Nanometer tungsten powder and method for preparing nanometer tungsten powder by adoption of sol-gel hydrogen reduction method

A nano-tungsten powder, sol-gel technology, applied in the field of tungsten materials, can solve the problems of difficult operation and high equipment requirements, and achieve the effects of easy operation, uniform grain distribution and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Dosage: Add 196.67g of ammonium tungstate and 314.74g of citric acid to 500mL of distilled water; in the present invention, the ratio of ammonium tungstate (chemically pure) and citric acid (chemically pure) is 1:1.1 according to the ratio of metal ion to citrate Measure and weigh.

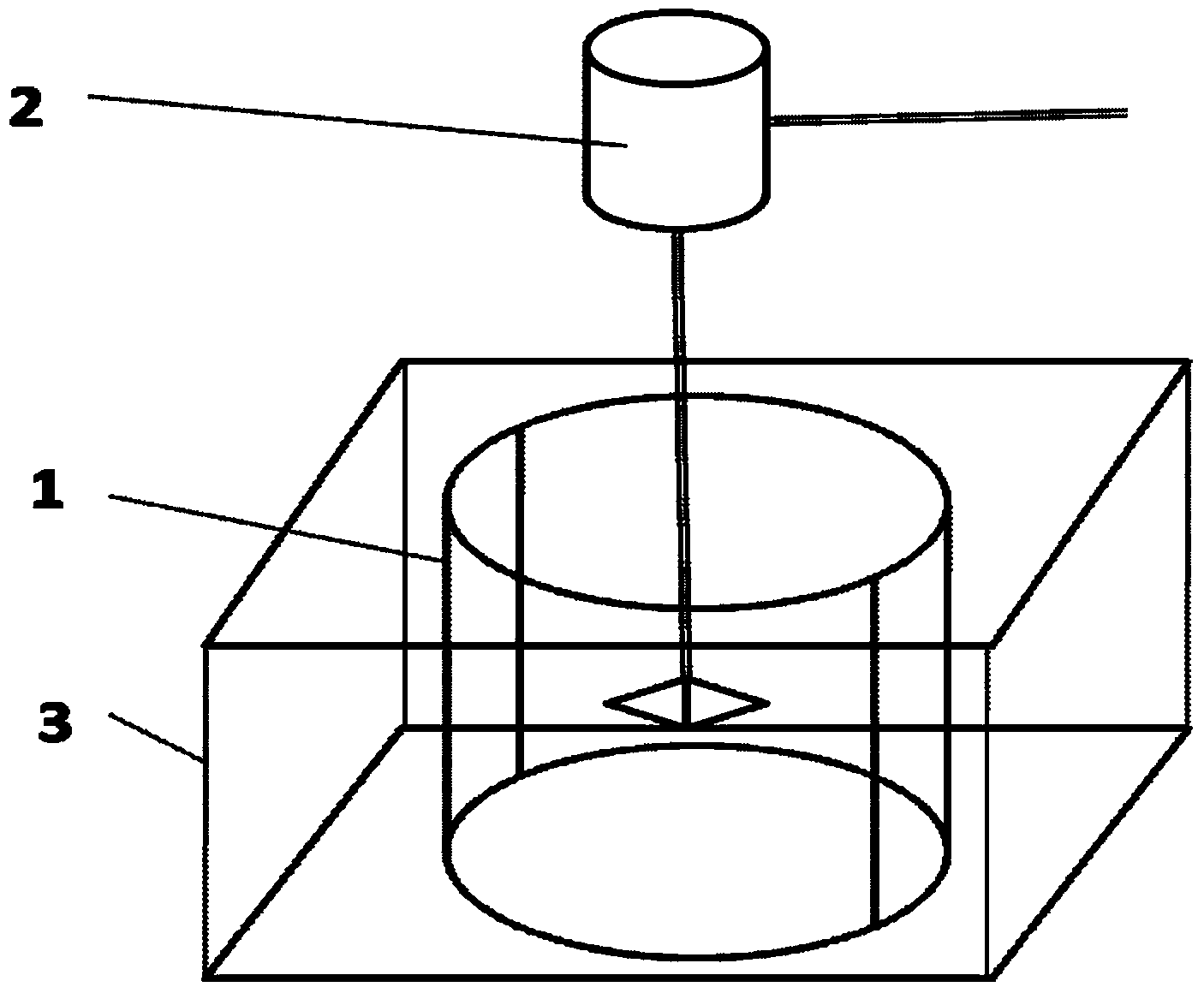

[0060] see figure 1 As shown, then pour the weighed ammonium tungstate and citric acid into the reaction vessel 1 filled with distilled water, stir with the stirrer 2 at a stirring speed of 120 rpm, and detect the solution after the ammonium tungstate and citric acid are dissolved When the pH value is lower than 6, use ammonia water (purchased in the market) to adjust the pH ≈ 6. Then turn on the constant temperature heater 3, set the temperature at 80°C, and stir continuously at the same time to form a wet gel with a complex structure through evaporation and polycondensation.

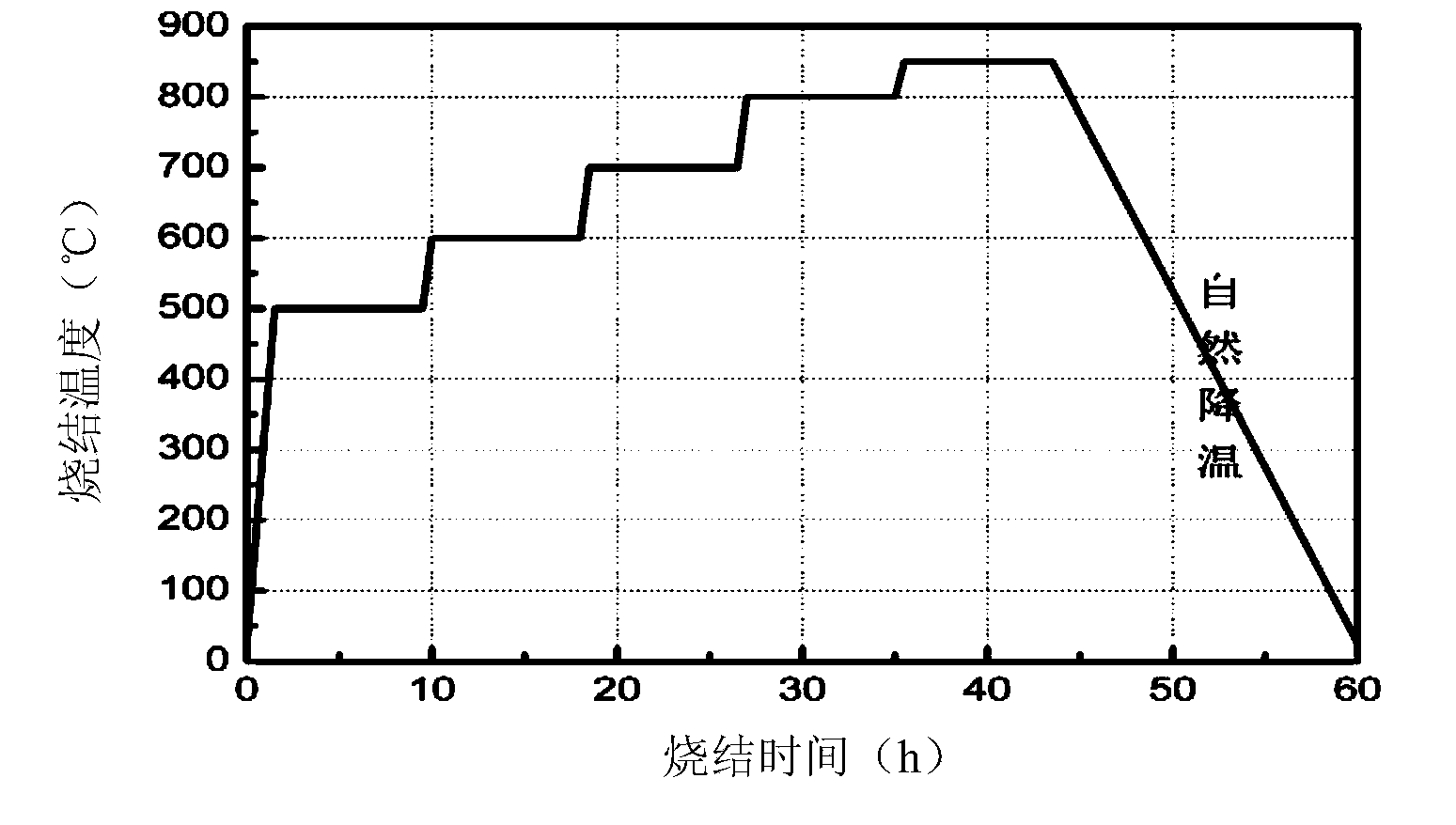

[0061] When the wet gel turns into a viscous paste, take it out and put it in an evaporating dish. Place the we...

Embodiment 2

[0076] Dosage: Add 150.0g of ammonium tungstate and 240.05g of citric acid to 500mL of distilled water.

[0077] see figure 1 As shown, then pour the weighed ammonium tungstate and citric acid into the reaction vessel 1 filled with distilled water, stir with the stirrer 2 at a stirring speed of 100 rpm, and detect the solution after the ammonium tungstate and citric acid are dissolved When the pH value is lower than 6, use ammonia water (purchased in the market) to adjust the pH to 6.5. Then turn on the constant temperature heater 3, set the temperature at 85°C, and stir continuously at the same time to form a wet gel with a complex structure through evaporation and polycondensation.

[0078] When the wet gel turns into a viscous paste, take it out and put it in an evaporating dish, place the wet gel and evaporating dish together in a drying oven, set the temperature at 110°C, and after drying for 20 hours, when the moisture is removed It turns into a porous xerogel.

[007...

Embodiment 3

[0093] Dosage: Add 170.0g of ammonium tungstate and 272.06g of citric acid to 500mL of distilled water.

[0094] see figure 1 As shown, then pour the weighed ammonium tungstate and citric acid into the reaction vessel 1 filled with distilled water, stir with the stirrer 2 at a stirring speed of 150 rpm, and detect the solution after the ammonium tungstate and citric acid are dissolved When the pH value is lower than 6, use ammonia water (purchased in the market) to adjust the pH to 6.2. Then turn on the constant temperature heater 3, set the temperature at 75° C., and keep stirring at the same time to form a wet gel with a complex structure through evaporation and polycondensation.

[0095] When the wet gel turns into a viscous paste, take it out and put it in an evaporating dish, place the wet gel and the evaporating dish together in a drying oven, set the temperature at 100°C, and dry for 48 hours, when the moisture is removed It turns into a porous xerogel.

[0096] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com