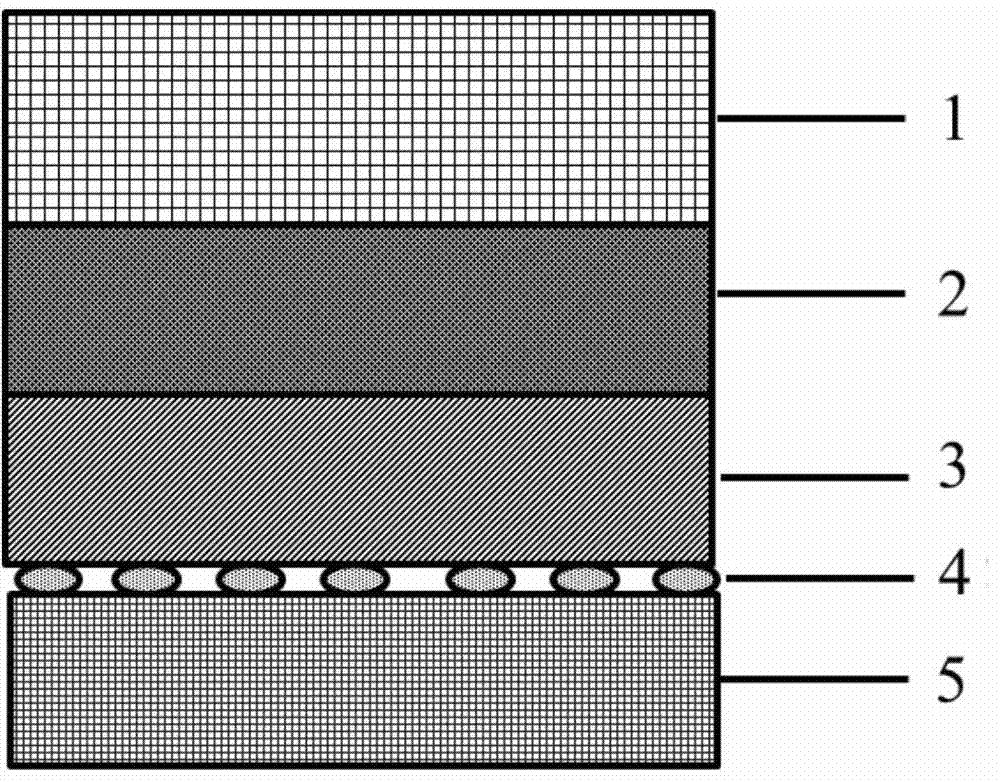

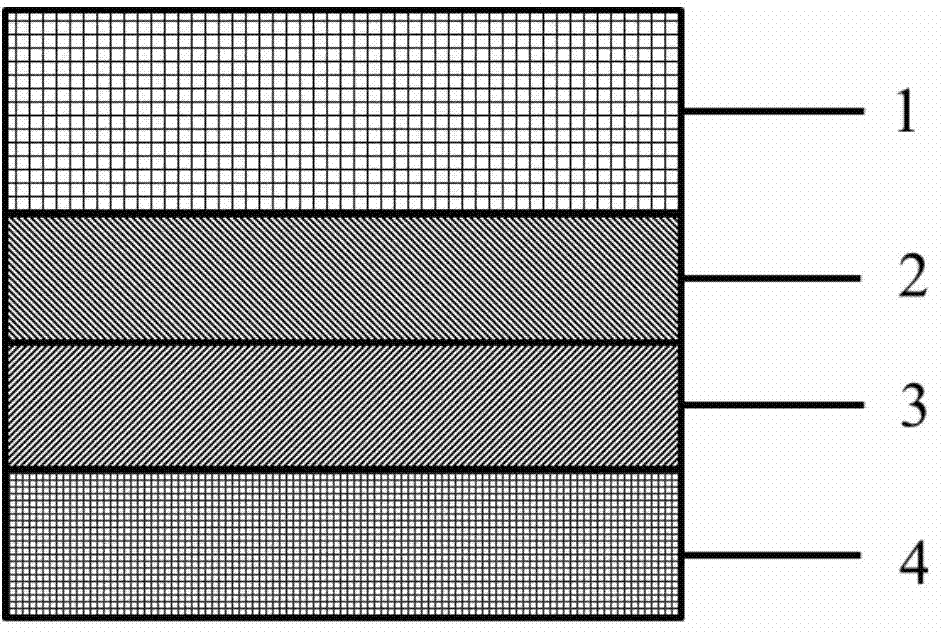

La2Zr2O7 transition-layer gradient film structure, preparation and application thereof

A technology of transition layer and thin film, which is applied in the direction of coating, liquid coating device on the surface, etc., to achieve the effect of smooth and compact surface, reducing complex transition layer structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

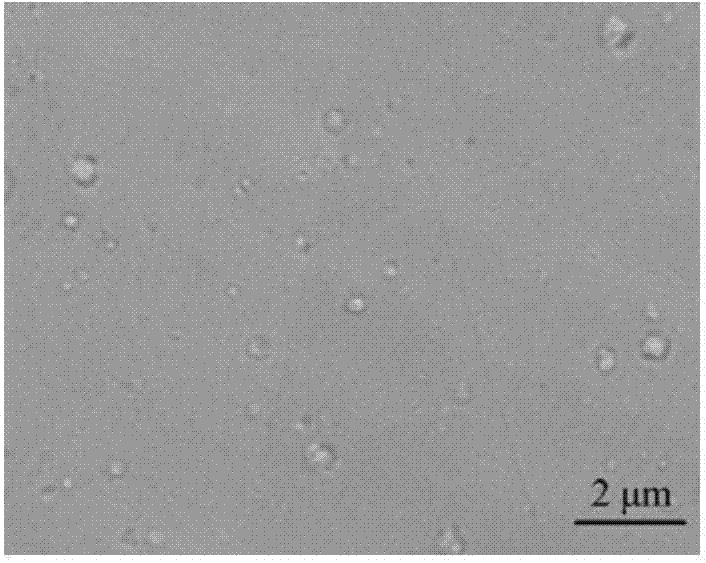

Examples

Embodiment 1

[0030] 1) Preparation of Ti-doped precursor solution: Titanium acetylacetonate and zirconium acetylacetonate, according to the molar ratio of titanium ions to zirconium ions is 1:9, where x=0.2, the total concentration of titanium ions and zirconium ions is 0.6mol / L, dissolved in propionic acid, and rotated and stirred at 40°C for 30 minutes to obtain a Ti-doped precursor solution;

[0031] 2) Preparation of Y-doped precursor solution: yttrium acetate and zirconium acetylacetonate, the molar ratio of yttrium ion to zirconium ion is 2:3, wherein, y=0.8, the total concentration of titanium ion and zirconium ion is 0.8mol / L, dissolved in propionic acid, and rotated and stirred at 40°C for 30 minutes to obtain a Y-doped precursor solution;

[0032] 3) Coating of the precursor solution: apply the Ti-doped precursor solution to the metal Ni substrate by spin coating to obtain the first layer of precursor film;

[0033] 4) High temperature sintering: in Ar4%H 2 Under the conditio...

Embodiment 2

[0037] 1) Preparation of Ti-doped precursor solution: Titanium acetylacetonate and zirconium acetylacetonate, according to the molar ratio of titanium ions to zirconium ions is 1:3, where x=0.5, the total concentration of titanium ions and zirconium ions is 0.6mol / L, dissolved in propionic acid, and rotated and stirred at 40°C for 30 minutes to obtain a Ti-doped precursor solution;

[0038] 2) Preparation of Y-doped precursor solution: yttrium acetate and zirconium acetylacetonate, the molar ratio of yttrium ion to zirconium ion is 1:1, where, y=1.0, the total concentration of titanium ion and zirconium ion is 1.0mol / L, dissolved in propionic acid, and rotated and stirred at 40°C for 30 minutes to obtain a Y-doped precursor solution;

[0039] 3) Coating of the precursor solution: apply the Ti-doped precursor solution to the metal Ni substrate by spin coating to obtain the first layer of precursor film;

[0040] 4) High temperature sintering: in Ar4%H 2 Under the condition ...

Embodiment 3

[0044] 1) Preparation of Ti-doped precursor solution: Titanium acetylacetonate and zirconium acetylacetonate, according to the molar ratio of titanium ions to zirconium ions is 1:1, where x=1.0, the total concentration of titanium ions and zirconium ions is 0.8mol / L, dissolved in propionic acid, and rotated and stirred at 40°C for 30 minutes to obtain a Ti-doped precursor solution;

[0045] 2) Preparation of Y-doped precursor solution: yttrium acetate and zirconium acetylacetonate, the molar ratio of yttrium ion to zirconium ion is 3:2, wherein, y=1.2, the total concentration of titanium ion and zirconium ion is 0.8mol / L, dissolved in propionic acid, and rotated and stirred at 40°C for 30 minutes to obtain a Y-doped precursor solution;

[0046] 3) Coating of the precursor solution: apply the Ti-doped precursor solution on the metal substrate by spin coating to obtain the first layer of precursor film;

[0047] 4) High temperature sintering: in Ar4%H 2 Under the condition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com