Carbon fiber heating paper and preparation method thereof

A technology of carbon fiber heat generation and carbon fiber, which is applied in fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, fiber dispersant addition, etc. Heating unevenness and other issues can be achieved to achieve more uniform heating, improved uniformity, and easy cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

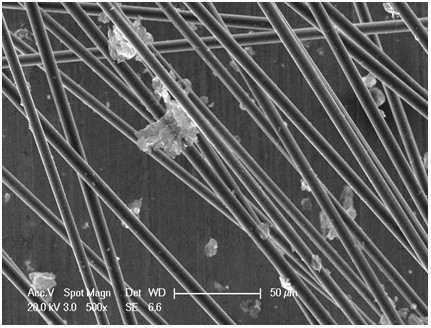

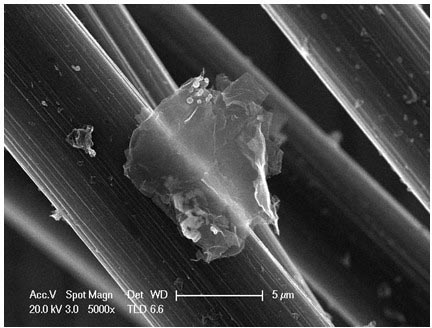

Image

Examples

Embodiment 1

[0031] Example 1: Weigh 2 g of polyacrylonitrile-based carbon fiber and 0.02 g of graphene, immerse them in 0.01 mol / L NaOH solution for 1 hour, and then wash with pure water until the pH is neutral. After mixing with the dispersant, disperse ultrasonically for 10 minutes, and then rinse with pure water until it is neutral. After the above mixture is added to the beater for beating, it is then mixed with 8 g of pulp for beating. Sheet the mixed pulp and dry it.

[0032] In the carbon fiber paper prepared by this example, the mass percentage of polyacrylonitrile carbon fiber is 20%, graphene is 0.2%, vegetable fiber is 78%, and other components such as adhesive are 1.8%. The specific indicators are as follows: unit area weight 44 g / m 2 , Thickness of 0.12 mm, resistivity of 0.22 Ω? cm, electric power density of radiating surface is 0.92 W / cm 2 , The conversion efficiency of electric-heat radiation is 97%, and the unevenness of the radiating surface temperature is 0%.

[0033] The ...

Embodiment 2

[0034] Example 2: Weigh 2 g of polyacrylonitrile-based carbon fiber and 0.002 g of graphene, immerse them in 0.01 mol / L NaOH solution for 2 hours, then wash with pure water until the pH is neutral, and combine the solutions of the two substances with After mixing the dispersant, disperse ultrasonically for 10 minutes, and then rinse with pure water until it is neutral. After the above mixture is added to the beating machine for beating, it is then mixed with 8 g of pulp to be beaten. Sheet the mixed pulp and dry it.

[0035] In the carbon fiber paper prepared by this example, the mass percentage of polyacrylonitrile carbon fiber is 20%, graphene is 0.02%, plant fiber is 78%, and other components such as adhesive are 1.98%. The specific indicators are as follows: unit area weight 44.5 g / cm 2 , Thickness of 0.12 mm, resistivity of 0.24 Ω?cm, electric power density of radiating surface is 0.91 W / cm 2 . The electric-heat radiation conversion efficiency is 96%, and the uniformity of...

Embodiment 3

[0037] Example 3 As a comparison with no graphene added: Weigh 2 g of polyacrylonitrile-based carbon fiber, immerse it in a 0.01 mol / L NaOH solution for 1 hour, and then wash with pure water until the pH is neutral. The solution of the two substances After mixing with the dispersant, disperse ultrasonically for 10 minutes, and then rinse with pure water until it is neutral. After the above mixture is added to the beating machine for beating, it is then mixed with 8 g of pulp to be beaten. Sheet the mixed pulp and dry it.

[0038] In the carbon fiber paper prepared by this example, the mass percentage of polyacrylonitrile carbon fiber is 20%, plant fiber 78%, and other components such as adhesive 2%. The specific indicators are as follows: unit area weight 44.9 g / cm 2 , Thickness of 0.12 mm, resistivity of 0.27 Ω?cm, electric power density of radiating surface is 0.6 W / cm 2 . The electric-heat radiation conversion efficiency is 59%, and the temperature unevenness of the radiatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com