Carbon nanofiber paper and preparation method thereof

A technology of carbon nanofiber paper and carbon nanofiber, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, non-fibrous pulp addition, fiber raw material treatment, etc. In order to solve problems such as large-scale low-cost production, it can achieve the effect of ensuring retention, reducing pore size requirements, and enhancing mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

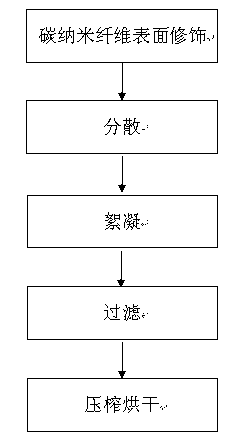

Method used

Image

Examples

Embodiment 1

[0038] Subjecting solid carbon nanofibers to HNO 3 / H 2 SO 4 (Volume ratio 1:3) Soak in mixed acid for 2 hours, take it out, wash with acid, and obtain carbon nanofibers with modified functional groups. Add 0.005 mol / L sodium lauryl sulfate solution to the carbon nanofibers modified with functional groups, stir well, and disperse evenly. Add flocculant iron sulfate, filter naturally, press, and dry at 40°C under low pressure to make carbon nanofiber paper.

Embodiment 2

[0040] Exposure of multi-walled carbon nanotubes to HNO 3 / H 2 SO 4 (Volume ratio 1:3) Soak in mixed acid for 4 hours, take it out, wash with acid, and obtain carbon nanofibers with modified functional groups. Add 0.01 mol / L sodium lauryl sulfate solution to the carbon nanofibers modified with functional groups, stir well, and disperse evenly. Add flocculant calcium chloride, naturally filter, press, and dry at 40°C under low pressure to make carbon nanofiber paper.

Embodiment 3

[0042] Subjecting single-walled carbon nanofibers to HNO 3 / H 2 SO 4 (Volume ratio 1:3) Soak in mixed acid for 2 hours, then place in H 2 o 2 / H 2 SO 4 (Volume ratio 1:4) soaked for 0.5 hours, taken out, washed with acid, and obtained carbon nanofibers with modified functional groups. Add 0.05 mol / L sodium lauryl sulfate solution to the carbon nanofibers modified with functional groups, stir well, and disperse evenly. Add flocculant acetone ferric sulfate, filter naturally, press, and dry under normal pressure at 80°C to make carbon nanofiber paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com