High-performance calcium sulfonate complex grease and preparation method thereof

A technology of composite calcium sulfonate and high base value calcium sulfonate, which is applied in the field of metallurgical grease, can solve the problems of poor high temperature performance, reduced total surface area of particle phase, low sintering load of grease, etc., and achieve extreme pressure and anti-wear performance Excellent, solve the problem of surface hardening, the effect of stable product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

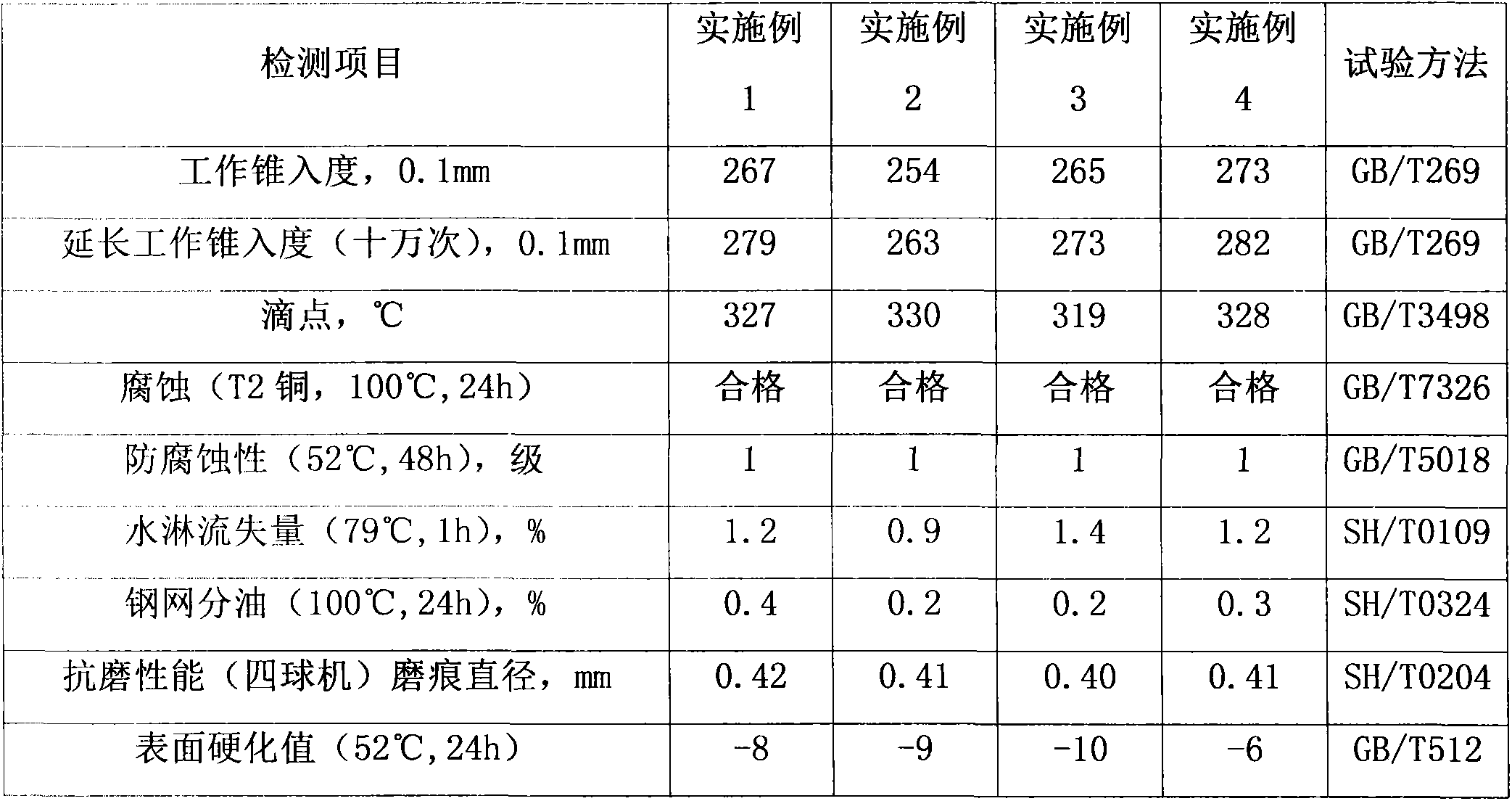

Examples

Embodiment 1

[0047] A preparation method of high-performance composite calcium sulfonate-based grease, comprising the steps of:

[0048] 1) Put 2409 base oil 150BS and 4239 high base value calcium sulfonate (TBN: 350mgKOH / g) in a reaction kettle, heat to 80-90°C, and keep stirring in this temperature range for 40min;

[0049] 2) Add 639 g of lauric acid, 5 g of methanol, 15 g of ethanol and 70 g of high-purity water to the mixture obtained in step 1), and keep stirring continuously at 80-90 ° C until the conversion is complete (detected by infrared spectroscopy);

[0050] 3) After the conversion is completed, heat up the tough material obtained in step 2) to 100-110°C, add 2.8g of boric acid and 5.7g of calcium hydroxide in sequence, and continue stirring for 30 minutes; then continue to heat up to 200-210°C, and add 2.4g of dihydrogen Aniline is used as an antioxidant, and stirred for 10min;

[0051] 4) Naturally cool the material obtained in step 3) to 90-100°C, and add 0.2g of HL-funct...

Embodiment 2

[0055] A preparation method of high-performance composite calcium sulfonate-based lubricating grease, comprising the steps of:

[0056] 1) Put 2409 base oil 150BS and 4239 high base value calcium sulfonate (TBN: 350mgKOH / g) in a reaction kettle, heat to 80-90°C, and keep stirring in this temperature range for 40min;

[0057] 2) Add 639 lauric acid, 229 ethanol and 709 high-purity water to the mixture obtained in step 1), and keep stirring continuously at 80-90°C until the conversion is complete (detected by infrared spectroscopy);

[0058]3) After the conversion is completed, heat up the material obtained in step 2) to 100-110°C, add 2.8g of boric acid and 5.7g of calcium hydroxide in sequence, and continue stirring for 30 minutes; then continue to heat up to 200-210°C, and add 2.4g of diphenylamine As an antioxidant, and stirred for 10 minutes;

[0059] 4) Naturally cool the material obtained in step 3) to 90-100°C, and add 0.2g of HL-functional agent;

[0060] 5) Finished ...

Embodiment 3

[0063] A preparation method of high-performance composite calcium sulfonate-based lubricating grease, comprising the steps of:

[0064] 1) Put 2409 base oil 150BS and 4239 high base value calcium sulfonate (TBN: 400mgKOH / g) in a reaction kettle, heat to 80-90°C, and keep stirring in this temperature range for 40min;

[0065] 2) Add 639 g of lauric acid, 5 g of methanol, 15 g of ethanol and 70 g of high-purity water into the mixture obtained in step 1), and keep fully and continuously stirring at 80-90 ° C, and react until the conversion is complete (detected by infrared spectroscopy);

[0066] 3) After the conversion is completed, heat up the material obtained in step 2) to 100-110°C, add 2.8g of boric acid and 5.7g of calcium hydroxide in sequence, and continue stirring for 30 minutes; then continue to heat up to 200-210°C, and add 2.4g of diphenylamine As an antioxidant, and stirred for 10 minutes;

[0067] 4) Naturally cool the material obtained in step 3) to 90-100°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com