Manufacture method of through flow type oxide particle filtering combustor

A particle filtration and manufacturing method technology, applied in chemical instruments and methods, combustion engines, chemical/physical processes, etc., can solve problems such as ineffectiveness and unsatisfactory effects, and achieve low cost, easy to hang pulp, and long-term use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

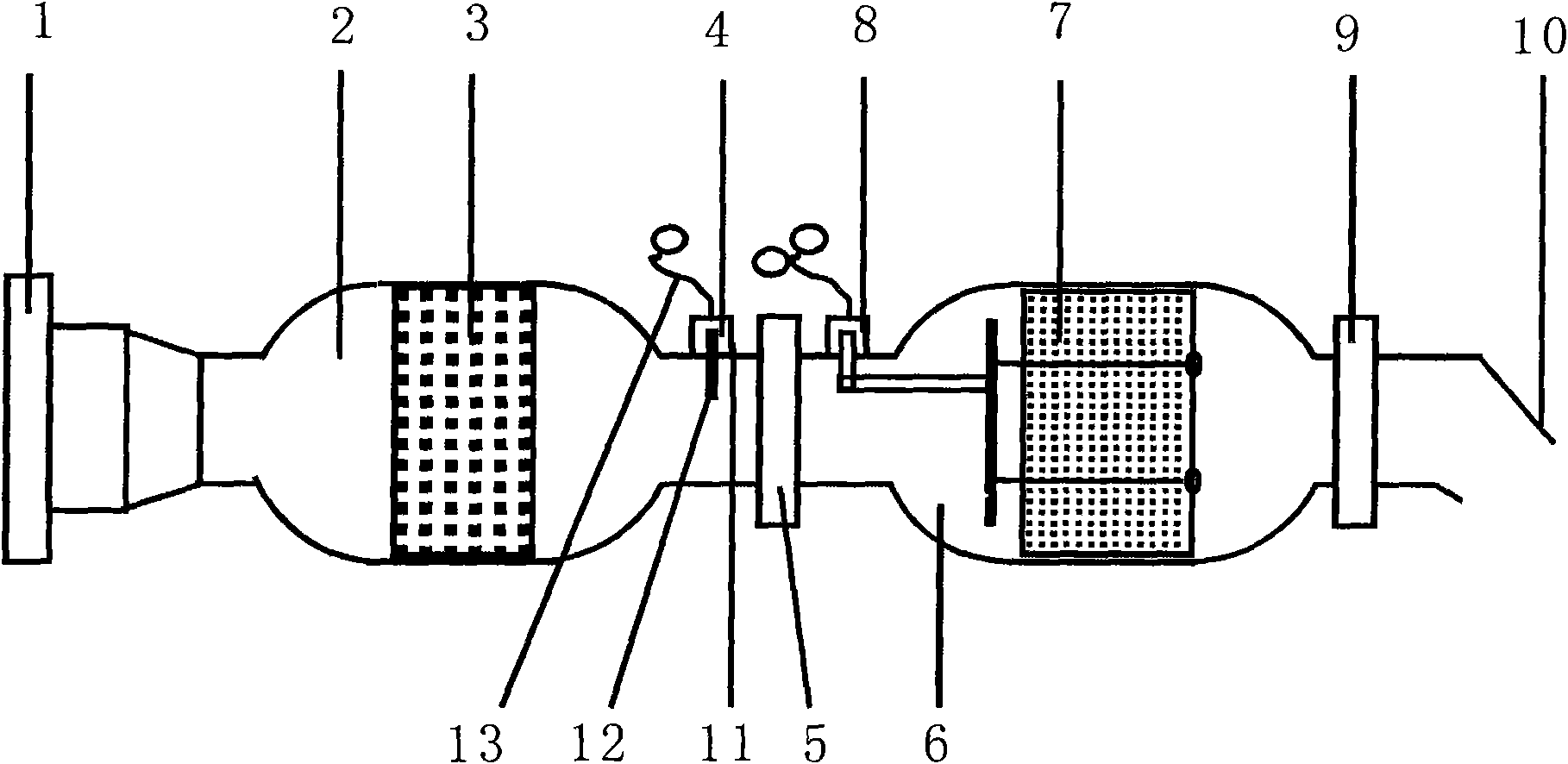

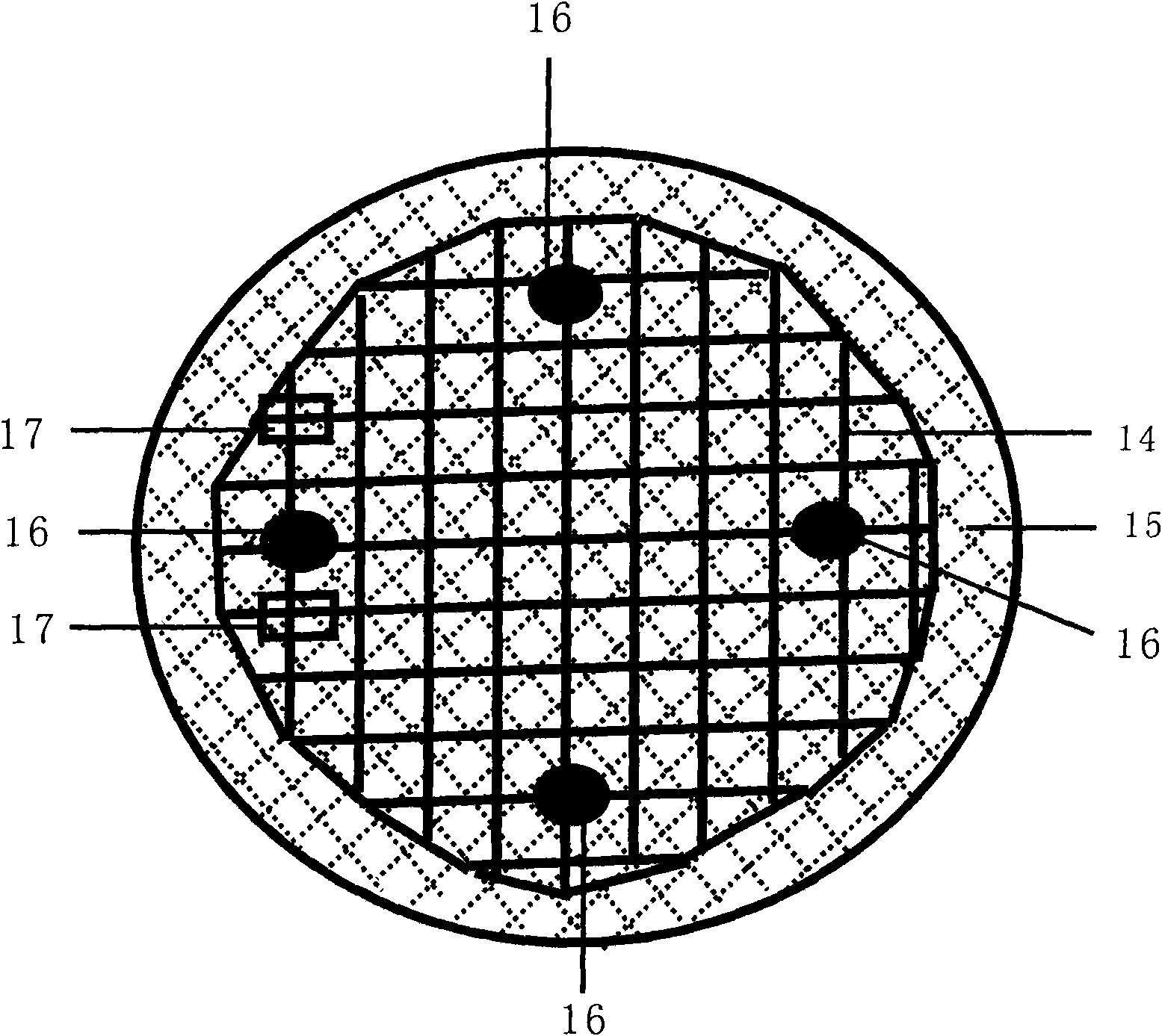

[0018] exist figure 1 In the schematic diagram of the cross-sectional perspective diagram of the manufacturing method of the through-flow oxidation type particle filter burner, one side of the front connection plate 1 is connected to the engine exhaust pipe, and the other side is connected to one end of the front metal shell 2; the front metal shell 2. It is a through-type hollow shell with a thick center and thin ends. The thick part in the middle is inlaid with a metal foam three-way catalyst carrier 3, and a temperature sensor 4 is inlaid in the upper middle of the end of the front metal shell 2; the front metal shell 2 The end is connected to one side of the connecting plate 5, and the other side of the connecting plate 5 is connected to one end of the rear metal shell 6; the shape of the rear metal shell 6 is basically similar to that of the front metal shell 2, and a ceramic honeycomb three-way catalyst is installed in the thick middle part Carrier 7, a carbon fiber part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com