Sputtering deposition method of flexible AZO transparent conductive film at room temperature

A transparent conductive film, sputtering deposition technology, applied in sputtering plating, ion implantation plating, metal material coating process and other directions, can solve the problems of low optical area transmittance, small grain size, easy deformation and so on , to achieve the effect of simple process operation, good crystallization performance, compact and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

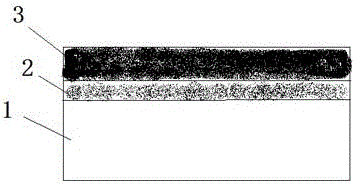

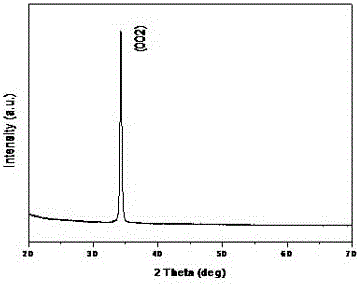

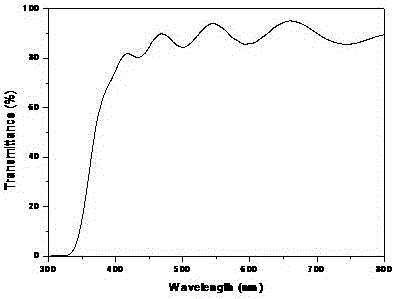

[0017] A polycarbonate (PC) film with a thickness of 0.3 mm was selected as the substrate, and the substrate was ultrasonically cleaned with acetone and absolute ethanol for 20 min, and deionized water for 15 min, and then dried and placed on the substrate holder , and the movable baffle is placed between the substrate and the target; the homogeneous buffer layer and the main layer are made of AZO ceramics with a mass ratio of aluminum oxide to zinc oxide of 2:98 as the target material, and the mechanical pump and molecular Pump vacuum to 5×10 -3 Pa, then fill the working gas with high-purity argon (99.99%) until the pressure of the vacuum chamber is 0.5 Pa, turn on the DC power supply for pre-sputtering for 15 minutes; open the movable baffle, and deposit AZO homogeneous buffer layer by DC magnetron sputtering, The sputtering conditions were as follows: sputtering power was 80 W, working pressure was 0.5 Pa, target base distance was 12 cm, substrate temperature was room temp...

Embodiment 2

[0019] A PC film with a thickness of 0.3 mm was selected as the substrate, and the substrate was ultrasonically cleaned with acetone and absolute ethanol for 20 min, and then with deionized water for 15 min. The plate is placed between the substrate and the target material; the homogeneous buffer layer and the main body layer use AZO ceramics with a mass ratio of aluminum oxide to zinc oxide of 2:98 as the target material, and turn on the mechanical pump and the molecular pump to evacuate to 5 ×10 -3 Pa, then fill the working gas with high-purity argon (99.99%) until the vacuum chamber pressure is 0.5 Pa, turn on the DC power supply for pre-sputtering for 15 minutes; open the movable baffle, and deposit AZO homogeneous buffer layer by DC magnetron sputtering, The sputtering conditions were as follows: sputtering power was 80 W, working pressure was 0.5 Pa, target base distance was 12 cm, substrate temperature was room temperature, sputtering time was 5 min, and the movable ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com