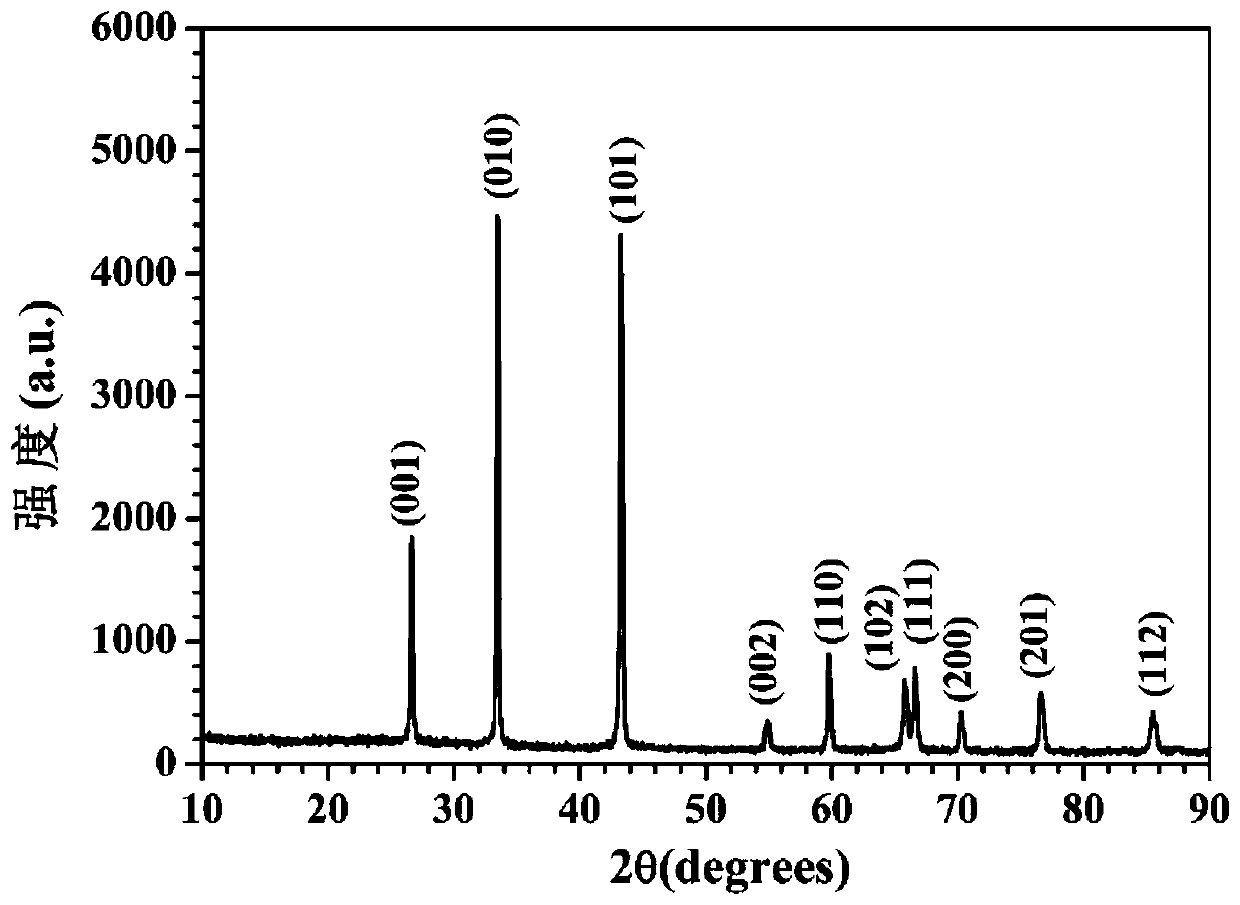

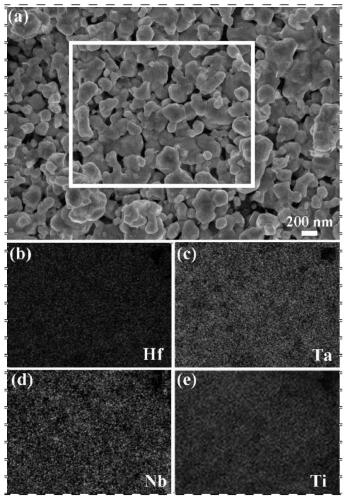

(Hf,Ta,Nb,Ti)B2 high-entropy ceramic powder and preparing method thereof

A ceramic powder and high-entropy technology, which is applied in the field of high-entropy material preparation, can solve the problems of low purity, low sintering activity of powder, high oxygen content of high-entropy borides, etc. The effect of small, low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A (Hf,Ta,Nb,Ti)B 2 The preparation of high-entropy ceramic powder includes the following steps:

[0027] (1) Weigh 1.05g of HfO respectively 2 Powder, 0.40g TiO 2 Powder, 1.10g Ta 2 O 5 Powder, 0.66g of Nb 2 O 5 Powder, 0.42g of C powder and 0.72g of B 4 C powder was placed in a 150ml teflon ball mill and added 56.00g ZrO 2 Ball mill (the molar ratio of Hf, Ti, Nb and Ta in the raw material is 1:1:1:1, and the TiO in the raw material is 2 Powder, HfO 2 Powder, Nb 2 O 5 Powder and Ta 2 O 5 The molar ratio of the total amount of powder to C powder is 1:2.33, TiO 2 Powder, HfO 2 Powder, Nb 2 O 5 Powder and Ta 2 O 5 The total amount of powder and B 4 The molar ratio of C powder is 1:0.87, and the mass ratio of ball mill beads to raw materials is 12.9:1). The ball mill tank is placed in a ball mill and ball milled at a speed of 400r / min for 13h to obtain mixed powder;

[0028] (2) put the mixed powder obtained in the step (1) into a graphite crucible wit...

Embodiment 2

[0031] A (Hf, Ta, Nb, Ti,) B 2 The preparation of high-entropy ceramic powder includes the following steps:

[0032] Weigh 1.05g of HfO respectively 2 Powder, 0.40g TiO 2 Powder, 1.10g Ta 2 O 5 Powder, 0.66g Nb 2 O 5 Powder, 0.42g of C powder and 0.66g of B 4 C powder was placed in a 150ml teflon ball mill and 21.45g ZrO was added 2 Ball mill (the molar ratio of Hf, Ti, Nb and Ta in the raw material is 1:1:1:1, and the TiO in the raw material is 2 Powder, HfO 2 Powder, Nb 2 O 5 Powder and Ta 2 O 5 The molar ratio of the total amount of powder to C powder is 1:2.33, TiO 2 Powder, HfO 2 Powder, Nb 2 O 5 Powder and Ta 2 O 5 The total amount of powder and B 4 The molar ratio of C powder is 1:0.8, and the mass ratio of ball mill beads to raw materials is 5:1). The ball mill tank is placed in a ball mill and ball milled at a speed of 300r / min for 5h to obtain mixed powder;

[0033] Put the mixed powder obtained in the step (1) into a graphite crucible with a lid...

Embodiment 3

[0035] A (Hf,Ta,Nb,Ti)B 2 The preparation of high-entropy ceramic powder includes the following steps:

[0036] Weigh 1.05g of HfO respectively 2 Powder, 0.40g TiO 2 Powder, 1.10g Ta 2 O 5 Powder, 0.66g Nb 2 O 5 Powder, 0.42g of C powder and 0.77g of B 4 C powder was placed in a 150ml teflon ball mill and added with 88.00g ZrO 2 Ball mill (the molar ratio of Hf, Ti, Nb and Ta in the raw material is 1:1:1:1, and the TiO in the raw material is 2 Powder, HfO 2 Powder, Nb 2 O 5 Powder and Ta 2 O 5 The molar ratio of the total amount of powder to C powder is 1:2.33, TiO 2 Powder, HfO 2 Powder, Nb 2 O 5 Powder and Ta 2 O 5 The total amount of powder and B 4 The molar ratio of C powder is 1:0.93, and the mass ratio of ball milling beads to raw materials is 19.3:1). The ball mill tank is placed in a ball mill and ball milled at a speed of 500r / min for 20h to obtain mixed powder;

[0037] Put the mixed powder obtained in the step (1) into a graphite crucible with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com