A device and method for simultaneous generation of artificial and self-organized composite plasmonic photonic crystals

A plasma and photonic crystal technology, applied in the field of plasma application technology and optics, to achieve the effect of convenient use, easy maintenance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

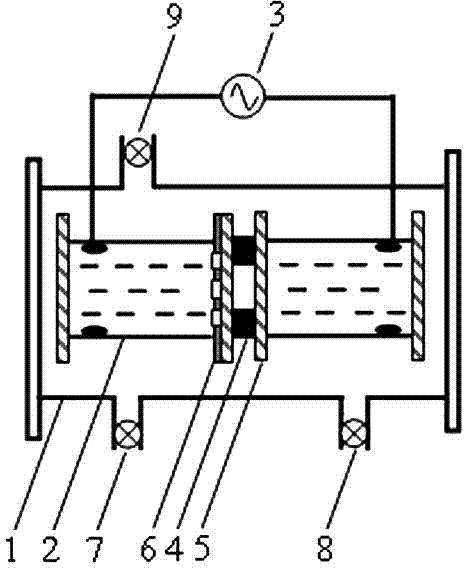

[0030] Such as figure 1 As shown, the device for simultaneously producing artificial and self-organized composite plasma photonic crystals of the present invention is to symmetrically arrange two airtight dielectric containers in a horizontal cylindrical vacuum reaction chamber 1, and inject water into the airtight dielectric containers to form Two water electrodes 2 opposite to each other, and the two water electrodes 2 are connected to a plasma generating power supply 3 . Water electrode 2 adopts the plexiglass tube that both sides use glass baffle plate as discharge medium plate 5 to seal and fill with water. The power lines of the plasma generating power supply 3 are respectively connected inside the two water electrodes 2 . An air inlet 7 and an air outlet 8 are provided on the wall of the vacuum reaction chamber 1 , and a pressure gauge 9 is also provided in the vacuum reaction chamber 1 for observing and adjusting the air pressure in the vacuum reaction chamber 1 .

...

Embodiment 2

[0038] refer to figure 1 Shown, the method for the present invention to produce artificial and self-organized composite plasma photonic crystals simultaneously is: a vacuum reaction chamber 1 is set, an air inlet 7 and an air outlet 8 are opened on its wall, and an air inlet 7 and an air outlet 8 are provided in the vacuum reaction chamber 1. An air pressure gauge 9 is provided for observing and adjusting the air pressure in the vacuum reaction chamber 1 . In the vacuum reaction chamber 1, two water electrodes 2 opposite to each other are arranged. The water electrode 2 adopts a plexiglass tube sealed with glass baffles on both sides as the discharge medium plate 5 and filled with water. The two water electrodes 2 are connected with the plasma The bulk power supply is connected in 3 phases. Among them, water is used as the electrode, and the glass baffle is used as the discharge medium.

[0039] A polyethylene plate 6 is bonded to the inner wall of the discharge dielectric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com