Preparation method and application of titanium dioxide modified lead dioxide electrode

A technology of lead dioxide and titanium dioxide, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of low catalytic efficiency, short electrode life, small electrode surface area, etc., and achieve simple preparation process and easy operation Convenience, the effect of improving the oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

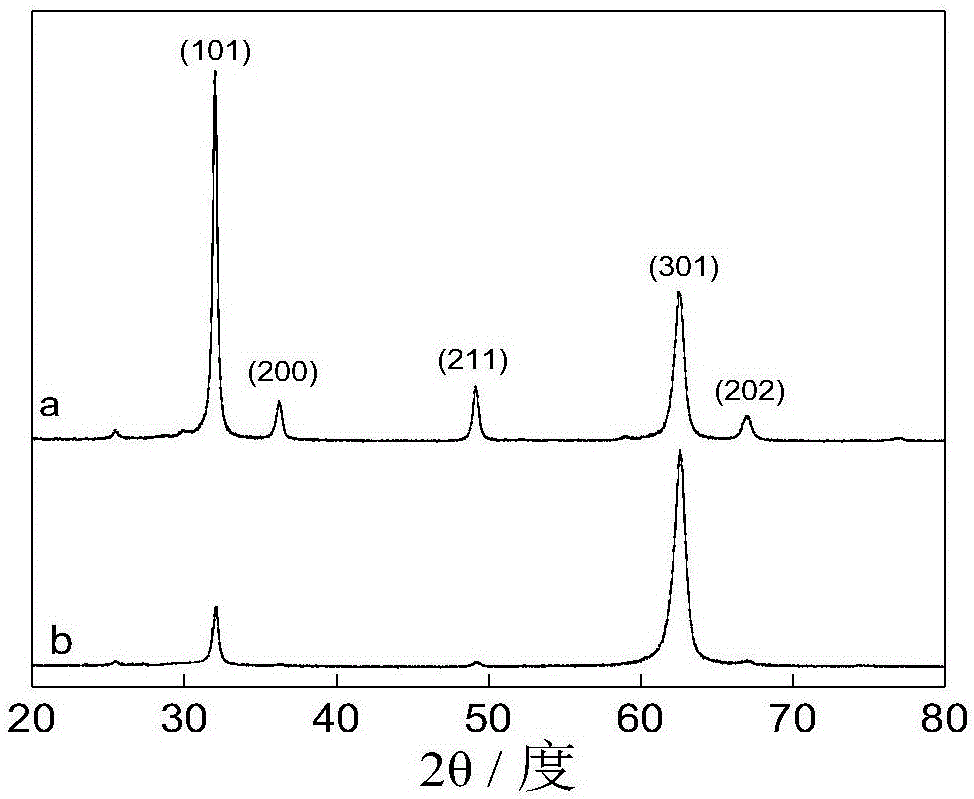

Embodiment 1

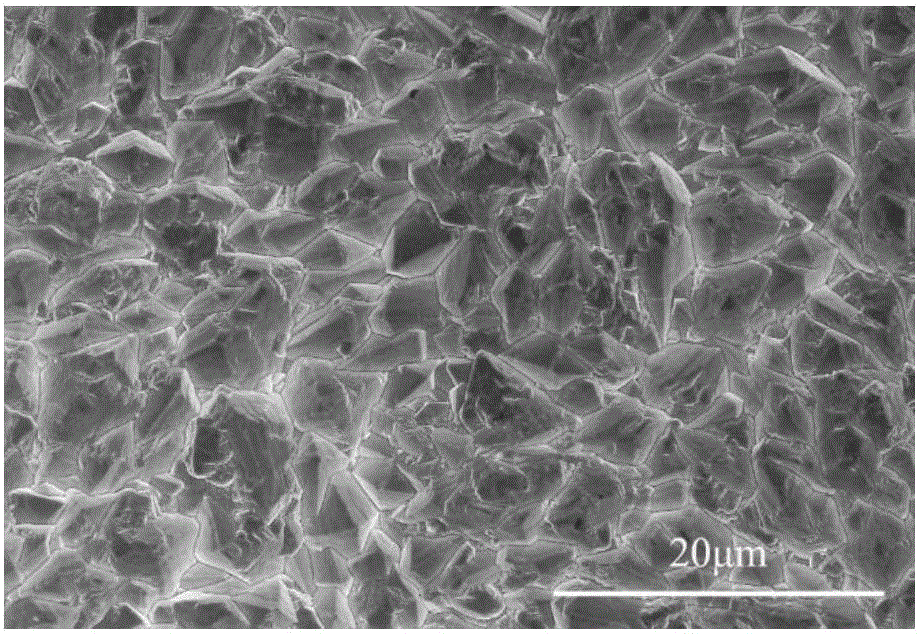

[0042] The preparation steps of a titanium dioxide modified lead dioxide electrode are as follows:

[0043] Step 1. Pretreatment of titanium plate

[0044] First immerse the titanium plate in ethanol to remove oil for 30 minutes, then polish the titanium plate with 320-mesh and 600-mesh sandpaper respectively, then cut the titanium plate into square pieces of 20mm×50mm and ultrasonically clean it for 15min, and then immerse the titanium plate until the temperature is 80°C and 20% oxalic acid aqueous solution for 1.5h to remove the oxide layer; after removing the titanium plate from the oxalic acid solution, wash it with deionized water and dry it;

[0045] Step 2. Preparation of tin antimony oxide interlayer

[0046] Coat the solution containing tin ions and antimony ions on the pretreated titanium plate in step 1, and then dry the titanium plate in a drying oven at 100°C for 10 minutes. After the solvent on the surface of the titanium plate evaporates, put the titanium plate...

Embodiment 2

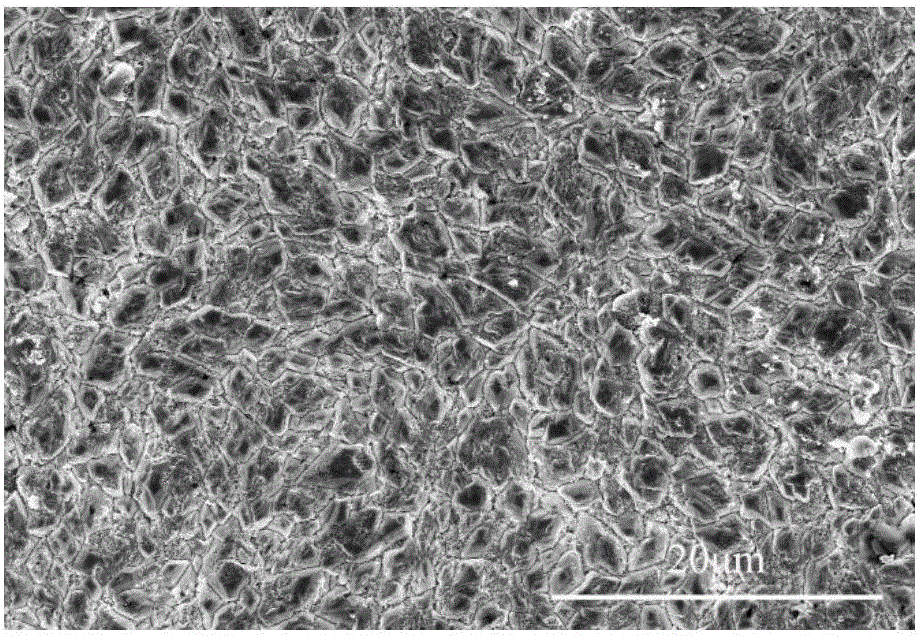

[0055] The preparation steps of a titanium dioxide modified lead dioxide electrode are as follows:

[0056] Step 1. Pretreatment of titanium plate

[0057] First immerse the titanium plate in ethanol to remove oil for 30 minutes, then polish the titanium plate with 320-mesh and 600-mesh sandpaper respectively, then cut the titanium plate into square pieces of 20mm×50mm and ultrasonically clean it for 15min, and then immerse the titanium plate until the temperature is 75°C and 12% oxalic acid aqueous solution for 3 hours to remove the oxide layer; after removing the titanium plate from the oxalic acid solution, wash it with deionized water and dry it;

[0058] Step 2. Preparation of tin antimony oxide interlayer

[0059] Coat the solution containing tin ions and antimony ions on the pretreated titanium plate in step 1, and then dry the titanium plate in a drying oven at 90°C for 15 minutes. After the solvent on the surface of the titanium plate evaporates, put the titanium pla...

Embodiment 3

[0067] The preparation steps of a titanium dioxide modified lead dioxide electrode are as follows:

[0068] Step 1. Pretreatment of titanium plate

[0069] First immerse the titanium plate in ethanol to remove oil for 30 minutes, then polish the titanium plate with 320-mesh and 600-mesh sandpaper respectively, then cut the titanium plate into square pieces of 20mm×50mm and ultrasonically clean it for 15min, and then immerse the titanium plate until the temperature is 90°C and 18% oxalic acid aqueous solution for 1.5h to remove the oxide layer; after taking the titanium plate out of the oxalic acid solution, wash it with deionized water and dry it;

[0070] Step 2. Preparation of tin antimony oxide interlayer

[0071] Coat the solution containing tin ions and antimony ions on the pretreated titanium plate in step 1, and then dry the titanium plate in a drying oven at 110°C for 15 minutes. After the solvent on the surface of the titanium plate evaporates, put the titanium plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com