Method for producing polycrystal ingot

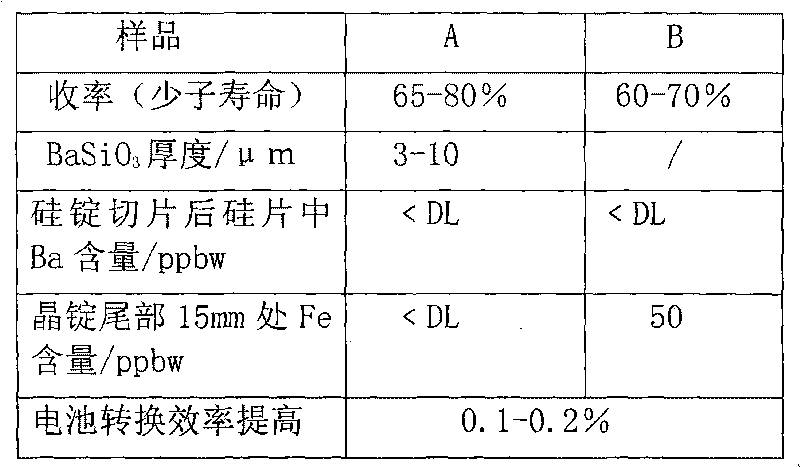

A production method and technology for polycrystalline ingots, which are applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as the inability to effectively inhibit the diffusion of impurity elements such as metals, so as to improve battery conversion efficiency, inhibit diffusion, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A production method of a polycrystalline ingot, the production method is as follows:

[0017] (1), prepare the solution of barium hydroxide or barium salts as coating solution;

[0018] (2), preheating the quartz ceramic crucible;

[0019] (3), on the inner surface of the preheated quartz ceramic crucible, evenly coat the coating solution of barium hydroxide or barium salts, and bake the coating solution of barium hydroxide or barium salts;

[0020] (4), after the quartz ceramic crucible is baked, spray and bake silicon nitride on its inner surface;

[0021] (5), the silicon material is packed into a quartz ceramic crucible, put into a polycrystalline furnace, the polycrystalline furnace is evacuated and a protective gas is added, and the silicon material is heated and melted;

[0022] (6) Through directional solidification, the molten silicon material is gradually crystallized from the bottom to the top, and finally annealed at high temperature to form a polycrystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com