Transition layer film with Gd mixed with CeO<2> and preparation method thereof

A transition layer and thin film technology, applied in the field of high temperature superconducting material preparation, achieves the effects of flat and compact surface, simple preparation process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) adding cerium acetate and gadolinium acetate into n-propionic acid, heating and stirring until dissolved, according to the molar ratio of cerium ion and gadolinium ion being 0.9:0.1, and the total concentration of cerium ion and gadolinium ion being 0.1mol / L, to obtain a precursor solution;

[0029] 2) Coating the precursor solution onto the NiW metal base tape by spin coating, the rotation speed is 2000rpm, and the time is 30s to obtain the precursor film;

[0030] 3) in H 2 Under gas protection conditions, the precursor film was sintered at 950 °C for 120 minutes to obtain a 30 nm thick Ce with cubic texture 0.9 Gd 0.1 o 2 Single transition layer film.

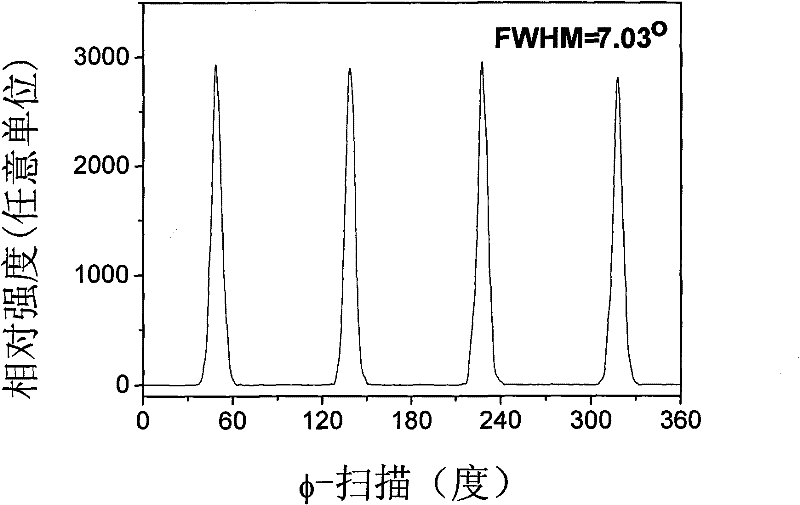

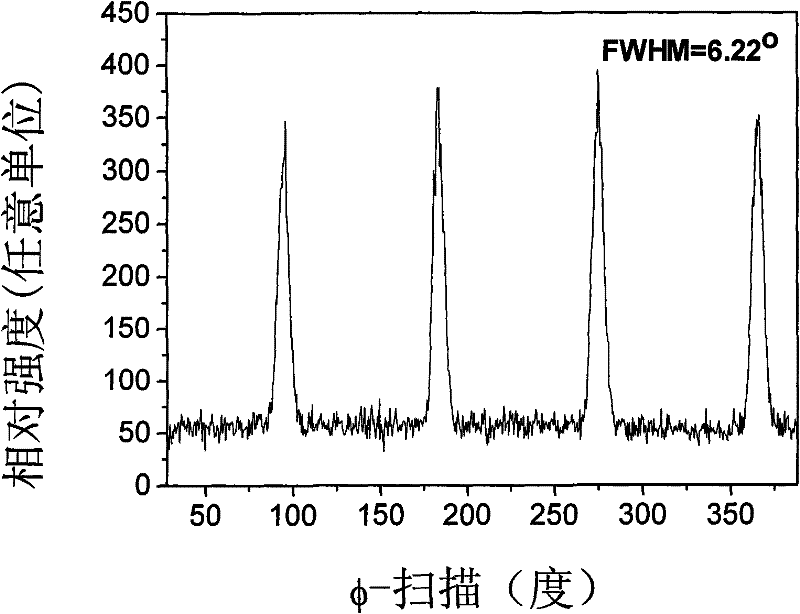

[0031] figure 1 It is the phi scanning diagram of the NiW alloy substrate (111) surface used, figure 2 for Ce 0.9 Gd 0.1 o 2 The (111) plane phi scan of the transition layer film has a FWHM (width at half maximum) of 6.22, which is 0.81 smaller than that of the NiW baseband, indicating that the Ce 0.9 Gd ...

Embodiment 2

[0033] 1) Add cerium acetate and gadolinium acetate to n-propionic acid, heat and stir until dissolved, according to the molar ratio of cerium ion to gadolinium ion is 0.8:0.2, and the total concentration of cerium ion and gadolinium ion is 0.4mol / L, to obtain a precursor solution ;

[0034] 2) Coating the precursor solution onto the NiW metal base tape by spin coating, the rotation speed is 5000rpm, and the time is 120s to obtain the precursor film;

[0035] 3) in H 2 Mixing with Ar (H 2 The volume percentages of Ar and Ar are 5% and 95%, respectively) under gas protection conditions, the precursor film was sintered at 1200 ° C for 15 minutes to obtain a 60nm thick Ce with cubic texture 0.8 Gd 0.2 o 2 Single transition layer film.

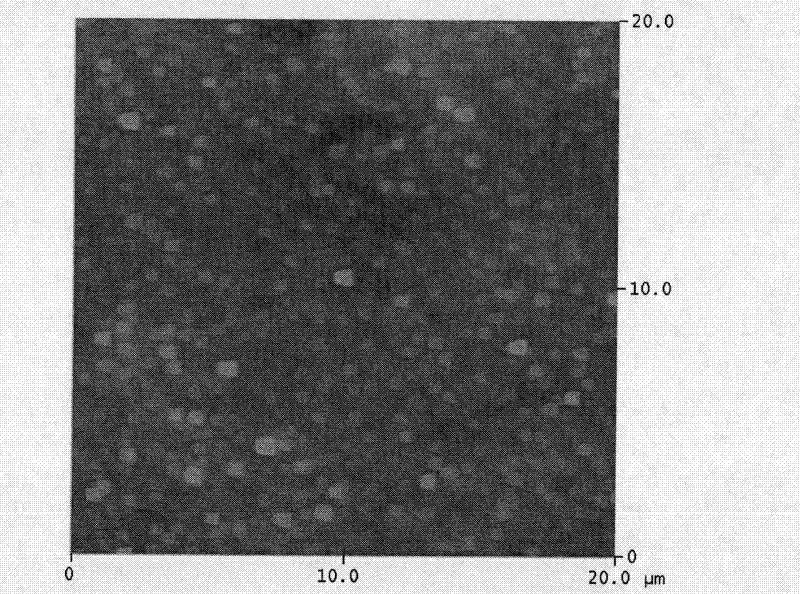

[0036] Ce 0.8 Gd 0.2 o 2 The surface morphology of the single-layer transition layer film is as follows: image 3 It can be seen from the AFM photo that the surface of the transition layer is flat and dense, the grains are fine and unifor...

Embodiment 3

[0038] 1) Add cerium acetate and gadolinium acetate to n-propionic acid, heat and stir until dissolved, at a molar ratio of cerium ions to gadolinium ions of 0.5:0.5, and a total concentration of cerium ions and gadolinium ions of 0.3 mol / L, to obtain a precursor solution ;

[0039]2) Coating the precursor solution onto the NiW metal substrate by dipping method, pulling the NiW metal substrate at a speed of 150 mm / min to obtain a precursor film;

[0040] 3) in N 2 Under gas protection conditions, the precursor film was sintered at 1150 °C for 60 minutes to obtain a 50 nm thick Ce with cubic texture 0.5 Gd 0.5 o 2 Single-layer transition layer film;

[0041] 4) Multi-layer coating: repeat steps 2) and 3) 4 times to obtain a Ce with a thickness of 250nm 0.5 Gd 0.5 o 2 5-layer transition layer film.

[0042] Ce 0.5 Gd 0.5 o 2 The XRD pattern of the five-layer transition layer film is as follows Figure 4 It can be seen from the figure that no impurity phase is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com