A kind of La-doped CeO2 transition layer thin film and preparation method thereof

A technology of transition layer and thin film, which is applied in the field of high-temperature superconducting material preparation, and achieves the effects of simple preparation process, precise and adjustable lattice constant, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 0.0144mol of cerium acetate and 0.0016mol of lanthanum acetylacetonate to a mixed solution of 28ml of n-propionic acid and 12ml of acetylacetone, heat and stir until dissolved to obtain Ce 3+ with La 3+ The total concentration is 0.4mol / L, Ce 3+ : La 3+ 9:1 precursor solution;

[0033] 2) The metal-textured NiW alloy base tape is ultrasonically cleaned with acetone and methanol in sequence, and after drying, the precursor liquid is dropped onto the metal NiW alloy base tape, and spin-coated by a spin-coating machine. The rotation speed of the spin-coating is 5000rpm. The spin time is 30 seconds to obtain the precursor film;

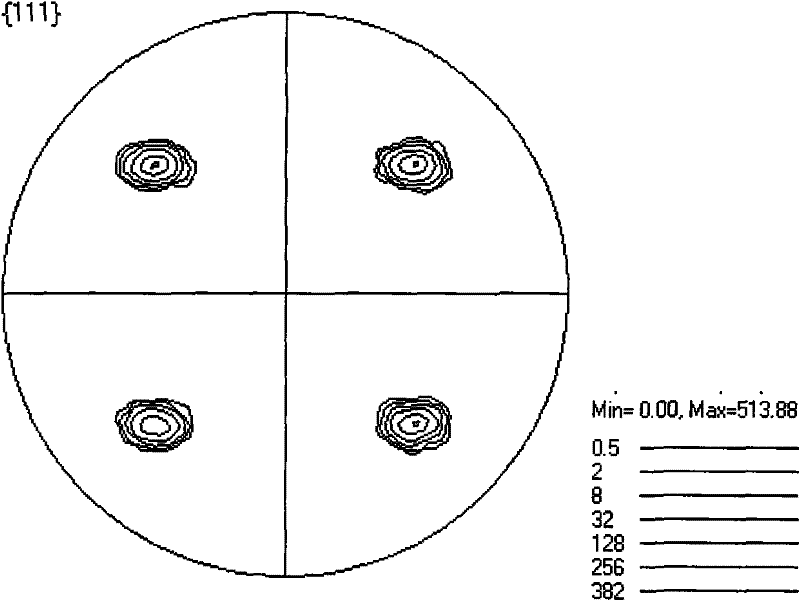

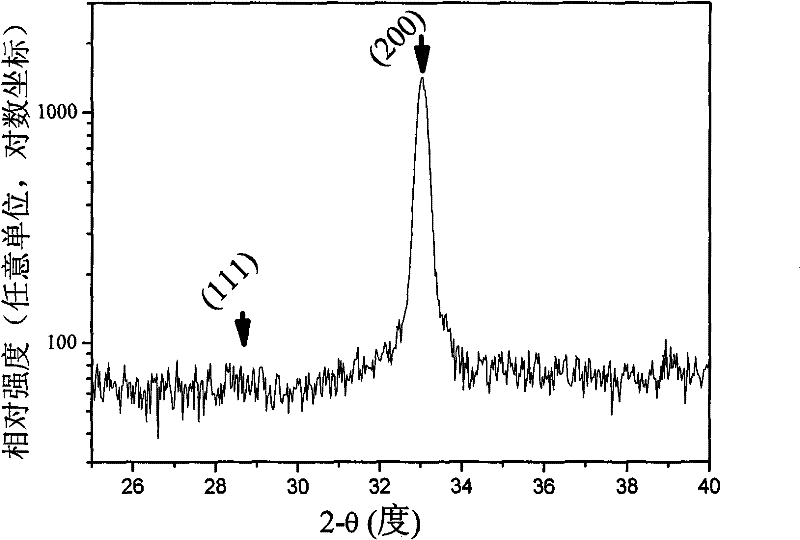

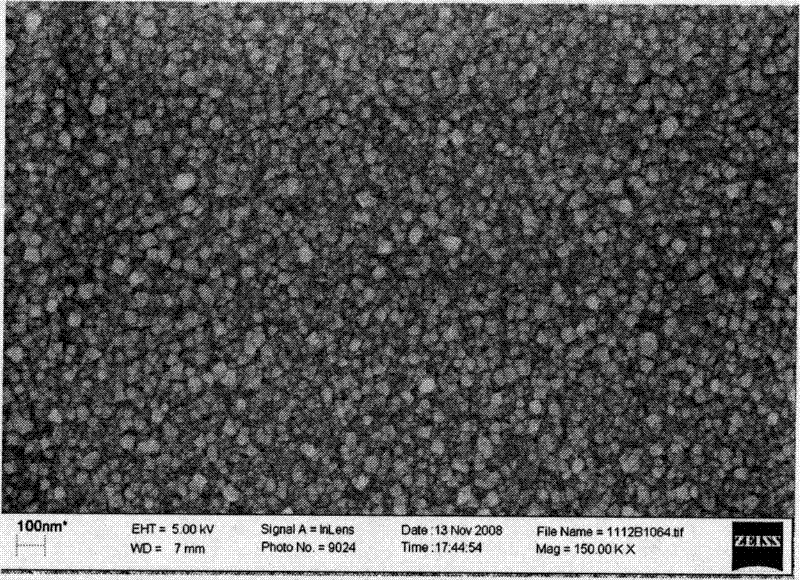

[0034] 3) Place the precursor film in a tube furnace, and inject H 2 Under gas conditions, sintering at 1200°C for 15 minutes to obtain 60nm thick Ce 0.9 La 0.1 o 2 Single-layer transition layer film;

[0035] 4) Repeat the process of step 2) coating and step 3) sintering once to obtain 120nm thick Ce 0.9 La 0.1 o 2 Two layers o...

Embodiment 2

[0040] 1) Add 0.0144mol of cerium acetylacetonate and 0.0016mol of lanthanum acetylacetonate into a mixed solution of 39ml of n-propionic acid and 1ml of methanol, heat and stir until dissolved to obtain Ce 3+ with La 3+ The total concentration is 0.4mol / L, Ce 3+ : La 3+ 9:1 precursor solution;

[0041] 2) The metal-textured NiW alloy base tape is ultrasonically cleaned with acetone and methanol in sequence, and after drying, the precursor liquid is dropped onto the metal NiW alloy base tape, and spin-coated by a spin-coating machine. The rotation speed of the spin-coating is 2000rpm. The spin time is 120 seconds to obtain the precursor film;

[0042] 3) Place the precursor film in a tube furnace and sinter at 950°C for 60 minutes under the condition of flowing Ar gas to obtain a 50nm thick Ce 0.9 La 0.1 o 2 Single-layer transition layer film;

[0043] 4) Repeat the process of step 2) coating and step 3) sintering 4 times to obtain 250nm thick Ce 0.9 La 0.1 o 2 Fiv...

Embodiment 3

[0045] 1) Add 0.0032mol of cerium acetylacetonate and 0.0008mol of lanthanum acetylacetonate into a mixed solution of 30ml of n-propionic acid and 10ml of methanol, heat and stir until dissolved, and obtain Ce 3+ with La 3+ The total concentration is 0.1mol / L, Ce 3+ : La 3+ 8:2 precursor solution;

[0046] 2) The metal-textured NiW alloy base tape is ultrasonically cleaned with acetone and methanol in sequence, and after drying, the precursor liquid is dropped onto the metal NiW alloy base tape, and spin-coated by a spin-coating machine. The rotation speed of the spin-coating is 3000rpm. The spin time is 60 seconds to obtain the precursor film;

[0047] 3) Place the precursor film in a tube furnace, and inject Ar and H 2 Mixed gas (Ar and H 2 The volume fractions are 96% and 4%, respectively) and sintered at 950°C for 120 minutes to obtain 10nm thick Ce 0.8 La 0.2 o 2 Single-layer transition layer film;

[0048] 4) Repeat step 2) coating and step 3) sintering process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com