Simple preparation method for mordenite membrane with low silica-alumina ratio

A technology of mordenite and low silicon-to-aluminum ratio, which is applied in the field of simple preparation of low-silicon-to-aluminum ratio mordenite membranes, can solve problems such as small permeation flux, increased separation factor, and increased flux of zeolite membranes, achieving a smooth and compact surface, Highly repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

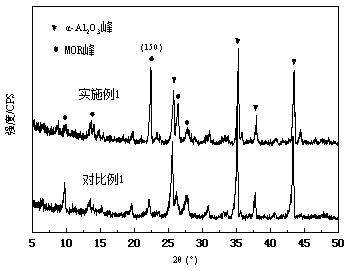

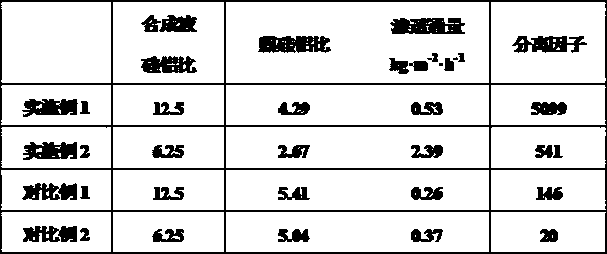

[0033] Divide deionized water into three parts, add sodium hydroxide to one part of deionized water to dissolve, slowly add silica sol to sodium hydroxide solution, stir for 14 hours to form silicon source precursor solution; add sodium metaaluminate to another part Dissolve in a portion of water to form an aluminum source precursor solution; slowly add the aluminum source precursor solution dropwise to the silicon source precursor solution under stirring, and stir at room temperature for 30 minutes; dissolve sodium fluoride in the last portion of deionized water, and add it to the aforementioned solution , stirred at room temperature for 2h to form a synthetic solution. The molar ratio of the synthetic solution is 10Na 2 O : 1.2Al 2 o 3 : 30SiO 2 : 780H 2 O: 15NaF. Soak the seed tube loaded with the seed crystal in deionized water for 20s, and put it at room temperature for 2h until there is no obvious water trace on the surface. After sealing the seed tube, put it in...

Embodiment 2

[0036] The crystal coating method is the same as in Example 1, except that the mother liquor molar ratio is 10Na 2 O : 2.4Al 2 o 3 : 30SiO 2 :780H 2 O: 15NaF. Soak the seed tube loaded with the seed crystal in deionized water for 20s, and put it at room temperature for 2h until there is no obvious water trace on the surface. After sealing the seed tube, put it in a stainless steel reaction kettle, add the synthesis mother liquor, and conduct hydrothermal synthesis at 150 ºC for 24 hours. After the synthesis, the membrane tube was washed to neutral and then dried.

[0037] The silicon-aluminum ratio of the zeolite membrane was measured by EDX. The mordenite membrane was used to separate 92 wt.% ethanol / water solution by pervaporation, and the permeation flux and separation factor of the zeolite membrane were tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com