Method for preparing CsPbX3 perovskite quantum dot film through one-step crystallization

A technology of perovskite and quantum dots, applied in chemical instruments and methods, devices for coating liquid on the surface, nanotechnology for materials and surface science, etc., can solve the industrial production of perovskite quantum dots in complex process links Road, low concentration of quantum dot colloidal dispersion, difficult to control the synthesis process, etc., to achieve the effect of good fluorescence performance, low cost, and uniform distribution of crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) 0.6 mol of cesium iodide and lead iodide were completely dissolved in 1 mL of DMF, and then 0.65 mol of adamantanemethylamine and 0.65 mol of hydroiodic acid were added as ligands, and the solution was stirred evenly as a precursor solution.

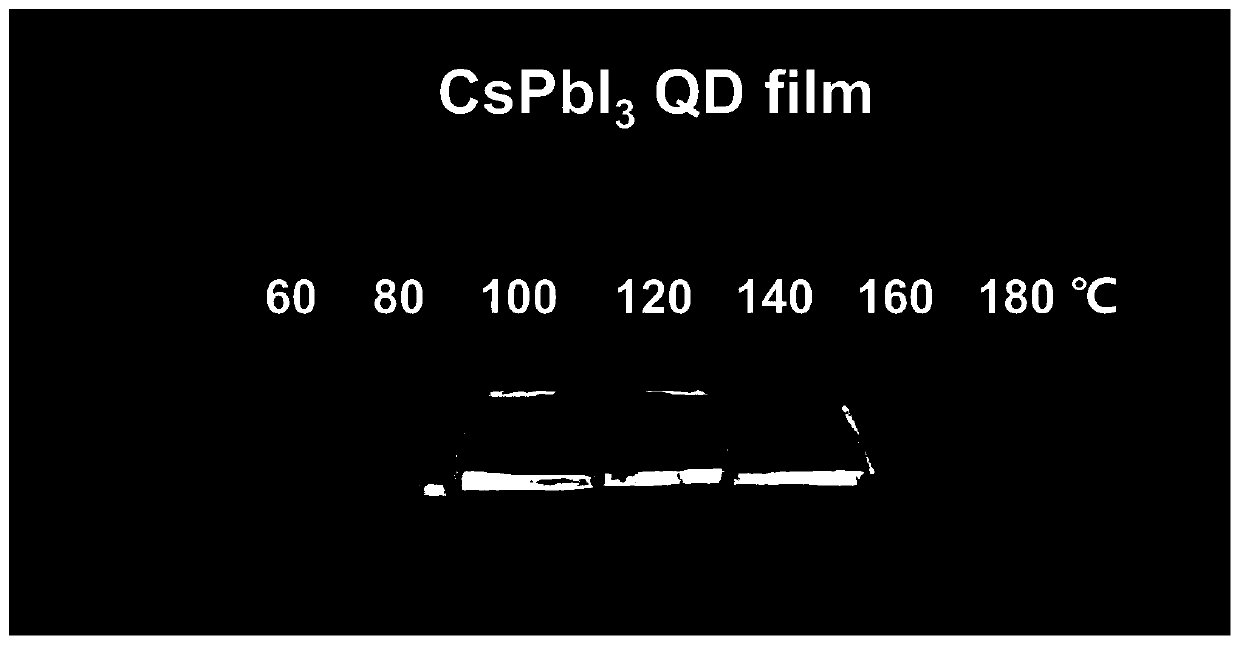

[0049] (2) Add the precursor solution dropwise on the substrate, spin-coat at 1000rpm for 10s with a homogenizer, then spin-coat at 2000rpm for 20s (the accelerations are 500 and 1000rpm·s respectively -1 ), the precursor solution after spin coating was divided into 7 groups, the heating temperature of each group was 60°C, 80°C, 100°C, 120°C, 140°C, 160°C and 180°C, the heating time was 3min, and the cooling CsPbI 3 Perovskite quantum dot films.

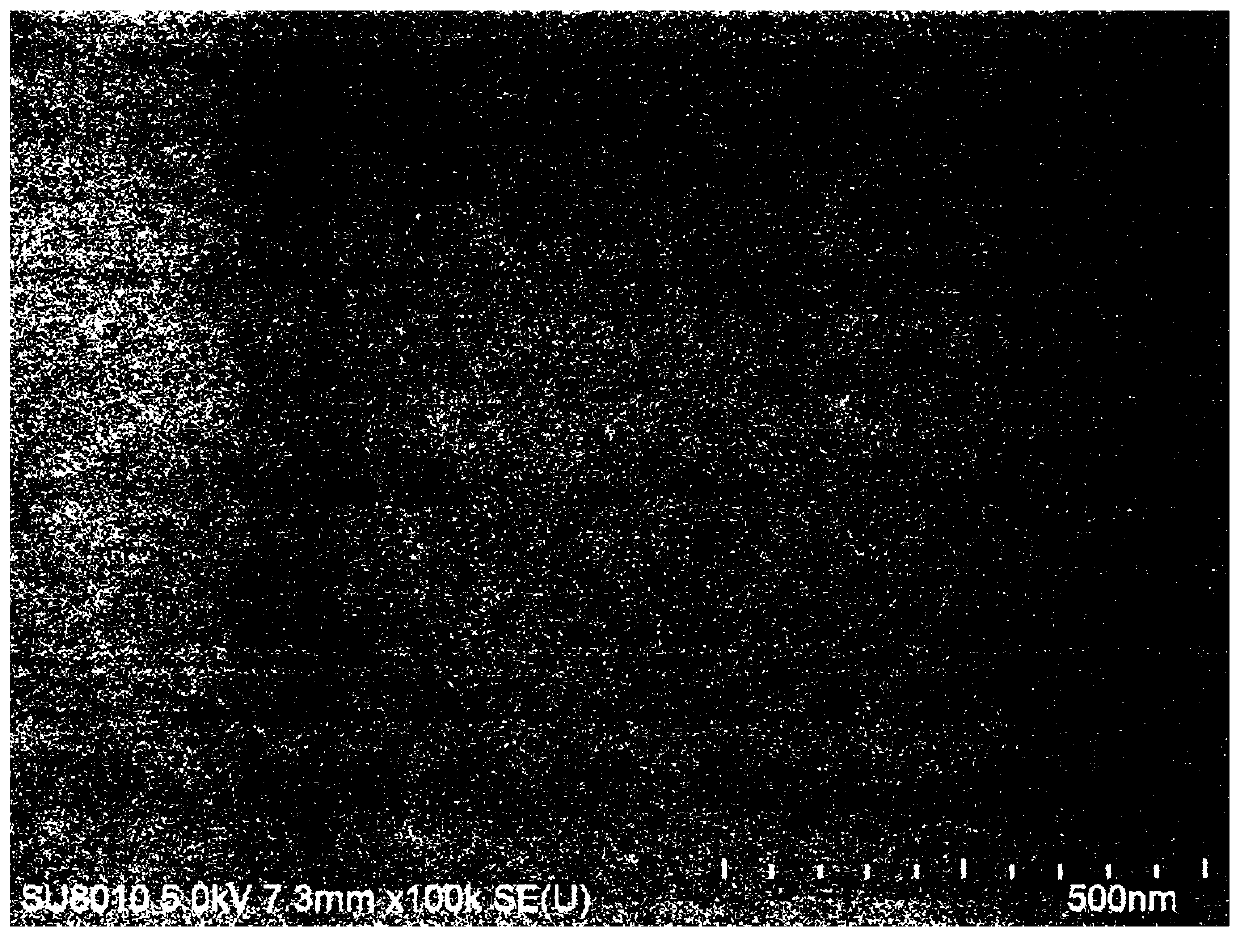

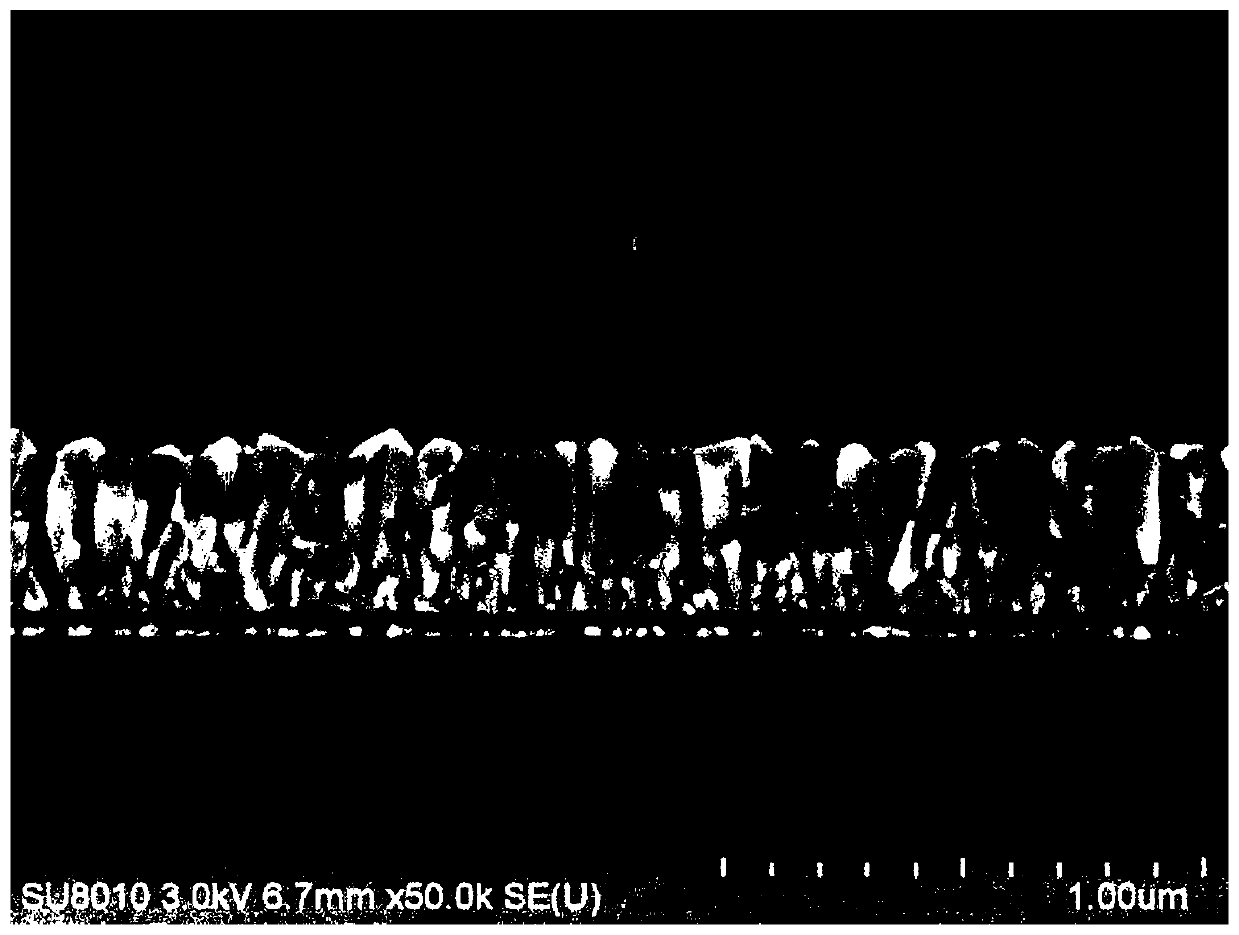

[0050] For CsPbI heated at 100°C 3 The surface of the perovskite quantum dot film was analyzed by scanning electron microscopy, and the results were as follows figure 1 shown. Depend on figure 1 As can be seen, the gained CsPbI of the present invention 3 The perovskite quantum ...

Embodiment 2

[0058] (1) Dissolve 0.5 mol of cesium bromide and lead bromide completely in 1 mL of DMSO respectively, then add 0.65 mol of adamantanemethylamine and 0.65 mol of hydrobromic acid as ligands, and stir the solution evenly as a precursor solution.

[0059] (2) Add the precursor solution dropwise on the substrate, spin-coat at 1000rpm for 10s with a homogenizer, then spin-coat at 2000rpm for 20s (the accelerations are 500 and 1000rpm·s respectively -1 ), the precursor solution after spin coating was divided into 6 groups, the heating temperature of each group was 60°C, 80°C, 100°C, 120°C, 140°C, 160°C, and the heating time was 3min, and CsPbBr was obtained after cooling 3 Perovskite quantum dot films.

[0060] CsPbBr prepared at different heating temperatures 3 Fluorescence photos of perovskite quantum dot films under ultraviolet light irradiation as shown in Figure 8 shown by Figure 8 As can be seen, the gained CsPbBr of the present invention 3 The surface of the perovskit...

Embodiment 3

[0065] (1) 0.2 mol of cesium chloride and lead chloride were completely dissolved in 1 mL of DMF, and then 0.65M adamantanemethylamine and 0.65M hydrochloric acid were added as ligands, and the solution was stirred evenly as a precursor solution.

[0066] (2) Add the precursor solution dropwise on the substrate, spin-coat at 1000rpm for 10s with a homogenizer, then spin-coat at 2000rpm for 20s (the accelerations are 500 and 1000rpm·s respectively -1 ), the heating crystallization temperature is 140°C, the heating time is 3min, and CsPbCl is obtained after cooling 3 Perovskite quantum dot films.

[0067] The resulting CsPbCl 3 The perovskite quantum dot film is scraped into powder and formulated into a chlorobenzene dispersion with a mass concentration of 5 mg / mL. The photo of the resulting dispersion emitting fluorescence under ultraviolet light is as follows: Figure 12 shown by Figure 12 As can be seen, the gained CsPbCl of the present invention 3 The chlorobenzene disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com