Method for enlarging metal interconnected lithography process window

A photolithography process and metal interconnection technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of metal interconnection failure, limited photolithography process window, collapse, etc., and achieve the goal of reducing the square resistance value Differences, expanding the photolithography process window, and improving the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

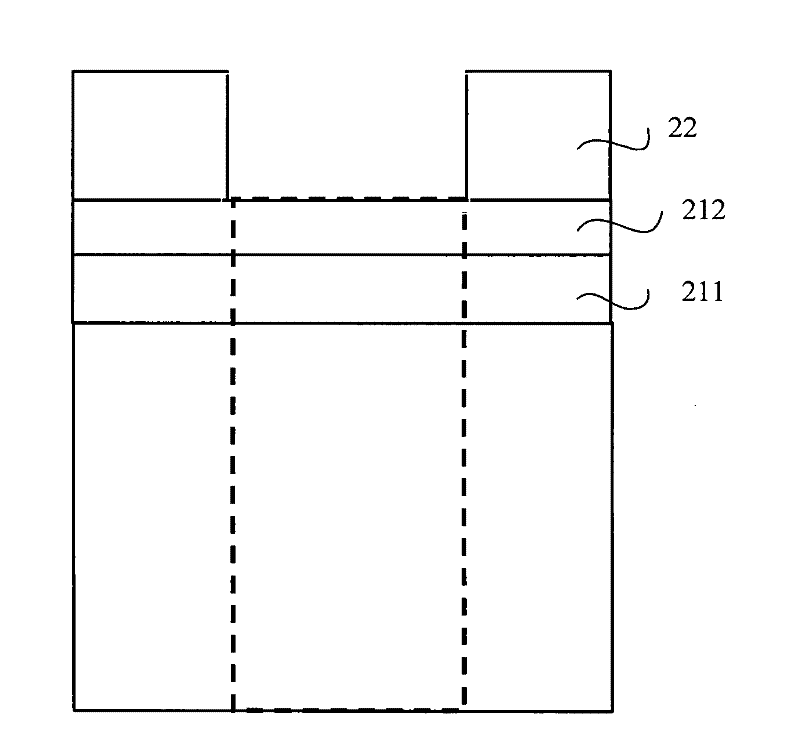

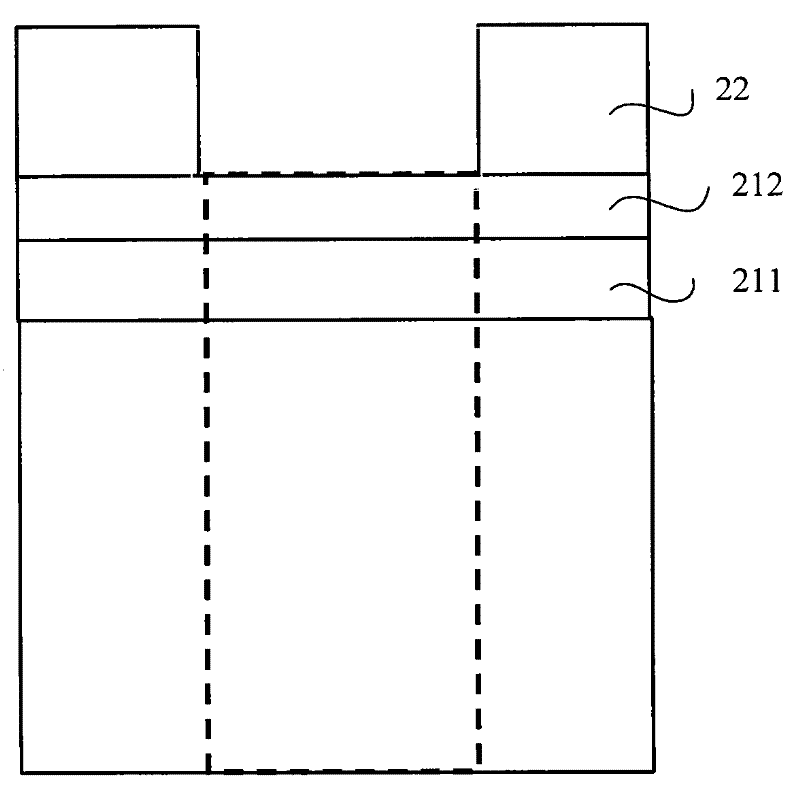

[0011] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] As mentioned in the background art, the adhesion between the low-temperature oxide layer and the organic bottom anti-reflective coating in the prior art is not high enough. After exposure with a smaller line width, it may cause damage to the organic bottom anti-reflective coating. Excessive corrosion will cause the photoresist pattern on the organic bottom anti-reflective coating to fail to maintain and collapse, resulting in the failure of the subsequently formed metal interconnection.

[0013] The core idea of the present invention is that by treating the surface of the low-temperature oxide layer with active gas plasma, the surface of the low-temperature oxide layer becomes flatter and denser, and the adhesion between the low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com