Method for continuously preparing two-sided texture high-temperature superconduction bibasic strip transition layer

A high-temperature superconducting and transition layer technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of lack, the large-scale application of strip preparation technology is restricted, and achieve smooth surface. , to ensure double-sided consistency and single-sided uniformity, and the effect of high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] A kind of specific embodiment of the present invention is:

[0033] A method for preparing a transition layer of a double-sided high-temperature superconducting tape by chemical solution deposition, which consists of the following steps in sequence:

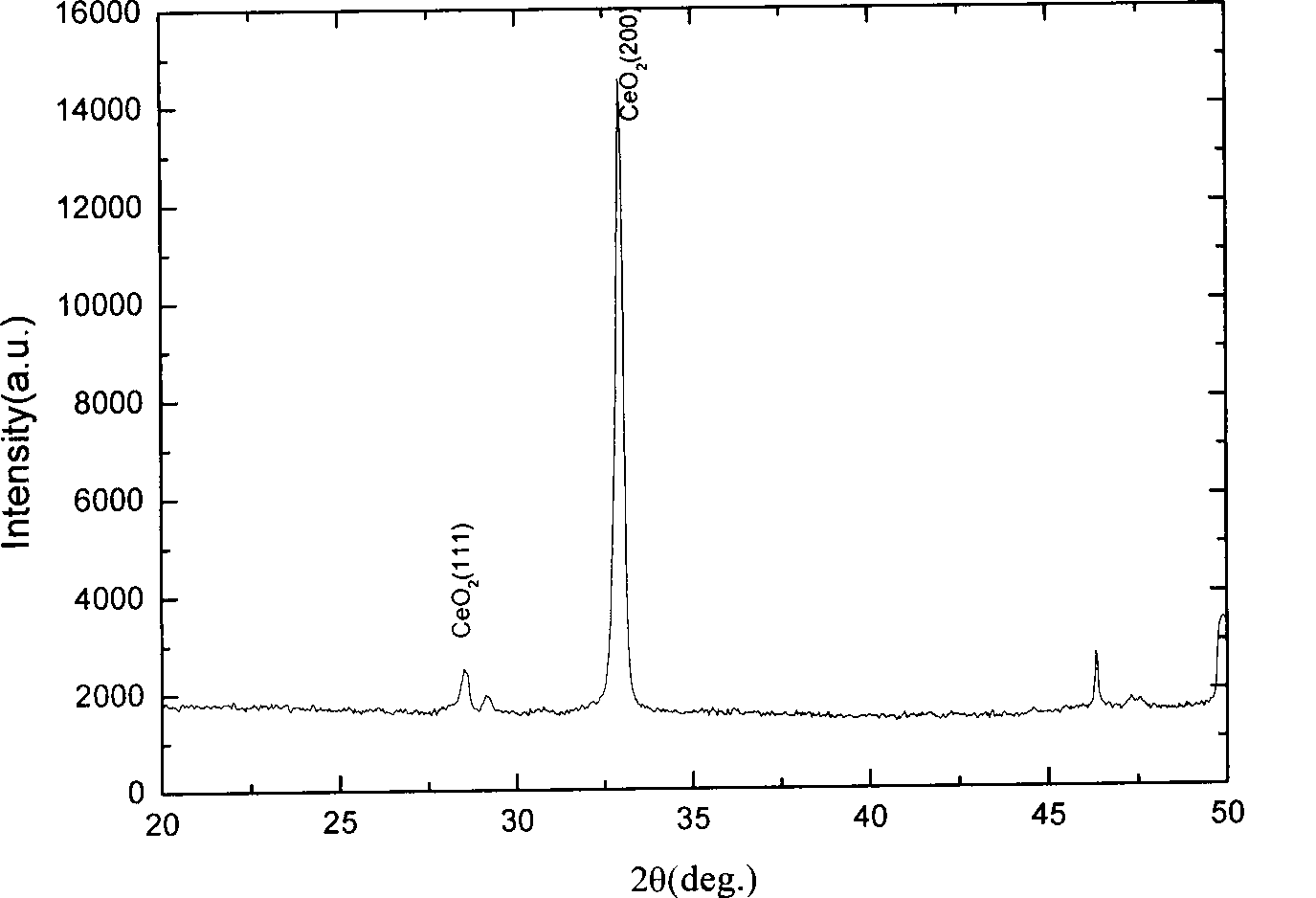

[0034] a, preparation of precursor solution: dissolving cerous nitrate in N,N-dimethylformamide (DMF) to form a precursor solution (that is, the ion ratio of rare earth ion and cerium in this example is 0:1);

[0035] b. Colloid preparation: add polyacrylic acid (PAA) to the precursor solution of step a to form a colloid with good film-forming properties;

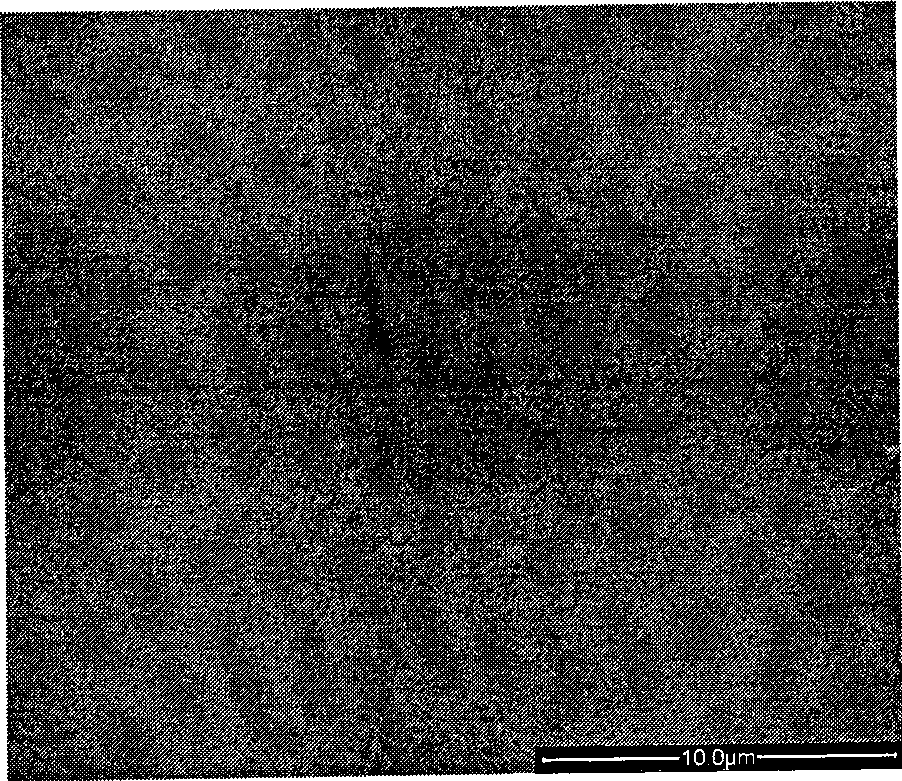

[0036] c. Film preparation and drying: the Ni alloy base tape is wound through the colloid obtained in step b (that is, a runner is set in the colloid, and the base tape walks around the runner from below, and the tape-out end and the tape-feed end are all in the colloid. above the colloid), at the end of the tape, the tape is pulled out vertically at a pulling speed o...

Embodiment 2

[0040] The preparation method of this example consists of the following steps in turn:

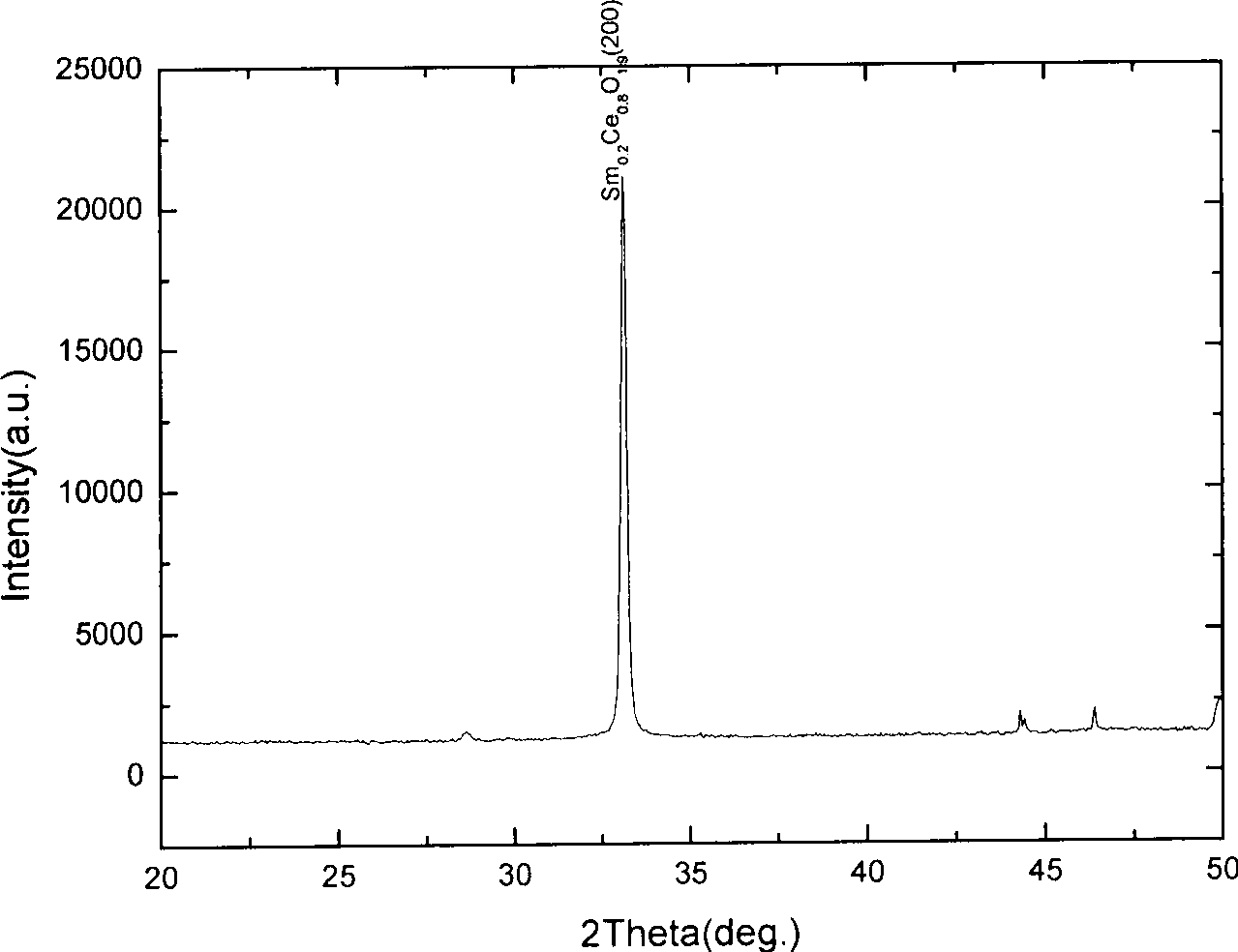

[0041] a. Preparation of precursor solution: Dissolve samarium nitrate and cerous nitrate in N,N-dimethylformamide (DMF) according to the ratio of cation ratio Sm:Ce=0.2:0.8 to form a precursor solution; that is, this example The doping element M used in is samarium Sm, and the final M x Ce 1-x o y x in the transition layer is equal to 0.2, and y is equal to 1.9, that is, the material of the transition layer made in this example is specifically Sm 0.2 Ce 0.8 o 1.9 ;

[0042] b. Colloid preparation: add polyacrylic acid (PAA) to the precursor solution of step a to form a colloid with good film-forming properties;

[0043] c. Film preparation and drying: wind the Ni alloy base tape into the colloid prepared in step b, and take out the tape vertically at the end of the strip at a pulling speed of 100mm / min, and make the Ni alloy base tape pass through the colloid for 10 seconds , after...

Embodiment 3

[0047] The preparation method of this example consists of the following steps in turn:

[0048] a. Preparation of precursor solution: Dissolve gadolinium nitrate and cerous nitrate in N,N-dimethylformamide (DMF) according to the ratio of cation ratio Gd:Ce=0.5:0.5 to form a precursor solution; that is, this example The doping element M used in is gadolinium Gd, and the final M x Ce 1-x o y x in the transition layer is equal to 0.5, and y is equal to 1.75, that is, the material of the transition layer prepared in this example is specifically Gd 0.5 Ce 0.5 o 1.75 ;

[0049] b. Colloid preparation: add polyacrylic acid (PAA) to the precursor solution of step a to form a colloid with good film-forming properties;

[0050] c. Film preparation and drying: wind the Ni alloy base tape into the colloid prepared in step b, and take out the tape vertically at the pulling speed of 50mm / min at the end of the tape, and make the Ni alloy base tape pass through the colloid for 20 second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com