Iron-based amorphous alloy strip and preparation method thereof

An iron-based amorphous alloy and strip technology, which is applied in the direction of magnetic materials, manufacturing tools, heat treatment equipment, etc., can solve the problems of increased iron content, reduced spraying time, and reduced yield, so as to achieve a dense and smooth surface, High saturation magnetic induction intensity, the effect of reducing soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present application also provides a method for preparing the above-mentioned iron-based amorphous alloy strip, comprising the following steps:

[0047] A) smelting and refining after batching according to the composition of the iron-based amorphous alloy shown in formula (I), to obtain molten steel;

[0048] B) performing single-roll rapid quenching on the molten steel, and then performing heat treatment to obtain an iron-based amorphous alloy strip;

[0049] In the process of single-roll rapid quenching, the roughness of the cooling roll surface is 0.1-0.5 μm;

[0050] Fe a Si b B c C d m f (I);

[0051] Wherein, M is a trace element;

[0052] a, b, c, d and f correspond to the atomic percentage of each element, 81.0≤a≤83.0, 0.5≤b≤6.5, 12.0≤c≤14.5, 0.1≤d≤1.3, f≤0.4, a+b +c+d+f=100.

[0053] In the process of preparing iron-based amorphous alloy strips, the applicant first smelts and refines the ingredients according to the ingredients of the iron-based am...

Embodiment 1

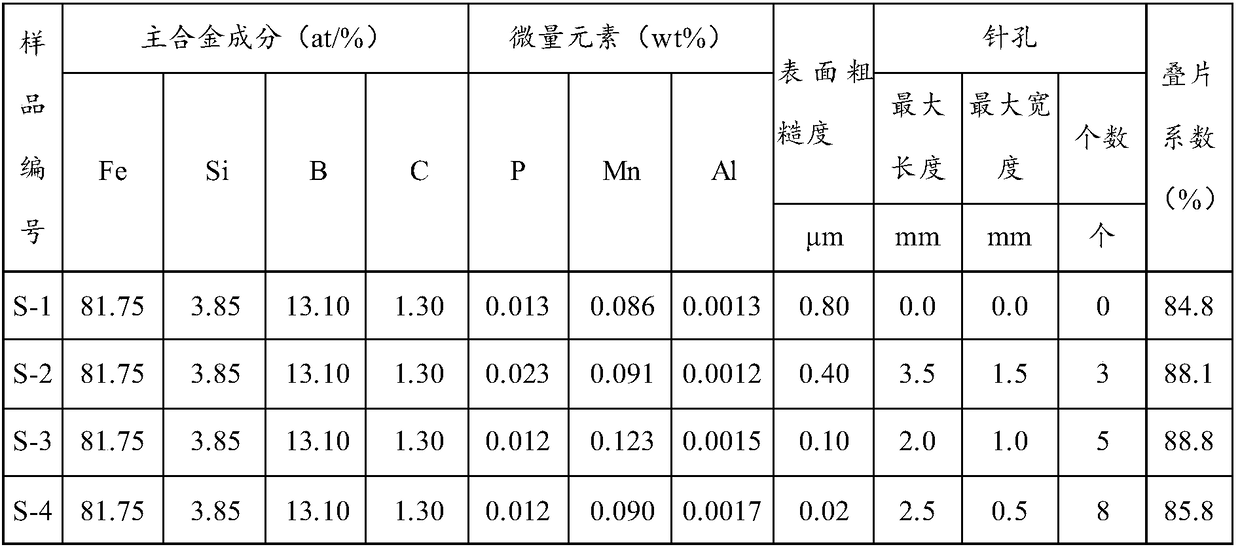

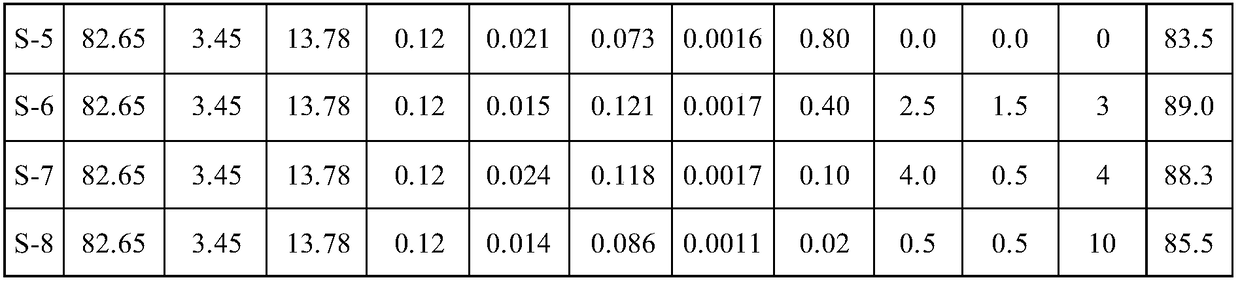

[0063] The present invention respectively according to Fe 81.75 Si 3.85 B 13.1 C 1.3 and Fe 82.65 Si 3.45 B 13.78 C 0.12 The alloy composition is smelted, and the iron-based amorphous strip with a width of 170mm and a thickness of 28μm is prepared; in the production process, the cooling roll needs to be pre-grinded after turning-coarse grinding and then fine grinding, and the roll surface after pre-grinding The surface flatness gradually increases and the roughness gradually decreases. During the belt spraying process, the online grinding stage is carried out. In this stage, only fine grinding is carried out, so that the roller surface has a surface roughness of 0.1-0.5μm in the entire rotation cycle and width range. degree (the specific surface roughness is shown in Table 1); when grinding, the grinding wheel swings perpendicular to the feeding direction. Table 1 lists the relationship data table between the number of pinholes on the surface and the strip lamination co...

Embodiment 2

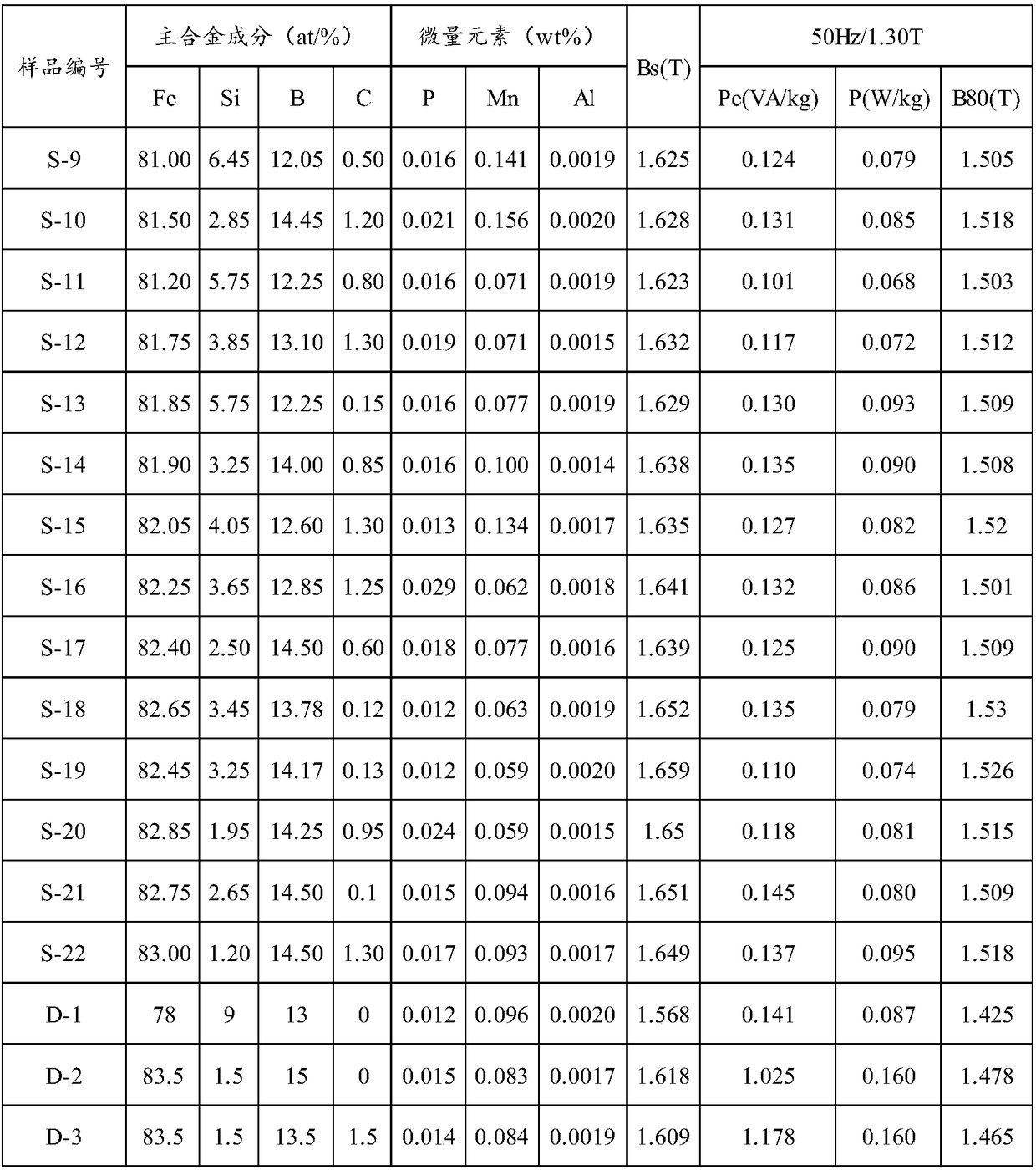

[0069] The present invention presses Fe a Si b B c C d m fRaw materials such as iron source and metal silicon, ferroboron and other raw materials with different proportions are remelted in intermediate frequency smelting furnaces. After the smelting is completed, the steel is tapped to the intermediate frequency bottom furnace. The iron-based amorphous broadband with a width of 240 mm and a thickness of 26 to 30 μm is prepared by using the method used; in the production process, the cooling roll needs to be pre-grinded after turning-coarse grinding and then finely ground, and the surface flatness of the roll surface is gradually reduced after pre-grinding increase, the roughness gradually decreases, and the on-line grinding stage is carried out during the belt spraying process. In this stage, only fine grinding is carried out, so that the roller surface has a surface roughness of 0.1-0.5 μm in the entire rotation cycle and width range; during grinding , the grinding wheel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com