratio, the Cizhu material uses 2%NaOH, 1.6%Na relative to the absolute dry material quality after extrusion 2 SO 3 Carry out chemical impregnation treatment with 0.2% DTMPA, the treatment temperature is 50 ℃, the treatment time is 30min, the treatment slurry is thick 20%wt, then carry out secondary screw extrusion, and then use a high-consistency refiner to refine, and the concentration of the slurry is 20%wt, control different refining energy inputs, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com