Carbon nanotube/short-fiber composited nano-carbon paper and continuous preparation method thereof

A technology of carbon nanotubes and short fibers, which is applied in the direction of fiber dispersant addition, paper, papermaking, etc., can solve the problems that it is difficult to prepare large-sized products, the preparation efficiency cannot be improved, and the brittleness of nano-carbon paper is large. The effect of broad commercialization prospects and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

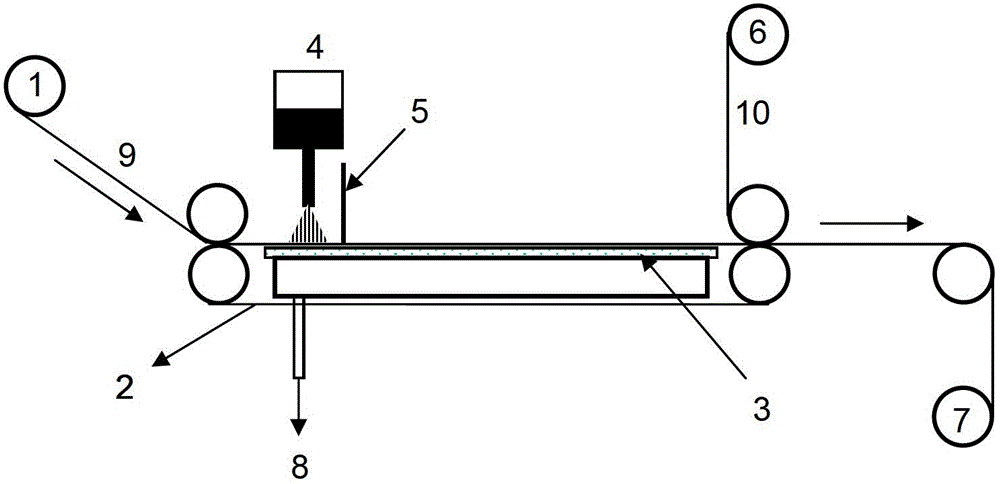

[0040] As another aspect of the technical solution of the present invention, the continuous preparation method of the carbon nanotube / short fiber composite nanocarbon paper comprises the following steps:

[0041] First, the carbon nanotubes are dispersed in a solvent with the aid of a dispersant to form a dispersion;

[0042] Subsequently, the short fibers are slowly mixed into the dispersion liquid under low-speed stirring, and the short fibers are well dispersed by high-speed shearing to obtain a slurry;

[0043] Then, the above-mentioned slurry is formed into a film by vacuum-assisted casting to form an initial composite nano-carbon paper, and the dispersant is removed through post-treatment to obtain a composite nano-carbon paper.

[0044] Further, the dispersion process of the aforementioned carbon nanotubes may adopt any one of high-speed shear dispersion, ultrasonic dispersion, grinding dispersion and ball mill dispersion, but is not limited thereto.

[0045] The foreg...

Embodiment 1

[0052] Example 1 Weigh 30 grams of multi-walled carbon nanotubes, dissolve them in 1 liter of Triton-100 aqueous solution with a concentration of 1%, then use a grinder to grind and disperse, stir and disperse at a speed of 3000 rpm for 1 hour, and sieve through a 200-mesh filter to obtain Uniform carbon nanotube dispersion ("dispersion" for short); add 5 grams of chopped carbon fibers with a length of 3 mm in slow stirring, and the weight ratio of carbon nanotubes to carbon fibers is 6:1. Disperse in a cutting disperser with a rotation speed of 3000 rpm, disperse for 20 minutes to form a stable slurry, and stand for 20 minutes to defoam before proceeding to film-forming processing. Afterwards, an initial composite nano-carbon paper with a thickness of 70 microns was prepared by means of a vacuum-assisted casting film-forming device, and the polymer was washed off after subsequent leaching, and the carbon paper could be directly peeled off from the filter membrane to obtain a...

Embodiment 2

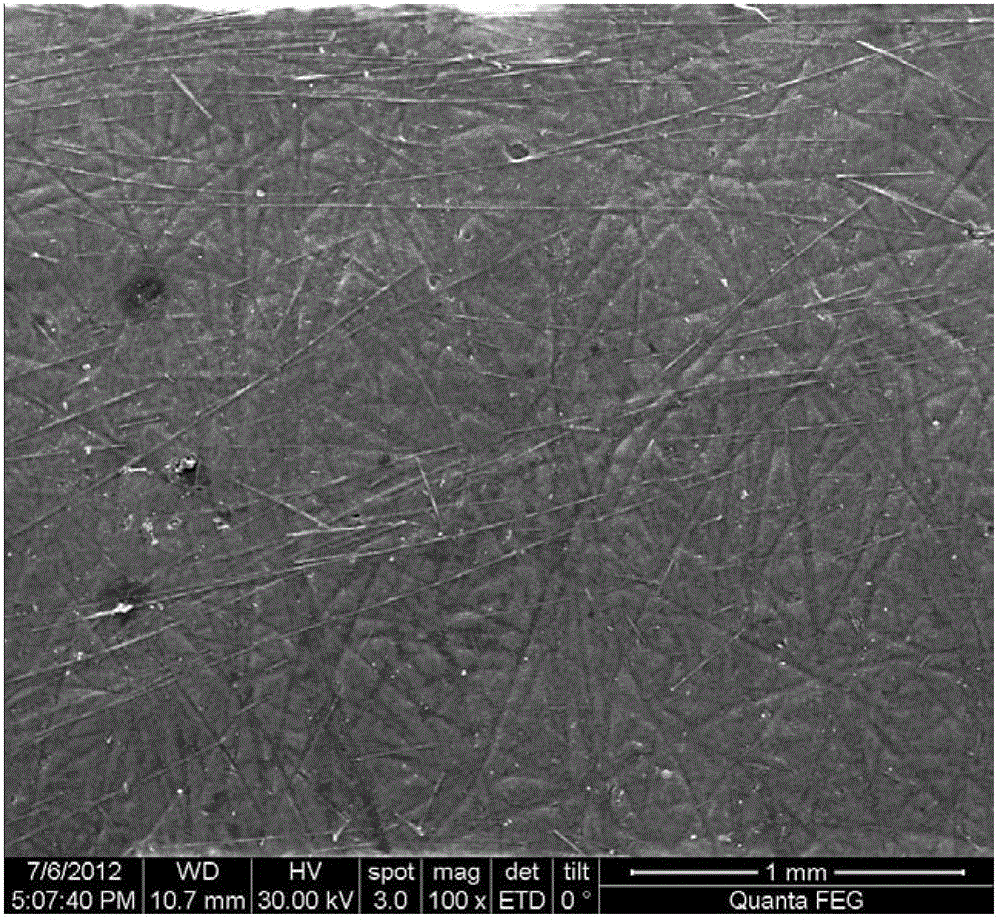

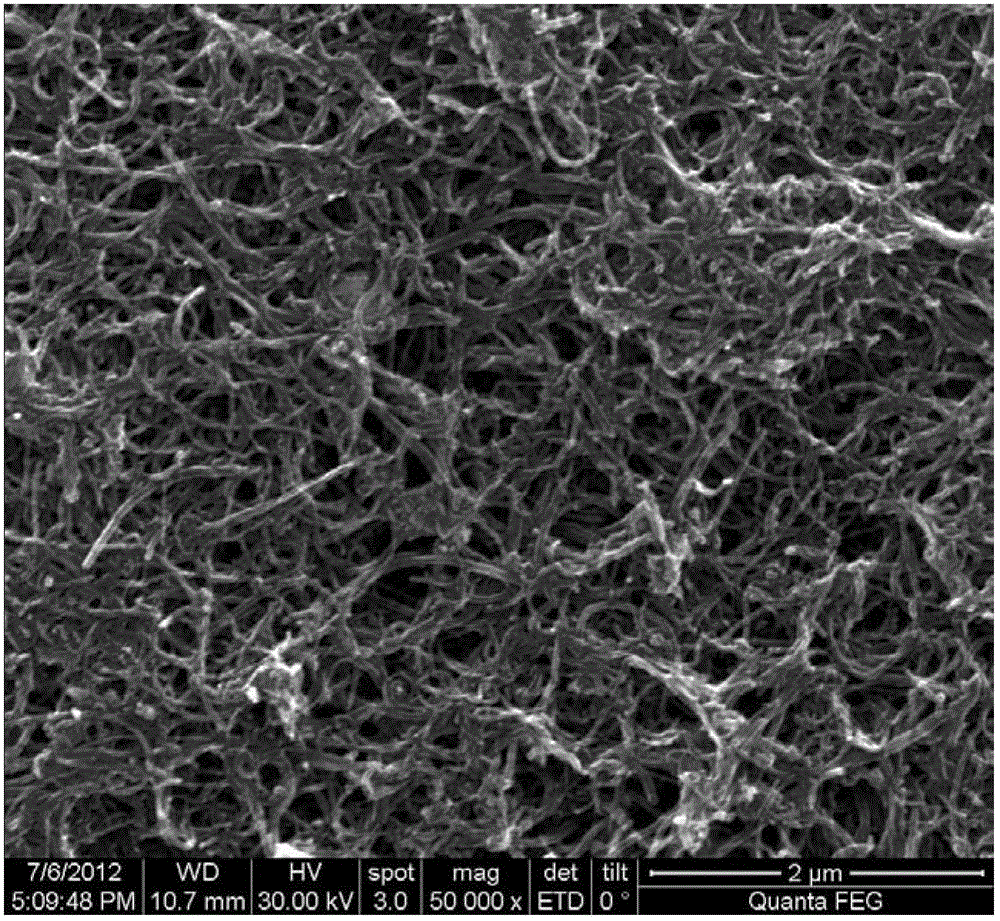

[0054] Example 2 This embodiment is basically the same as Embodiment 1, the difference is that the weight ratio of carbon nanotubes to carbon fibers is 8:1, Figure 3a-Figure 3c Shown is the scanning electron micrograph of the carbon nano paper prepared in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com