Method for preparing molybdenum dioxide coated lithium titanate negative electrode material

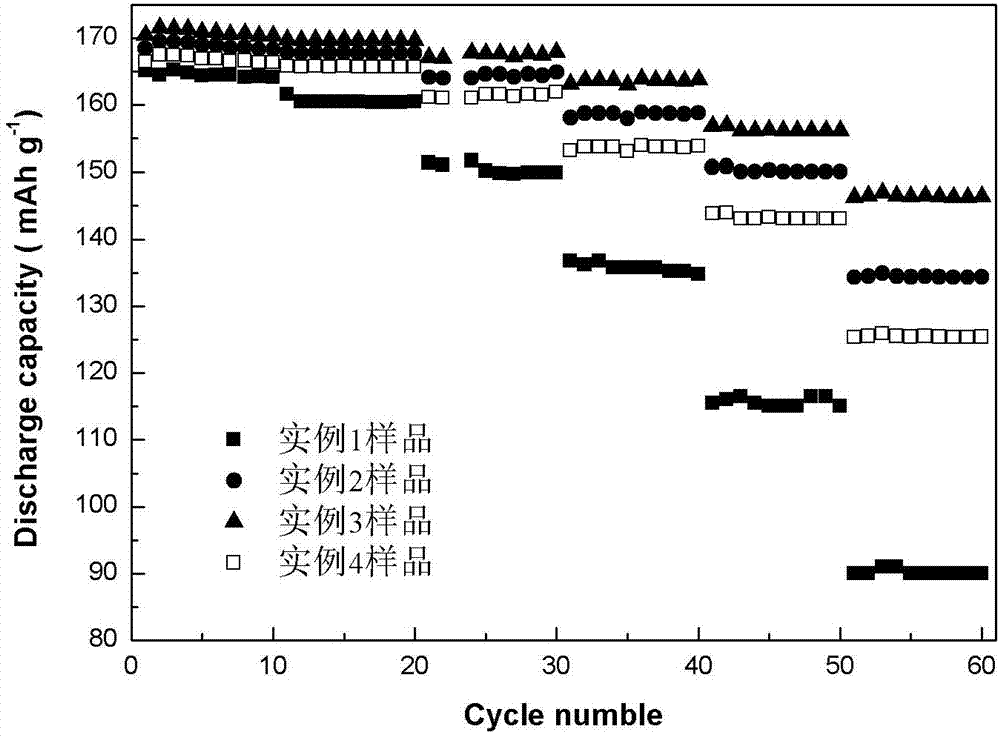

A technology of coating lithium titanate and molybdenum dioxide, which is applied to battery electrodes, electrical components, circuits, etc., can solve problems such as poor electronic conductivity, and achieve high rate performance, good cycle performance, and uniform grain distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Li 4 Ti 5 o 12 Preparation of negative electrode materials

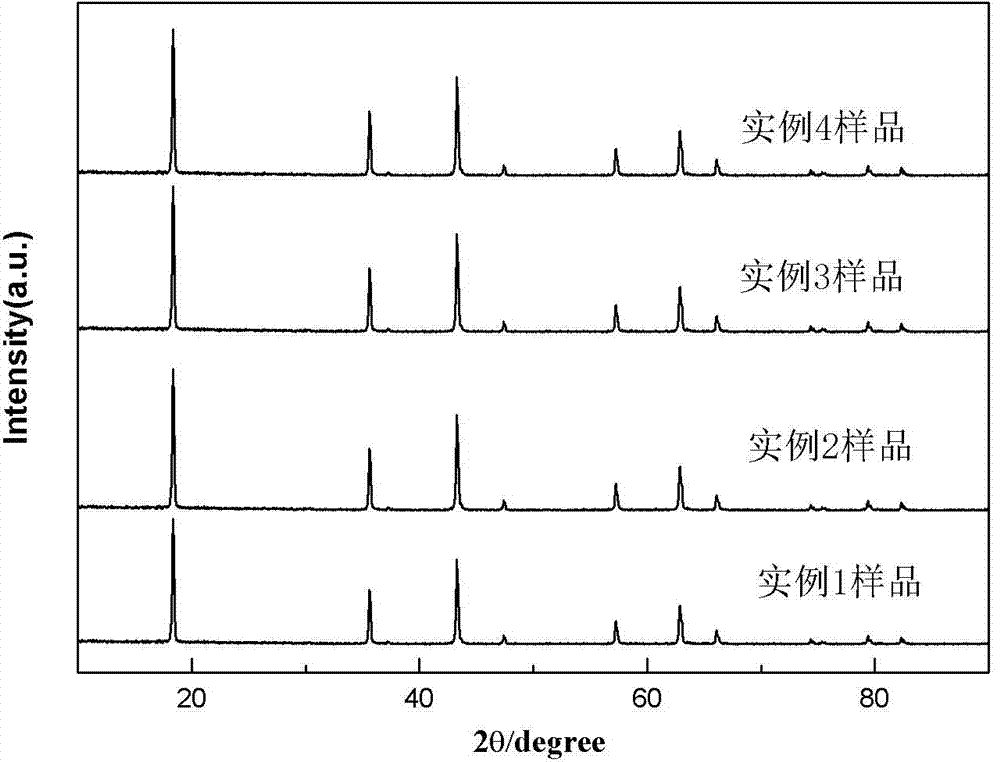

[0026] Weigh 0.06mol lithium acetate and 1.5g polyvinylpyrrolidone (PVP), dissolve them in 500mL distilled water; add 0.075mol nano-titanium dioxide, and stir magnetically for 1 hour to obtain a slurry; spray dry the slurry at 110°C to obtain a lithium titanate precursor ; The lithium titanate precursor was calcined at 750° C. for 8 hours in an air atmosphere to obtain a pure lithium titanate negative electrode material. X-ray diffraction pattern see figure 1 .

Embodiment 2

[0028] 2% molybdenum dioxide coated Li 4 Ti 5 o 12 Preparation of negative electrode materials

[0029] Weigh 0.06mol lithium acetate and 1.5g polyvinylpyrrolidone (PVP), dissolve them in 500mL distilled water; add 0.075mol nano-titanium dioxide, and stir magnetically for 1 hour to obtain a slurry; spray dry the slurry at 110°C to obtain a lithium titanate precursor ; The lithium titanate precursor was roasted at 750°C for 8 hours in an air atmosphere to obtain a pure lithium titanate negative electrode material; weigh 0.216g ammonium molybdate and 0.005mol tartaric acid, dissolve them in 500mL distilled water; add pure lithium titanate negative electrode material , magnetic stirring for 1 h; after evaporating the solvent at 100°C, vacuum drying at 80°C for 1 h to obtain the molybdenum dioxide-coated lithium titanate precursor; Calcined for 6 hours at the bottom to obtain molybdenum dioxide-coated lithium titanate negative electrode material. X-ray diffraction pattern see ...

Embodiment 3

[0031] 4% molybdenum dioxide coated Li 4 Ti 5 o 12 Preparation of negative electrode materials

[0032] Weigh 0.06mol lithium acetate and 1.5g polyvinylpyrrolidone (PVP), dissolve them in 500mL distilled water; add 0.075mol nano-titanium dioxide, and stir magnetically for 1 hour to obtain a slurry; spray dry the slurry at 110°C to obtain a lithium titanate precursor ;The lithium titanate precursor was roasted at 750°C for 8 hours in an air atmosphere to obtain a pure lithium titanate negative electrode material; weighed 0.443g ammonium molybdate and 0.005mol tartaric acid, dissolved in 500mL distilled water; added pure lithium titanate negative electrode material , magnetic stirring for 1 h; after evaporating the solvent at 100°C, vacuum drying at 80°C for 1 h to obtain the molybdenum dioxide-coated lithium titanate precursor; Calcined for 6 hours at the bottom to obtain molybdenum dioxide-coated lithium titanate negative electrode material. X-ray diffraction pattern see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com