Method for magnetron sputtering deposition of aluminum film for surface protection of NdFeB workpiece

A magnetron sputtering, workpiece surface technology, applied in sputtering plating, metal material coating process, ion implantation plating and other directions, can solve the problems of film performance influence, achieve uniform thickness, smooth and dense surface, bonding force excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

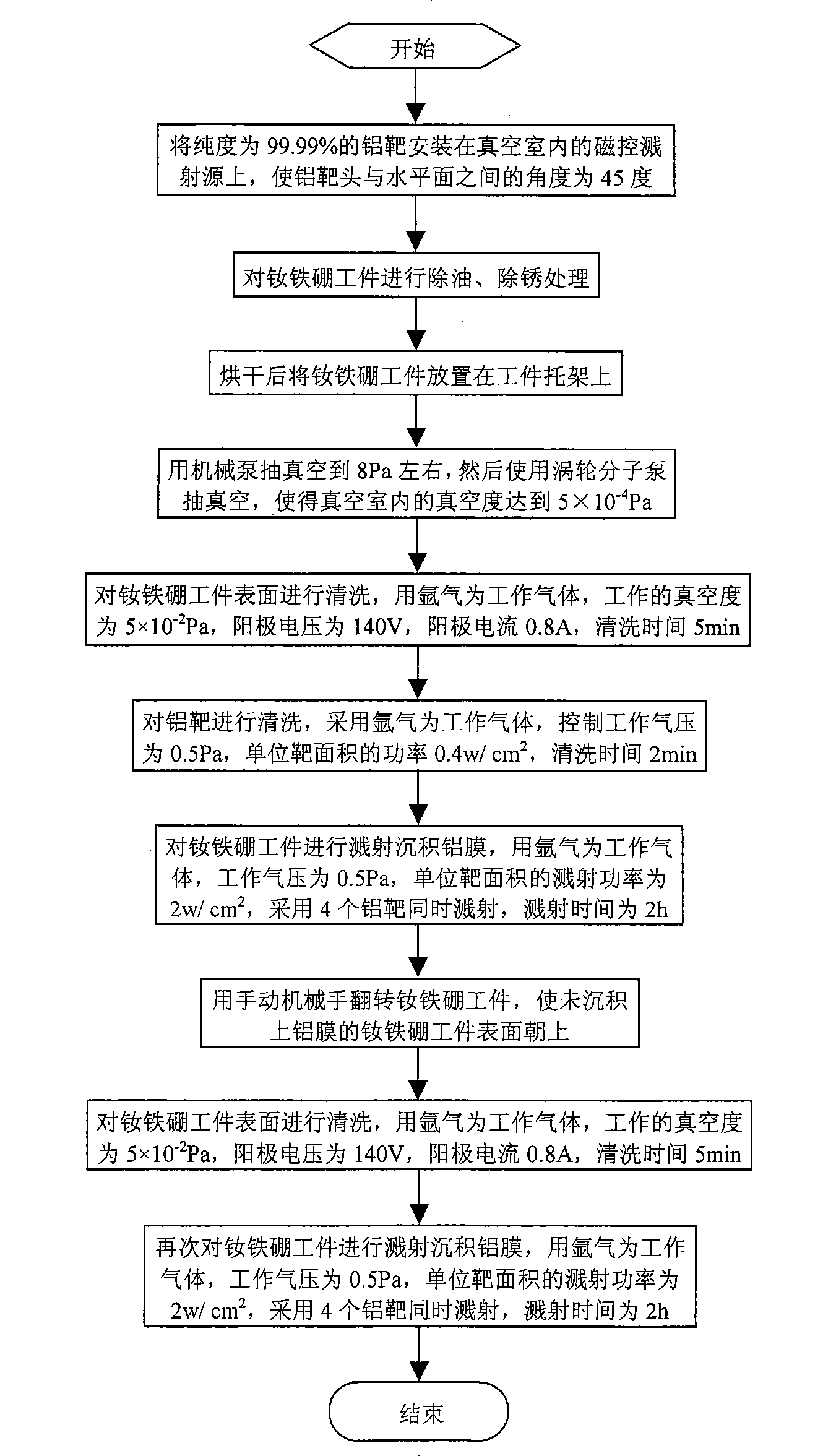

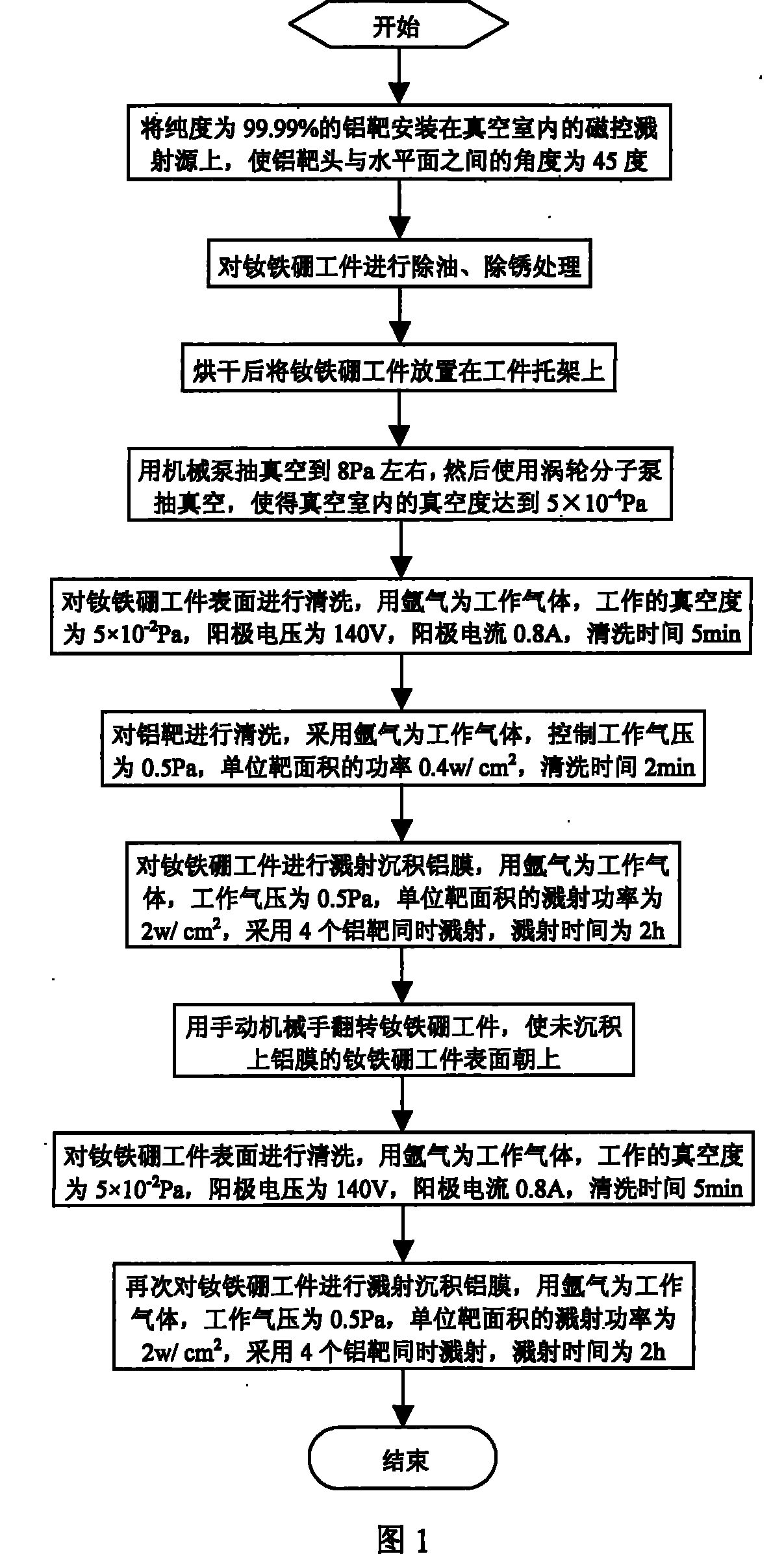

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The method for depositing an aluminum film by magnetron sputtering for surface protection of NdFeB workpieces provided by the present invention, the magnetron sputtering device adopted includes a vacuum chamber, a magnetron sputtering source, an ion source and a workpiece bracket, and the magnetron The sputtering source and ion source are installed on the top of the vacuum chamber in a sealed connection structure, and the target head connected to the magnetron sputtering source extends into the vacuum chamber, and the connecting shaft between the target head and the magnetron sputtering target is rotatably connected , the workpiece bracket is installed on the bottom of the vacuum chamber, and the side of the vacuum chamber is equipped with a manual manipulator for turning over the workpiece. The method for depositing an aluminum film by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com